Quantum dot film, preparation method thereof, backlight module and display device

A quantum dot film and quantum dot technology, which are applied in the field of liquid crystal display, can solve the problems of low luminous efficiency of quantum dot film, and achieve the effects of improving surface passivation effect, improving luminous efficiency and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

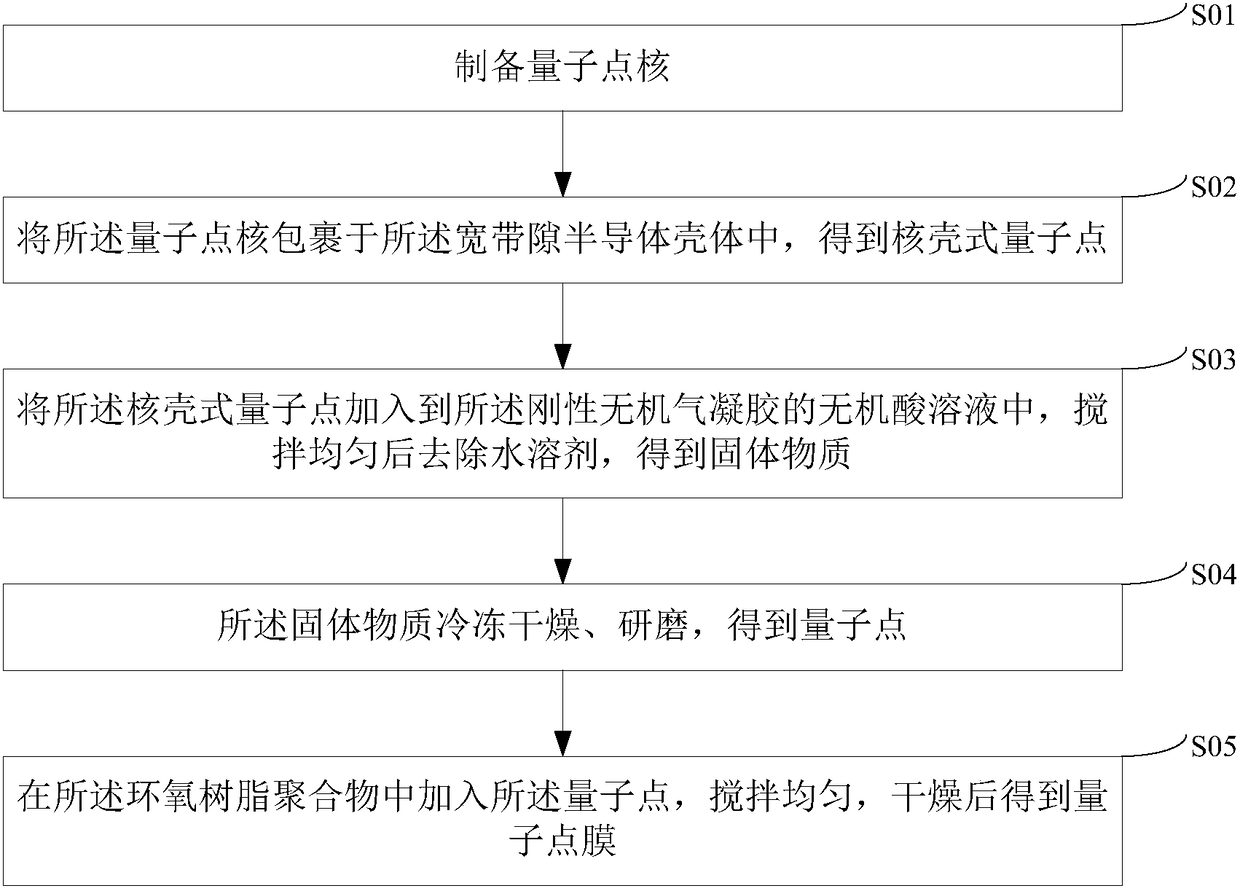

[0035] Please refer to the attached image 3 , with image 3 A schematic flow chart of the preparation method of the quantum dot film provided by the embodiment of the present invention is shown. attached by image 3 It can be seen that the preparation method of the quantum dot film provided by the embodiment of the present invention includes:

[0036] S01: preparing quantum dot cores.

[0037] The quantum dot core is prepared by the quantum dot hydrothermal method or other methods to form the core of the quantum dot. Since the selected quantum dot cores are different, the preparation materials of the quantum dot cores are different, which is not limited in the embodiments of the present invention.

[0038] S02: Wrap the quantum dot core in a wide bandgap semiconductor shell to obtain a core-shell quantum dot.

[0039] The prepared quantum dot core is placed in the material for preparing the wide band gap semiconductor shell, and a layer of wide band gap semiconductor she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com