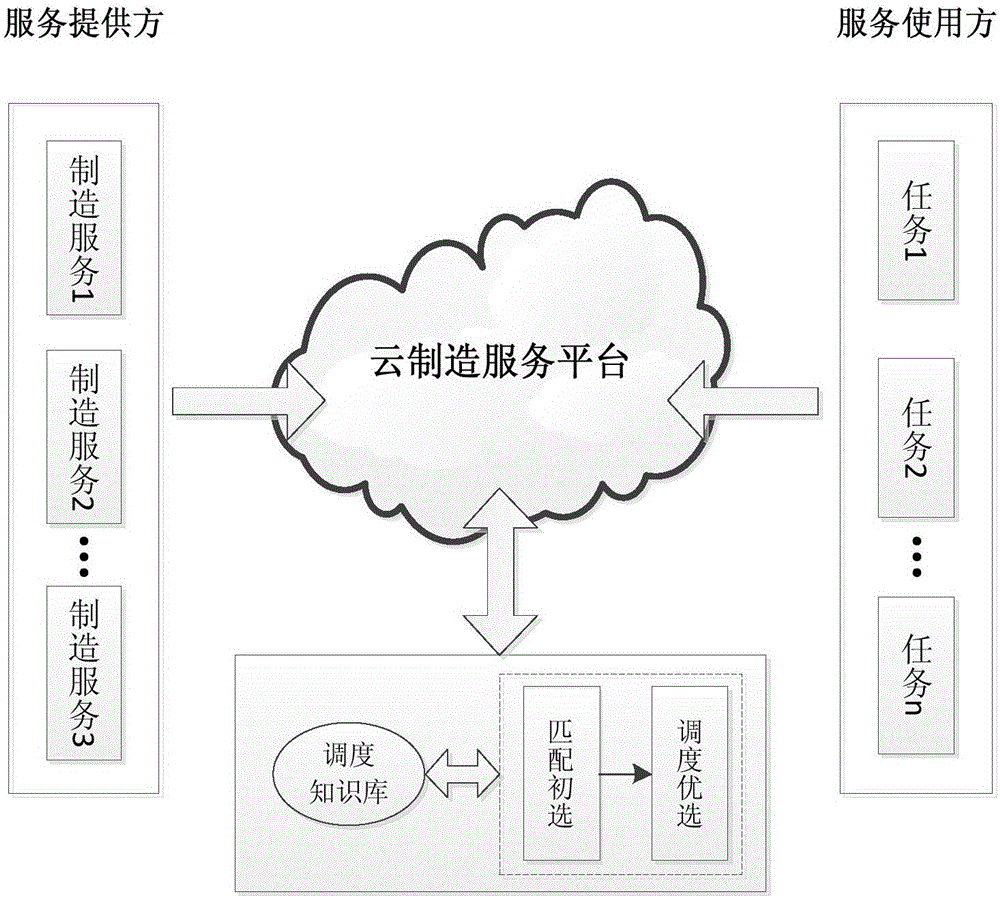

Cloud manufacturing service scheduling method and system

A manufacturing service and scheduling system technology, applied in transmission systems, electrical components, etc., can solve problems such as the disconnection between manufacturing services and combination optimization links, and achieve the effect of improving utilization and realizing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0049] Specific embodiment 1 (manufacturing task is automobile manufacturing, and preferred scheduling is human-computer interaction mode)

[0050] 1) A manufacturing enterprise that needs cloud manufacturing services submits an automobile manufacturing task to the cloud manufacturing service platform. The task name is automobile manufacturing, the task type is automobile, and there are no restrictions;

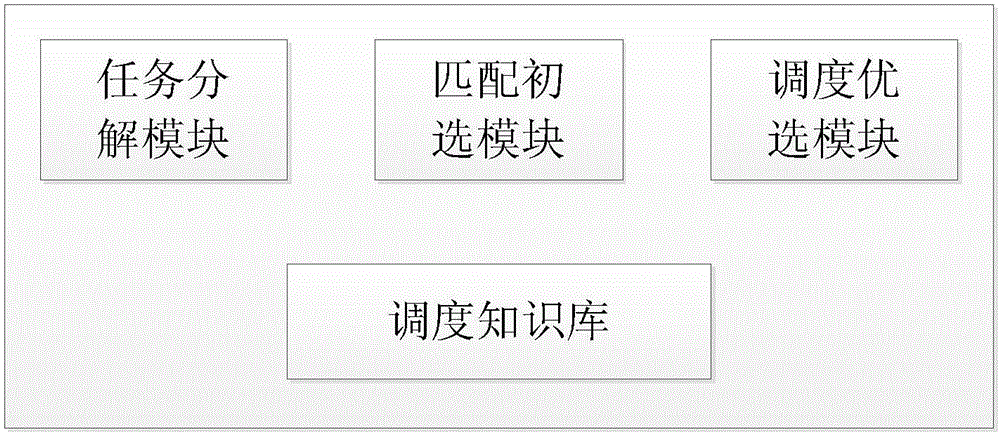

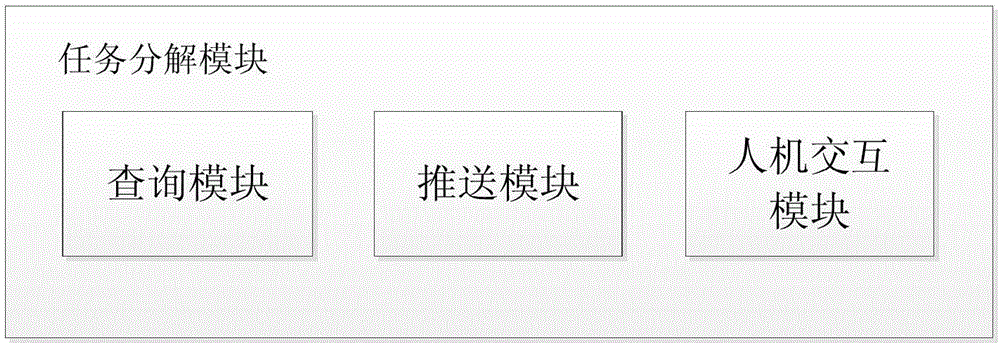

[0051] 2) The task decomposition module in the cloud manufacturing service platform obtains all subtasks consistent with the task type from the subtask database in the scheduling knowledge base according to the task name and task type, and pushes them to the manufacturing enterprise on the human-computer interaction interface. For all subtasks of this task type, the manufacturing enterprise selects subtasks according to its own needs, and the subtasks include: subtask name and subtask ID;

[0052] 3) The matching primary selection module searches the matching manufacturing se...

specific Embodiment 2

[0056] Specific embodiment 2 (manufacturing task is automobile manufacturing, and optimal scheduling is algorithm optimization mode)

[0057] 1) A manufacturing enterprise that needs cloud manufacturing services submits an automobile manufacturing task to the cloud manufacturing service platform. The task name is automobile manufacturing, the task type is automobile, and there are no restrictions;

[0058] 2) The task decomposition module in the cloud manufacturing service platform obtains all subtasks consistent with the task type from the subtask database in the scheduling knowledge base according to the task name and task type, and pushes them to the manufacturing enterprise on the human-computer interaction interface. For all subtasks of this task type, the manufacturing enterprise selects subtasks according to its own needs, and the subtasks include: subtask name and subtask ID;

[0059] 3) The matching primary selection module searches the matching manufacturing service ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com