Method for preparing loosened polyimide infrared absorption film

A technology of polyimide and infrared absorption, which is applied in gaseous chemical plating, manufacturing microstructure devices, and techniques for producing decorative surface effects. It can solve problems such as poor mechanical strength, difficulty in patterning, and high thermal mass. Achieve easy patterning, strong adhesion, and low thermal mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

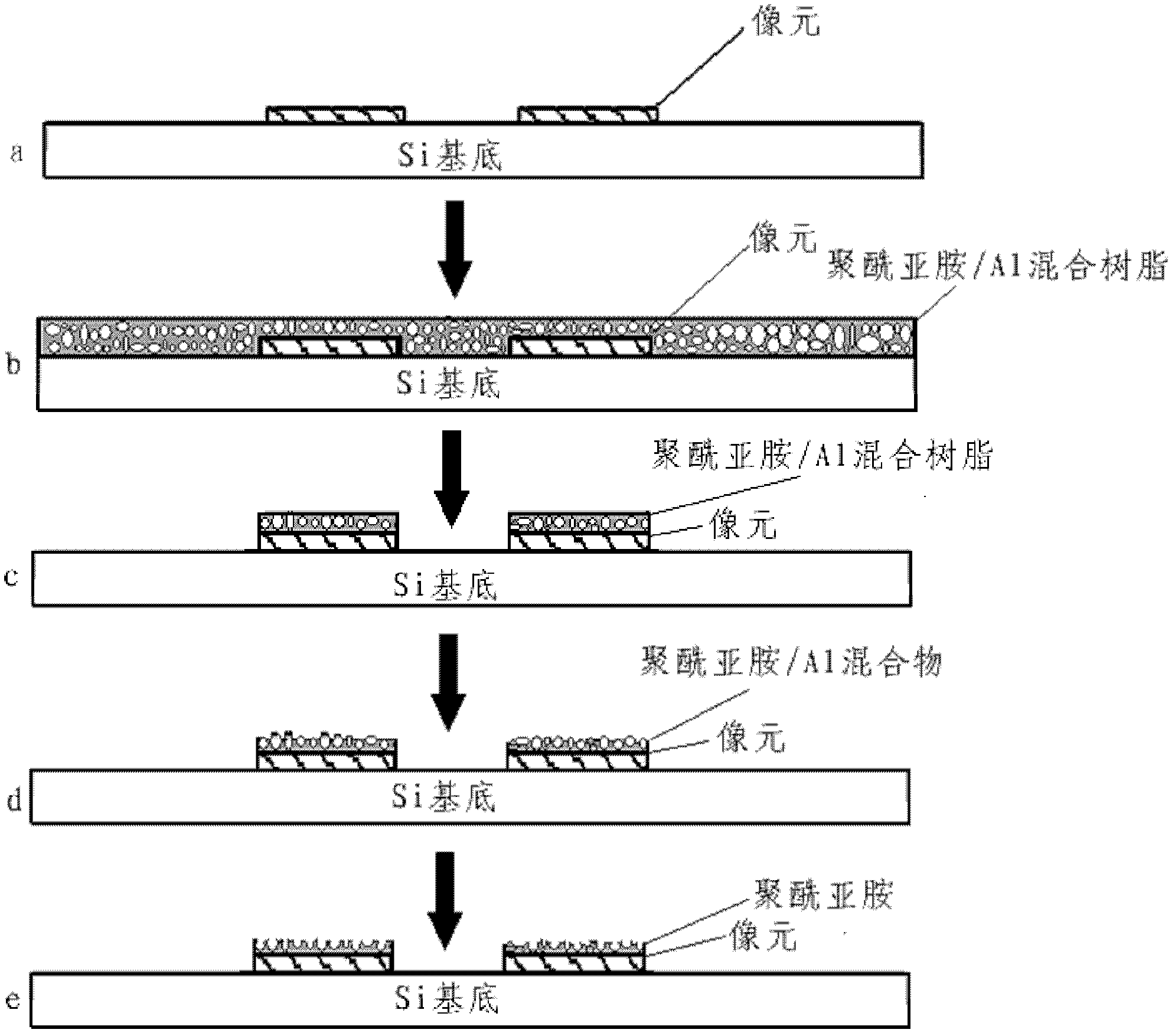

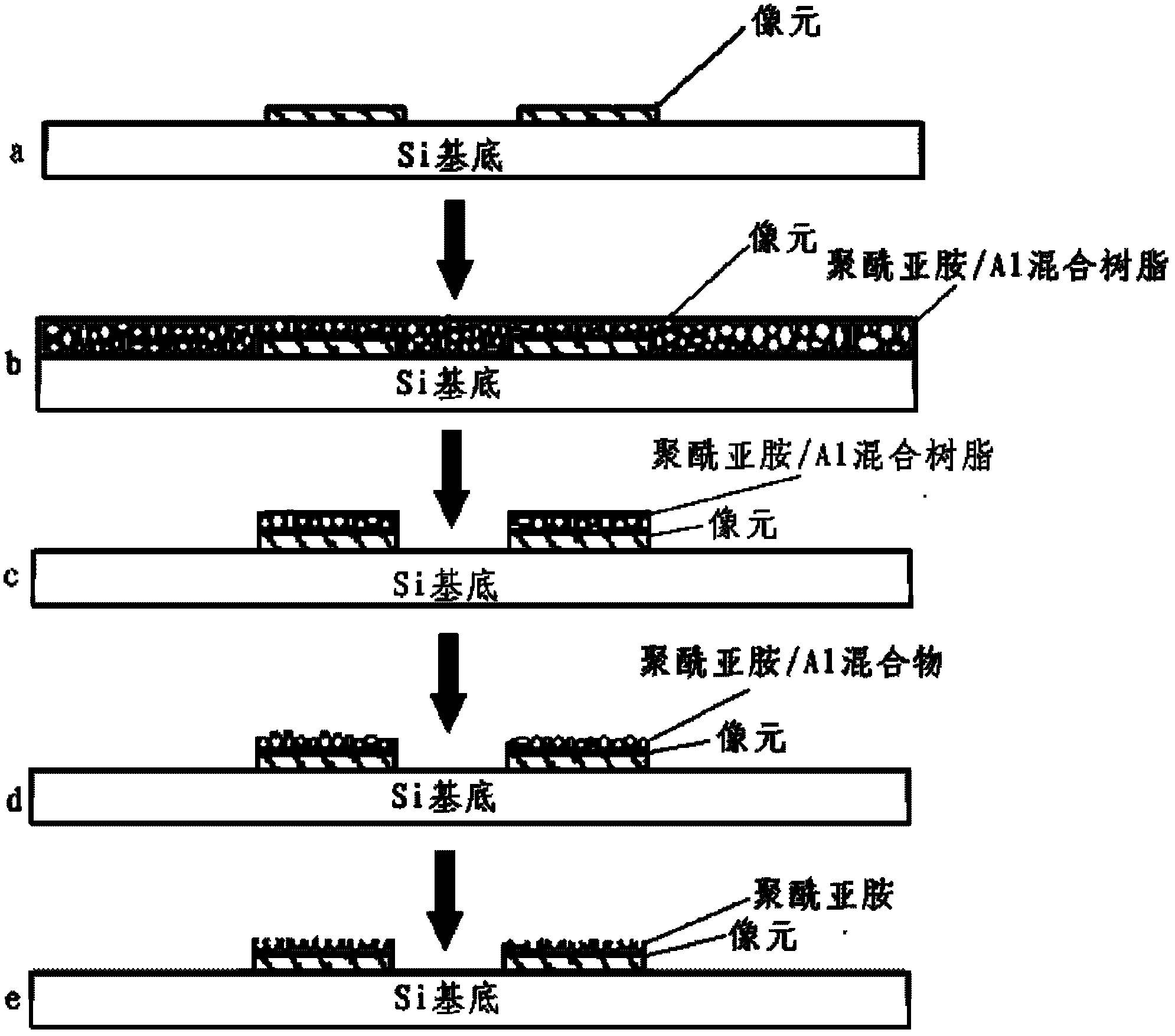

[0028] In order to further illustrate content of the present invention, the present invention is described in detail below, wherein:

[0029] 1. Stir and mix photosensitive polyimide resin with aluminum powder with a diameter of 3-4 microns, so that the aluminum powder particles are evenly distributed in the resin to form a resin mixture, and the mass mixing ratio of the two is 1:2;

[0030] 2. The resin mixture is evenly coated on the surface of the silicon substrate by means of spin coating on the glue leveler. Control the rotation speed of the rotating disk of the homogenizer to make the thickness of the resin mixture about 5 microns; the silicon substrate coated with the resin mixture is pre-baked on a hot plate, the baking temperature is 120 ° C, and the baking time is 3 minutes;

[0031] 3. Expose the silicon substrate coated with the resin mixture, and lithographically engrave a pattern of the same size as the pixel on the surface of the uncooled detector pixel; after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com