Method using one-step template method to prepare ordered ferroelectric nanodot array

A nano-dot array and template method, applied in the fields of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of limited application prospects and harsh growth conditions, and achieve low preparation cost, simple process, excellent epitaxy and iron. electrical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

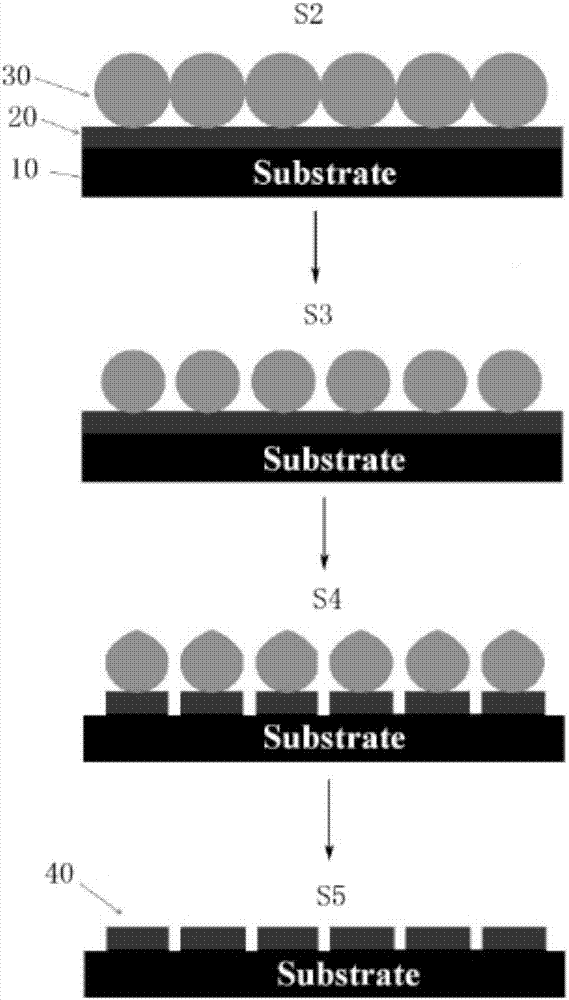

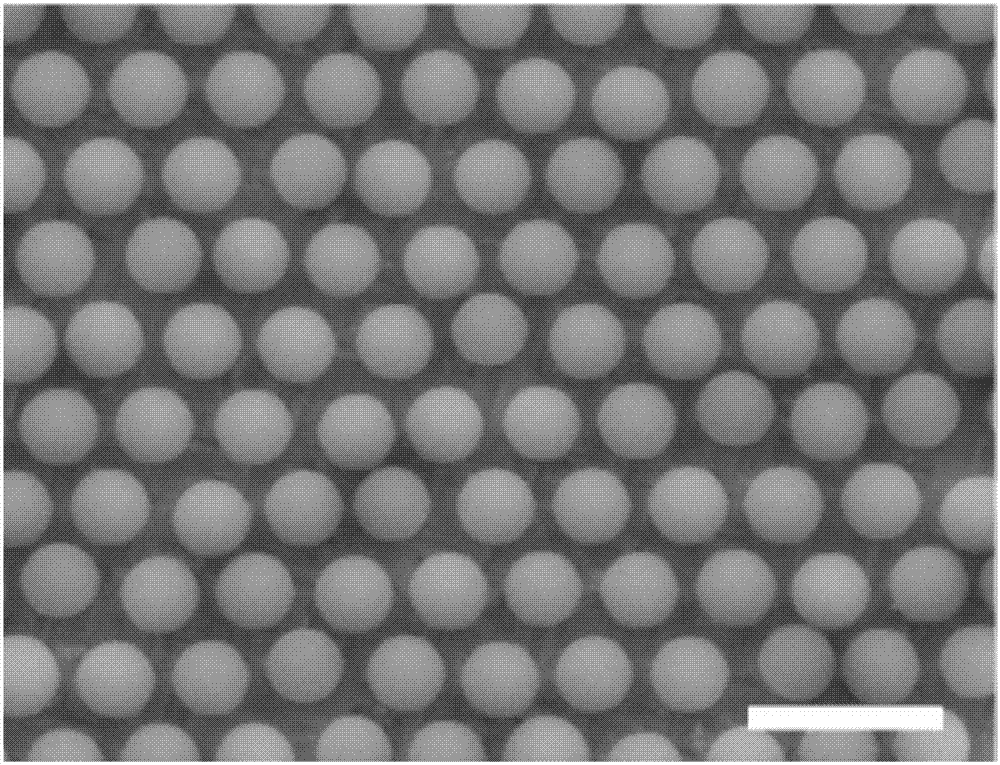

[0038] see figure 1 , which is a schematic diagram of the preparation process of the ordered ferroelectric nano-dot array of this embodiment. The method for preparing an ordered ferroelectric nano-dot array by the one-step template method of this embodiment comprises the following steps:

[0039] S1: Preparation of high-performance epitaxial ferroelectric thin films: Selecting 7% Nb-doped (001)-oriented SrTiO 3 (Nb:STO) single crystal substrate 10, deposited 40 nm thick BiFeO on the substrate by laser pulse deposition 3 (BFO) thin film 20; The preparation parameter of pulsed laser deposition method is as follows:

[0040] Energy (mJ / cm 3 )

Pulse frequency (Hz)

temperature(℃)

Oxygen pressure (Pa)

1

8

660

15

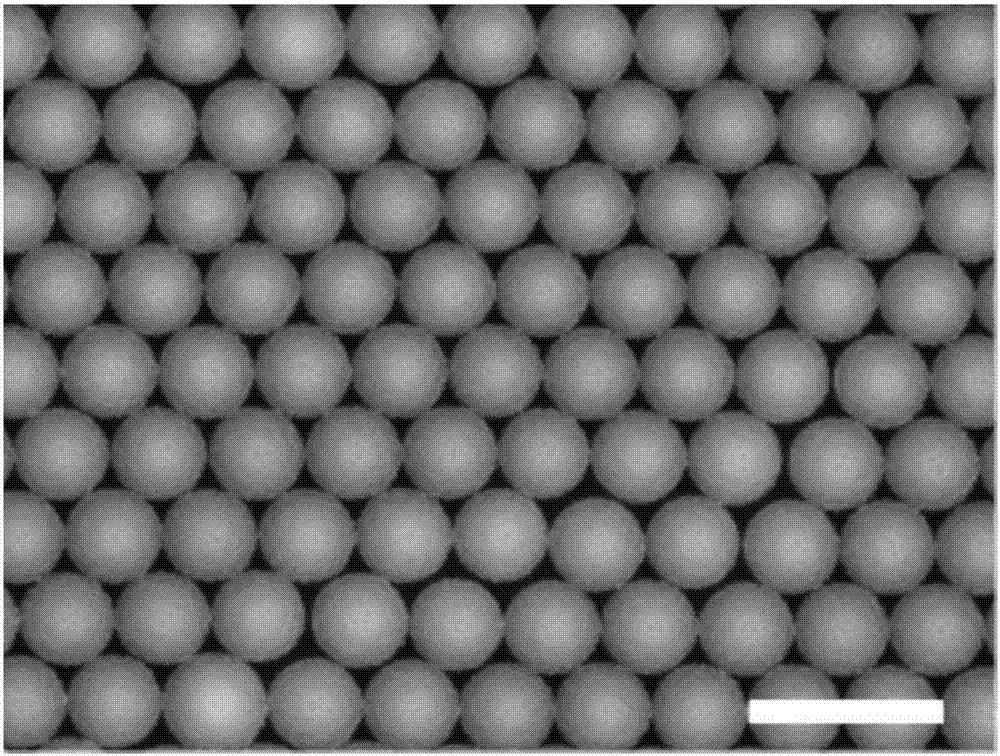

[0041] S2: Transfer the single-layer PS beads 30 to the surface of the ferroelectric film as a mask; specifically, drop a mixed solution of PS beads with a diameter of 500 nm and ethanol into a petri dish filled with deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com