Back full-passivation contact solar cell and preparation method thereof

A solar cell and backside technology, applied in the field of solar cells, can solve problems such as incompatibility with production lines, and achieve the effects of improving production line yield, simplifying process steps, and enhancing tunnel effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

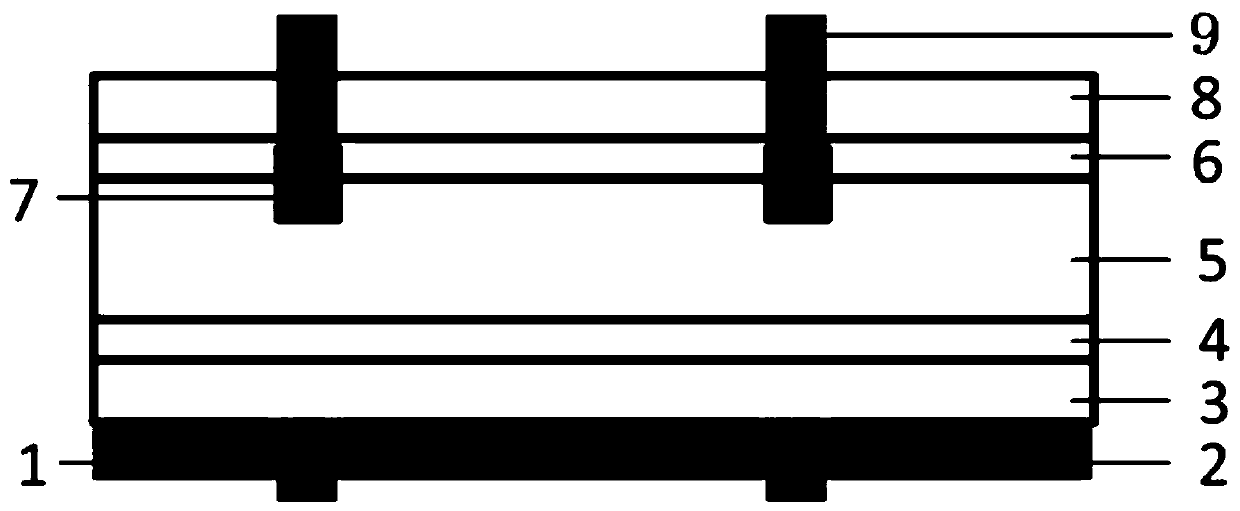

[0034] Such as figure 1 As shown, the back fully passivated contact solar cell, including back electrode 1, all aluminum back electric field 2, nanocrystalline boron hydride doped silicon carbide layer 3, silicon oxide layer 4, P-type silicon 5, n+ emitter layer 6, heavy Doped n++ emitter 7, silicon nitride anti-reflection passivation film 8 and front electrode 9, in which all-aluminum back electric field 2, nanocrystalline boron hydride doped silicon carbide layer 3, silicon oxide layer 4, P-type silicon 5, n+ The emitter layer 6 and the silicon nitride anti-reflection passivation film 8 are connected sequentially from bottom to top; one end of the heavily doped n++ emitter 7 is connected to the front electrode 9, and the other end passes through the n+ emitter layer 6 and is embedded in the P-type silicon 5 in.

[0035] In this embodiment, the back electrode 1 and the front electrode 9 are Ag electrodes.

[0036] In this embodiment, the heavily doped n++ emitter 7 is prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com