Preparation method of passivation contact type IBC (interdigitated back contact) cell

A battery and equipment technology, applied in the field of solar cells, can solve problems such as laser damage and passivation effect damage, achieve high open circuit voltage and conversion efficiency, reduce silicon wafer damage, and save production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

[0040] A kind of preparation method of the IBC cell of passivation contact of the present embodiment, comprises the following steps:

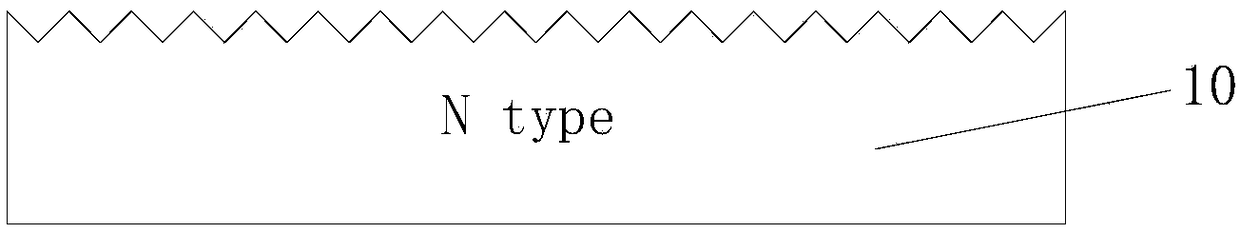

[0041] (1), select the N-type crystalline silicon substrate 10 of 156mm*156mm, and do texture processing to the front surface of the N-type crystalline silicon substrate 10; The resistivity of the N-type crystalline silicon substrate 10 is 0.5~15Ω·cm, preferably 1 ~5Ω·cm; the thickness of the N-type crystalline silicon substrate 10 is 50-300 μm, preferably 80-200 μm; the battery structure after this step is as follows figure 1 shown.

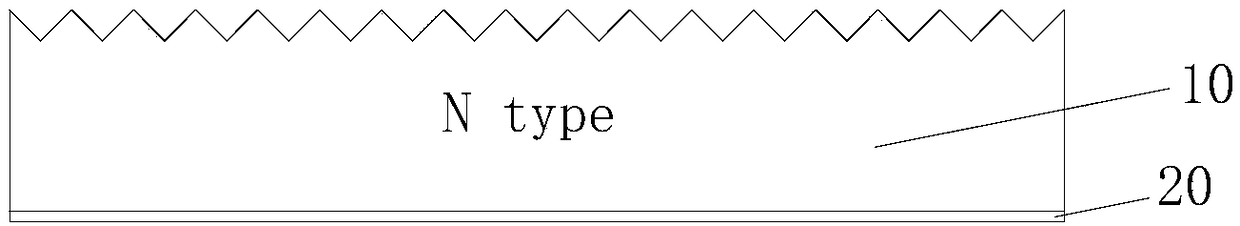

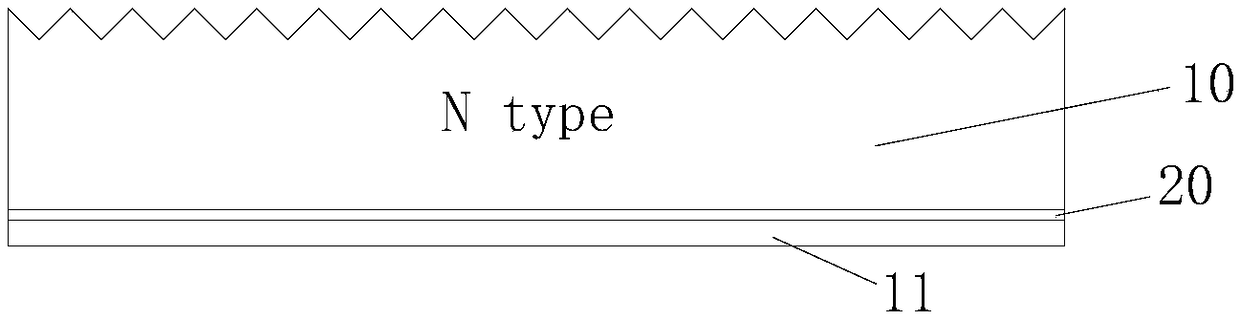

[0042] (2), the back surface oxide layer 20 is grown on the back surface of the N-type crystalline silicon substrate 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com