Method for achieving passivation of tunneling oxide layer of N-type double-sided battery

A technology for tunneling oxide layers and double-sided cells is applied in the field of solar cells, which can solve the problems of lack of mass production data and successful cases of mass production, and achieve the effects of good surface passivation, reduced concentration, and efficient transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

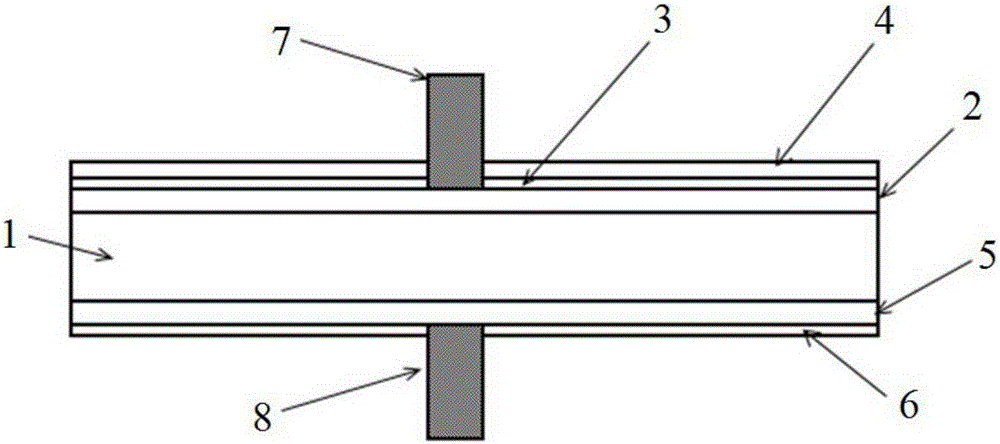

[0036] A method for realizing the passivation of the tunnel oxide layer of an N-type double-sided cell, using the following steps:

[0037] (1) Texture treatment: Alkali texturing process is adopted, the texturing liquid is ethylene glycol solution of KOH, the alkali concentration is 1wt%, the texturing temperature is 70°C, and the texturing time is 30min;

[0038] (2) Fabrication of the front PN junction: The boron diffusion process is used to prepare the PN junction, and the obtained square resistance is 30Ω / □;

[0039] (3) Tunneling oxide layer: Tubular diffusion furnace is used to prepare tunneling oxide layer, and an oxide film with a thickness of 4nm is obtained on the front surface of N-type silicon wafers. Send it into the diffusion furnace, raise the temperature to 750°C, and then pass in N 2 , N 2 -BBR 3 and O 2 mixed gas, N 2 -BBR 3 and O 2 The volume ratio is 1:500, O 2 and N 2 The volume ratio of the silicon wafer is 1:1. After 10 minutes of treatment, th...

Embodiment 2

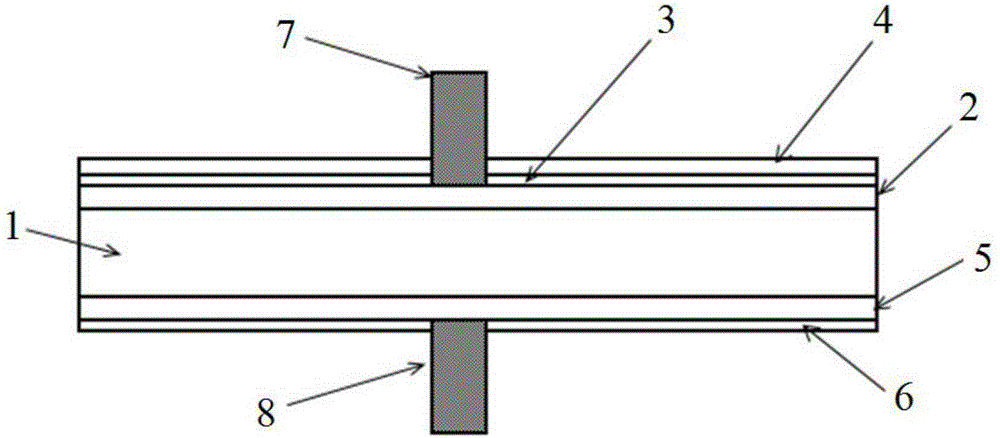

[0044] A method for realizing the passivation of the tunnel oxide layer of an N-type double-sided cell, using the following steps:

[0045] (1) Texture treatment: using alkali texturing process, the texturing liquid is ethylene glycol solution of KOH, the alkali concentration is 2wt%, the texturing temperature is 80°C, and the texturing time is 20min;

[0046] (2) Fabrication of the front PN junction: the PN junction is prepared by the boron diffusion process, and the square resistance obtained by the treatment is 50Ω / □;

[0047] (3) Tunneling oxide layer: Tubular diffusion furnace is used to prepare the tunneling oxide layer, and an oxide film with a thickness of 3nm is obtained on the front surface of the N-type silicon wafer. Send it into the diffusion furnace, raise the temperature to 800°C, and then pass in N 2 , N 2 -BBR 3 and O 2 mixed gas, N2 -BBR 3 and O 2 The volume ratio is 2:500, O 2 and N 2 The volume ratio is 1:3. After 20 minutes of treatment, the silico...

Embodiment 3

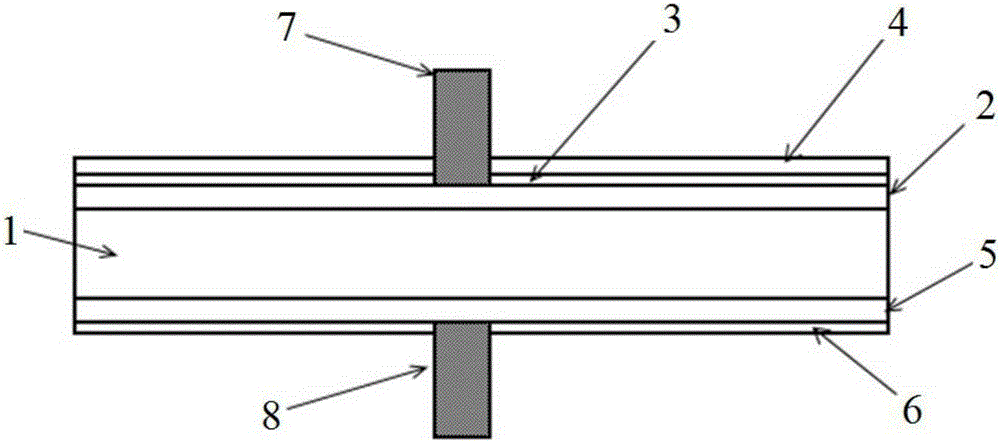

[0052] A method for realizing the passivation of the tunnel oxide layer of an N-type double-sided cell, using the following steps:

[0053] (1) Texture treatment: adopt alkali texturing process, the texturing liquid is the isopropanol solution of NaOH, the concentration of lye is 1wt%, the texturing temperature is 85°C, and the texturing time is 15min;

[0054] (2) Fabrication of the front PN junction: the PN junction is prepared by the boron diffusion process, and the square resistance obtained by the treatment is 65Ω / □;

[0055] (3) Tunneling oxide layer: Tubular diffusion furnace is used to prepare tunneling oxide layer, and an oxide film with a thickness of 2nm is obtained on the surface of N-type silicon wafers. Specifically, silicon wafers with PN junctions prepared on the front side are sent back to back into the diffusion furnace, raise the temperature to 850°C, and then pass N 2 , N 2 -BBR 3 and O 2 mixed gas, N 2 -BBR 3 and O 2 The volume ratio is 3:500, O 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com