Polymer plane nano-channel production method

A production method and polymer technology, which are applied in the fields of micro-nanofluidic chip manufacturing, analytical chemistry, medicine, and life sciences, can solve the problems of complex process and long production cycle, and achieve simple production process, low cost and short cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

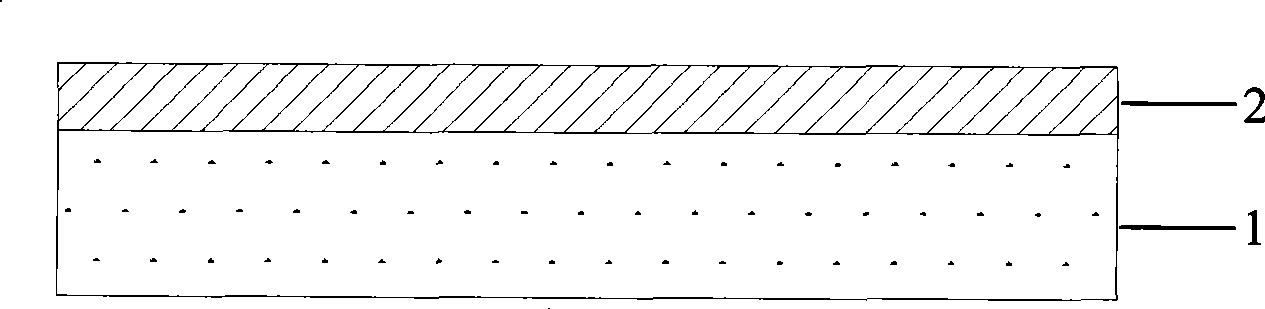

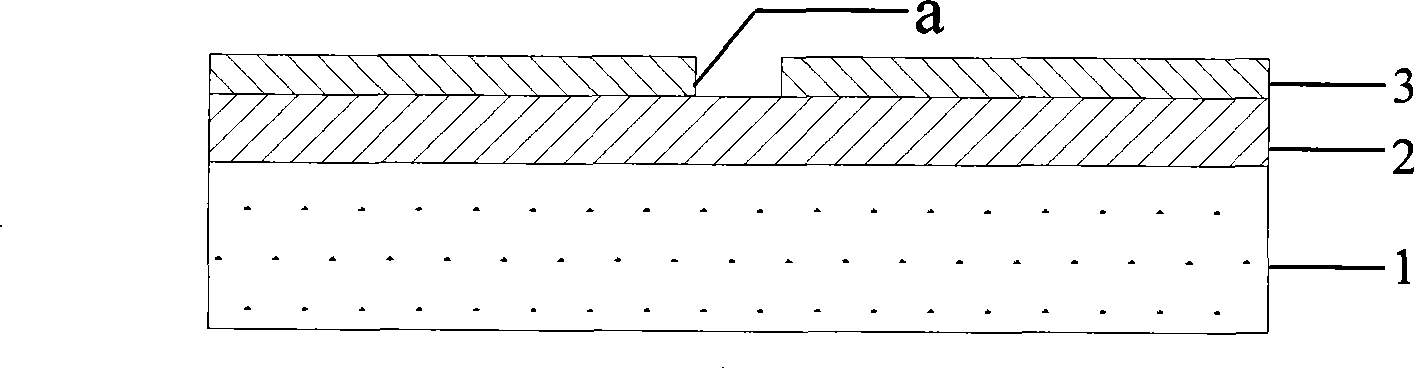

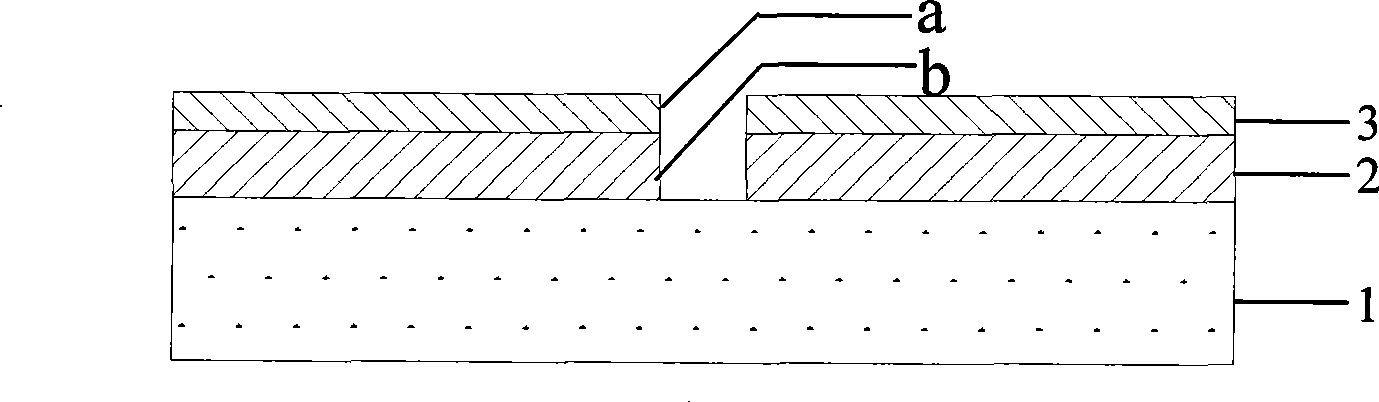

[0016] Embodiments of the present invention will be described in detail below in conjunction with technical solutions and drawings. as attached figure 1 , 2 , 3, 4, 5 and 6, a layer of copper with a thickness of about 80nm is sputtered on the polymer substrate 1 using the JS3X-80B magnetron sputtering station produced by Beijing Chuangweina Technology Co., Ltd. Film 2; adopt the model of Delta 80RC produced by SUSS MicroTec Company in Germany to spin-coat a layer of positive photoresist produced by AZ ElectronicMaterials Company on the surface of the copper film and be the positive photoresist of AZ MiR701. / min, and pre-bake on a hot plate at 55°C for 1 hour, then cover the mask plate on the photoresist 3, and use the UV photolithography machine model MA / BA6 produced by SUSS MicroTec, Germany, to photoresist 3 Expose for 30 seconds, put it into the developer solution for development, and obtain a photoresist pattern a with a width of micron order, and put it on a hot plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com