Method for preparing molybdenum powders with low ferrum

An iron-molybdenum and powder technology, applied in the field of preparation of low-iron-molybdenum powder, can solve the problems of complicated preparation process, high production cost, increase of electron emission coefficient, etc., and achieve stable and controllable reaction, small size dispersion, easy to use control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

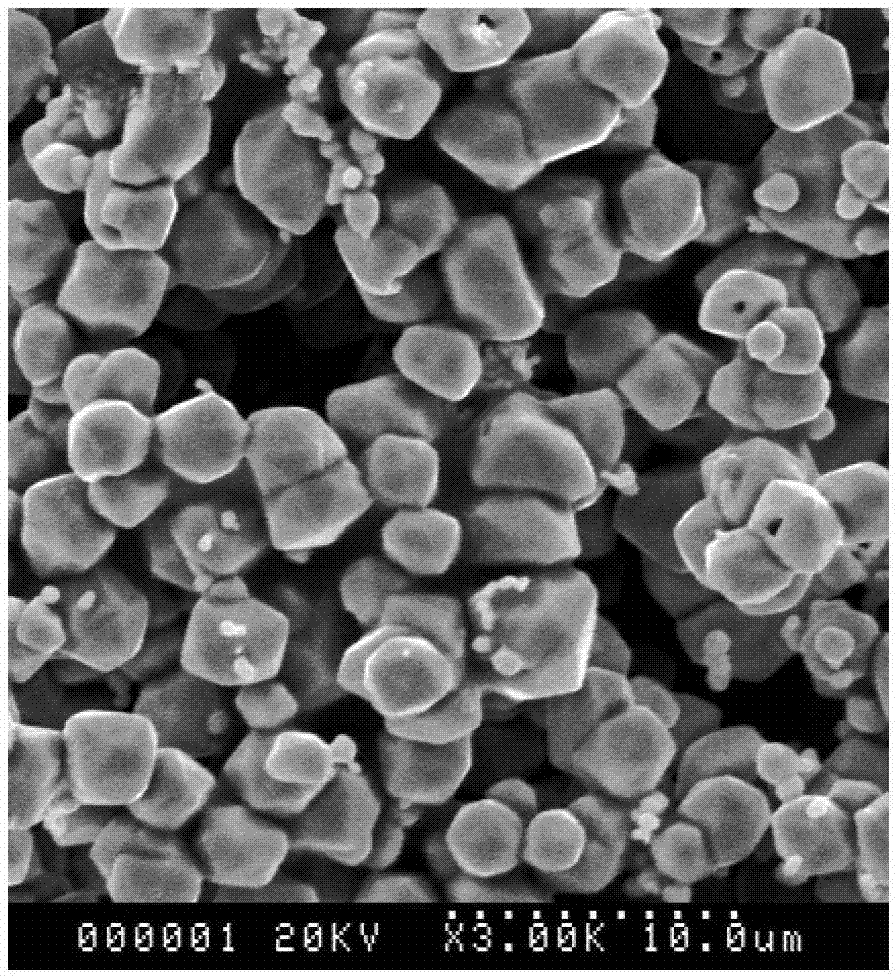

Embodiment 1

[0021] The preparation method of the low-iron molybdenum powder of the present embodiment may further comprise the steps:

[0022] Step 1. Put the molybdenum trioxide powder with a mass purity ≥ 99.95%, an average particle size of 250 μm, and a Fe mass content of 1 ppm into a molybdenum material boat with a mass purity ≥ 98%, and pair the material boat in the reduction temperature zone of the primary reduction furnace. The molybdenum trioxide powder is subjected to a hydrogen reduction. After the first hydrogen reduction, the material boat is placed in the cooling zone of the primary reduction furnace to cool to 25°C room temperature, and the primary reduction product molybdenum dioxide is obtained in the material boat; Hydrogen reduction is a three-temperature-zone reduction system. The reduction temperature in the first temperature zone is 400°C, the reduction temperature in the second temperature zone is 500°C, and the reduction temperature in the third temperature zone is 6...

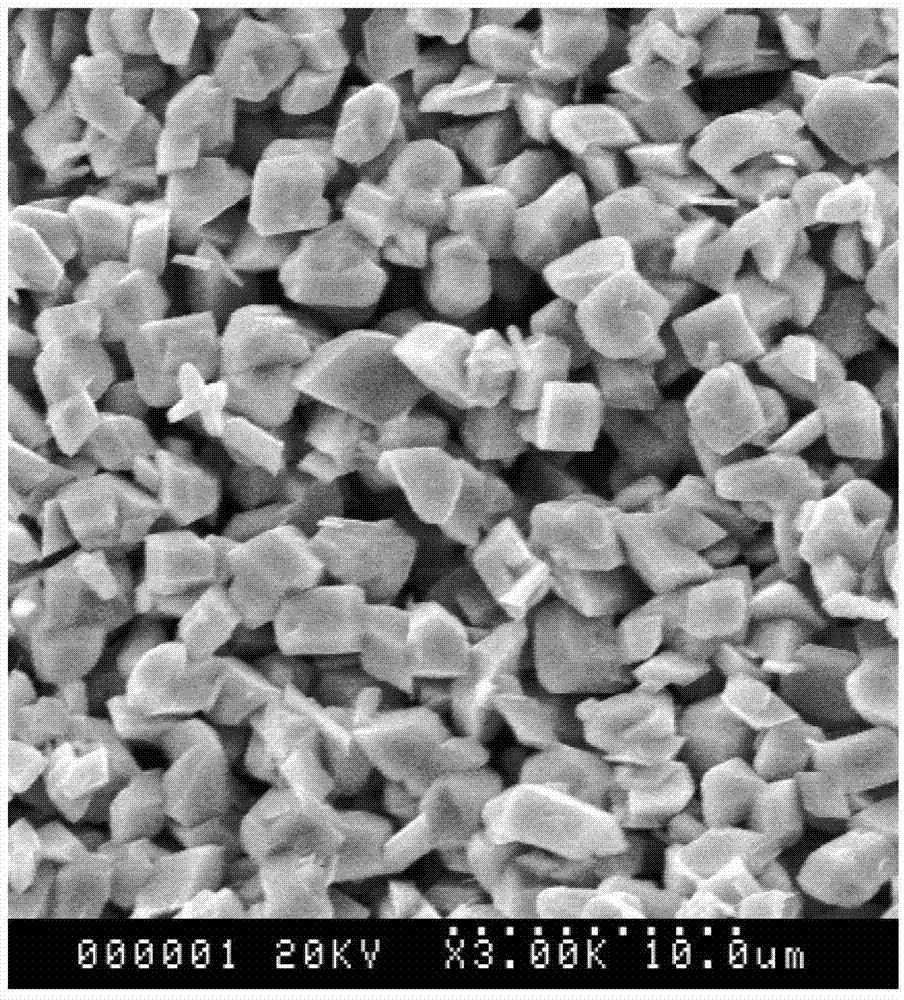

Embodiment 2

[0027] The preparation method of the low-iron molybdenum powder of the present embodiment may further comprise the steps:

[0028] Step 1. Put molybdenum trioxide powder with mass purity ≥ 99.95%, average particle size of 290 μm, and Fe mass content of 2 ppm into molybdenum material boat with mass purity ≥ 98%, and put it in the reduction temperature zone of the primary reduction furnace. The molybdenum trioxide powder is subjected to a hydrogen reduction. After the first hydrogen reduction is completed, the material boat is placed in the cooling zone of the primary reduction furnace and cooled to 25°C room temperature, and the primary reduction product molybdenum dioxide is obtained in the material boat; Hydrogen reduction is a three-temperature-zone reduction system. The reduction temperature in the first temperature zone is 420°C, the reduction temperature in the second temperature zone is 520°C, and the reduction temperature in the third temperature zone is 580°C. The reduc...

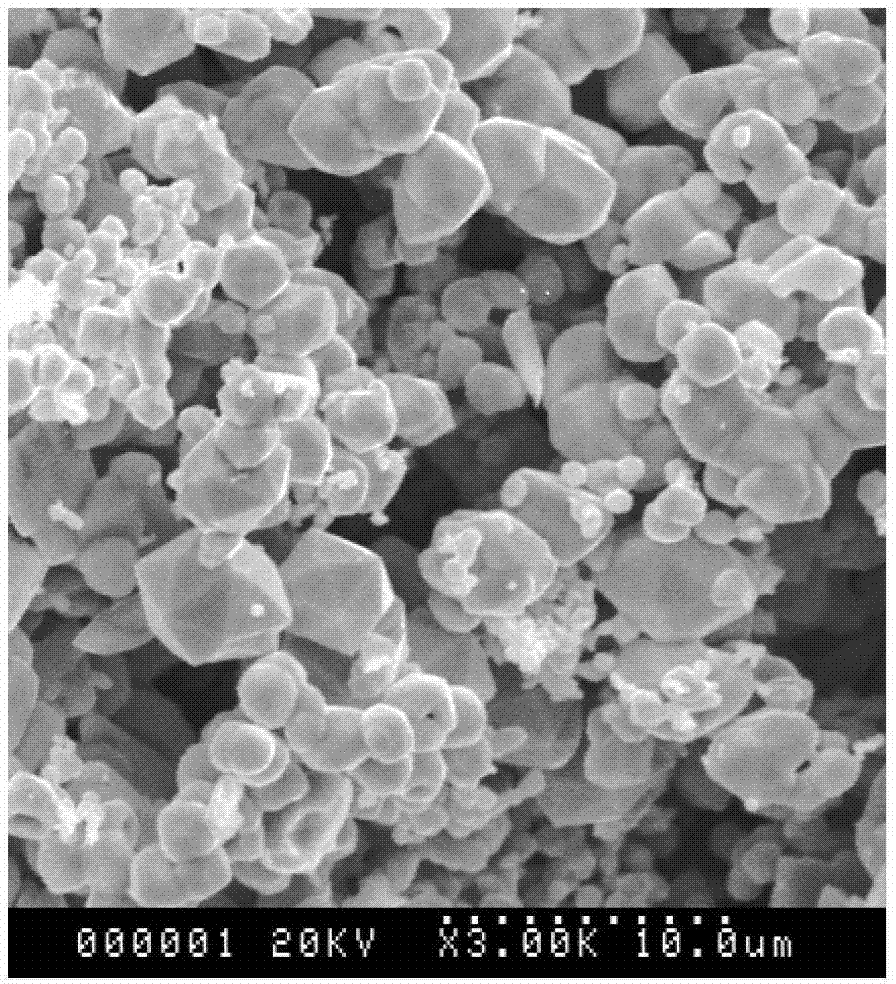

Embodiment 3

[0033] The preparation method of the low-iron molybdenum powder of the present embodiment may further comprise the steps:

[0034]Step 1. Put molybdenum trioxide powder with a mass purity ≥ 99.95%, an average particle size of 350 μm, and a Fe mass content of 2 ppm into a molybdenum material boat with a mass purity ≥ 98%, and place it in the material boat in the reduction temperature zone of the primary reduction furnace The molybdenum trioxide powder is subjected to a hydrogen reduction. After the first hydrogen reduction is completed, the material boat is placed in the cooling zone of the primary reduction furnace and cooled to 25°C room temperature, and the primary reduction product molybdenum dioxide is obtained in the material boat; Hydrogen reduction is a three-temperature-zone reduction system. The reduction temperature in the first temperature zone is 400°C, the reduction temperature in the second temperature zone is 500°C, and the reduction temperature in the third temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com