Method for preparing patterned graphene

A patterned graphene and graphene technology, which is applied in the photoplate making process of the patterned surface, optical mechanical equipment, instruments, etc., can solve the problems of high cost and complex template manufacturing process, and achieve low cost and low device performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

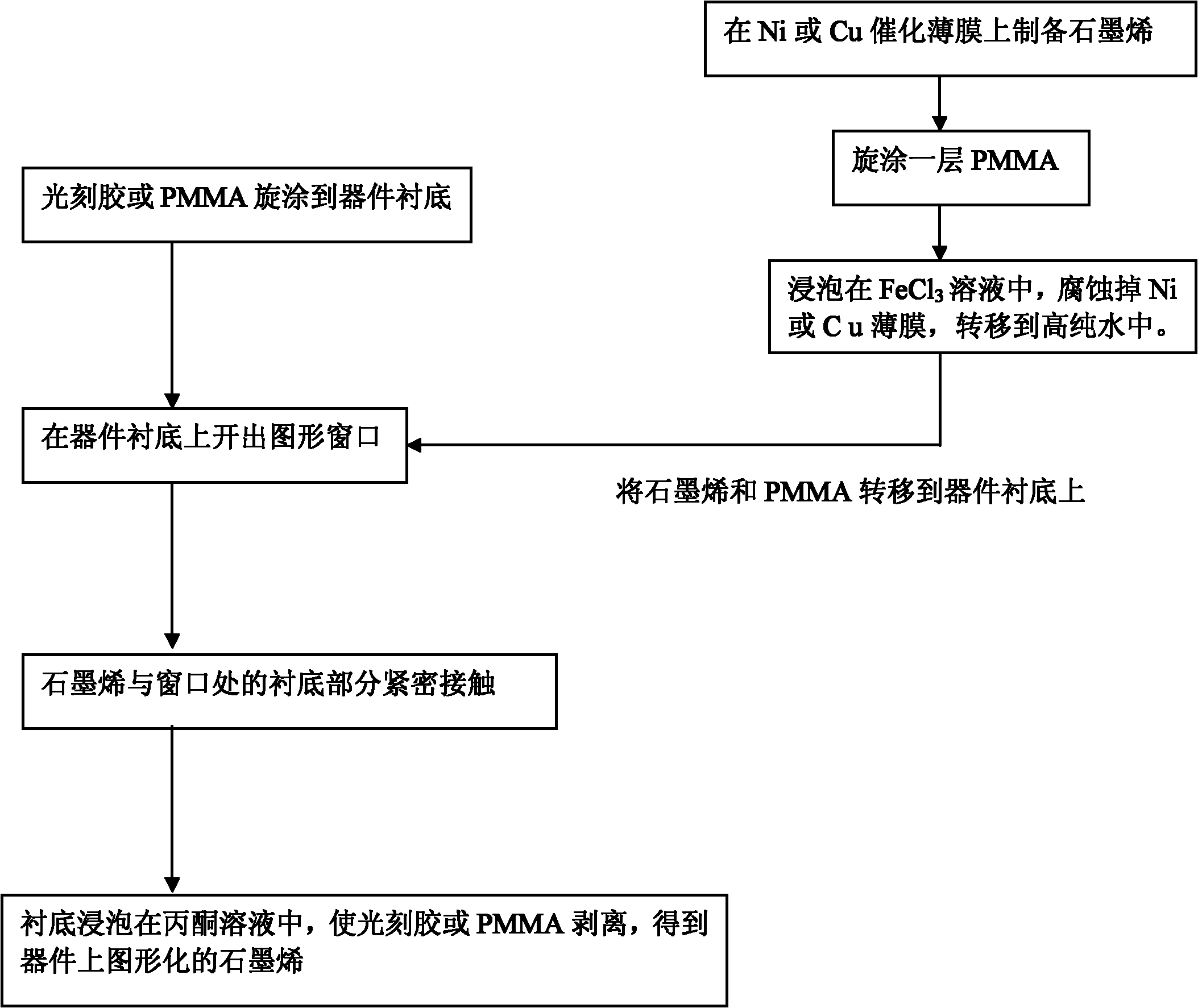

[0020] The invention adopts traditional micro-processing techniques such as photolithography, heat treatment, and stripping, and combines the conventional method of graphene transfer to prepare patterned graphene at the required place of the device substrate. This new etching-free graphene patterning method has broad application prospects in new devices with graphene as the functional unit. The main experimental process is as figure 1 As shown, the steps are as follows:

[0021] 1. Prepare large-area high-quality graphene on Ni or Cu catalytic film by chemical vapor deposition.

[0022] 2. Spin-coat a layer of PMMA on the graphene-grown substrate, for example: 2000rpm, 2 minutes.

[0023] 3. Soak the substrate with PMMA and graphene in 1M FeCl 3 solution, eg: 6 hours. The Ni layer is etched away, leaving the graphene and PMMA layers floating in the solution.

[0024] 4. Spin-coat photoresist (or PMMA) onto the target device substrate.

[0025] 5. Through ultraviolet lith...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com