Rapid annealing method for preparing tunneling oxygen passivation contact structure

A contact structure and rapid annealing technology, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of reducing production efficiency, increasing the surface state density of silicon wafers, and increasing application costs, so as to reduce production Cost, reduction of annealing time, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

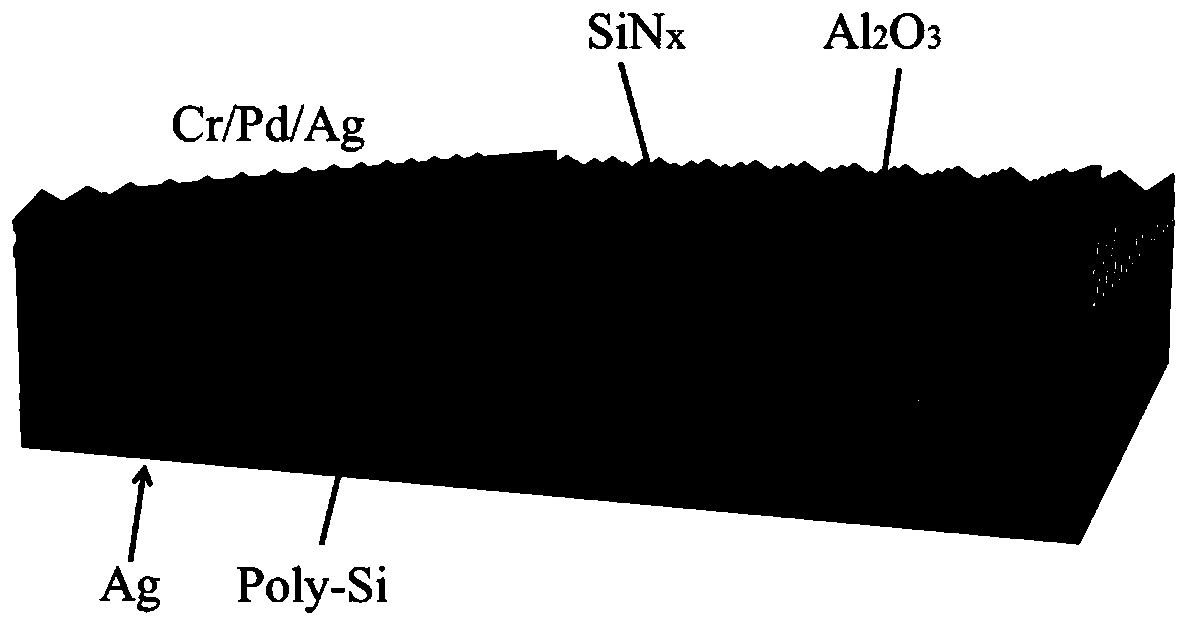

[0036] Double-sided n-TOPCon passivation structure: n + poly-Si / SiO 2 / n c-Si / SiO 2 / n + poly-Si. The basic sample preparation process is as follows: silicon wafer RCA cleaning → hot 68% nitric acid growth ultra-thin oxide layer → PECVD double-sided deposition of phosphorus-doped amorphous silicon 100nm each → rapid annealing.

[0037] The rapid annealing process is:

[0038] (1) Place the sample to be annealed in the equipment, and in a nitrogen atmosphere, first raise the temperature to 200°C at a rate of 15°C / s, and keep it warm for 2 minutes;

[0039] (2) Raise the temperature to 500°C at a rate of 30°C / s and keep warm for 5 minutes;

[0040] (3) Raise the temperature to 800°C at a rate of 10°C / s and keep warm for 5 minutes;

[0041] (3) Cool down to 600°C in 2 minutes, and take out the sample.

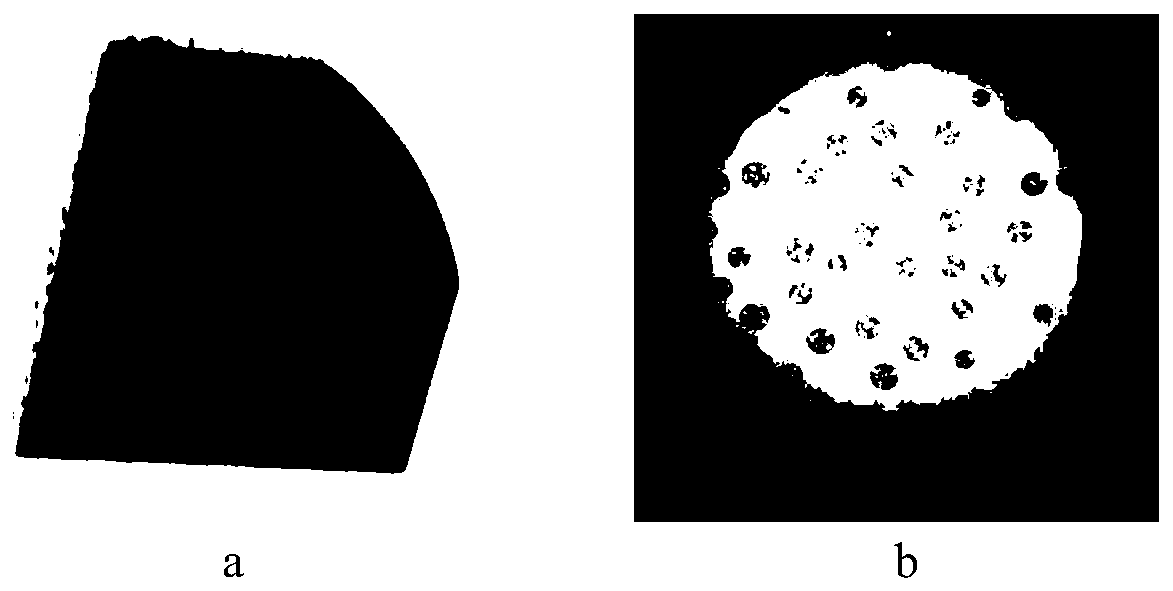

[0042] Using an optical microscope to observe the surface morphology of the polysilicon film, such as Figure 4 As shown, it is confirmed that the membrane structure is co...

Embodiment 2

[0044] Double-sided n-TOPCon passivation structure: n + poly-Si / SiO 2 / n c-Si / SiO 2 / n + poly-Si. The basic sample preparation process is as follows: silicon wafer RCA cleaning → hot 68% nitric acid growth ultra-thin oxide layer → PECVD double-sided deposition of phosphorus-doped amorphous silicon 100nm each → rapid annealing.

[0045] The rapid annealing process is:

[0046] (1) Place the sample to be annealed in the equipment, and in an argon atmosphere, first raise the temperature to 200°C at a rate of 15°C / s, and keep it warm for 2 minutes;

[0047] (2) Raise the temperature to 300°C at a rate of 30°C / s and keep it warm for 1 minute; then raise the temperature to 400°C at a rate of 30°C / s and keep it warm for 1 minute; then raise the temperature to 500°C at a rate of 30°C / s and keep it warm 1 minute; then raise the temperature to 600°C at a rate of 30°C / s, and hold for 1 minute;

[0048] (3) Raise the temperature to 900°C at a rate of 10°C / s and keep it warm for 2 minu...

Embodiment 3

[0052] Double-sided n-TOPCon passivation structure: n + poly-Si / SiO 2 / n c-Si / SiO 2 / n + poly-Si. The basic sample preparation process is as follows: silicon wafer RCA cleaning → hot 68% nitric acid growth ultra-thin oxide layer → PECVD double-sided deposition of phosphorus-doped amorphous silicon 100nm each → rapid annealing.

[0053] The rapid annealing process is:

[0054] (1) Place the sample to be annealed in the equipment, and raise the temperature to 200°C at a rate of 15°C / s in an atmosphere of nitrogen-hydrogen mixture (hydrogen content 5%), and keep it warm for 2 minutes;

[0055] (2) Raise the temperature to 300°C at a rate of 30°C / s and keep it warm for 1 minute; then raise the temperature to 400°C at a rate of 30°C / s and keep it warm for 1 minute; then raise the temperature to 500°C at a rate of 30°C / s and keep it warm 1 minute; then raise the temperature to 600°C at a rate of 30°C / s, and hold for 1 minute;

[0056] (3) Raise the temperature to 700°C at a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com