Passivated contact N-type solar cell, preparation method, assembly and system

A solar cell, N-type technology, applied in the field of solar cells, to achieve good compatibility, high open-circuit voltage and short-circuit current, and reduce the effect of recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] see Figure 1 to Figure 6 As shown, a method for preparing a passivated contact N-type solar cell of the present embodiment mainly includes the following steps:

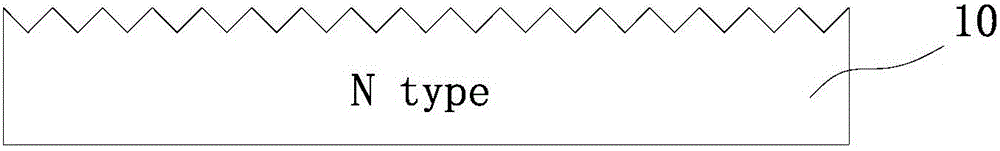

[0034] (1), select the N-type crystalline silicon substrate 10 of 156mm * 156mm, and do texture processing to the front surface of the N-type crystalline silicon substrate 10; The resistivity of the N-type crystalline silicon substrate 10 is 0.5~15Ω·cm, preferably 1 ~5Ω·cm; the thickness of the N-type crystalline silicon substrate 10 is 50-300 μm, preferably 80-200 μm; the battery structure after this step is as follows figure 1shown.

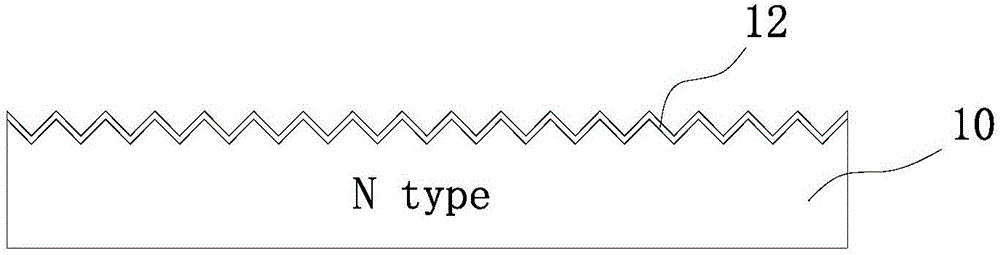

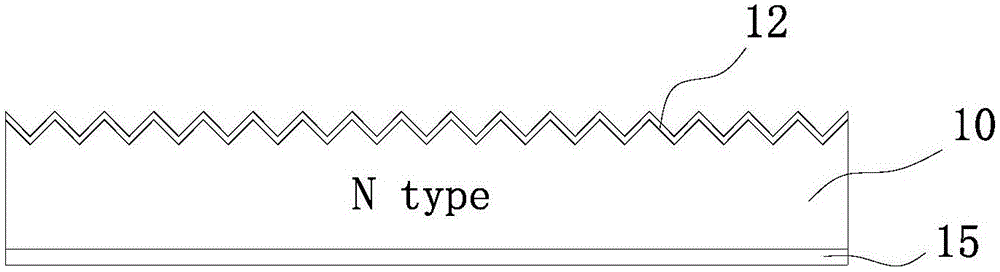

[0035] (2), put the N-type crystalline silicon substrate 10 processed in step (1) into an industrial diffusion furnace to carry out boron diffusion to the suede surface to form a front p+ doped region 12, the boron source adopts boron tribromide, and the diffusion The temperature is 900-1000° C., and the time is 60-180 minutes. The square resistance after boron diffusion is ...

Embodiment 2

[0044] (1), select the N-type crystalline silicon substrate 10 of 156mm * 156mm, and do texture processing to the front surface of the N-type crystalline silicon substrate 10; The resistivity of the N-type crystalline silicon substrate 10 is 0.5~15Ω·cm, preferably 1 ~5Ω·cm; the thickness of the N-type crystalline silicon substrate 10 is 50-300 μm, preferably 80-200 μm; the battery structure after this step is as follows figure 1 shown.

[0045] (2), put the N-type crystalline silicon substrate 10 processed in step (1) into an industrial diffusion furnace to carry out boron diffusion to the suede surface to form a front p+ doped region 12, the boron source adopts boron tribromide, and the diffusion The temperature is 900-1000° C., and the time is 60-180 minutes. The square resistance after boron diffusion is 40-100Ω / sqr, preferably 50-70Ω / sqr.

[0046] (3) Put the boron-diffused N-type crystalline silicon substrate 10 into an etching cleaning machine, and remove the boron dif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com