Full-back-electrode solar cell structure and preparation method therefor

A solar cell, full-back electrode technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of complex process, rising series resistance, etc., and achieve the effect of avoiding compounding, maintaining fill factor, and reducing process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

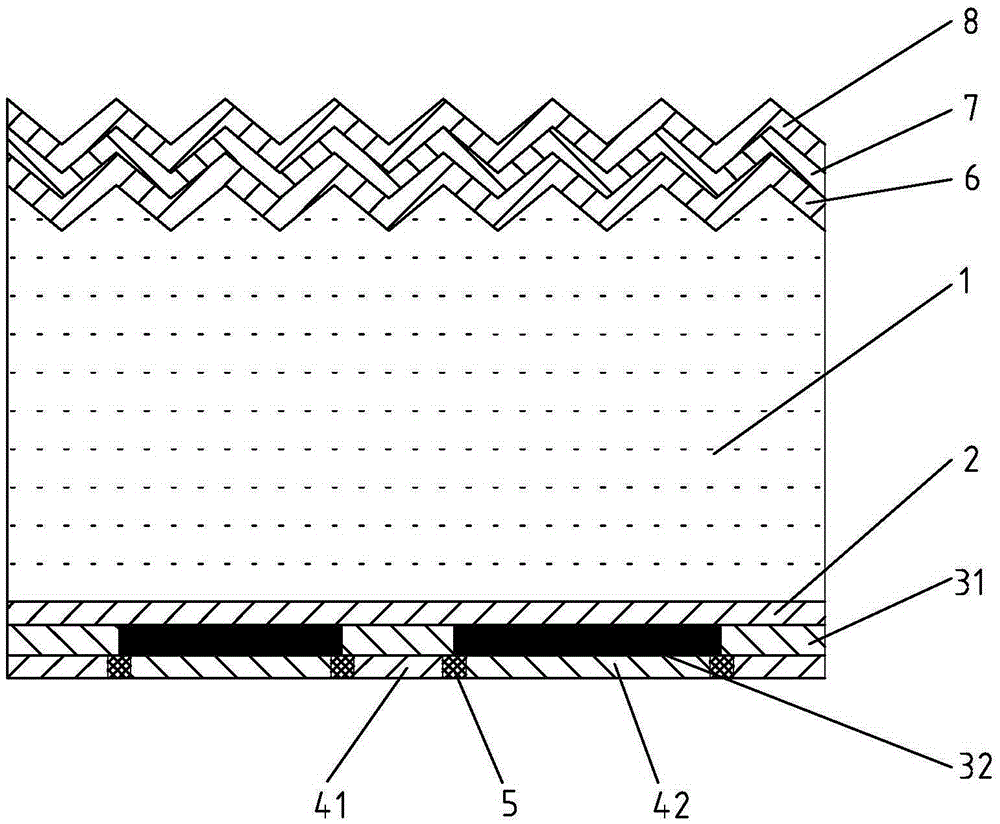

[0048] Such as figure 1 As shown, a full back pole solar cell structure, it includes:

[0049] battery substrate 1;

[0050] a tunneling passivation layer 2, the tunneling passivation layer 2 is arranged on the back side of the battery substrate 1;

[0051] A polysilicon layer, the polysilicon layer is disposed on the lower surface of the tunnel passivation layer 2 , and the polysilicon layer has an N-type heavily doped polysilicon layer 31 and a P-type polysilicon layer 32 arranged side by side.

[0052] The full back pole solar cell structure also includes an electrode layer, the electrode layer is arranged on the lower surface of the polysilicon layer, and the electrode layer has a negative electrode 41 in contact with the N-type heavily doped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com