Patents

Literature

103 results about "Manufacturing grid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and arrangement for layout and manufacture of nonmanhattan semiconductor integrated circuit using simulated euclidean wiring

InactiveUS20050240893A1Semiconductor/solid-state device detailsSolid-state devicesManufacturing gridEngineering

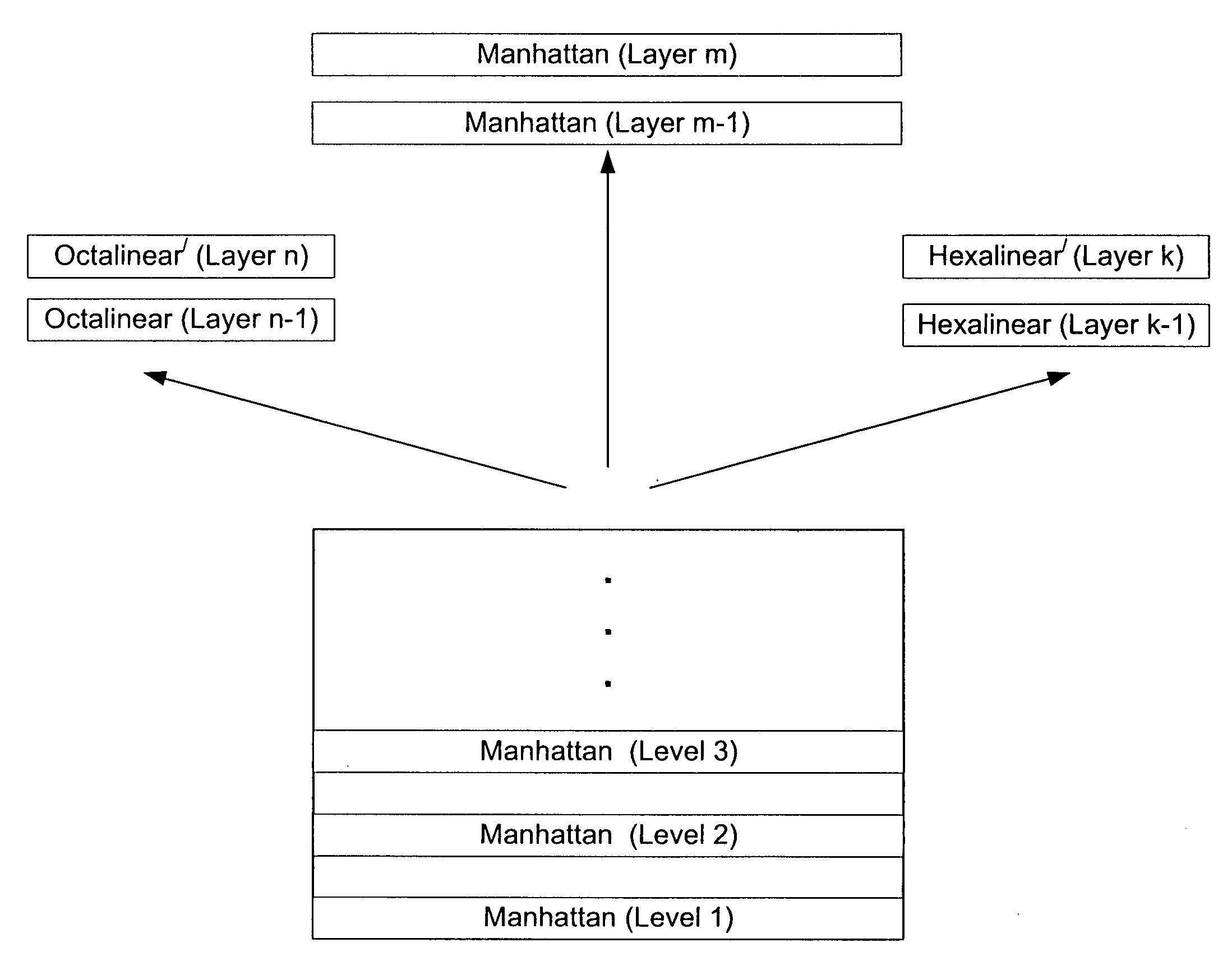

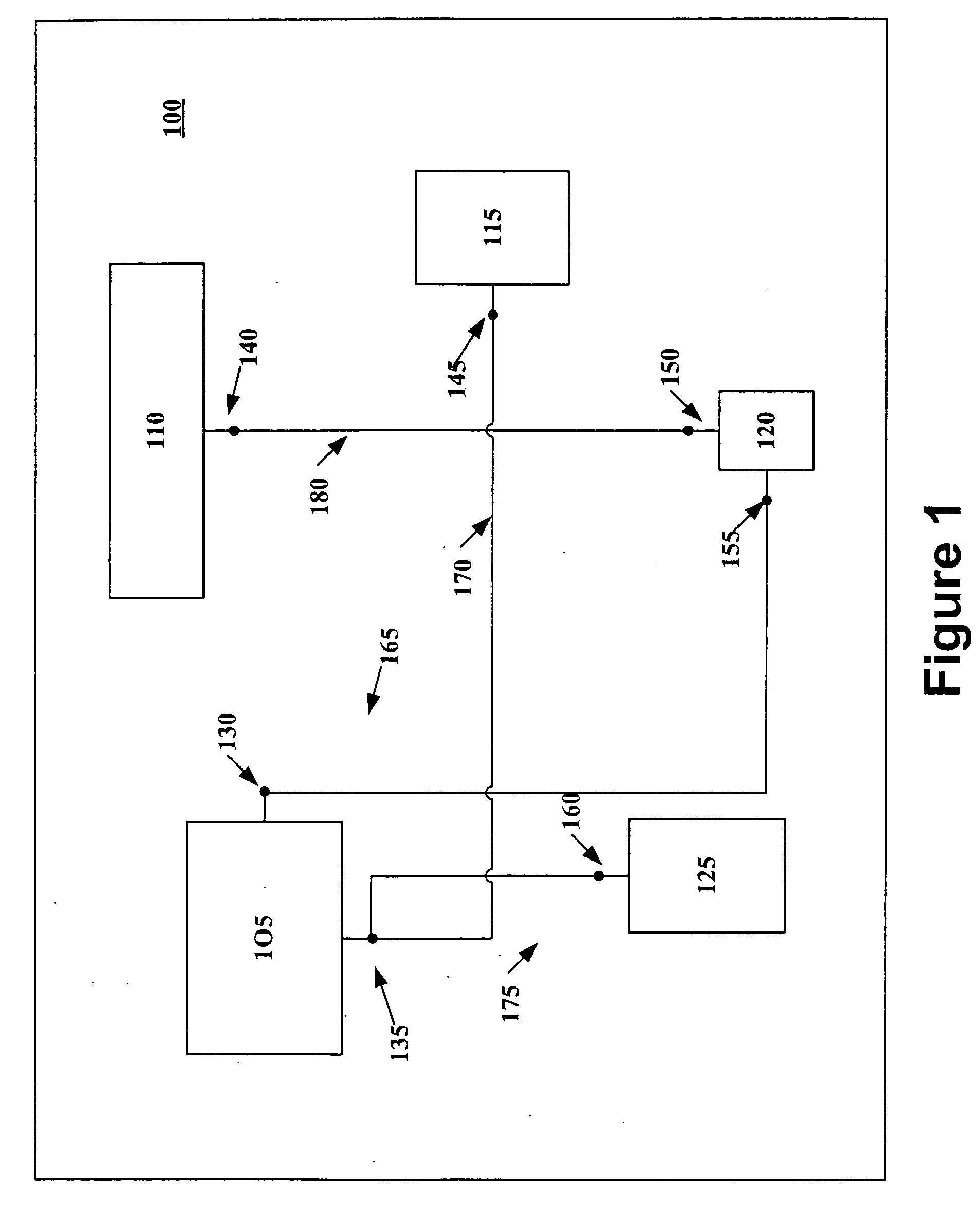

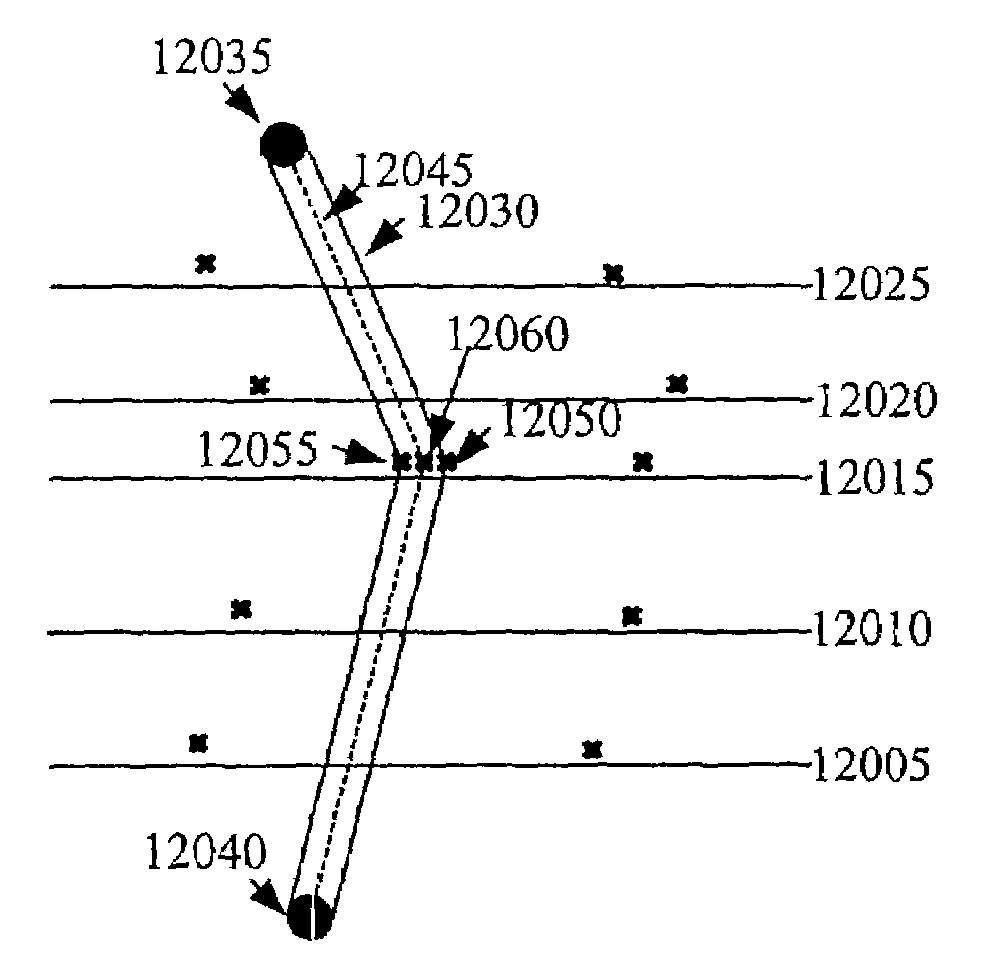

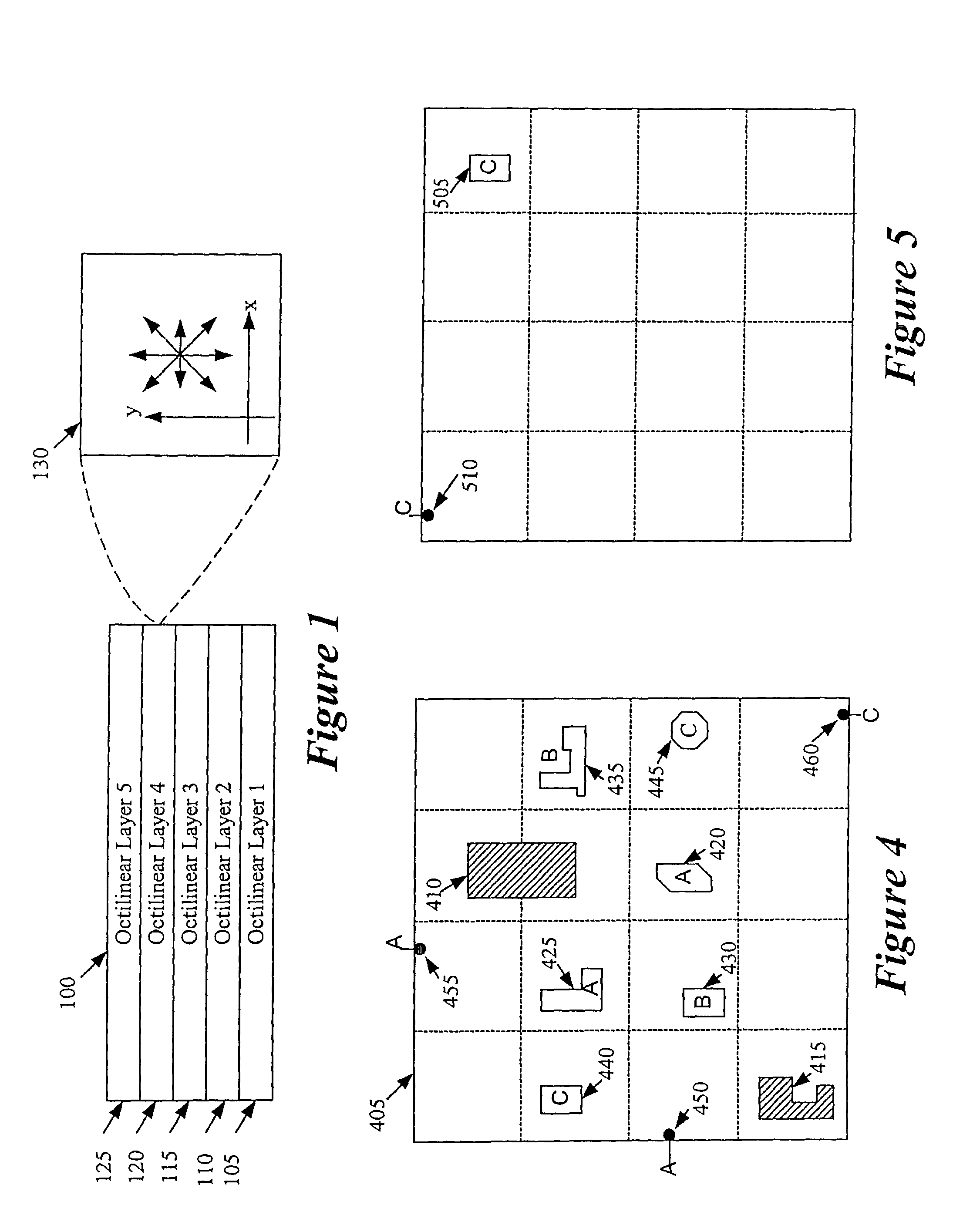

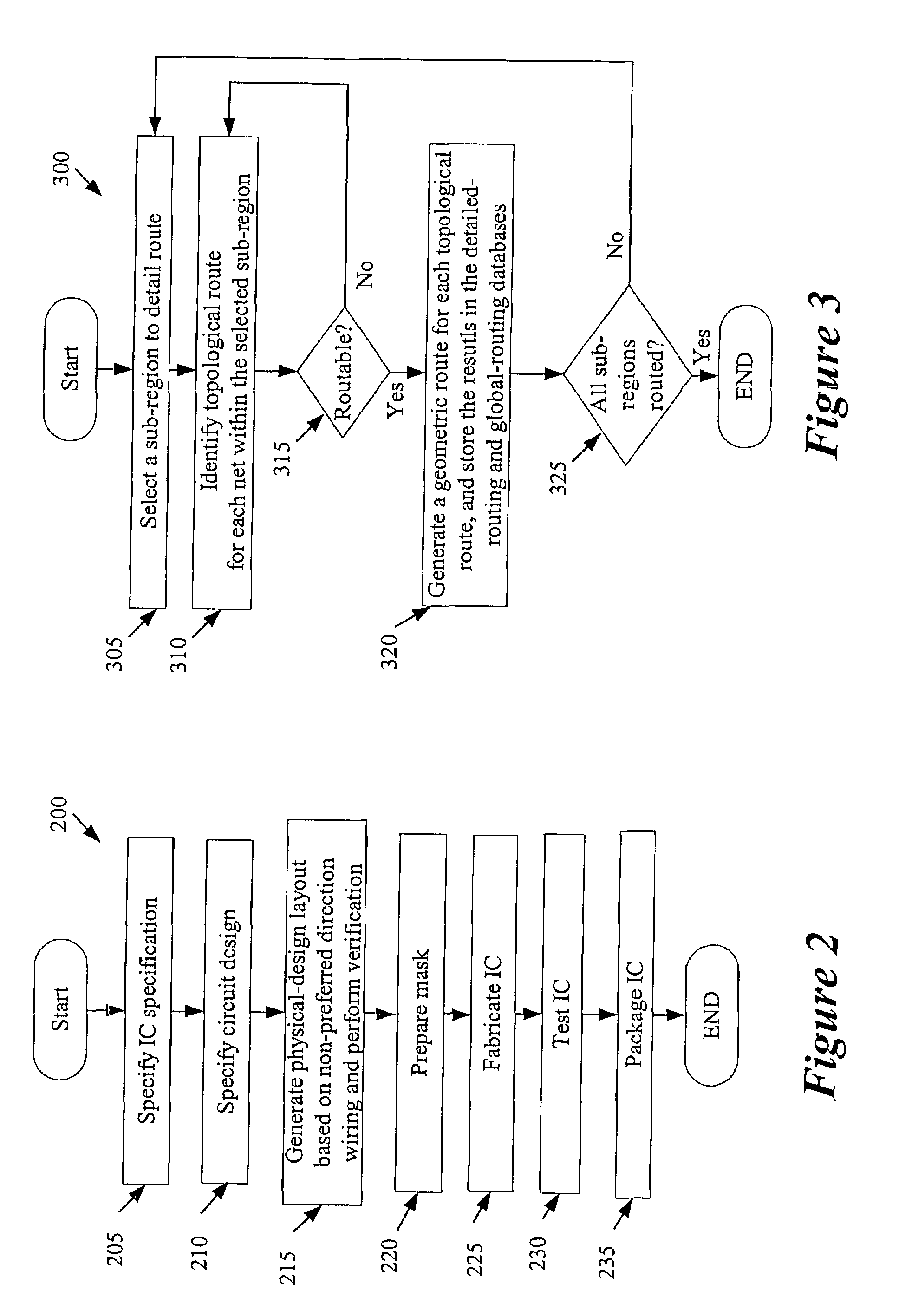

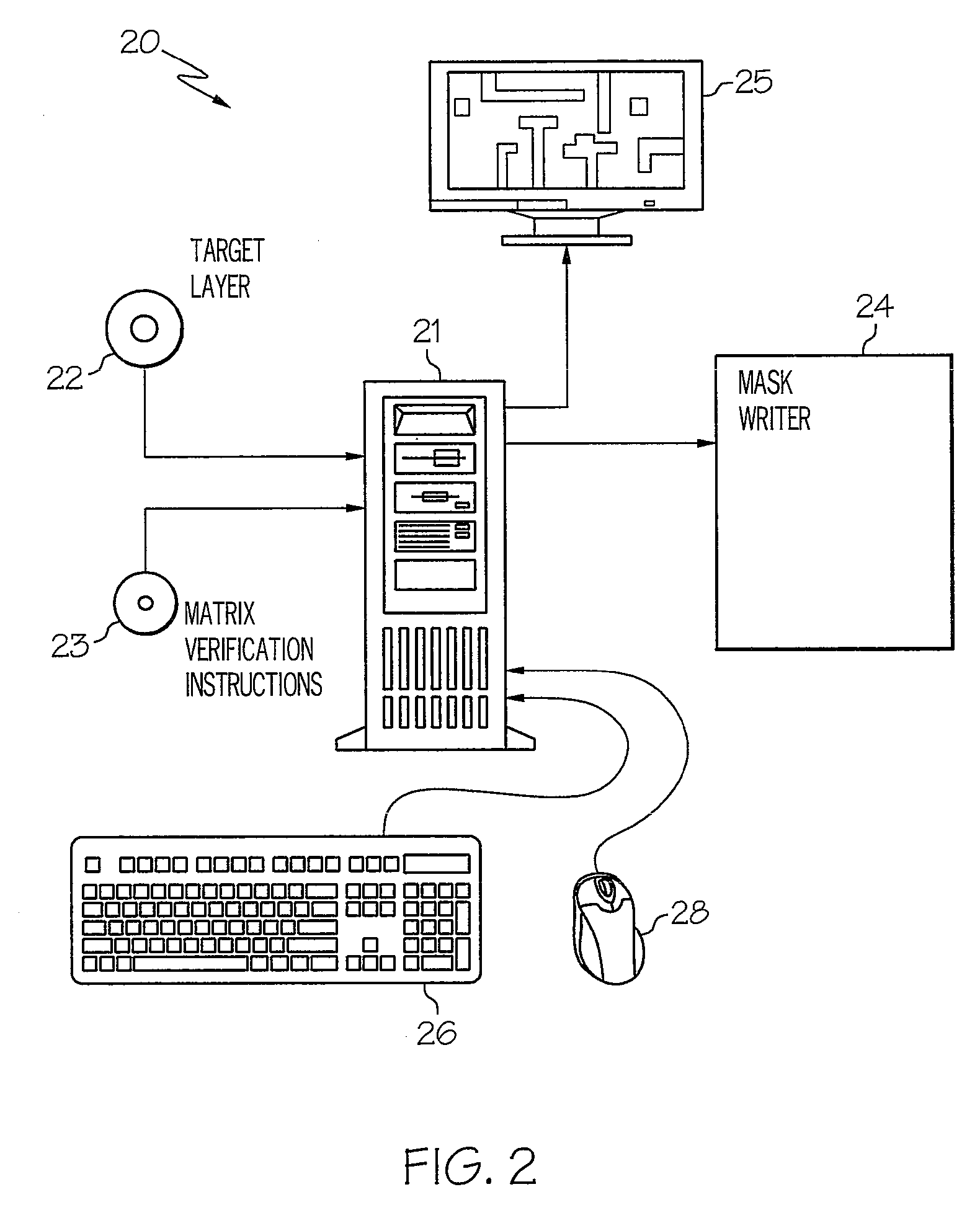

Some embodiments provide an integrated circuit that includes several circuits. The integrated circuit further includes a first interconnect wiring layer that has a first preferred direction of interconnect wiring. The integrated circuit also includes a second interconnect wiring layer that has a second preferred direction of interconnect wiring, where the first and second preferred directions of interconnect wiring are neither orthogonal nor parallel. The integrated circuit also includes several interconnect wiring on the first and second interconnect wiring layers that couples the circuits and are not aligned with any grid other than a manufacturing grid.

Owner:CADENCE DESIGN SYST INC

Gridless IC layout and method and apparatus for generating such a layout

InactiveUS6957411B1Solid-state devicesOriginals for photomechanical treatmentMethod selectionManufacturing grid

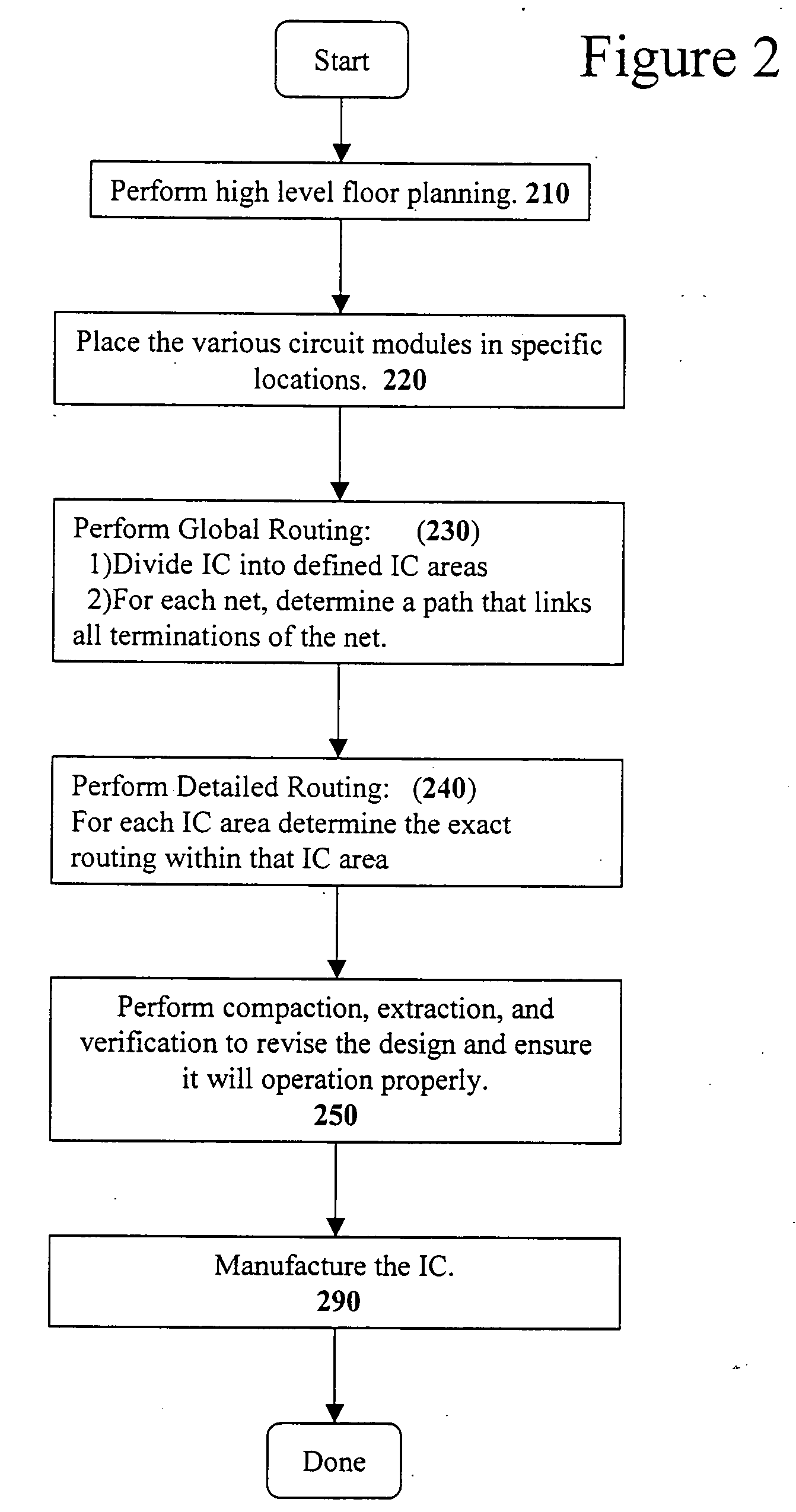

Some embodiments of the invention provide a method of routing nets in a region of an integrated-circuit (“IC”) layout. The method selects a net that has several routable elements. It then defines a route for the net. To define the route, the method uses a wiring model that specifies preferred non-Manhattan wiring directions. It also uses a manufacturing grid as the only grid for constraining the location of interconnect lines for connecting the net's routable elements.

Owner:CADENCE DESIGN SYST INC

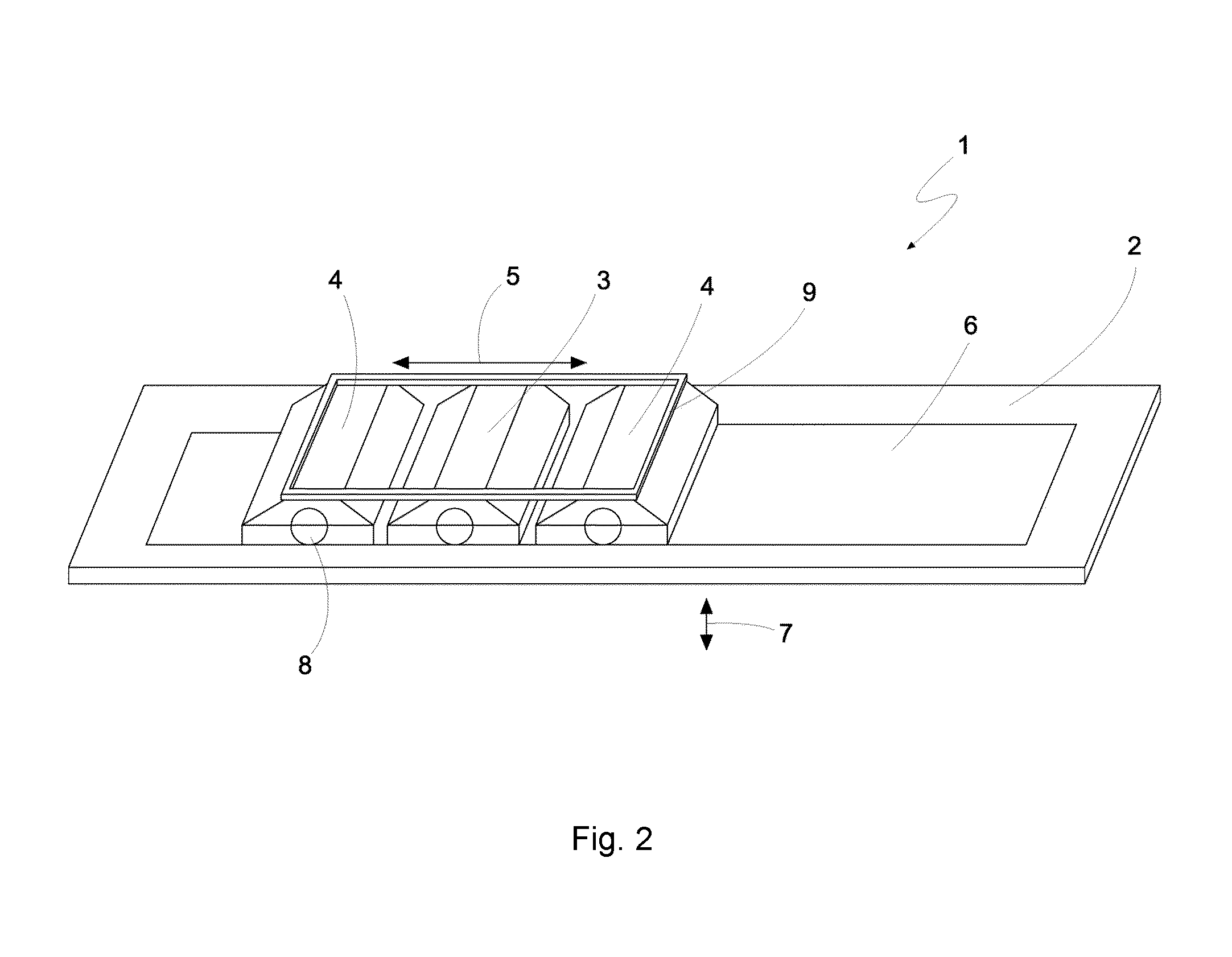

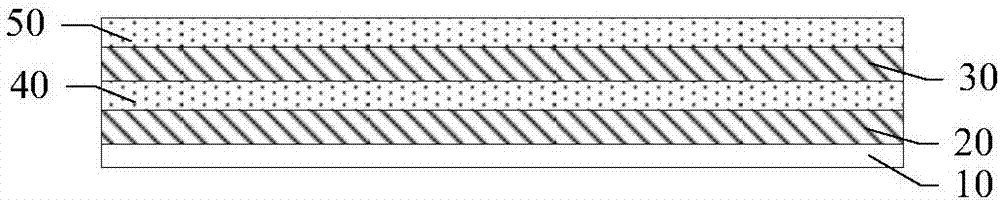

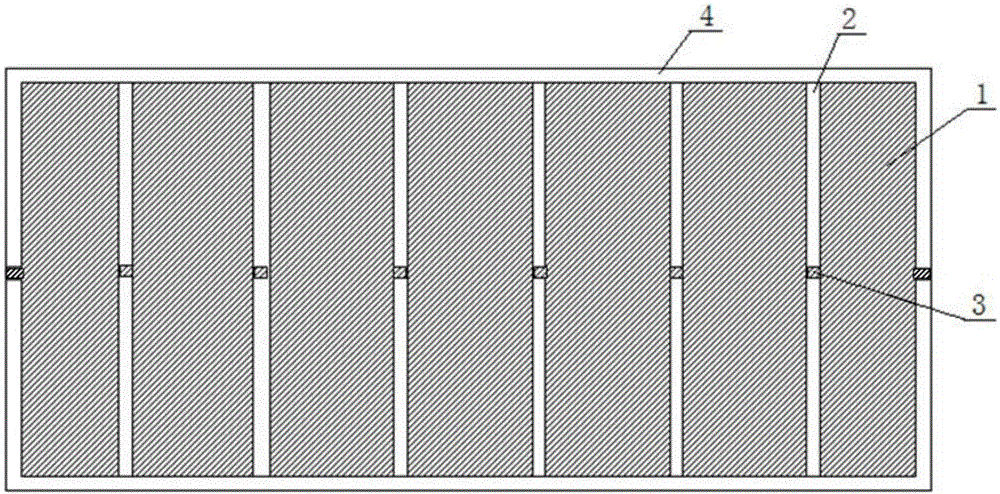

Additive manufacturing apparatus and method for operating the same

InactiveUS20160339542A1Quick and accurate layered manufacturingFast formingIncreasing energy efficiencyAdditive manufacturing with liquidsManufacturing gridManufactured apparatus

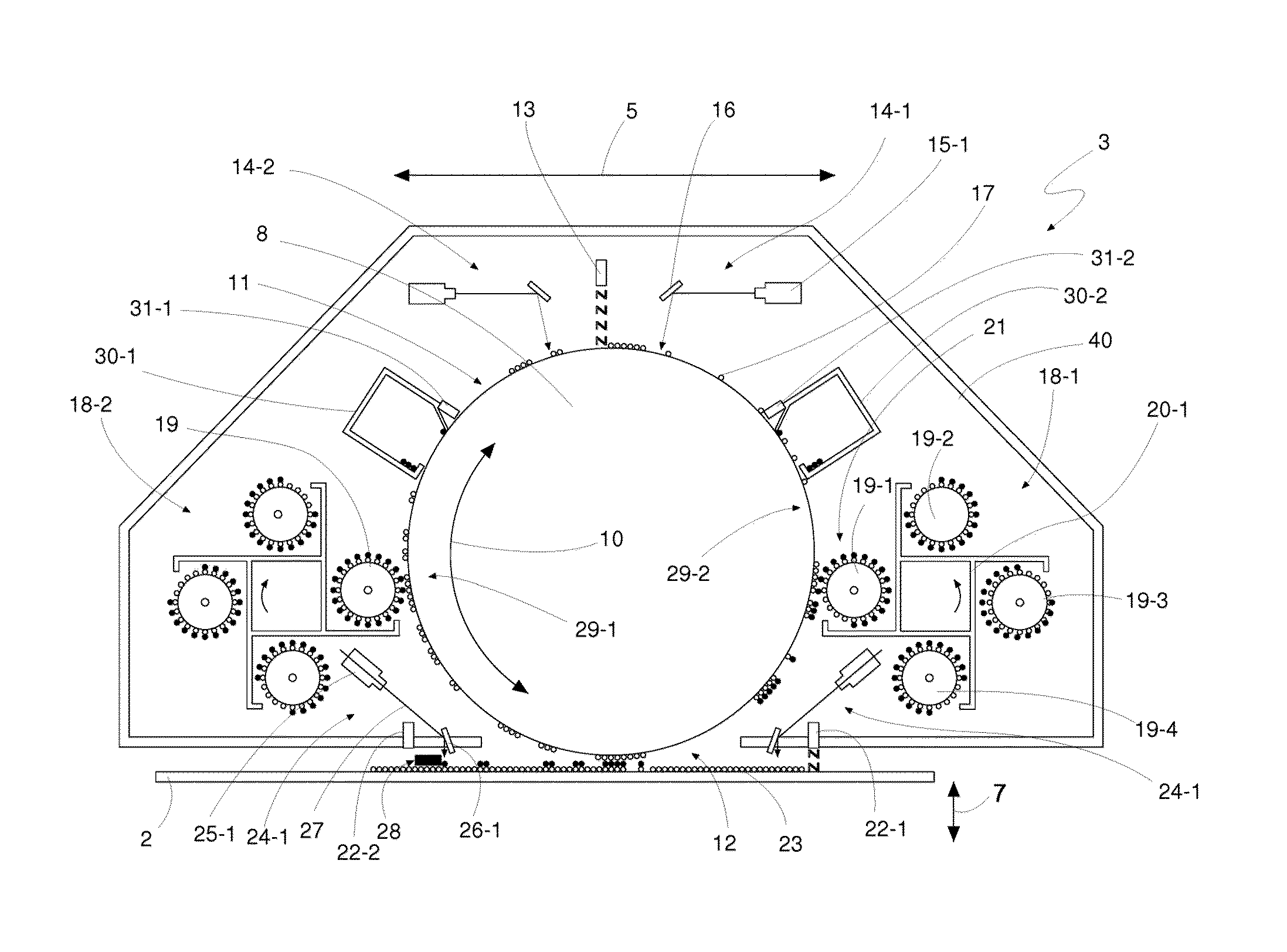

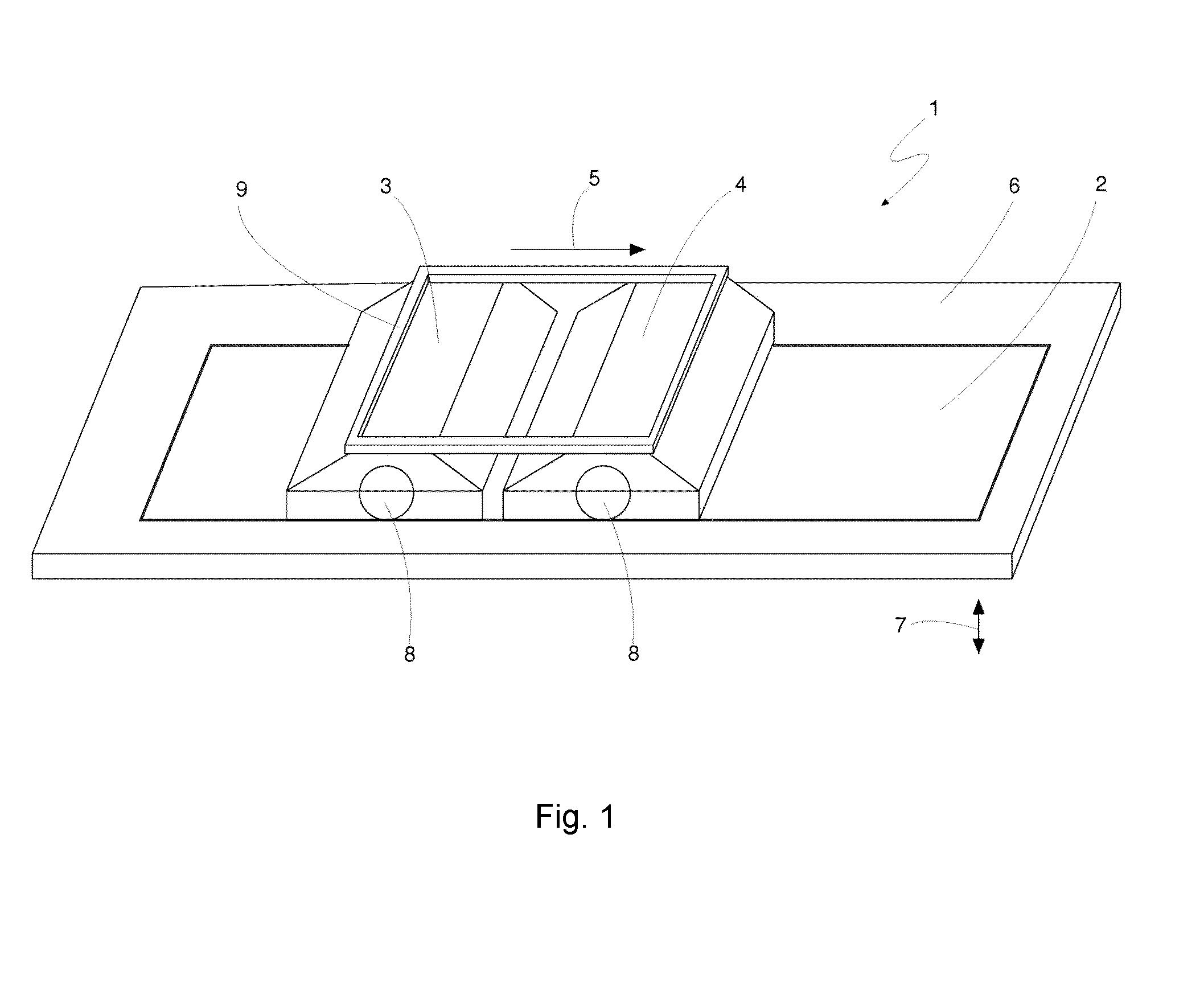

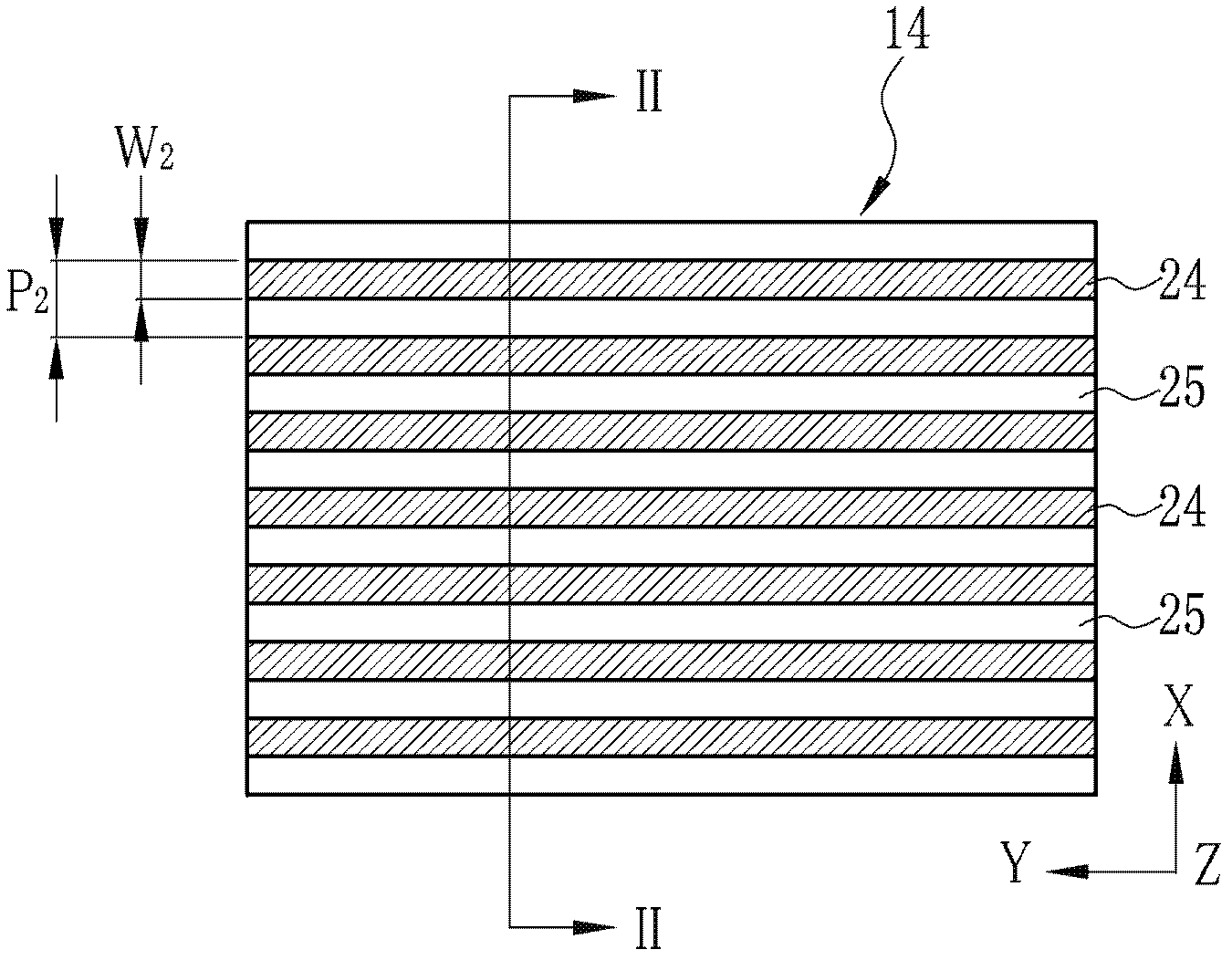

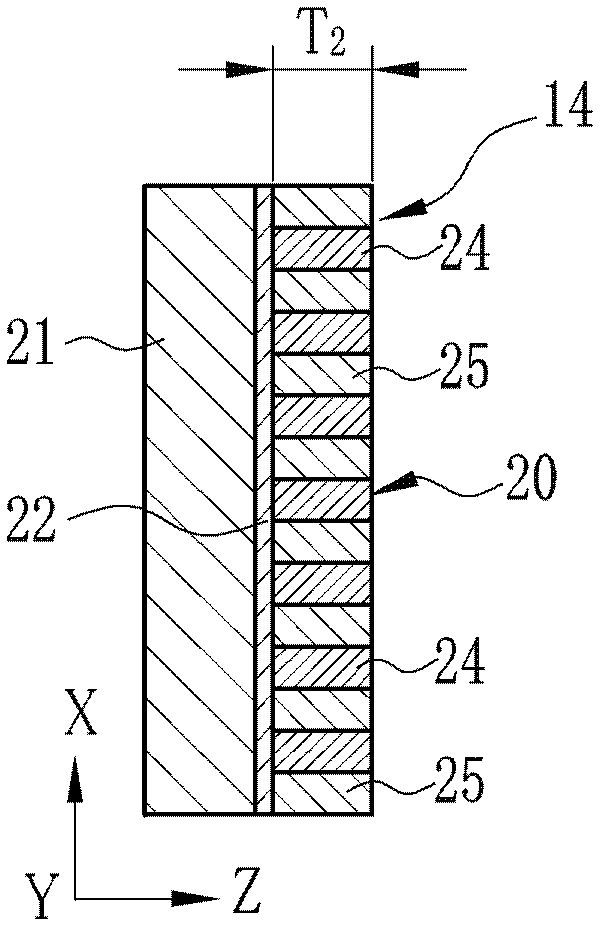

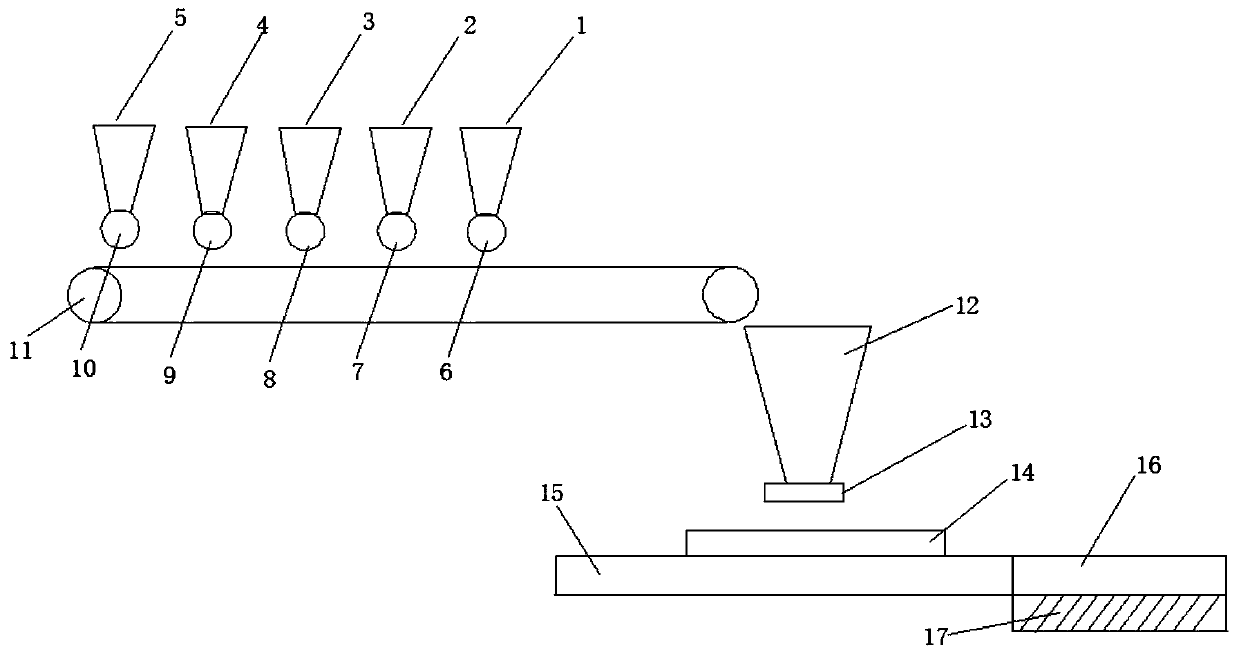

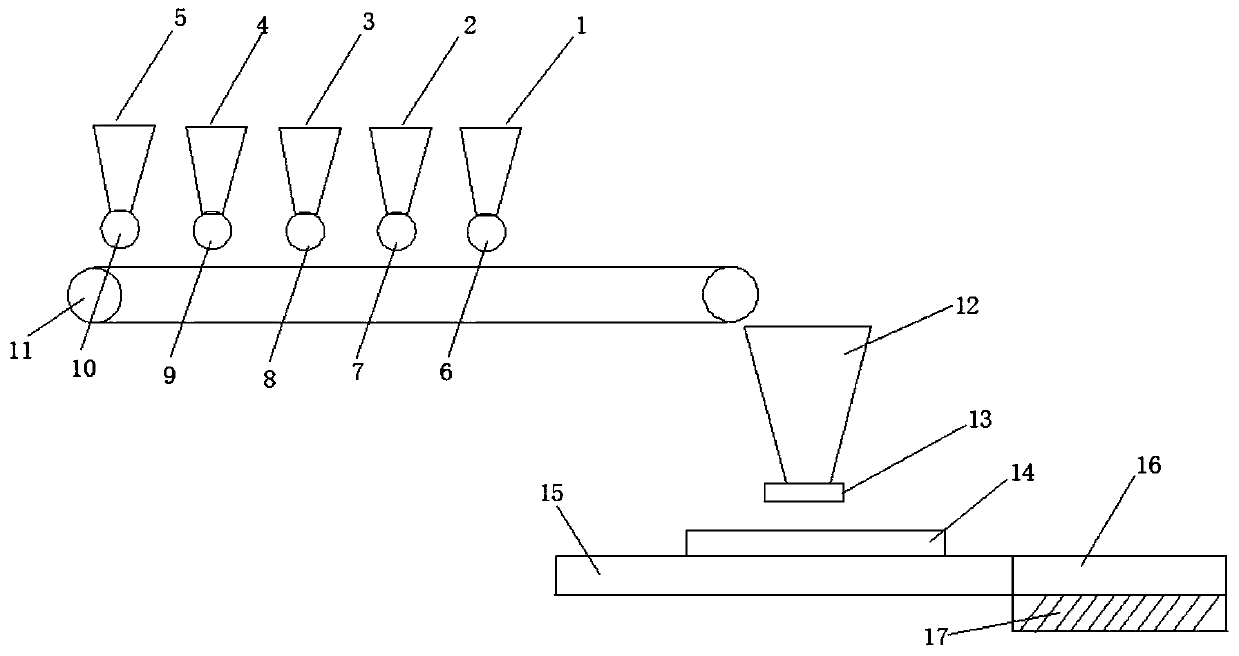

A rapid prototyping device for the layered additive manufacturing of three-dimensional objects with a manufacturing base and at least one manufacturing head, which is developed to dispense manufacturing material selectively according to location at the manufacturing site in grid positions according to predetermined manufacturing grids for each layer. In order to create a prototyping device which ensures fast and accurate three-dimensional workpieces in layers with the possibility of processing a plurality of manufacturing materials, a fuser unit of the manufacturing head is developed to fuse the manufacturing material located on the respective grid positions to the grid positions selectively according to location.

Owner:PAETZ DOMINIQUE

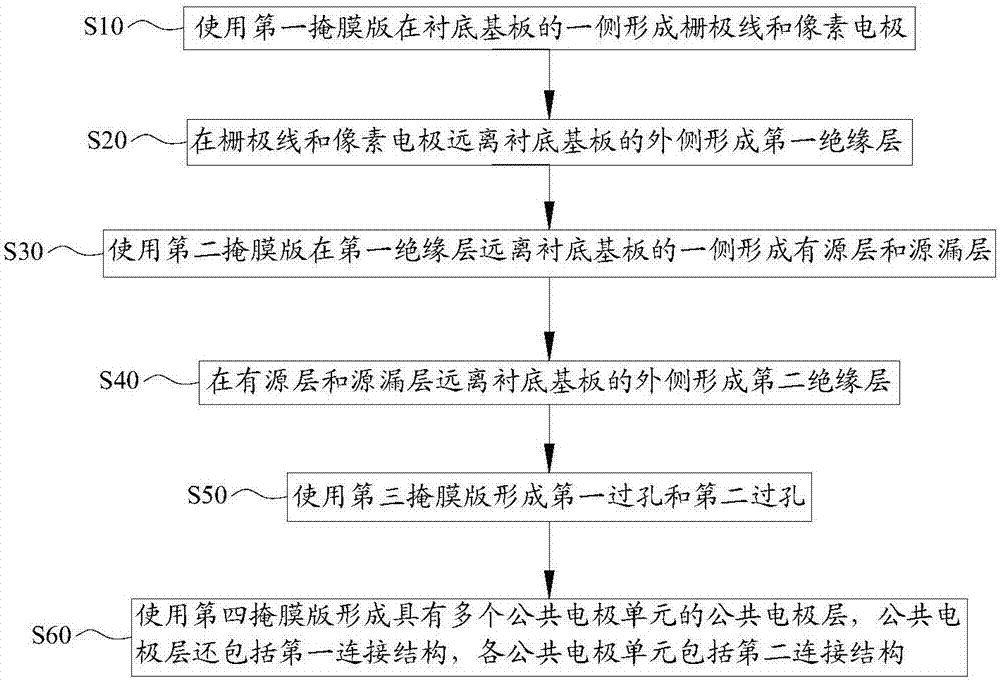

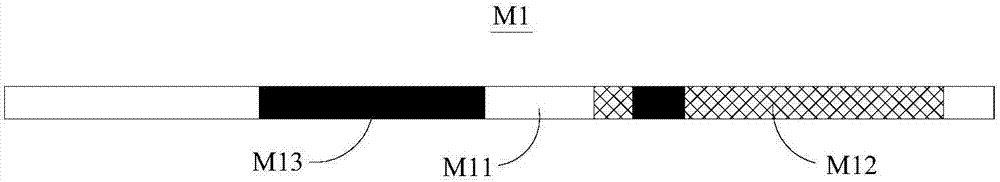

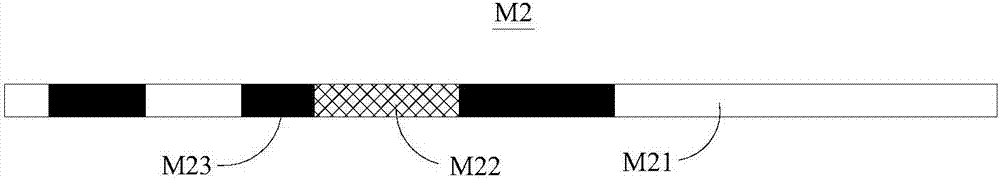

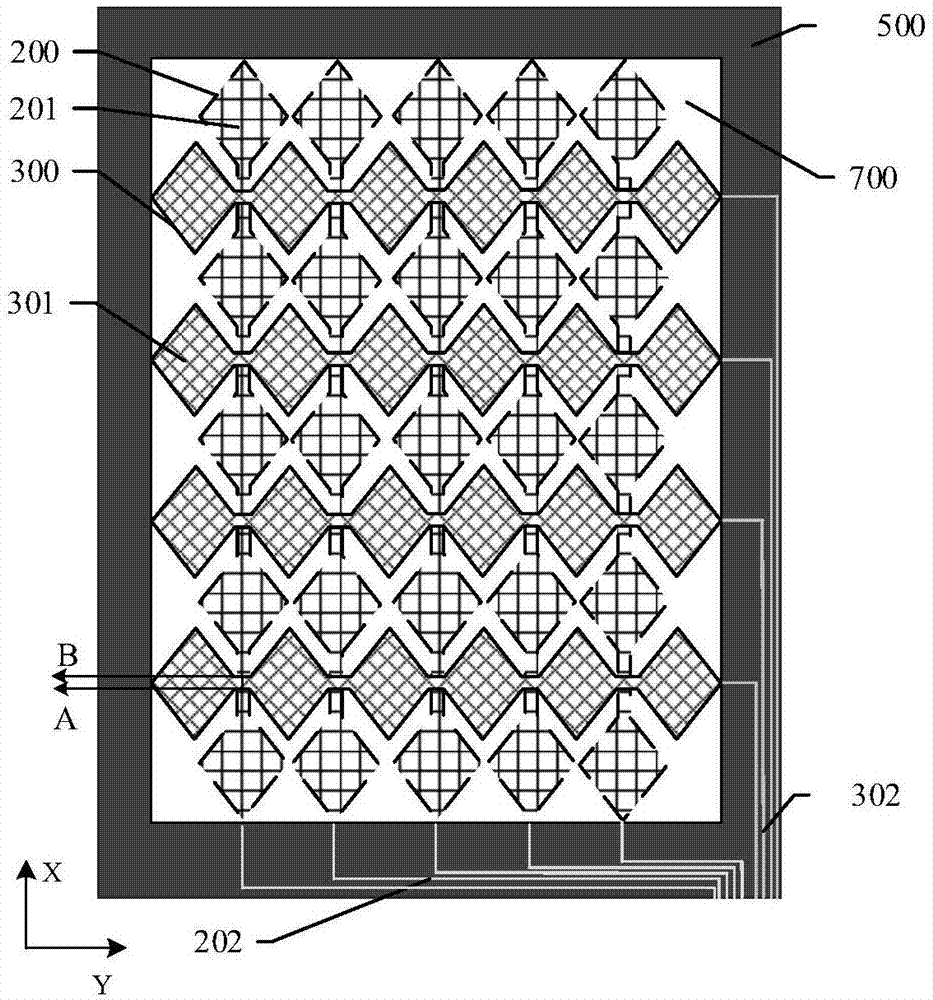

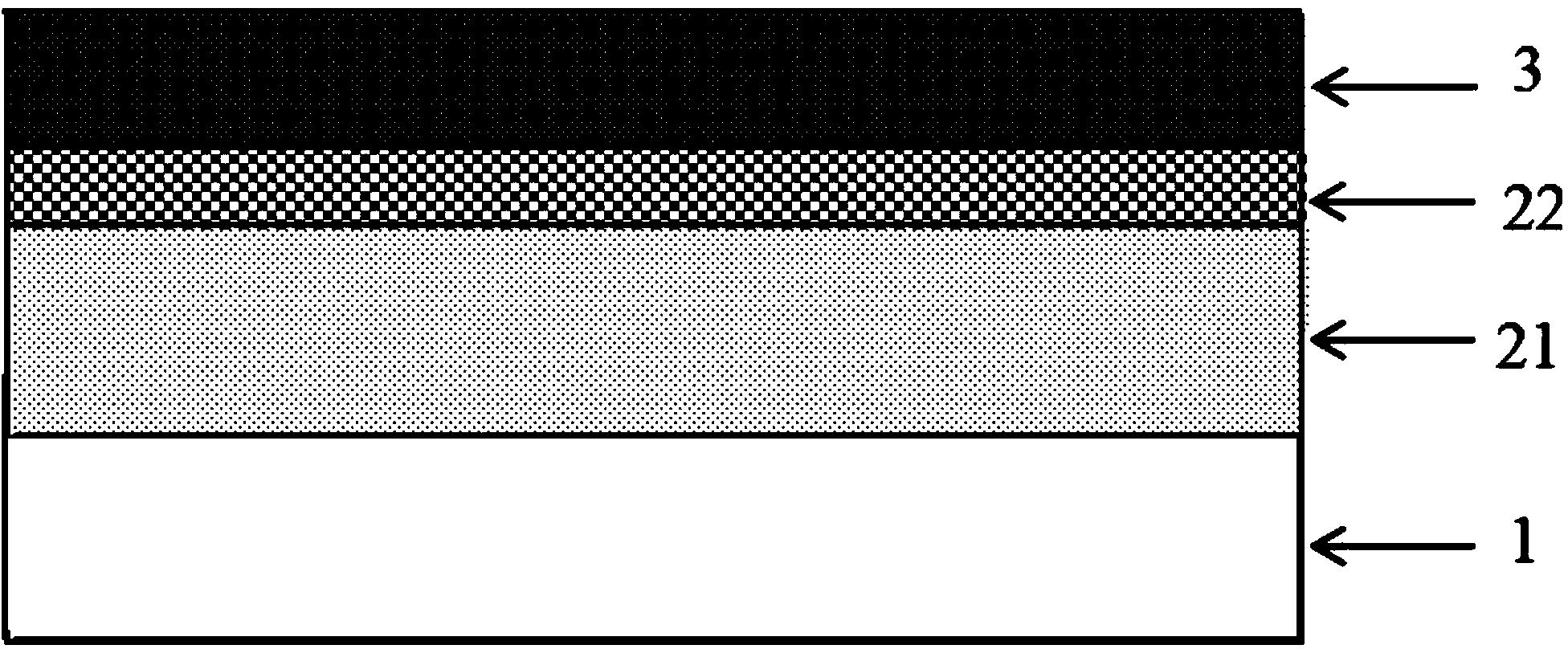

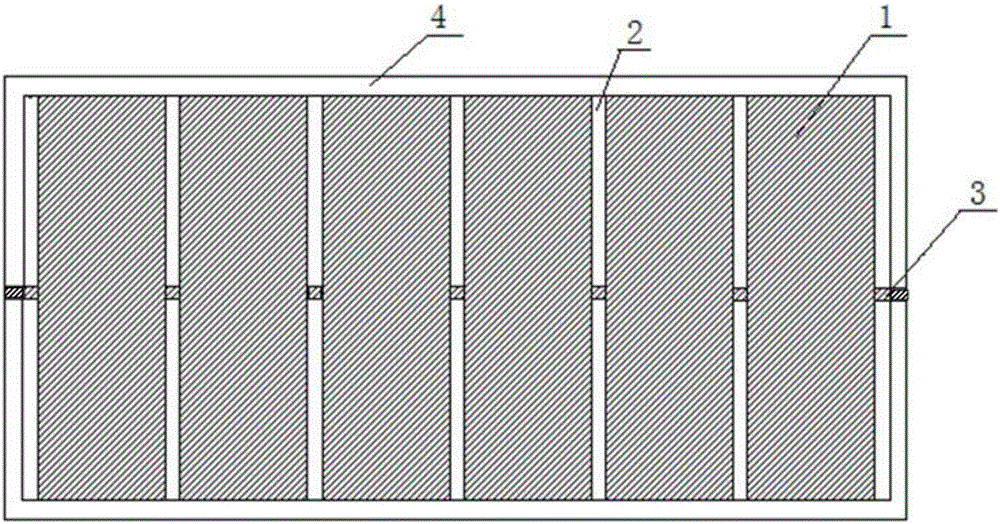

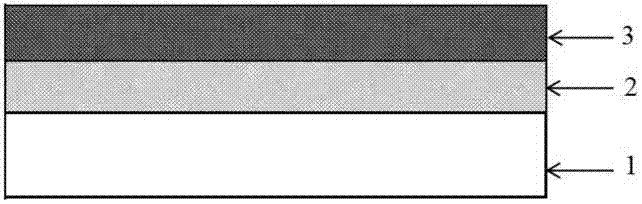

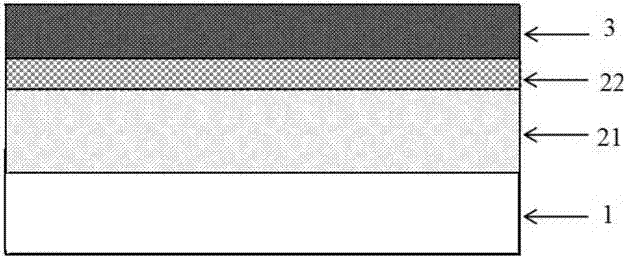

Array substrate, display panel, display device and manufacturing method of array substrate

ActiveCN107093584AReduce in quantityReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingManufacturing cost reductionManufacturing grid

The invention relates to the technical field of display, and particularly relates to an array substrate, a display panel, a display device and a manufacturing method of the array substrate. The manufacturing method comprises the steps of manufacturing grid lines and pixel electrodes by adopting a first mask plate, manufacturing a thin film transistor and a touch signal line by adopting a second mask plate, manufacturing a first via hole and a second via hole by adopting a third mask plate, and manufacturing a common electrode layer by adopting a fourth mask plate, wherein the common electrode layer comprises a first connecting structure and a common electrode unit, the common electrode unit comprises a second connecting structure, the first connecting structure is contacted with a drain electrode and the pixel electrodes through the first via hole, and the second connecting structure is contacted with the touch signal line through the second via hole. According to the invention, manufacturing of the array substrate is realized through the four mask plates, the number of the mask plates is reduced, and thus the manufacturing cost can be reduced.

Owner:SHANGHAI AVIC OPTOELECTRONICS

Grid polarizing film, method for manufacturing grid polarizing film, optical laminate, method for manufacturing optical laminate, and liquid crystal display apparatus

InactiveCN101185013APrecision control distributionImprove utilization efficiencyPolarising elementsNon-linear opticsLiquid-crystal displayBand shape

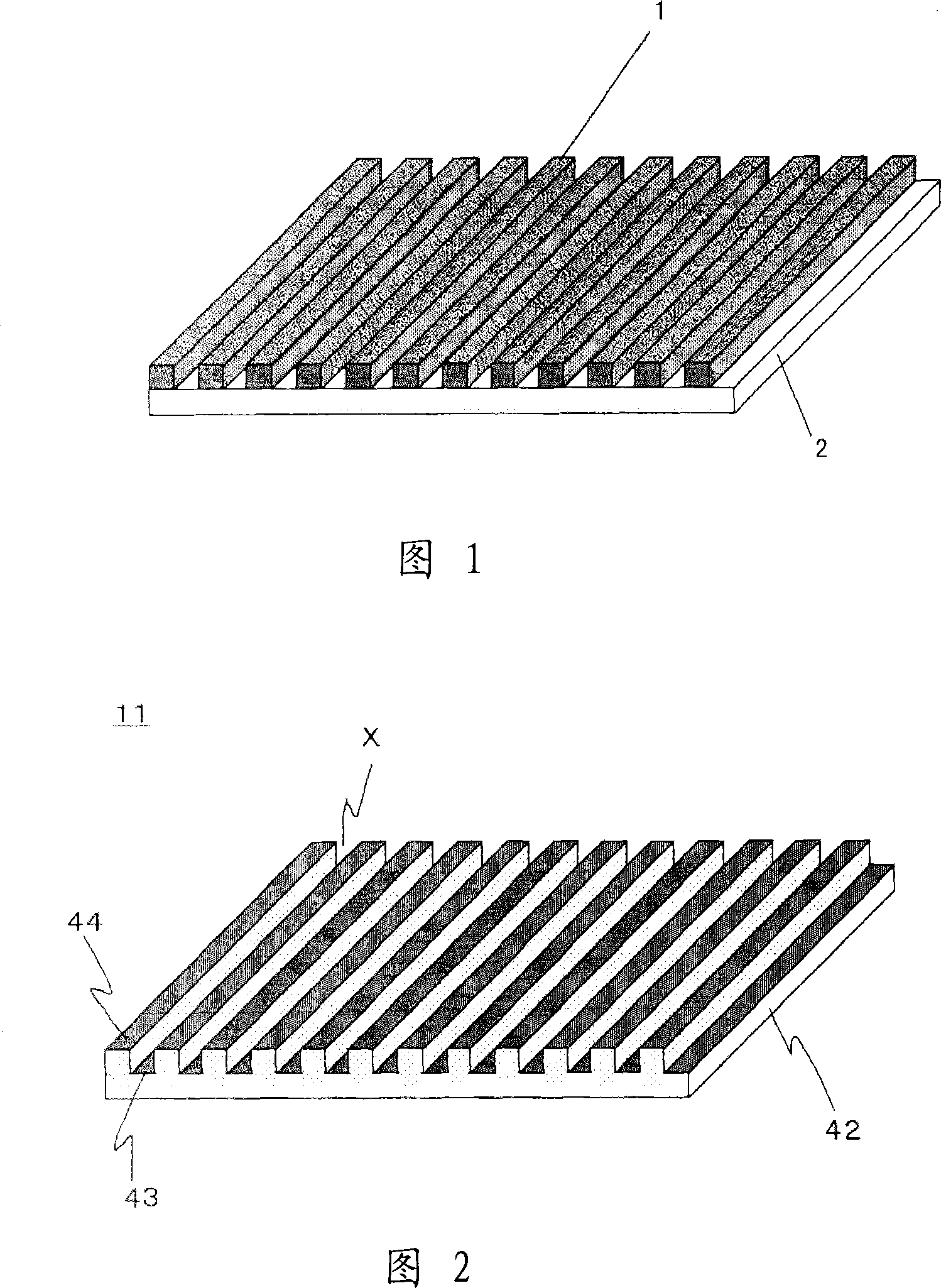

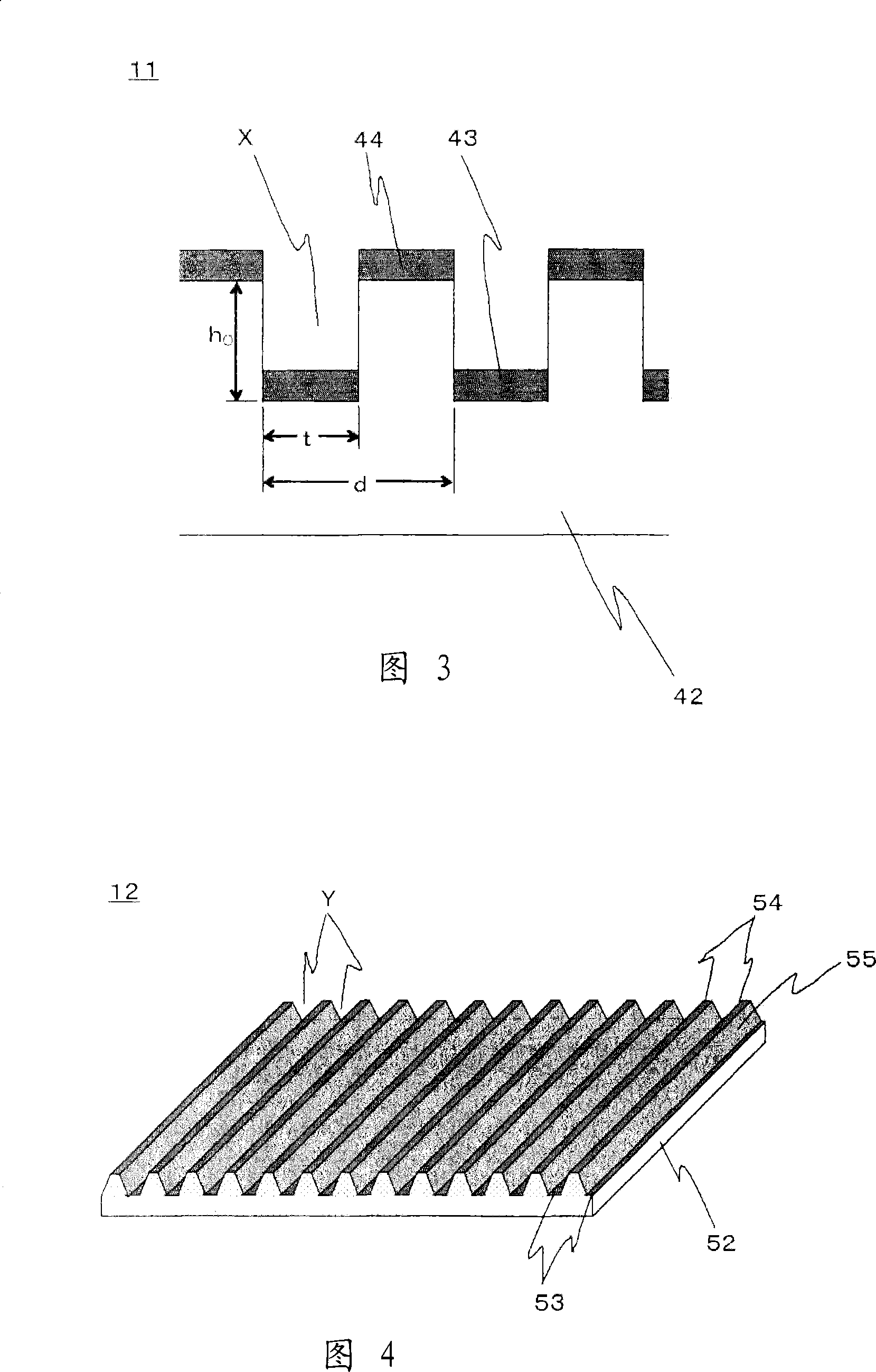

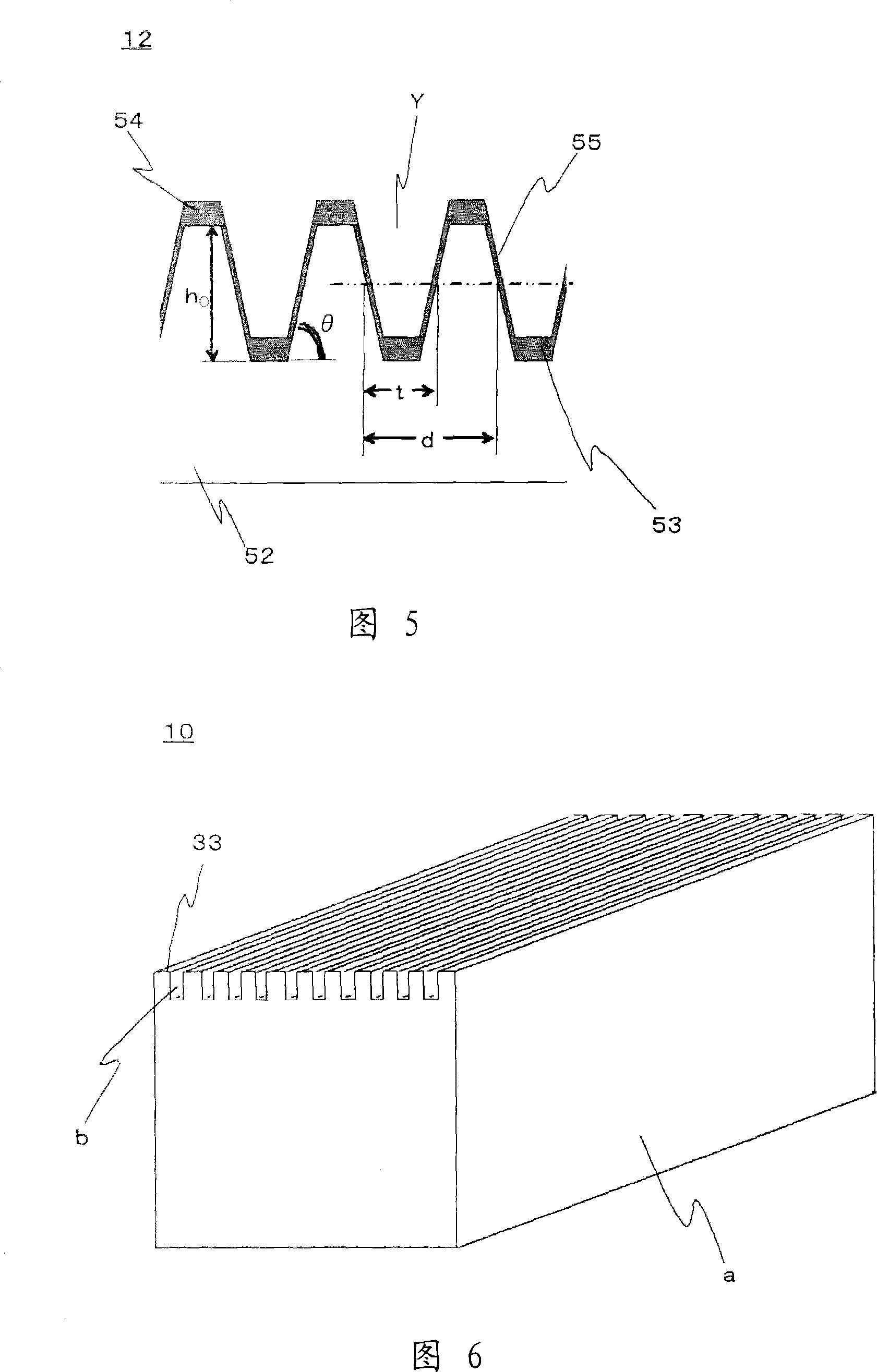

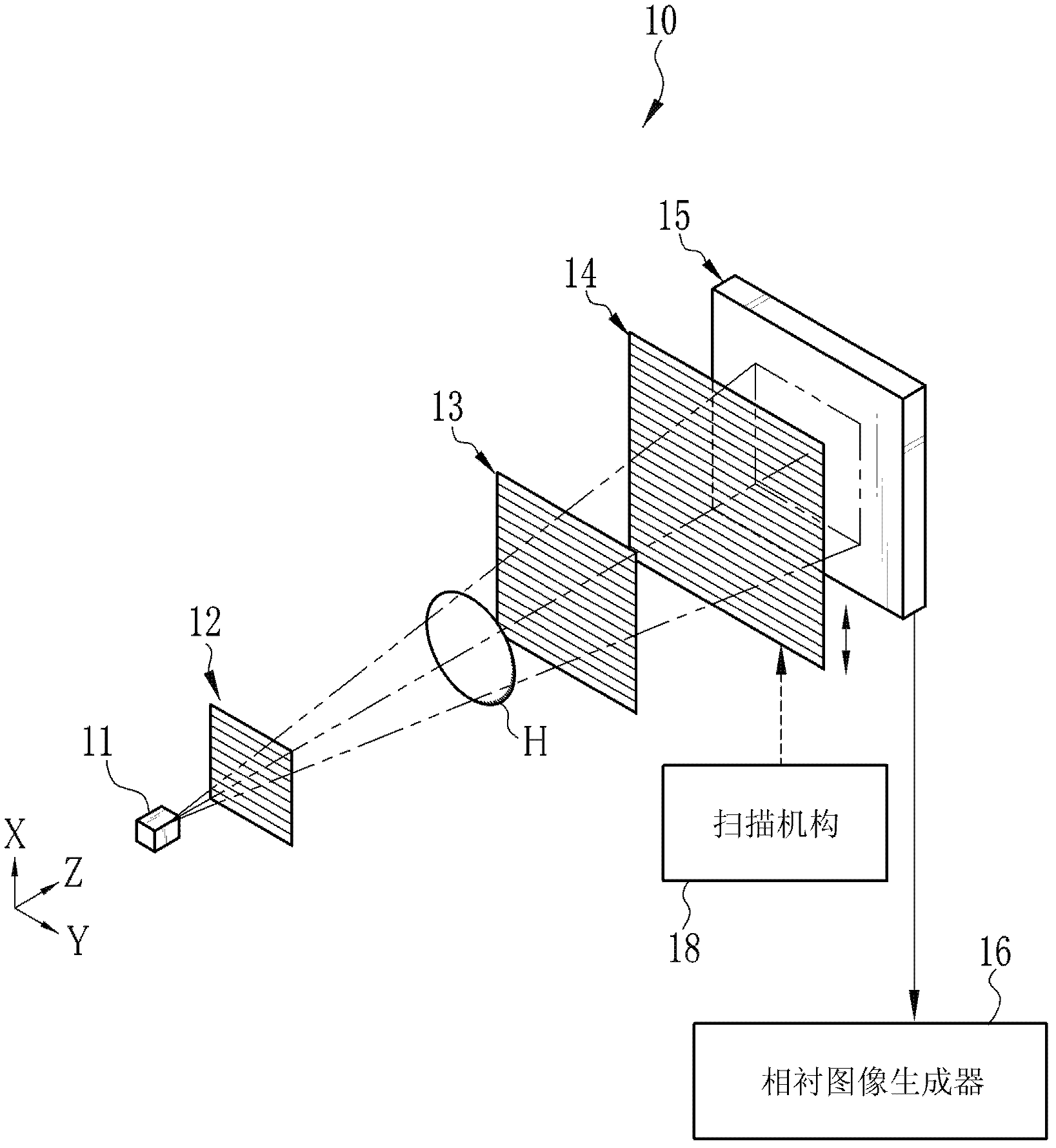

The present invention provides a strip-shaped grid polarizing film, which includes: a strip-shaped resin film and a plurality of grid lines extending approximately parallel to each other arranged on the surface and / or inside of the resin film, the grid The line is made of a material G having an absolute value of 1.0 or more of the difference between the real part n1 and the imaginary part κ1 of the birefringence index (N1=n1-iκ1), and a plurality of grooves extending approximately parallel to each other are formed on the surface of the resin film, The above-mentioned grid lines are composed of a thin film of material G laminated on the bottom surface of the grooves and / or on the top surface of the ridges between adjacent grooves. Also provided is an elongated optical laminate comprising the elongated elongated grid polarizing film and other elongated elongated polarizing optical films.

Owner:ZEON CORP

Grid for radiography, radiation image detector, radiation imaging system, and method for manufacturing grid

InactiveCN102590913APrevent proliferationReduce vignettingDiffraction gratingsTomographyEtchingX-ray

Owner:FUJIFILM CORP

Preparation method and preparation device of marble tiles with entire-body textures

InactiveCN109702862ATexture stretches consistentlySolve the problem of unsightly appearanceFeeding arrangmentsShaping press ramSurface layerManufacturing grid

The invention discloses a preparation method and a preparation device of marble tiles with entire-body textures. The preparation method comprises the following steps: scanning selected natural marblestones to obtain a big design sketch; manufacturing grids for performing material pushing and material distribution on blank bodies according to texture characteristics of the design sketch; conveyingand distributing powder and compressing by the material pushing and distributing grids so as to obtain tile blank bodies after the materials are distributed by a material distributing device; and inputting the big design sketch into an on-line working 8D ink-jet printer and performing glaze-decorated printing patterns on the surface of the tile blank body. According to the tile blank bodies manufactured by adopting the method and the device disclosed by the invention, stone line textures, blocks and layers of colored blanks, positioned from a bottom layer to a surface layer, arranged in the tile blank bodies correspond to glazed textures which are arranged on the surfaces of the tiles and printed by the ink-jet printer, so that the problem that deep processing of the various tiles, such as tile grooving and chamferring are carried out after ink-jet printing so as to result in bottom exposure and no attractiveness is solved, and up-down, left-right and front-back three-dimensional extension of the textures of the tile products can be achieved to ensure that the tiles are vivid like natural stones.

Owner:广西南宁武鸣启行陶瓷有限公司

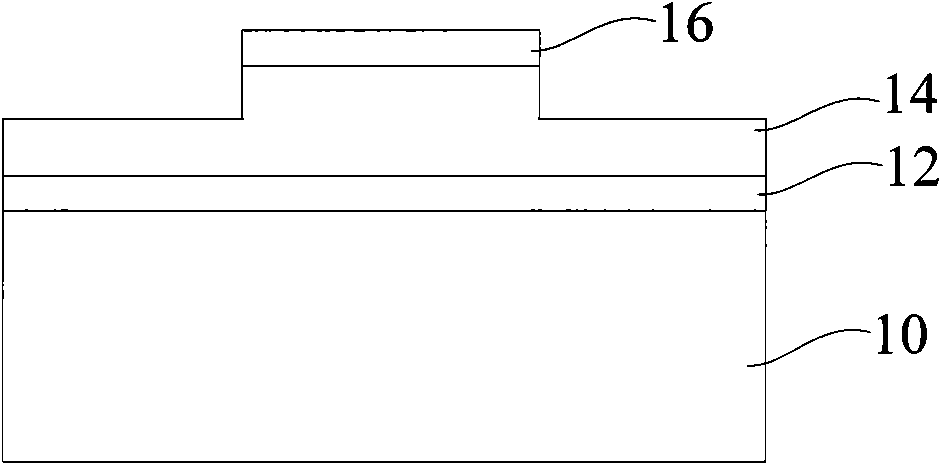

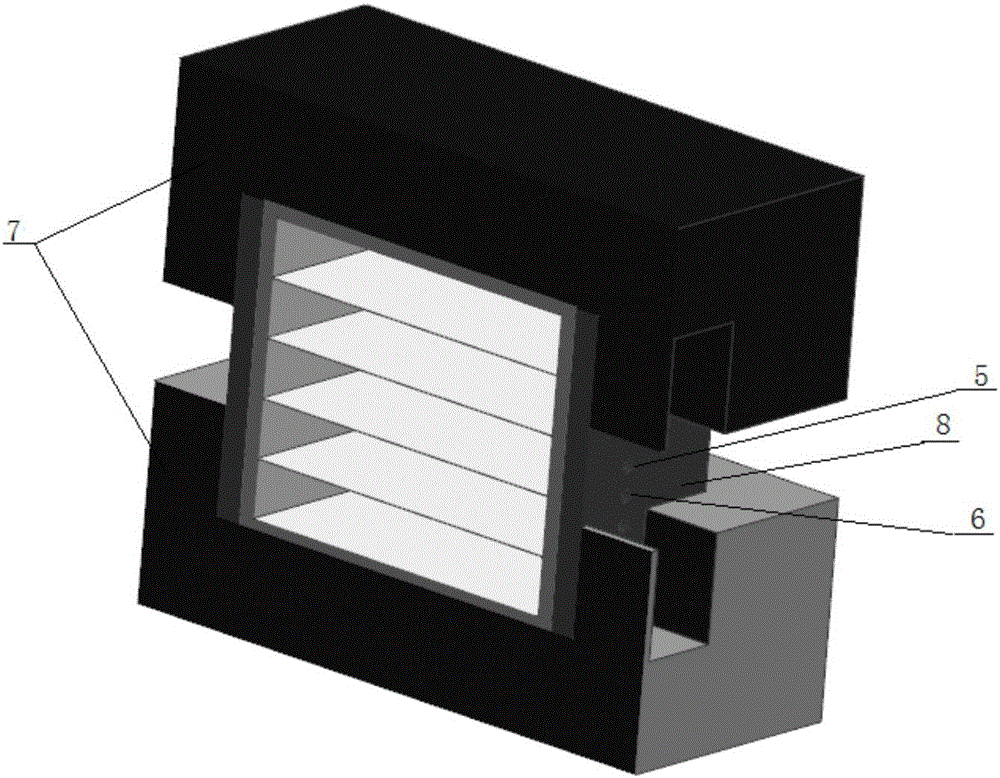

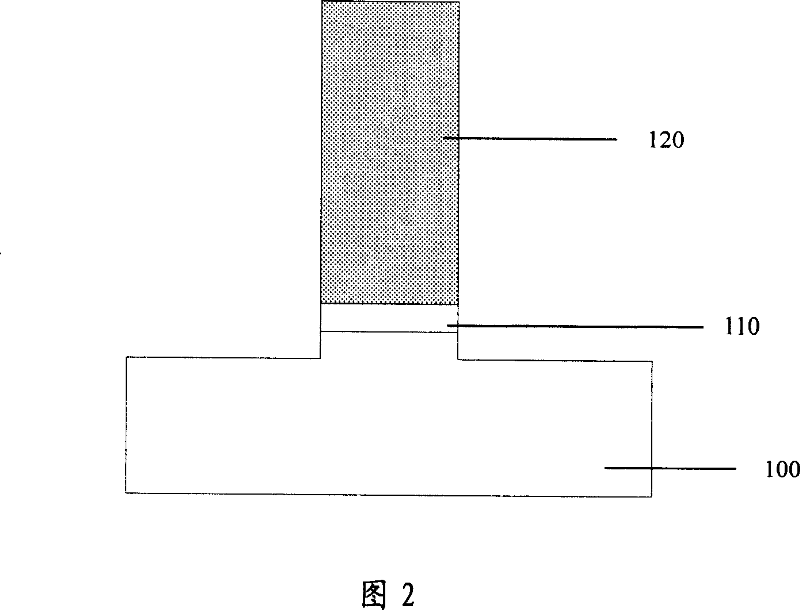

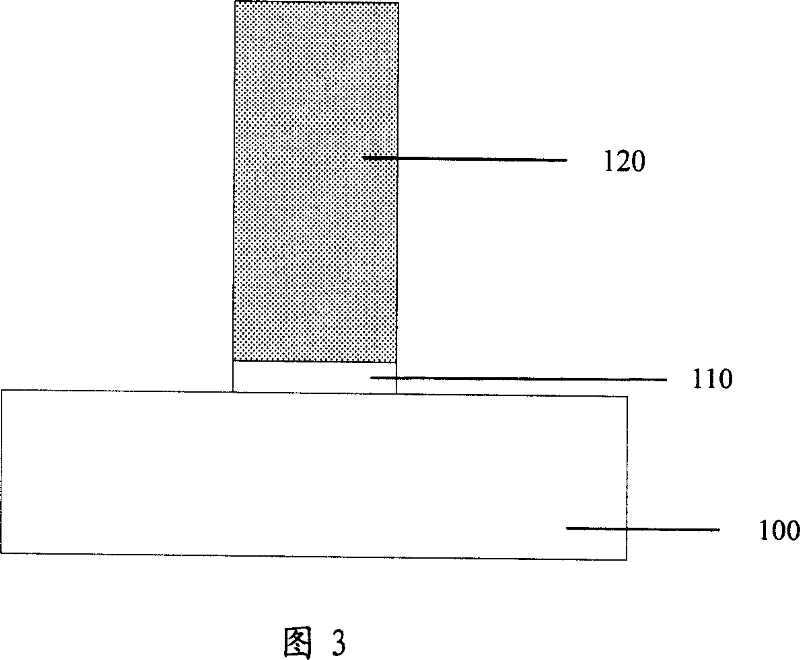

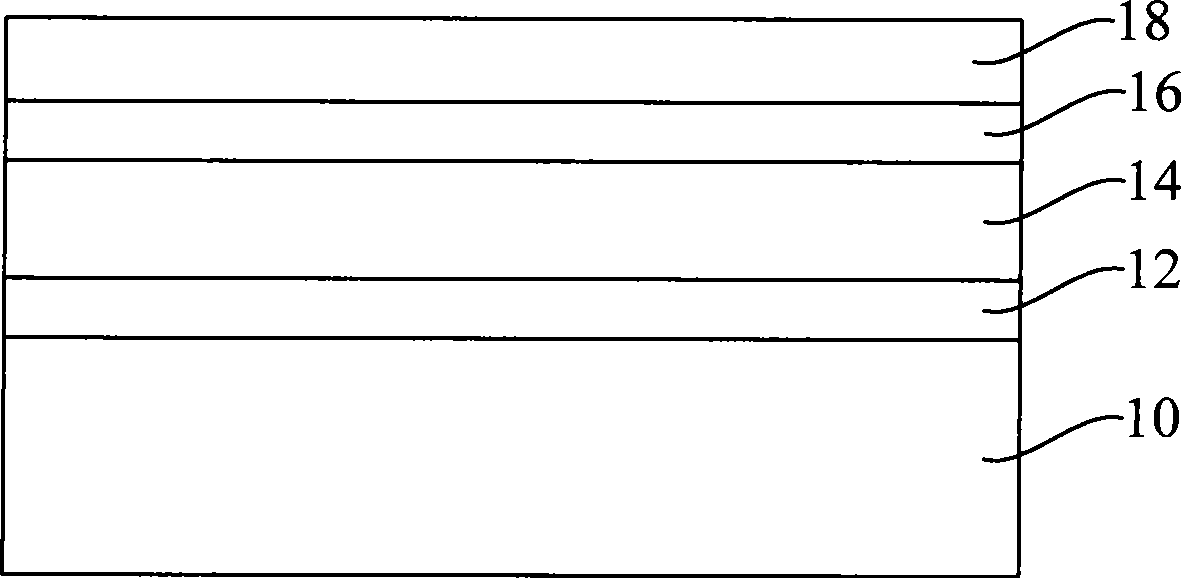

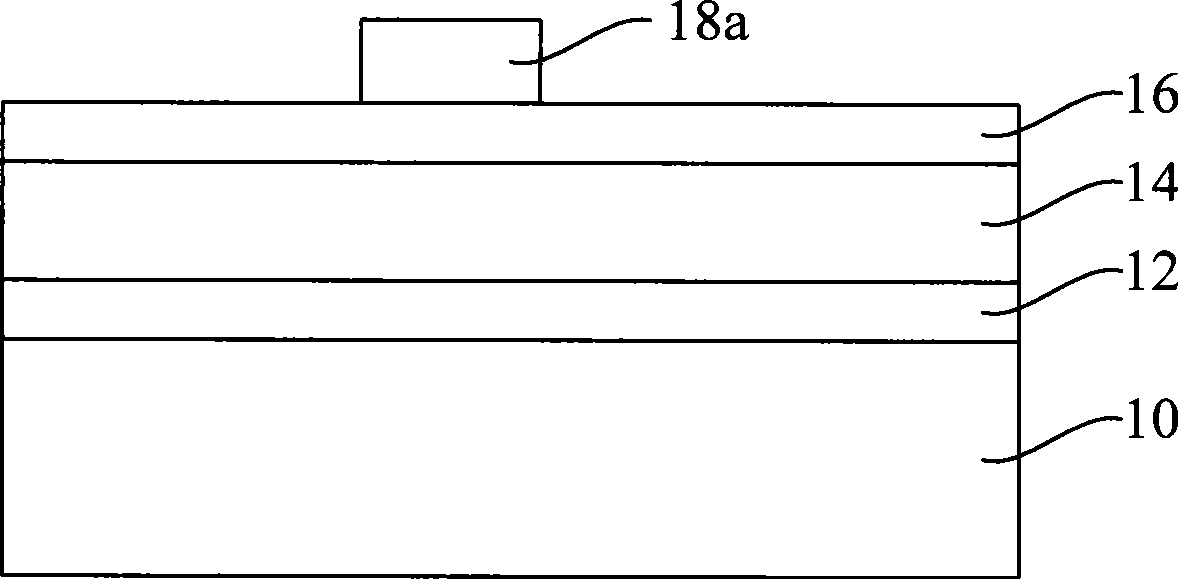

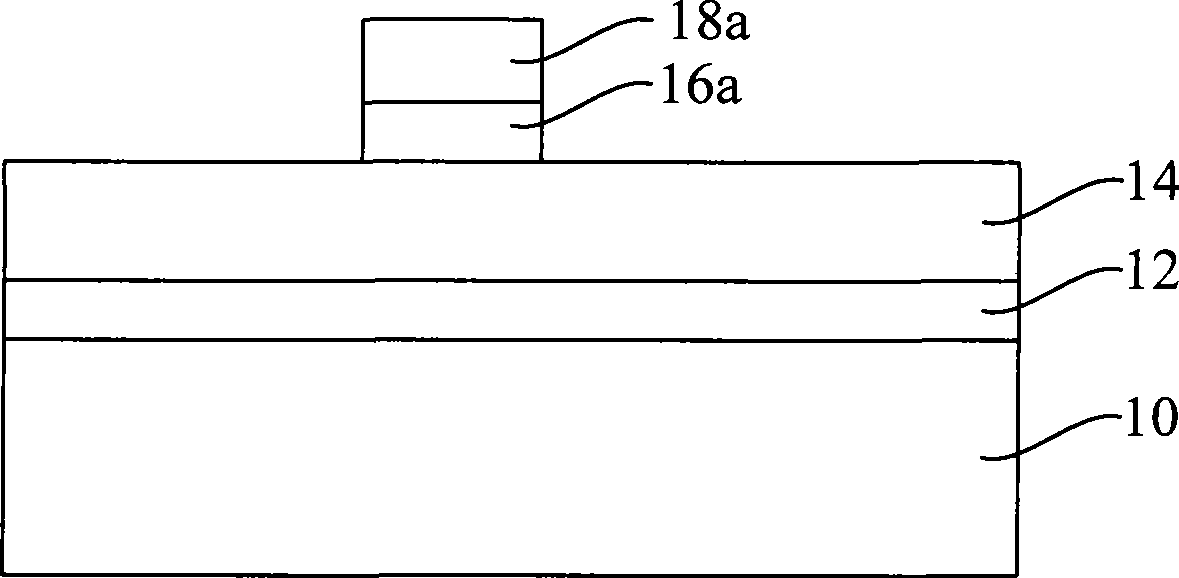

Manufacturing method for grid and semiconductor device, construction for manufacturing grid

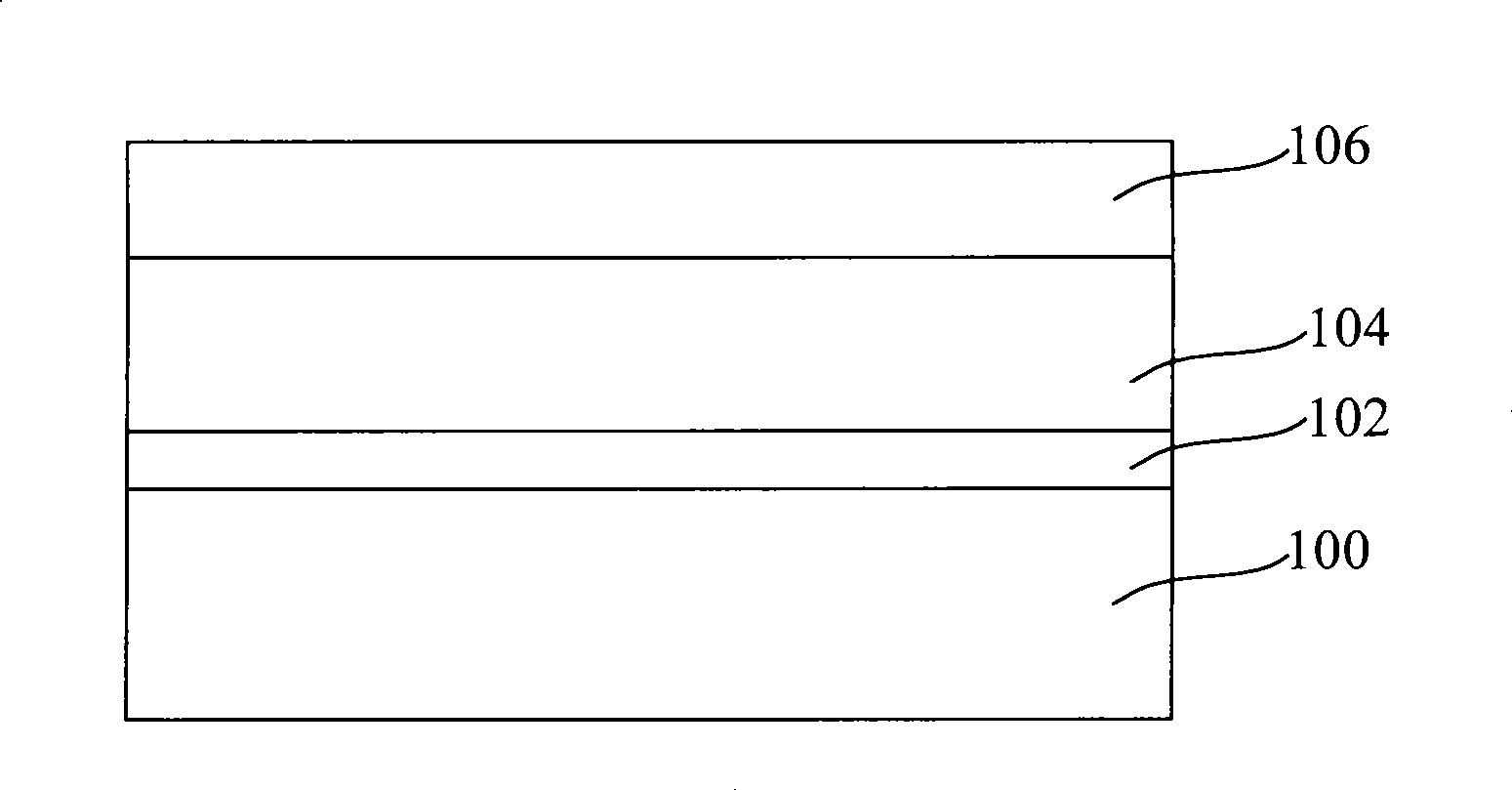

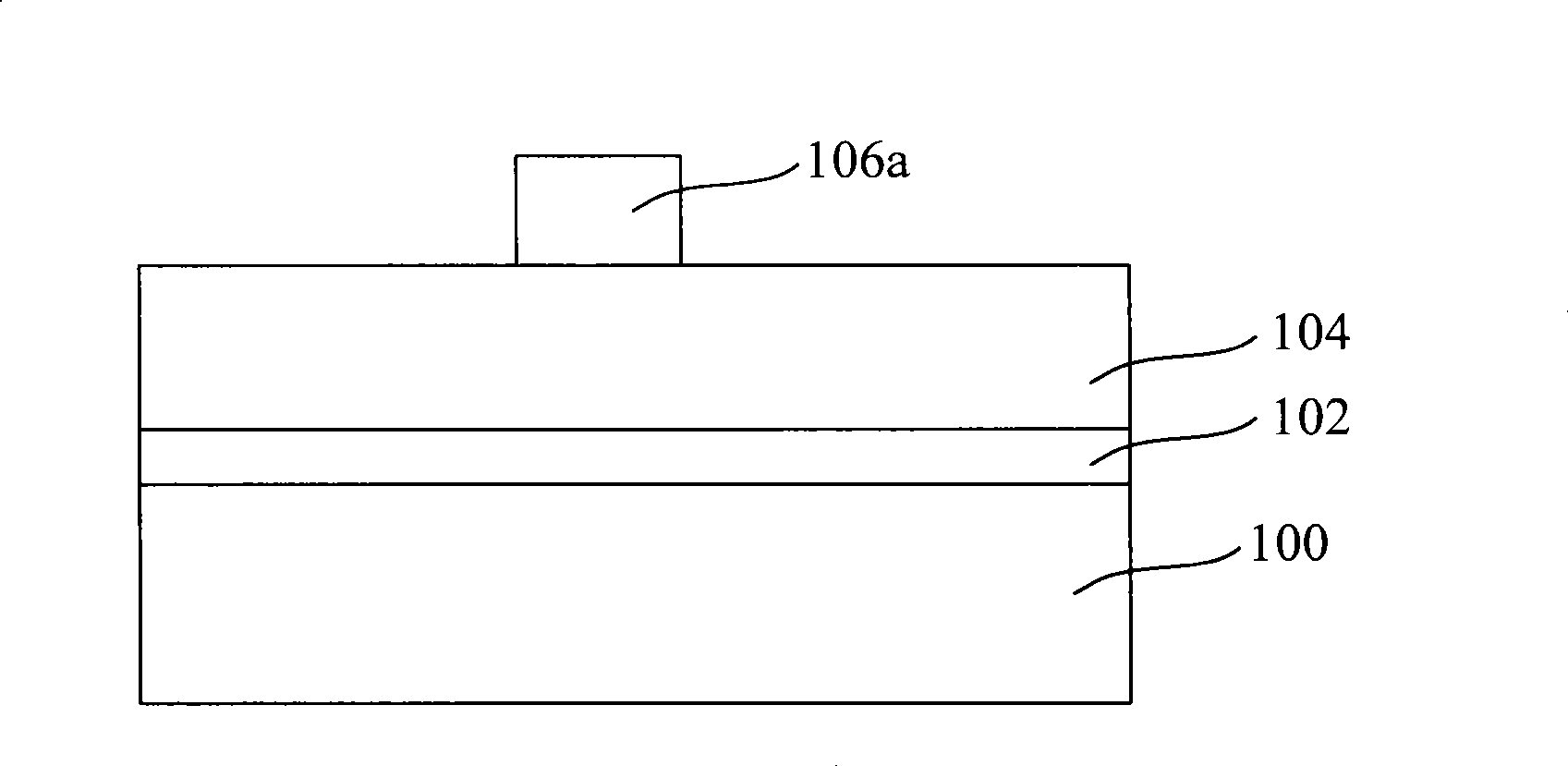

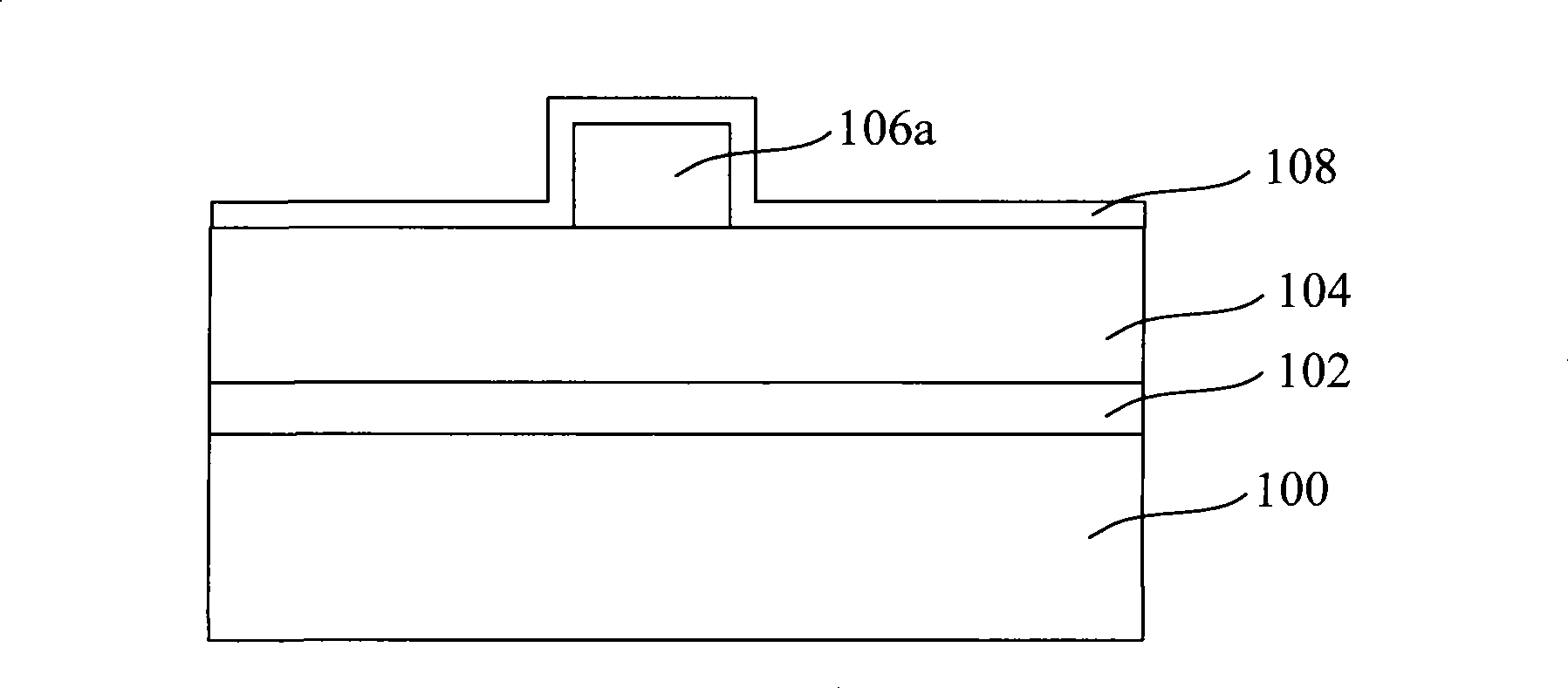

ActiveCN101364537AWell profiled side wallsTurn on high sensitivitySemiconductor/solid-state device manufacturingSemiconductor devicesManufacturing gridSemiconductor

A method for grid electrode manufacture comprises the following steps: providing a semiconductor substrate with a grid layer; forming a first material layer on the grid layer; forming a second material layer on the first material layer; patterning the second material layer to form a second material layer pattern; forming a sidewall layer on the side wall of the second material layer pattern; removing the second material layer pattern; and etching the first material layer and the grid layer which are not covered by the sidewall layer to form a grid electrode. The invention also provides a manufacturing method of a semiconductor device and a structure for forming the grid electrode. The grid electrode formed by using the method has better profile.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

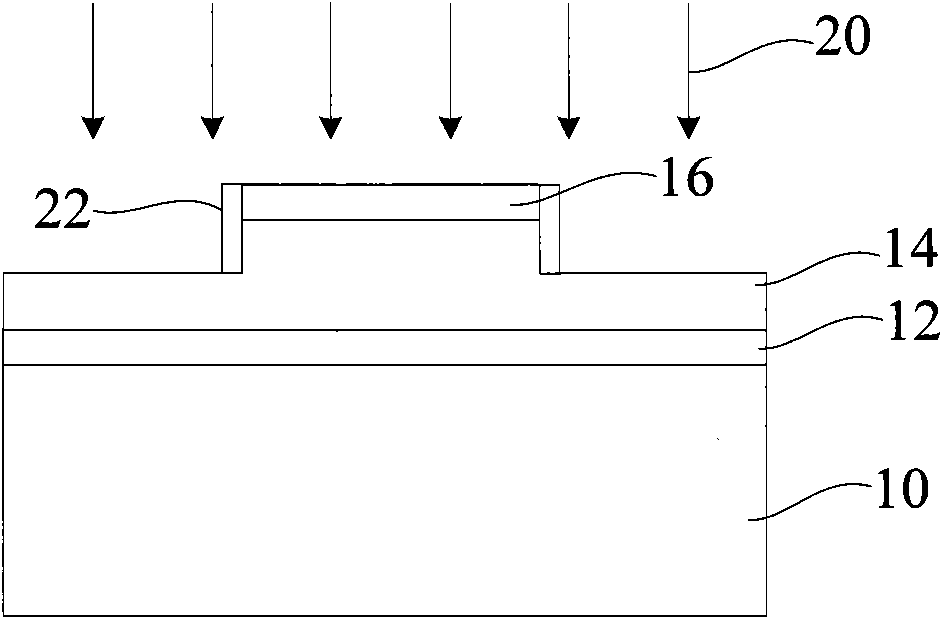

Method for improving thickness consistency of oxide layer on side wall of grid electrode and method for manufacturing grid electrode

InactiveCN101572230AImprove thickness uniformityImprove electrical performanceSemiconductor/solid-state device manufacturingSemiconductor devicesManufacturing gridWater vapor

The invention relates to a method for improving the thickness consistency of an oxide layer on the side wall of a grid electrode, and provides a semiconductor substrate, wherein the grid electrode comprising a polysilicon layer is arranged on the semiconductor substrate, and foreign ions are doped in the polysilicon layer; and the grid electrode is subjected to in-situ water vapor generation oxidation process, and the oxide layer is formed on the side wall of the grid electrode, wherein the temperature in the in-situ water vapor generation oxidation process is between 800 and 1,500 DEG C. The invention also provides a method for manufacturing the grid electrode. The method can improve the thickness consistency of the oxide layer on the side wall of the grid electrode and has simple process.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

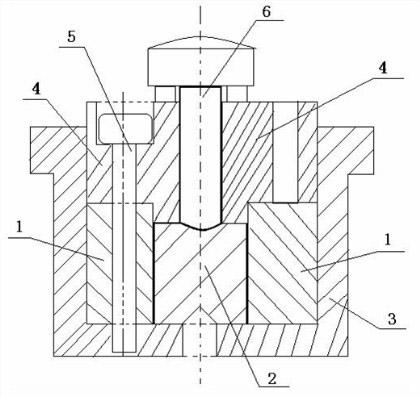

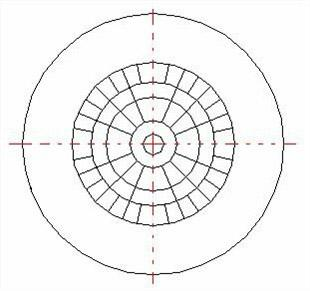

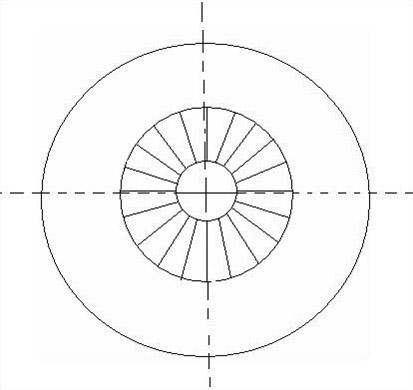

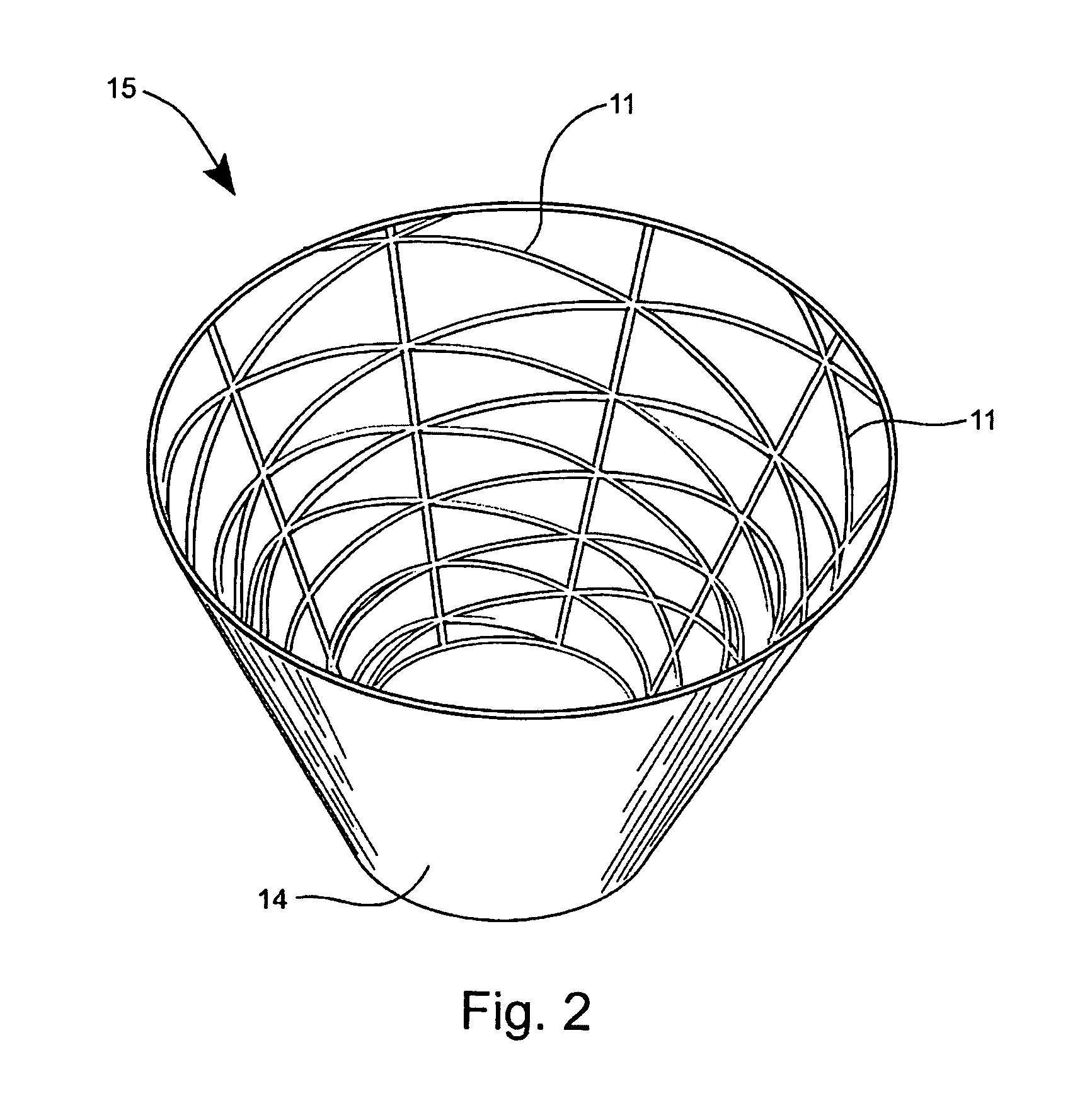

Method for manufacturing grid of millimeter-wave traveling wave tube

InactiveCN102184821AImprove performanceReduce the chance of sparkingPhotomechanical apparatusNon-emitting electrodes manufactureManufacturing gridWave tube

The invention discloses a method for manufacturing a grid of a millimeter-wave traveling wave tube. The method comprises the following steps of: firstly etching to obtain a planar grid with a required shape on a grid substrate by applying a photoetching technology, then, processing and forming the planar grid by a special spherical forming mold to obtain a spherical-crown-shaped grid, finally polishing the grid to obtain the grid of the millimeter-wave traveling wave tube. The method for manufacturing the grid of the millimeter-wave traveling wave tube, provided by the invention, has the advantages of strong maneuverability and reasonable technical design, and can be used for processing and manufacturing small-size, thin and complexly-shaped spherical grids with special size requirement; the grid manufactured with the method disclosed by the invention has the advantages of no burrs on the surface, low fire striking probability, high qualification rate, stable performances and very important application value.

Owner:NANJING SANLE ELECTRONICS INFORMATION IND GRP

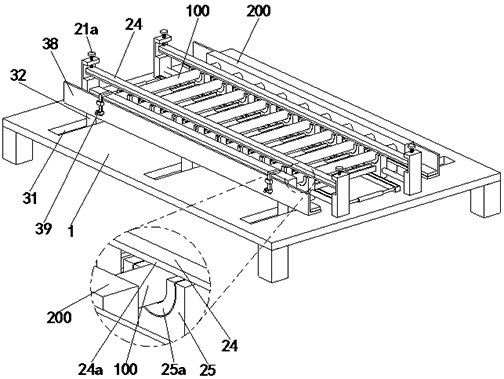

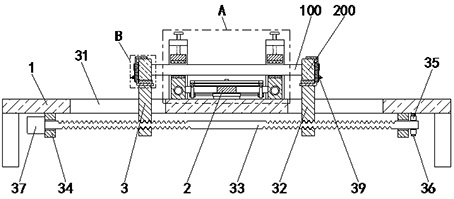

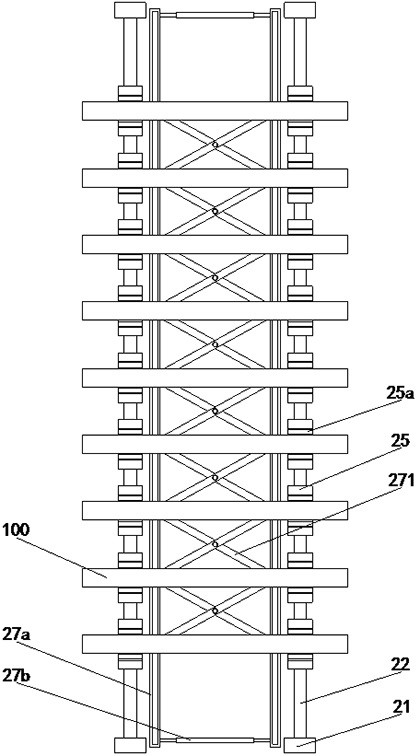

Welding tool clamp for manufacturing grid type guardrails

ActiveCN113523697ARealize welding productionAdjustable spacingWelding/cutting auxillary devicesAuxillary welding devicesManufacturing gridEngineering

The invention relates to the technical field of guardrail welding and manufacturing, in particular to a welding tool clamp for manufacturing grid type guardrails. The welding tool clamp comprises a workbench, a clamping mechanism and alignment mechanisms, wherein the clamping mechanism and the alignment mechanisms are arranged on the workbench, and the alignment mechanisms are located on the two sides of the clamping mechanism. According to the welding tool clamp, a function of welding and manufacturing the grid type guardrails in different shapes can be fulfilled, meanwhile, the distance between every two adjacent grid bars can be adjusted, so that the grid type guardrails with different specifications can be welded and manufactured; and the grid bars with different lengths can be welded and manufactured, so that the guardrails with different specifications and heights can be manufactured.

Owner:烟台佑利技术有限公司

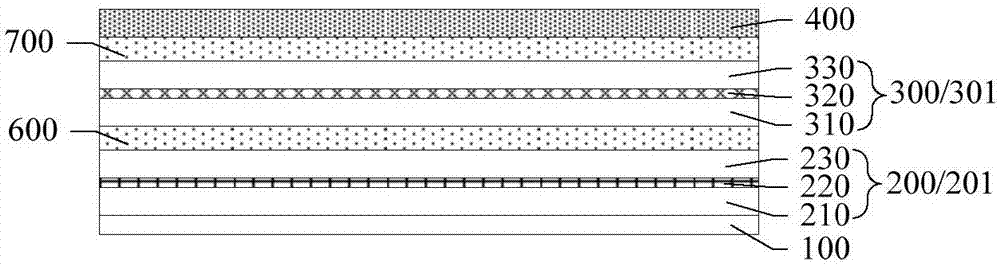

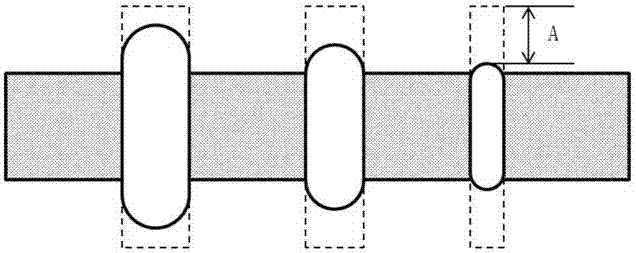

Touch control panel, manufacturing method of touch control panel and touch control display device

ActiveCN107512050AInput/output processes for data processingMetal layered productsManufacturing gridDisplay device

The invention provides a touch control panel, a manufacturing method of the touch control panel and a touch control display device. The touch control panel comprises a substrate base plate and a plurality of first touch control electrodes, wherein the first touch control electrodes are positioned on the substrate base plate; each first touch control electrode comprises a plurality of first touch control electrode wires in crossed arrangement; in addition, the first touch control electrode wires comprise at least two layers of transparent conductive layers in laminated arrangement in the direction vertical to the substrate base plate; the transparent conductive layers comprise a first metal oxide layer and a first metal layer, or the first metal oxide layer and a first graphene layer. The touch control panel uses at least two transparent conductive layers in pairwise laminated arrangement for replacing the metal lattice for manufacturing grid touch control electrode wires in the touch control electrode; the moire is eliminated, so that the optical quality of the touch control panel is improved.

Owner:BOE TECH GRP CO LTD +1

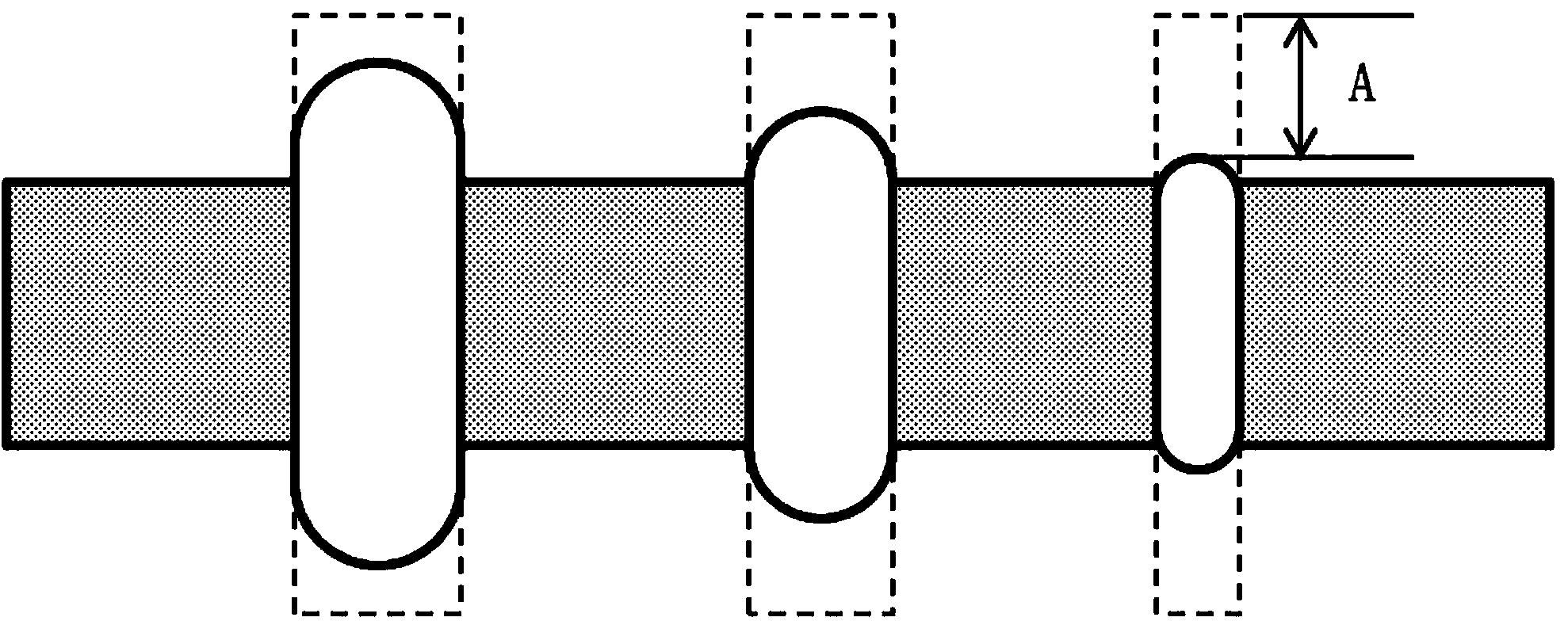

Method for manufacturing grid lines with high uniformity through double exposure

ActiveCN103400753ASimple manufacturing processMeet the requirements of structural uniformitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPhotoresistManufacturing grid

A method for manufacturing grid lines with high uniformity through double exposure comprises the following steps: depositing a polycrystalline silicon film, an amorphous carbon film and a carbonaceous silicon oxide film and coating a first photoresist; carrying out exposure and development to form a first grid line structure in the films of the first photoresist; coating alkyl-amino solidification materials to solidify the first grid line structure in the first photoresist, heating to enable solidification materials and the surface of the first photoresist to react, so as to form isolation films undissolved in a second photoresist, and removing residual solidification materials; coating the second photoresist; forming a first line end cutting pattern in second photoresist films; etching the isolation films and first grid lines to form a second line end cutting pattern, and then removing the second photoresist; etching the carbonaceous silicon oxide film, the amorphous carbon film and the polycrystalline silicon film in sequence by taking the residual isolation films and the first grid lines as masks, and removing the residual carbonaceous silicon oxide film and the amorphous carbon film, so as to form a second grid line structure on a polycrystalline silicon film layer.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

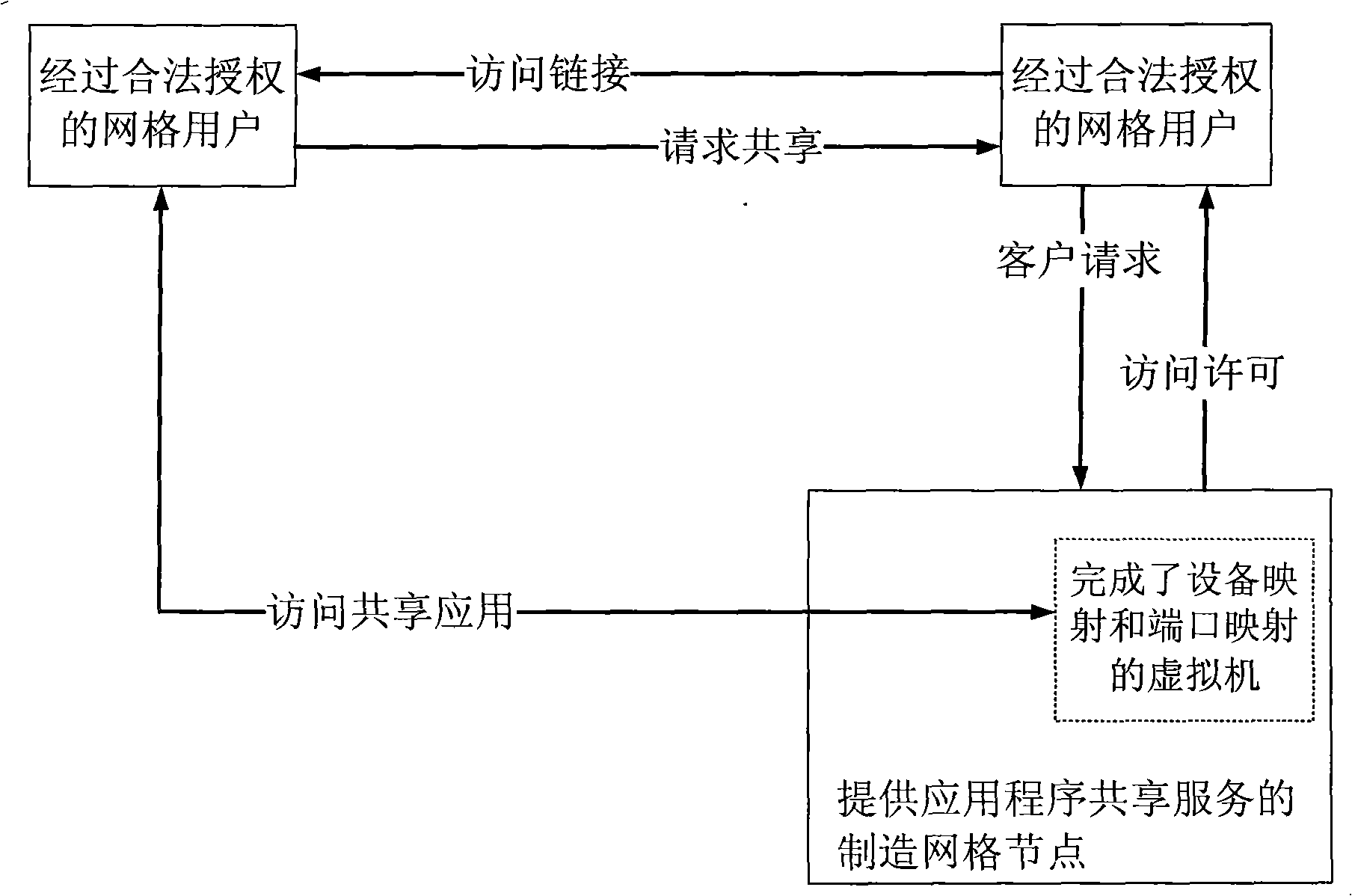

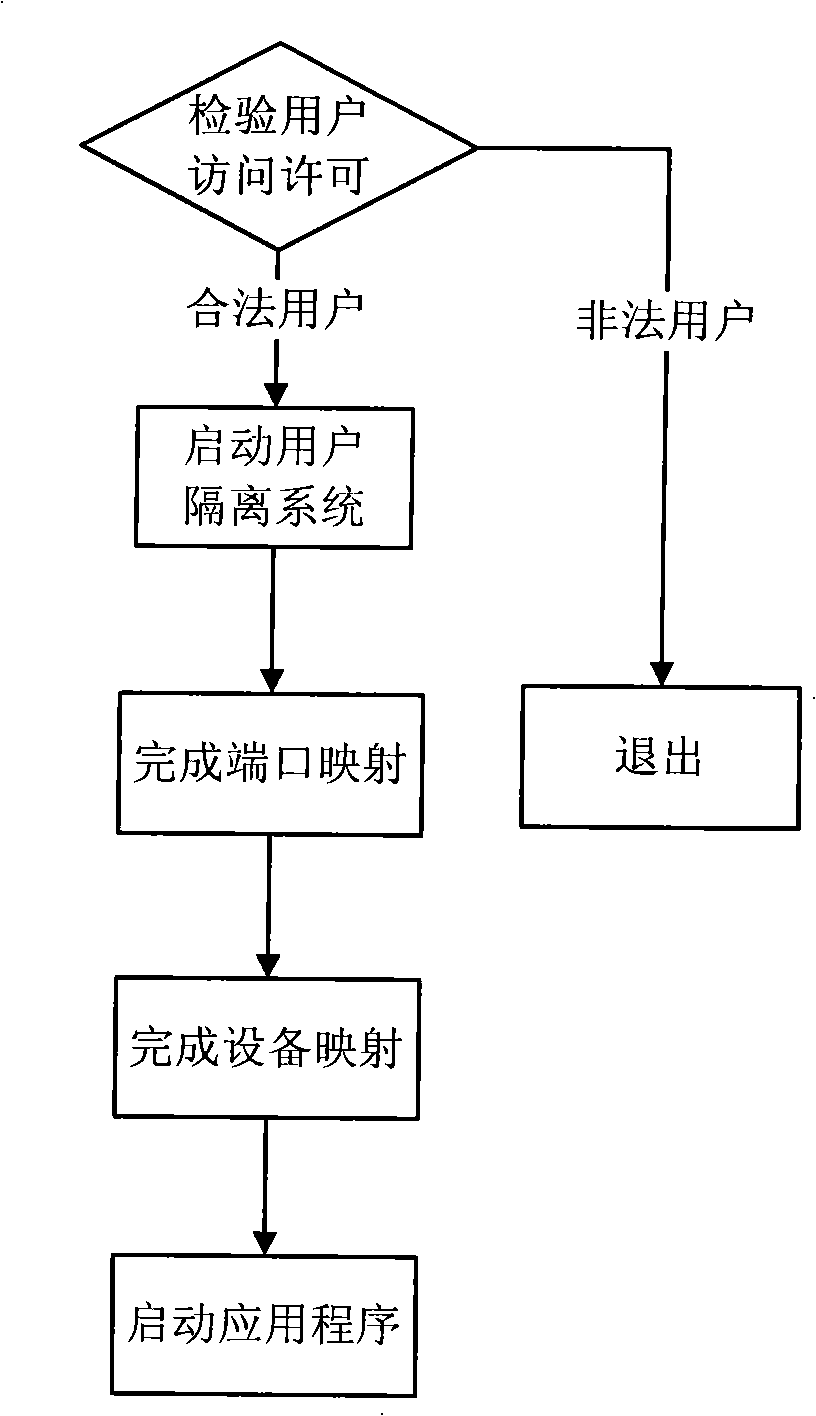

Method for implementing application program sharing under graticule manufacturing environment

InactiveCN101329639AEasy to integrateAchieve sharingMultiprogramming arrangementsData switching networksManufacturing gridApplication software

The invention relates to a method for realizing the sharing of application program in a manufacturing grid environment, which comprises the steps that: a port mapping technology and an equipment mapping technology are utilized on a manufacturing grid node that needs to share an application program to map equipment and a port of a client node on a service node, thus causing grid users to be capable of visiting application programs on a long-distance service node like visiting a local computer; simultaneously, in order to ensure that multiple users visiting the application programs of the same service node do not interfere each other, a user isolation technology is used for realizing isolation and scheduling. By adopting the method of the invention, the users can finish work independently or by coordinating with other users. Simultaneously, as for the suppliers of application program share service, an application program aiming at the manufacturing grid environment is not required to be written specially, and the full utilization and seamless migration of the existing application software resources can be realized, thus achieving the purposes of high integration and efficient share of a manufacturing grid and solving the problem that the existing application software resources can not be shared in the current manufacturing grid environment.

Owner:WUHAN UNIV OF TECH

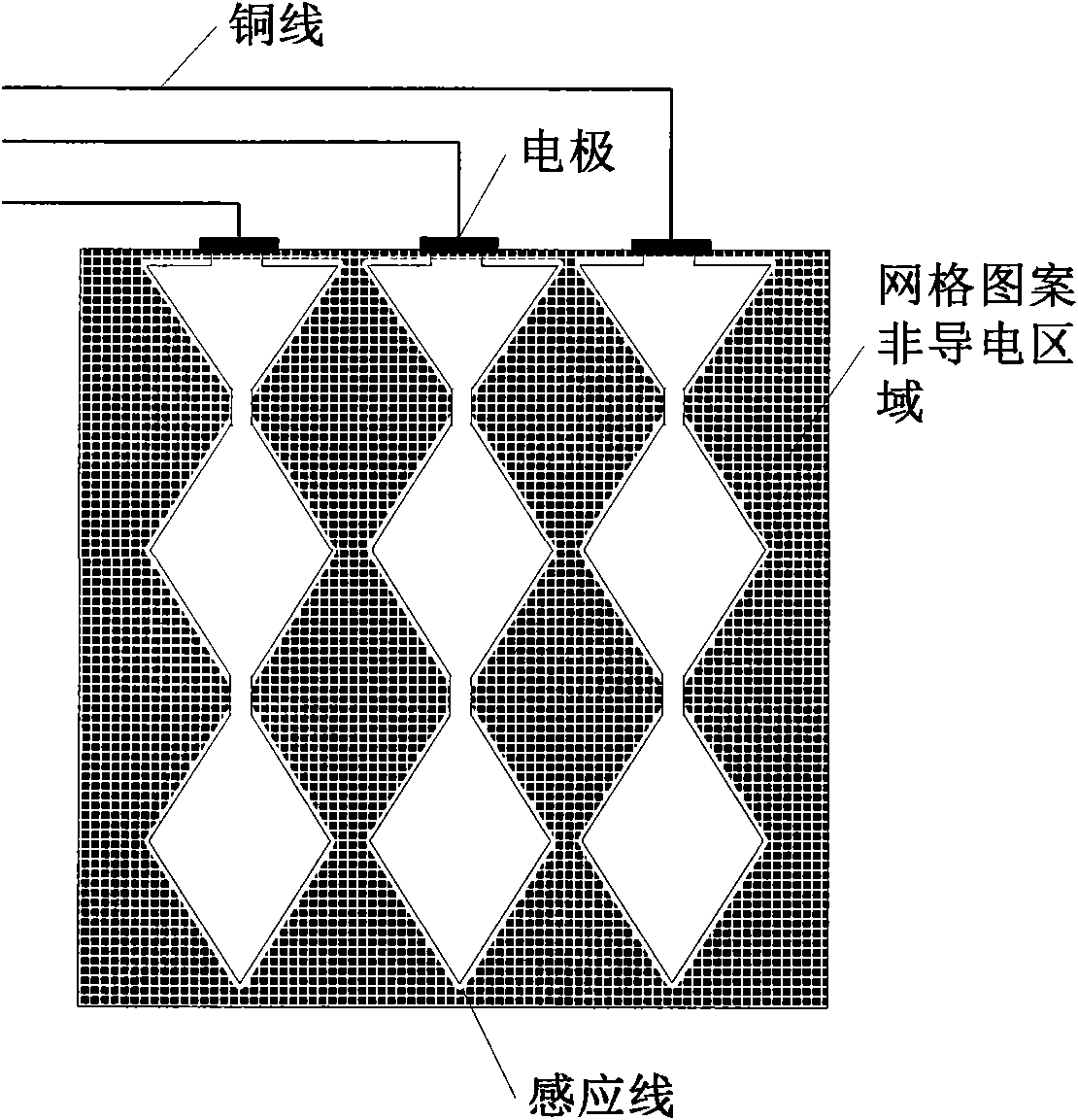

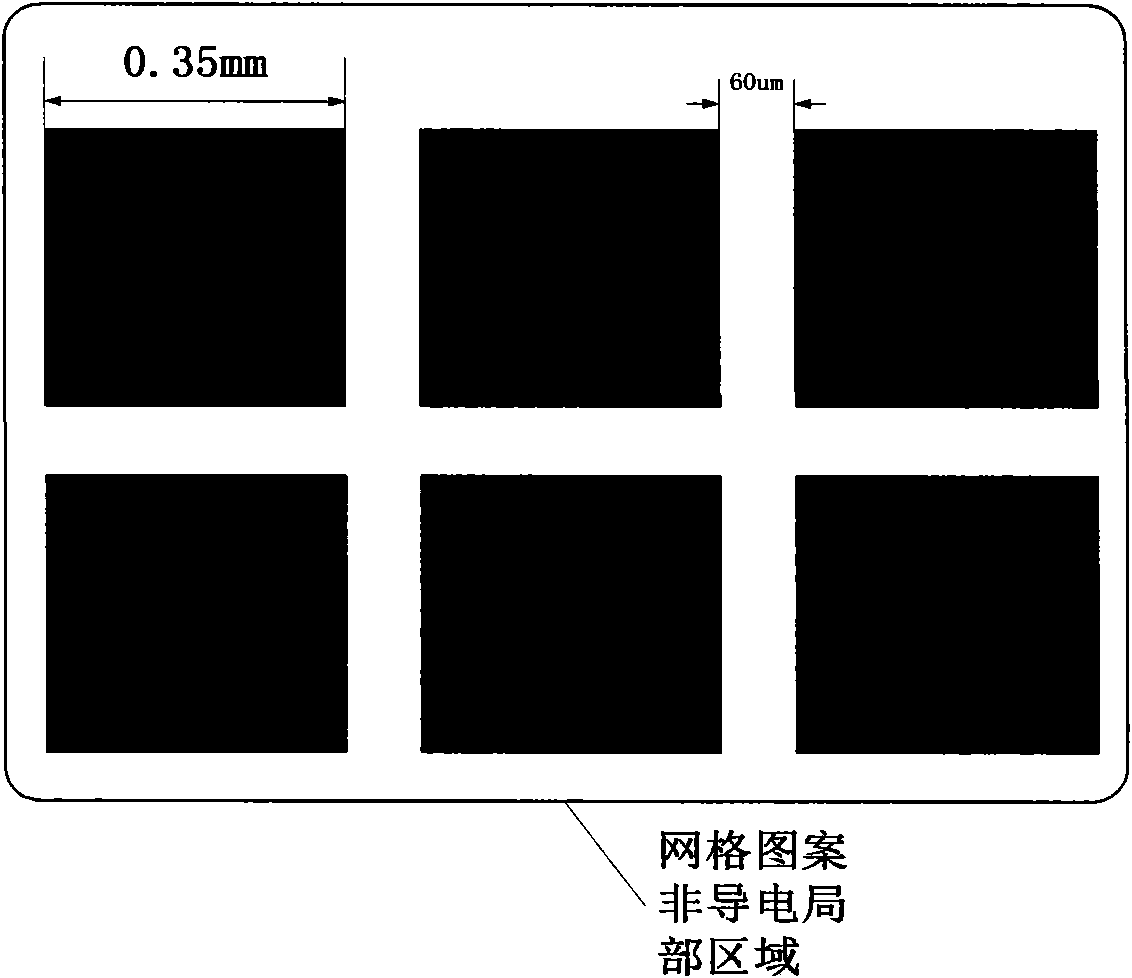

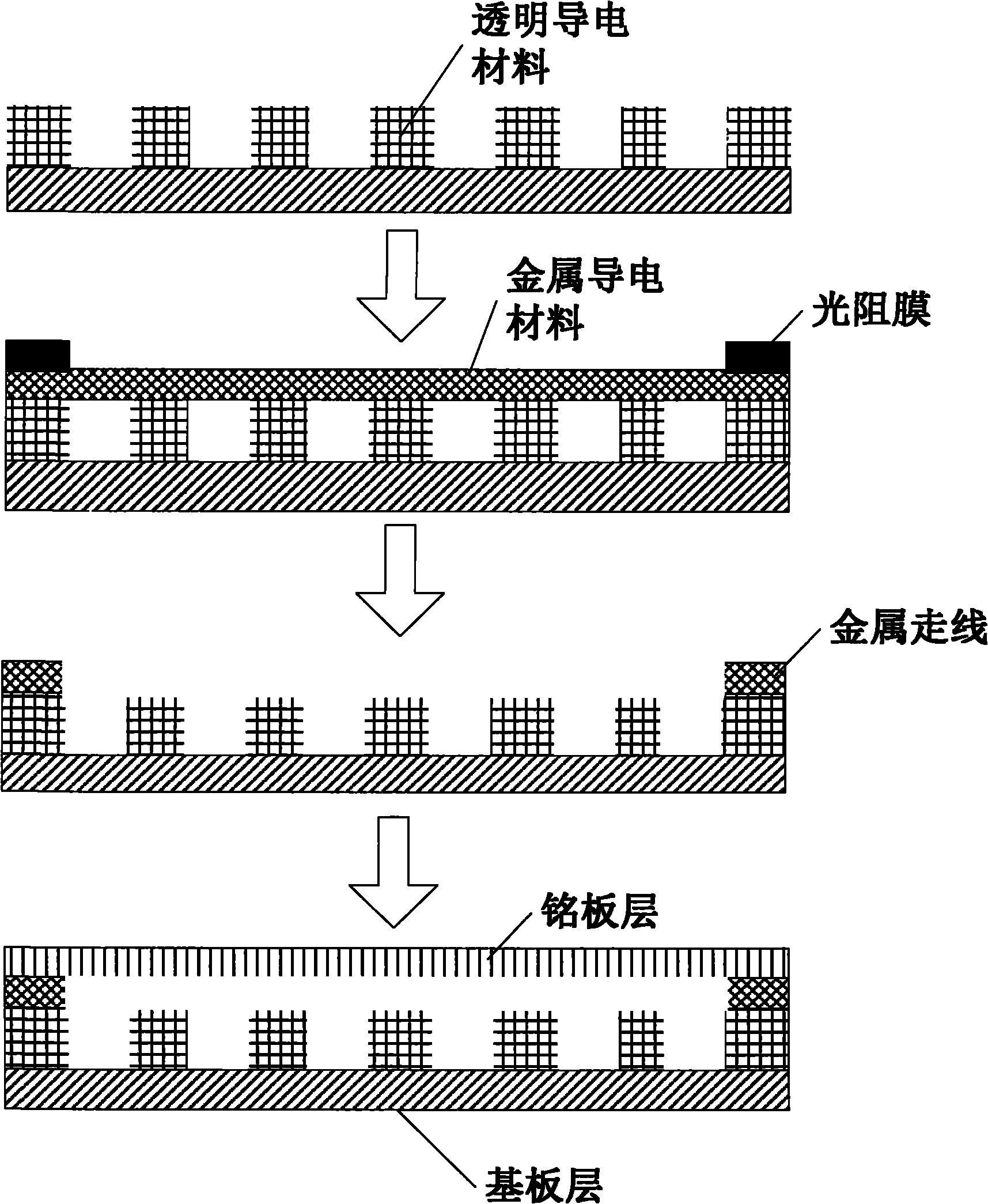

Method for manufacturing grid-pattern touch panel

ActiveCN101968697AReduce Thickness WeightReduce etch marksInput/output processes for data processingManufacturing cost reductionGrid pattern

The invention discloses a method for manufacturing a grid-pattern touch panel, which belongs to the technical field of the manufacturing of touch panels. In the method, a transparent conductive material is etched into a grid-pattern non-conductive area by photoresist technology so as to reduce etching trace and reduce etching waste liquid for environmental protection; moreover, a metal conductive material is electroplated, a photoresist film is stuck on the metal conductive material, and metal wiring is formed by exposure, development and etching; and the method is easy to operate and the manufacturing cost can be lowered.

Owner:牧东光电科技有限公司

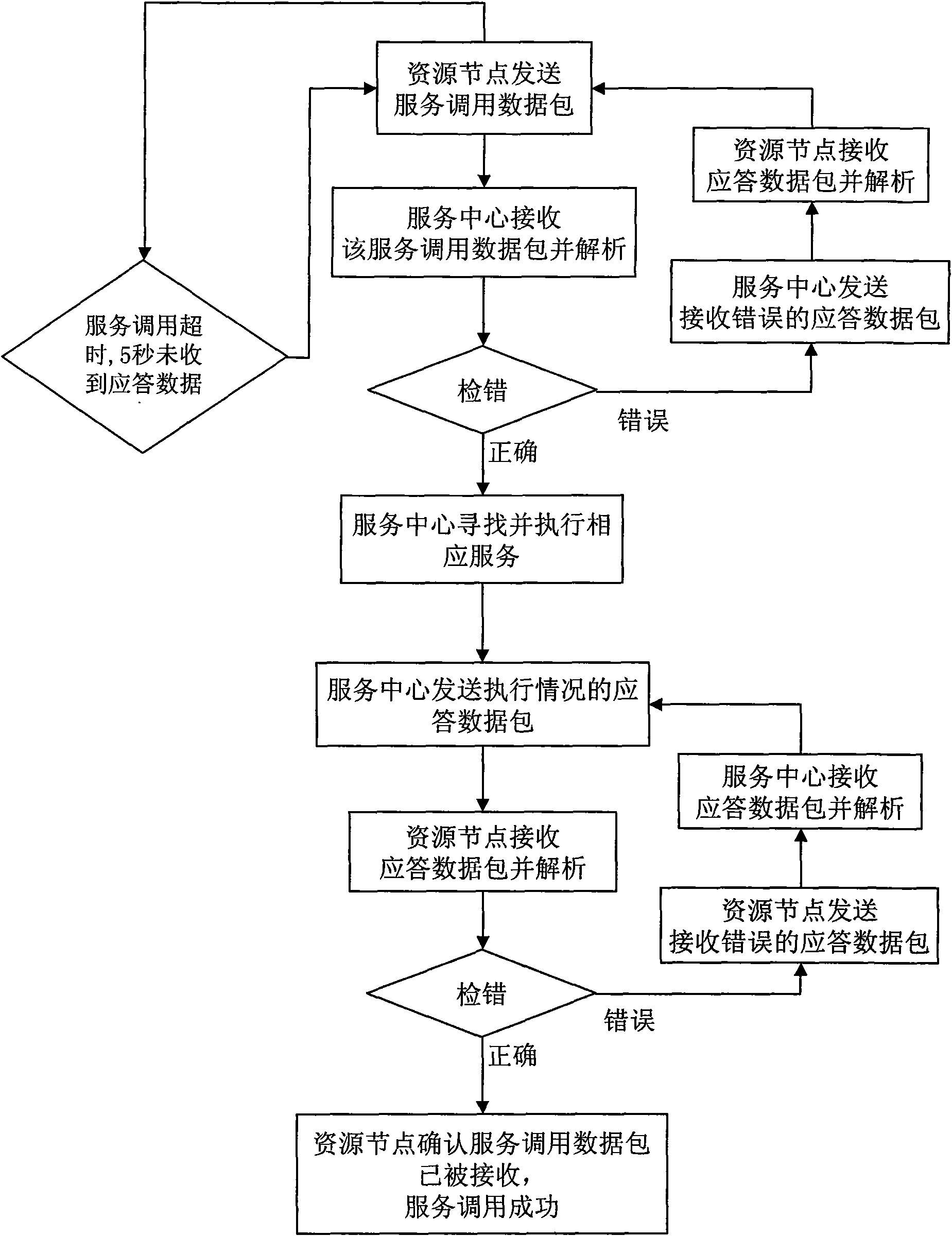

Communication method of manufacturing grid service center and resource nodes

InactiveCN101668014ASimplify the way data is passedEnhanced interactionError prevention/detection by using return channelNetwork packetManufacturing grid

The invention relates to a communication method of the manufacturing grid service center and the resource nodes. The manufacturing grid service center and the resource nodes mutually send out the service calling data packets of the standard format and the receiving party sends back the service replying data packets of the standard format so as to realize the communication of both parties. The command head of the standard data packet comprises a command starting symbol, a command word, a command code, a serial number, a source node address and a destination node address. The command body of thestandard data packet comprises related parameters, a check code and a command ending symbol, which are arranged in sequence. Space characters are provided among the items of the command head and thecommand body of the standard data packet, and parameter space characters are provided among the related parameters. The manufacturing grid service center allocates the only node address of the resource nodes; the manufacturing grid service center and the resource nodes realize the service calling in an initiative communication way and a timing communication way; the receiving party obtains the related content according to the analysis of the arrangement order of the data packets so as to check and detect errors of the content, search corresponding services according to the command word and implement the services. The communication method simplifies the data transfer way between the manufacturing grid service center and the resource nodes, ensures the effective and accurate communication ofthe same and facilitates the running of a manufacturing grid platform.

Owner:GUILIN UNIV OF ELECTRONIC TECH

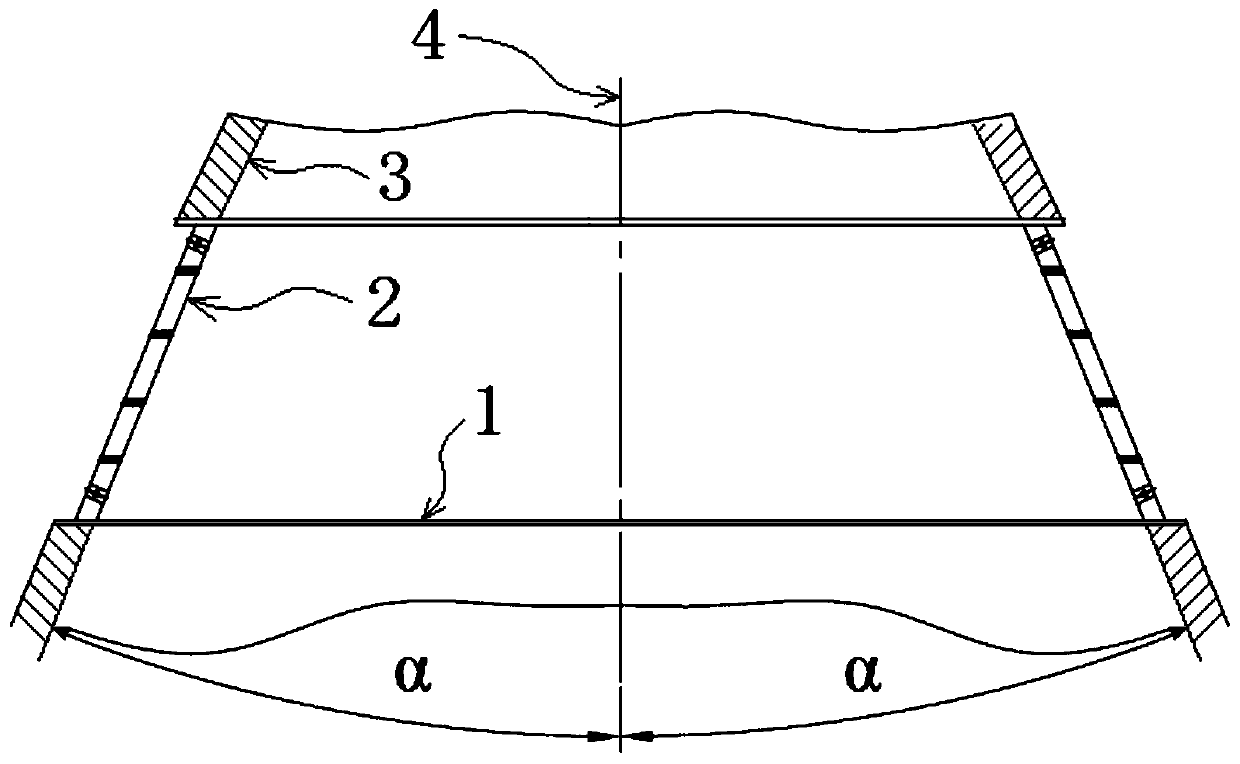

Method for manufacturing grid rudder

The invention discloses a method for manufacturing a grid rudder, which relates to the field of metal processing. The method comprises the steps of (a) dividing one surface of a billet material into a plurality of stop welding flux coating areas (1) and a plurality of diffusion areas (2) which are distributed at intervals for each other, forming vent grooves, applying stop welding fluxes, then aligning with four sides of the other billet material, and sealing and welding, so as to form billet bags; (b) putting a plurality of billet bags into a mold in parallel and at intervals, respectively putting border billets on both ends of two adjacent billet bags, and making the projections of the diffusion areas (2) in billet pieces of the two adjacent billet bags keep parallel and distribute at intervals on a plane parallel to the billet bags; and (c) applying pressure to the mold, then leading air between the two adjacent billet bags, and then leading air to the vent groove (3) in the billet piece of each billet bag. The grid rudder prepared by using the method has the advantages of good integrality and high material utilization.

Owner:北京普惠三航科技有限公司 +1

Method for manufacturing grid structure of semiconductor device

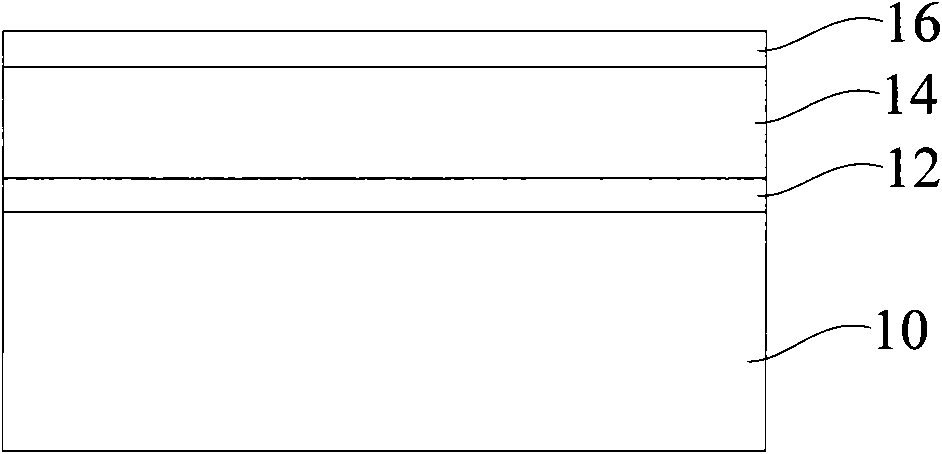

ActiveCN101038870APrecise thickness controlPrecisely control the depth of etchingSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorManufacturing grid

The invention provides a mehtod for making grid structure of semiconductor device, which includes providing a semiconductor substrate, and forming a grid medium layer on the substrate, and forming a grid electrode layer on the grid medium layer, and forming a mask layer on the grid electrode layer, and then inducing etching gas to etch the polysilicon grid electrode layer by employing plasma output by a plasma source, wherein the plasma source etches the grid medium layer in pulse outputting power manner. The invention provide method for making grid structure of semiconductor device is very effective for accuracy controlling the thickness of the grid oxide layer in a process node no more then 65 nm, and the etching depth can perfectly stop at the surface of the grid oxide layer without hurting the surface of an active region.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

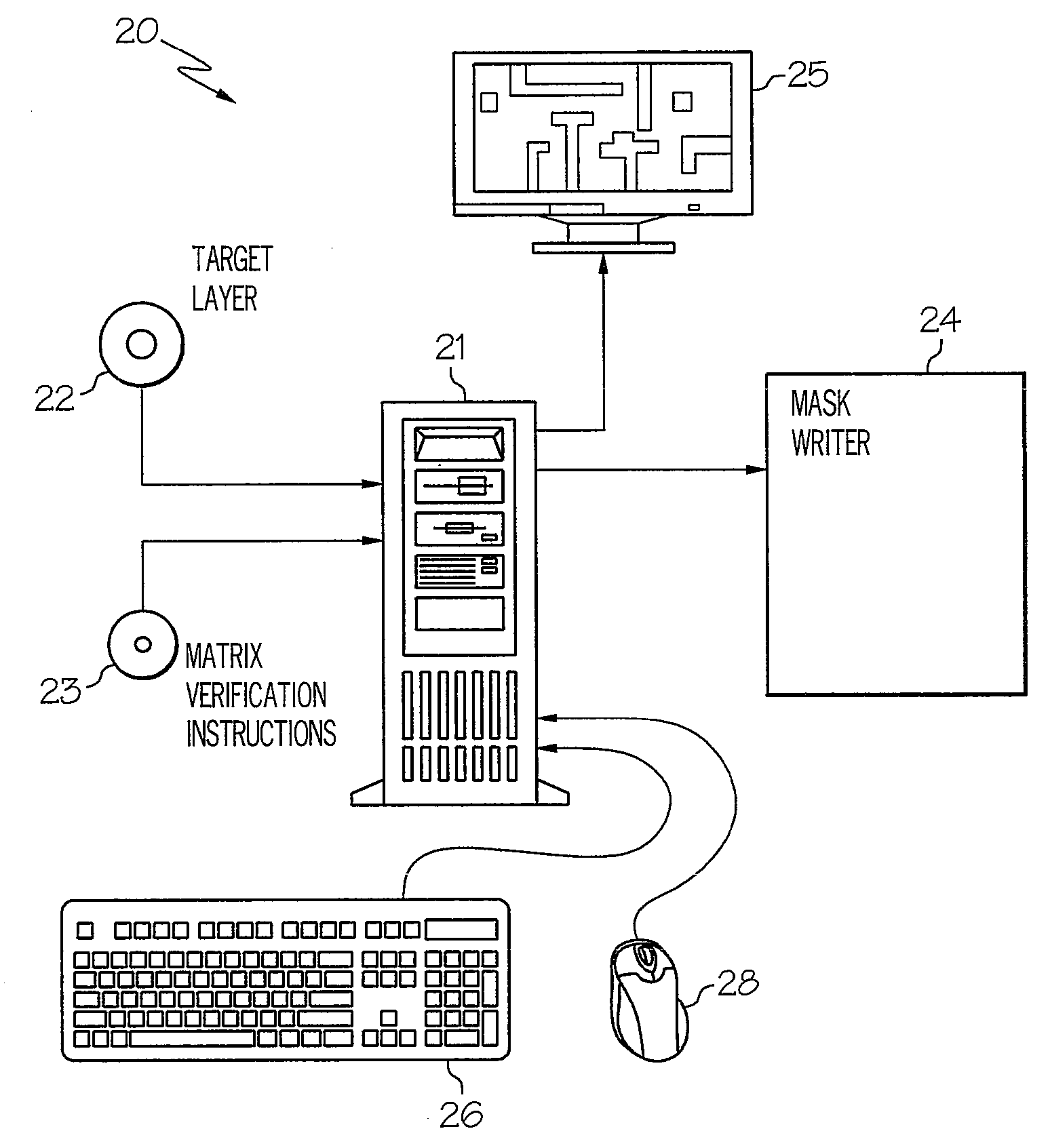

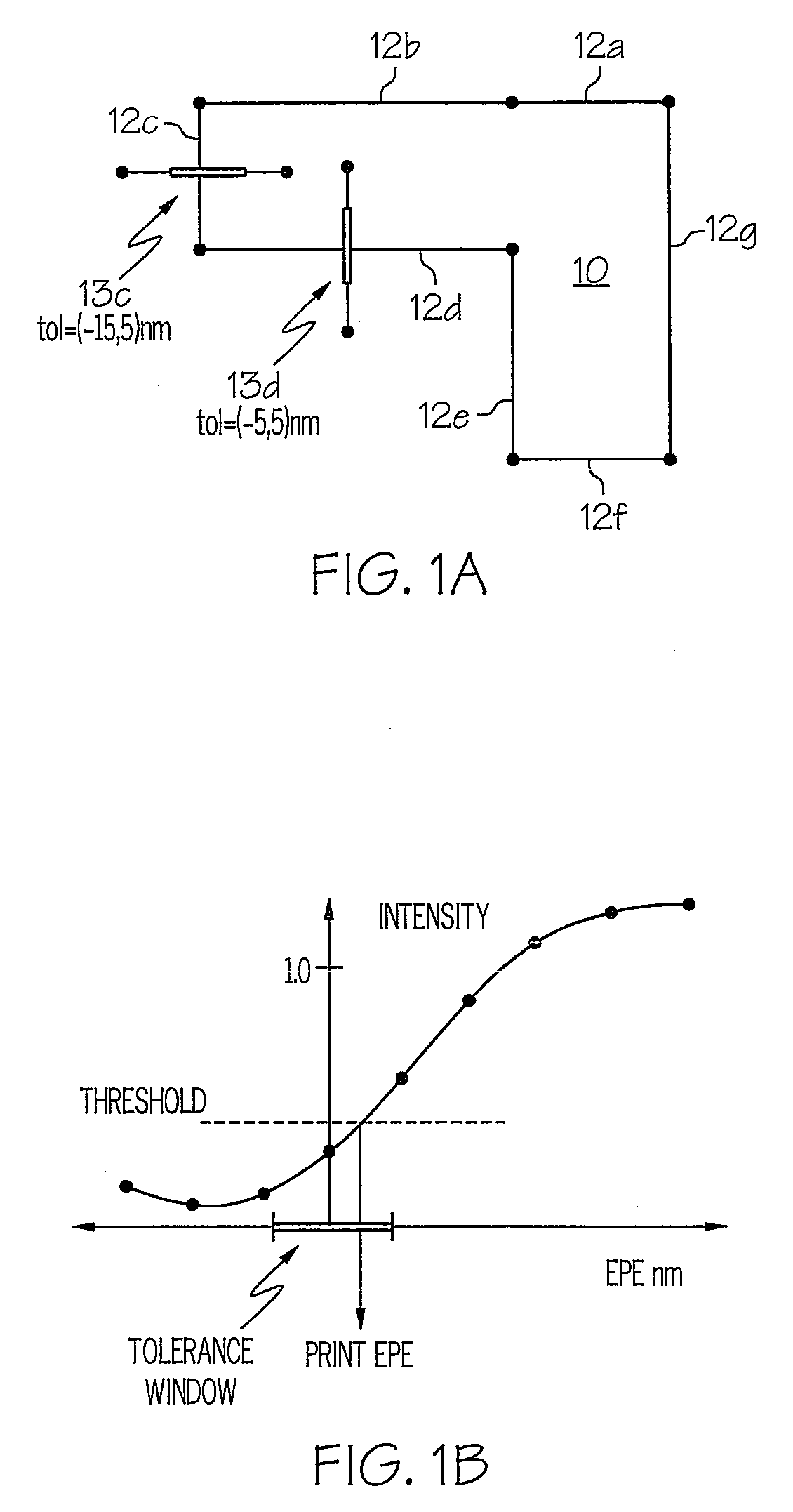

Method and System for Performing Optical Proximity Correction with Process Variations Considerations

InactiveUS20090030636A1Electrical measurementsTesting/calibration of speed/acceleration/shock measurement devicesManufacturing gridSpatial image

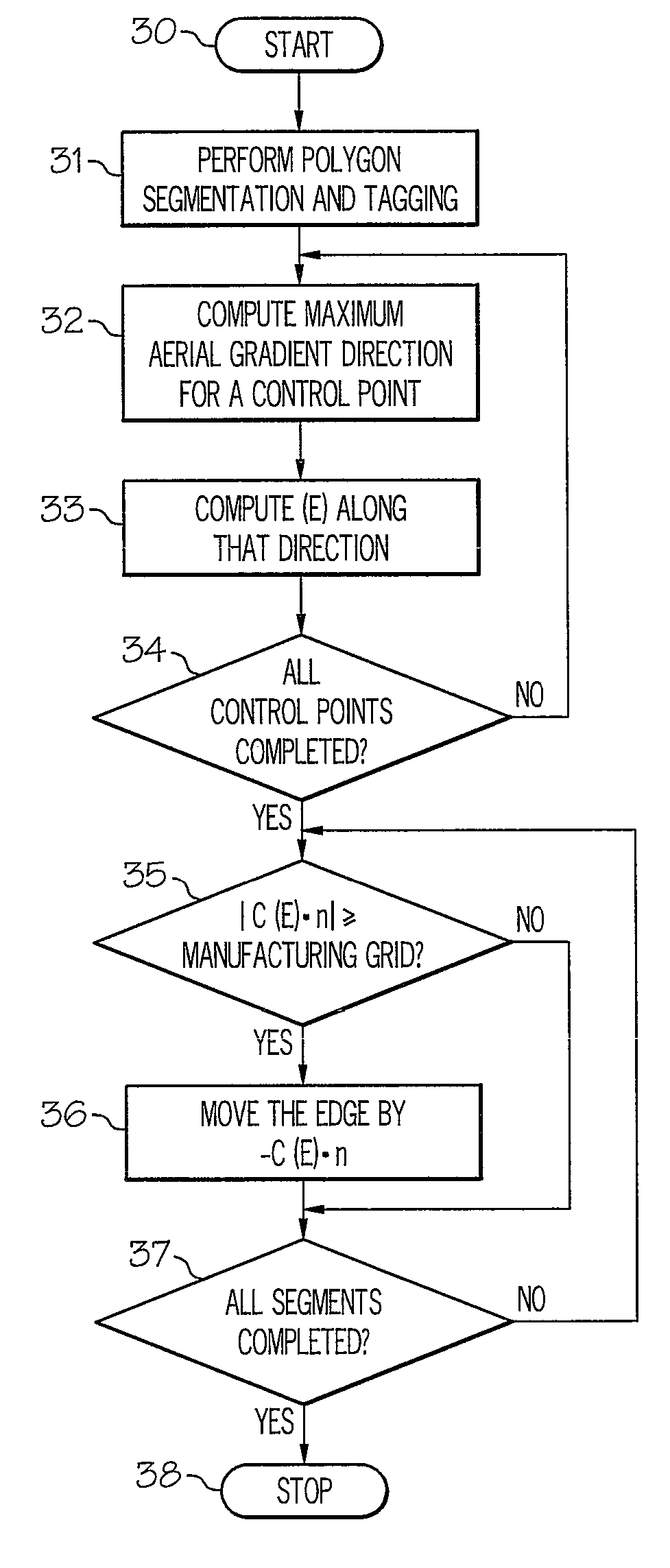

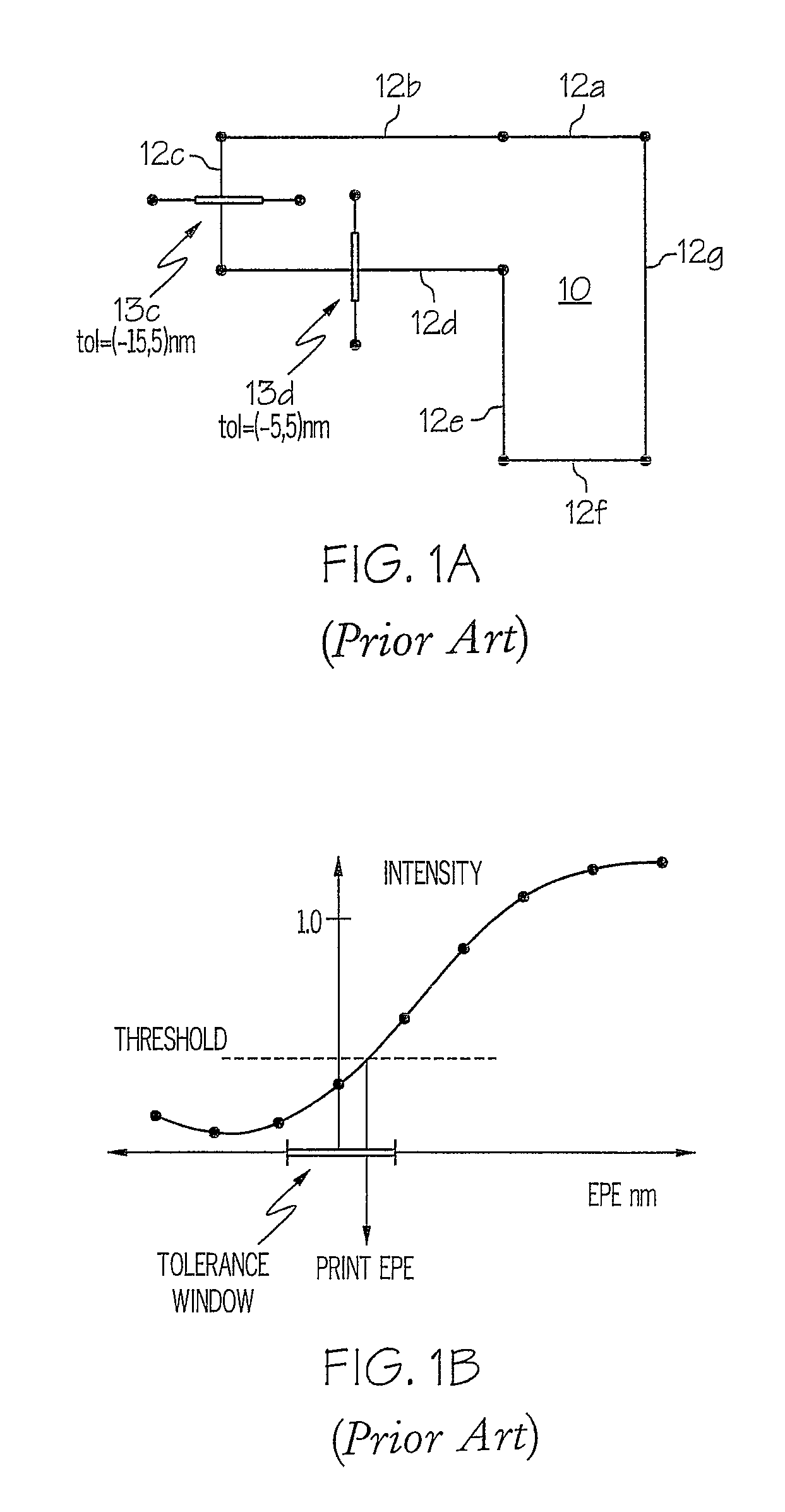

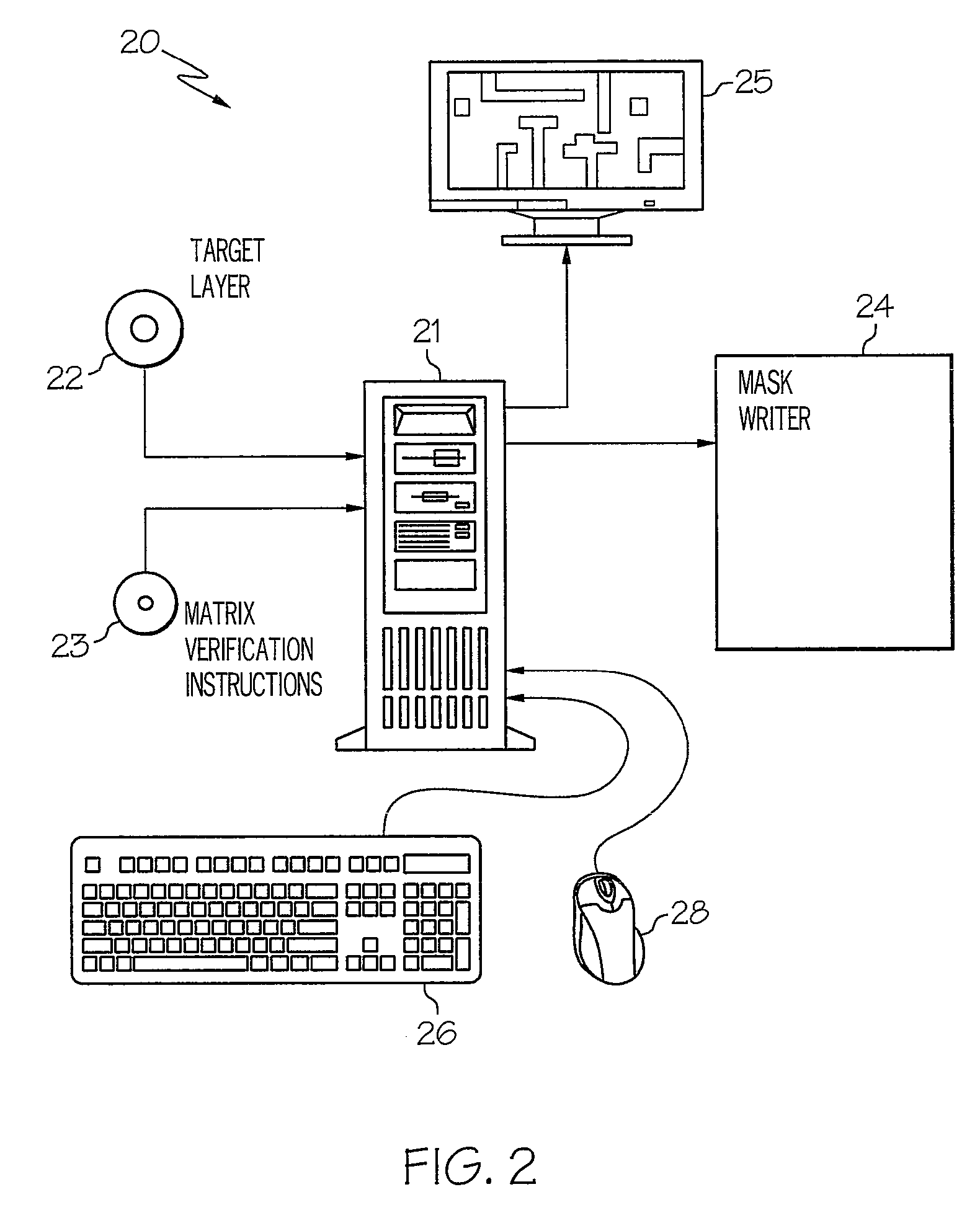

A method for performing optical proximity correction with process variations considerations is disclosed. The maximum aerial gradient direction for a control point associated with an edge is initially determined. Then, a variational edge placement error E along the maximum aerial image intensity gradient direction of the control point is calculated. A determination is made whether or not |CE·n| is equal or greater than a manufacturing grid, where n is the direction perpendicular to a segment pointing outward, and C is a constant. If |CE·n| is equal or greater than a manufacturing grid, moving said edge by −CE·n.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Control method of wind power and hydrogen manufacturing grid connection power generation system

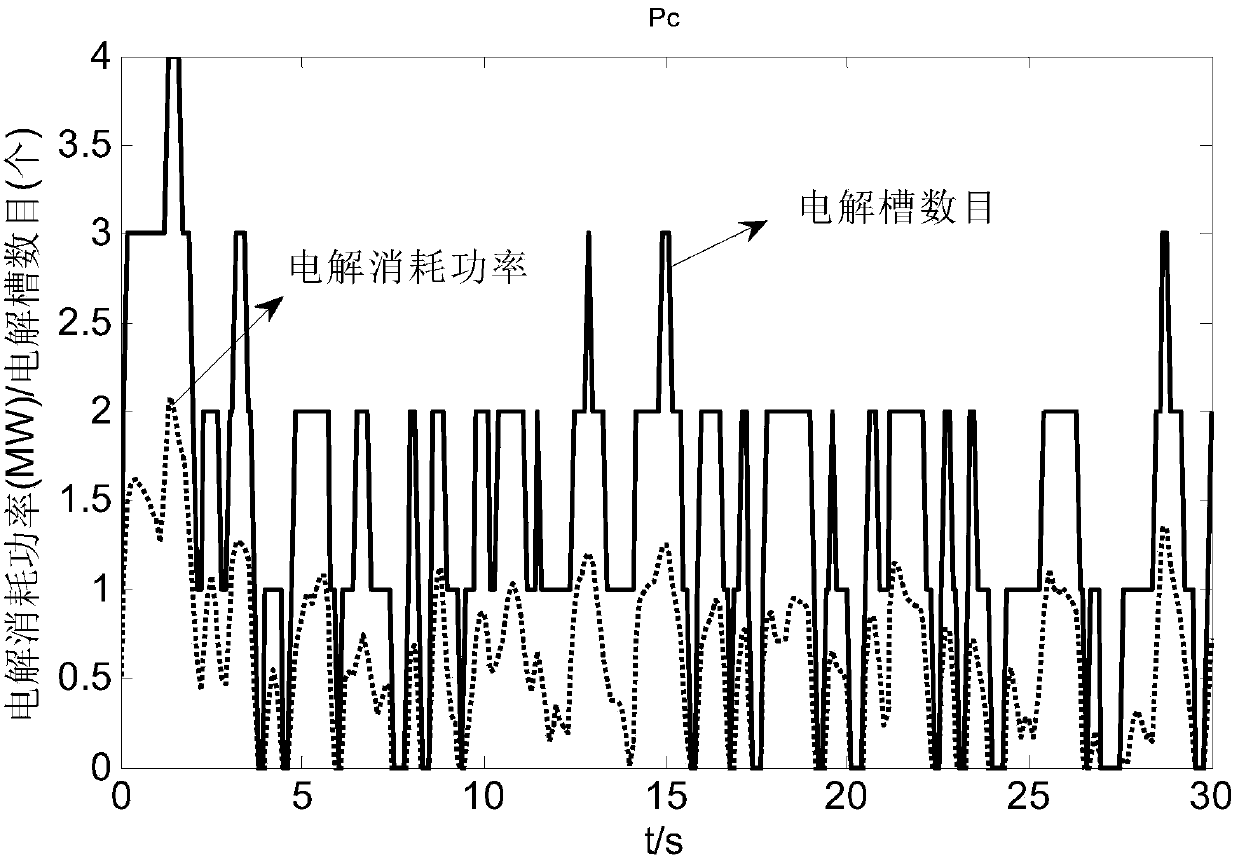

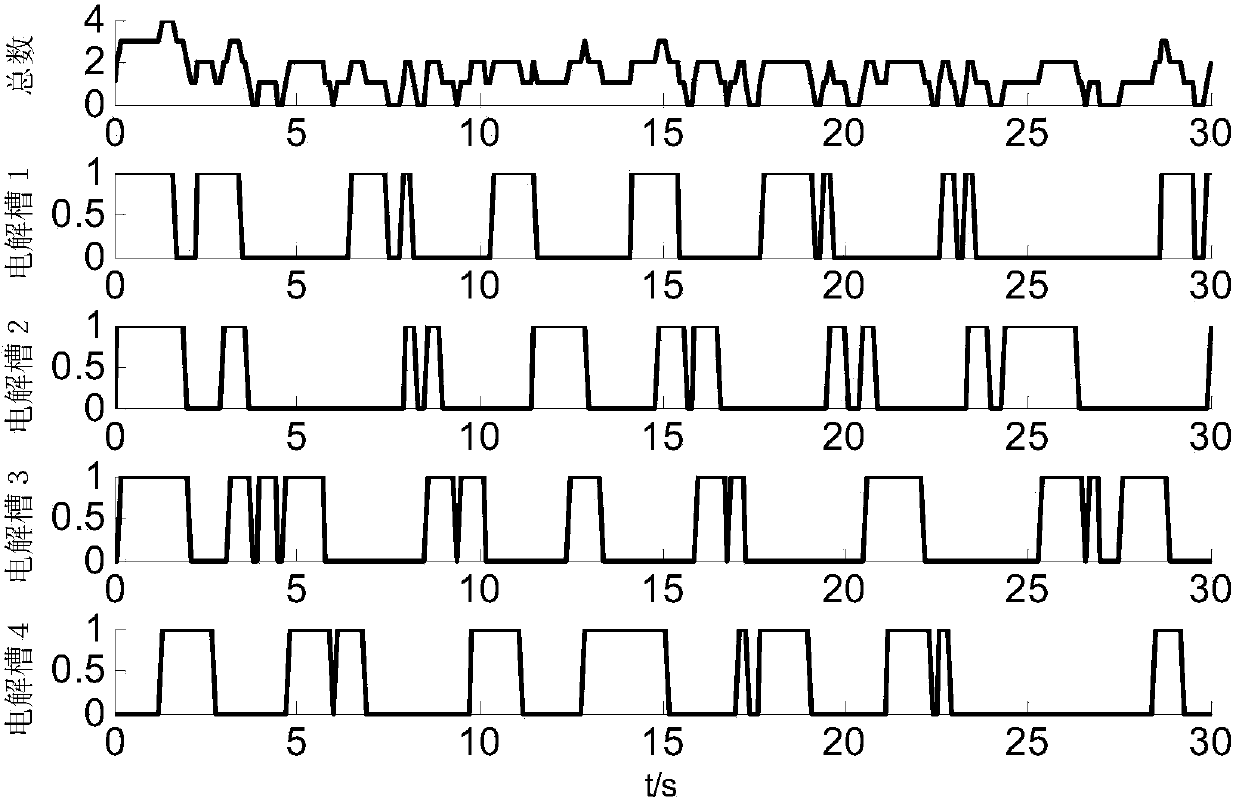

InactiveCN104113084AImprove receptivityAdaptableSingle network parallel feeding arrangementsWind energy generationElectricityHydrogen

The invention provides a control method of a wind power and hydrogen manufacturing grid connection power generation system. The control method comprises establishing a double-fed induction power generator based wind power generation set model, establishing an electrolytic tank model, controlling the grid connection power generation system and the like. According to the control method of the wind power and hydrogen manufacturing grid connection power generation system, the effectiveness of modeling and control on the wind power and hydrogen manufacturing grid connection power generation system can be fully reflected, the capability of the acceptance of a power grid to the new energy is improved, the adaptability is high, and the practical application value is high.

Owner:NORTHEAST DIANLI UNIVERSITY

Method and system for performing optical proximity correction with process variations considerations

InactiveUS7711504B2Electrical measurementsTesting/calibration of speed/acceleration/shock measurement devicesManufacturing gridSpatial image

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Method for manufacturing grid artificial board core strip

InactiveCN104015232AReduce weightNot affected by widthWood veneer joiningWood layered productsManufacturing gridEngineering

The invention discloses a method for manufacturing a grid artificial board core strip. According to the method for manufacturing the grid artificial board core strip, wooden sheet materials serve as base materials, and the wooden sheet materials are machined into comb-shaped or arched plates in the length direction of the sheet materials; the special-shaped plates are spliced in the width direction, so that special-shaped laminates with certain widths are obtained; the special-shaped laminates are glues in a mutually crossed and stacked mode in the thickness directions, wherein the included angle, in the length direction, of every two adjacent special-shaped laminates ranges from 0 degree to 90 degrees; finally, sawing is conducted in the direction parallel to the thickness direction and perpendicular to the bisector of the included angle of the axes of every two adjacent special-shaped laminate strips. When the method is used for manufacturing the artificial board core strip, the manufactured artificial board core strip is light, materials are saved, the influence of the anisotropy of wood is avoided, the artificial board has the advantages in the aspects of heat preservation and sound insulation, the method provides an important approach to utilize low-quality fast-growing wood, the economical value of the fast-growing wood is improved easily, and the development of the forestry economy and the positive cycle of the forest ecology are promoted. The method can be widely used for manufacturing cross-band veneers of artificial boards with various functions.

Owner:黑龙江省木材科学研究所

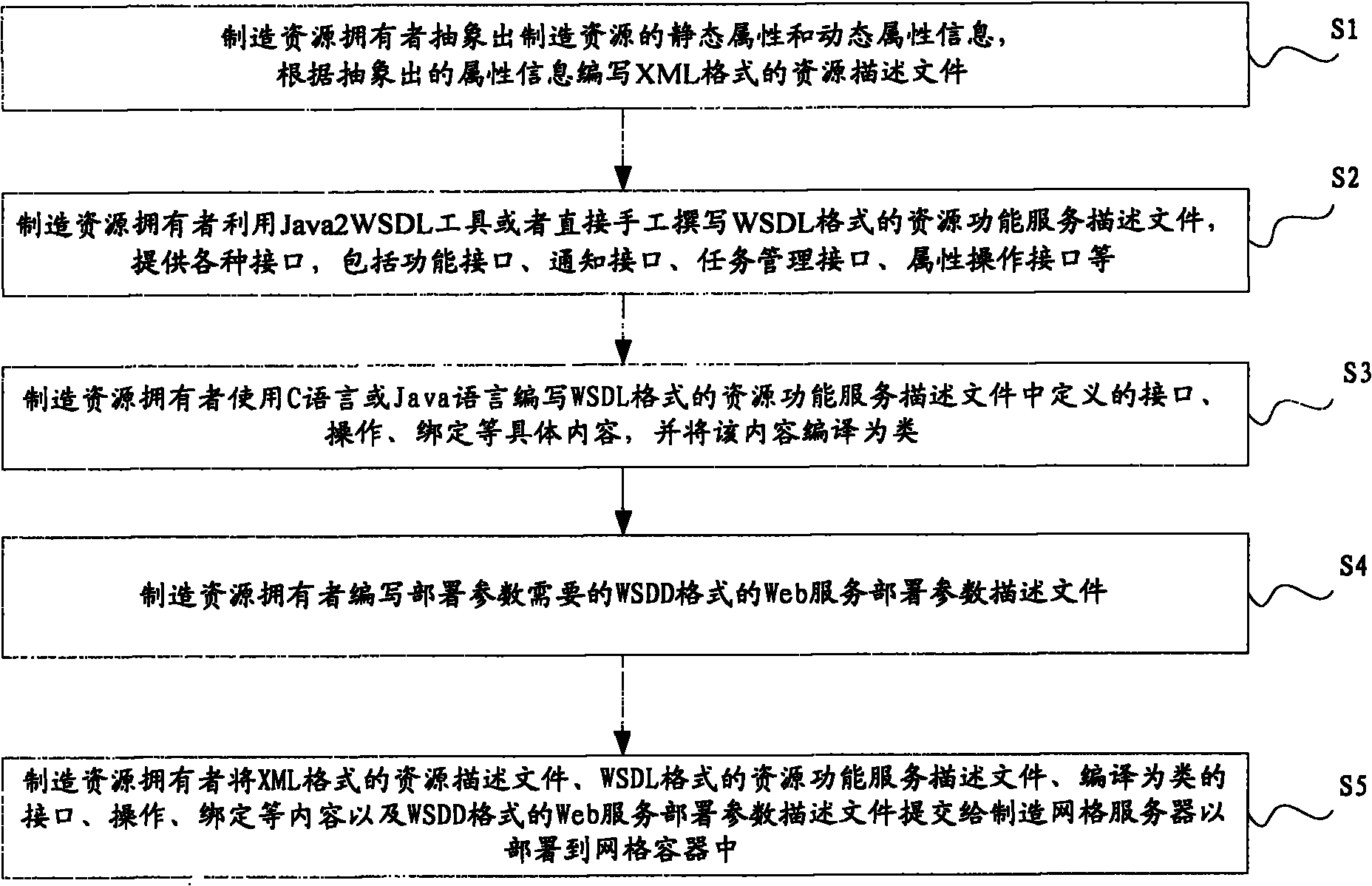

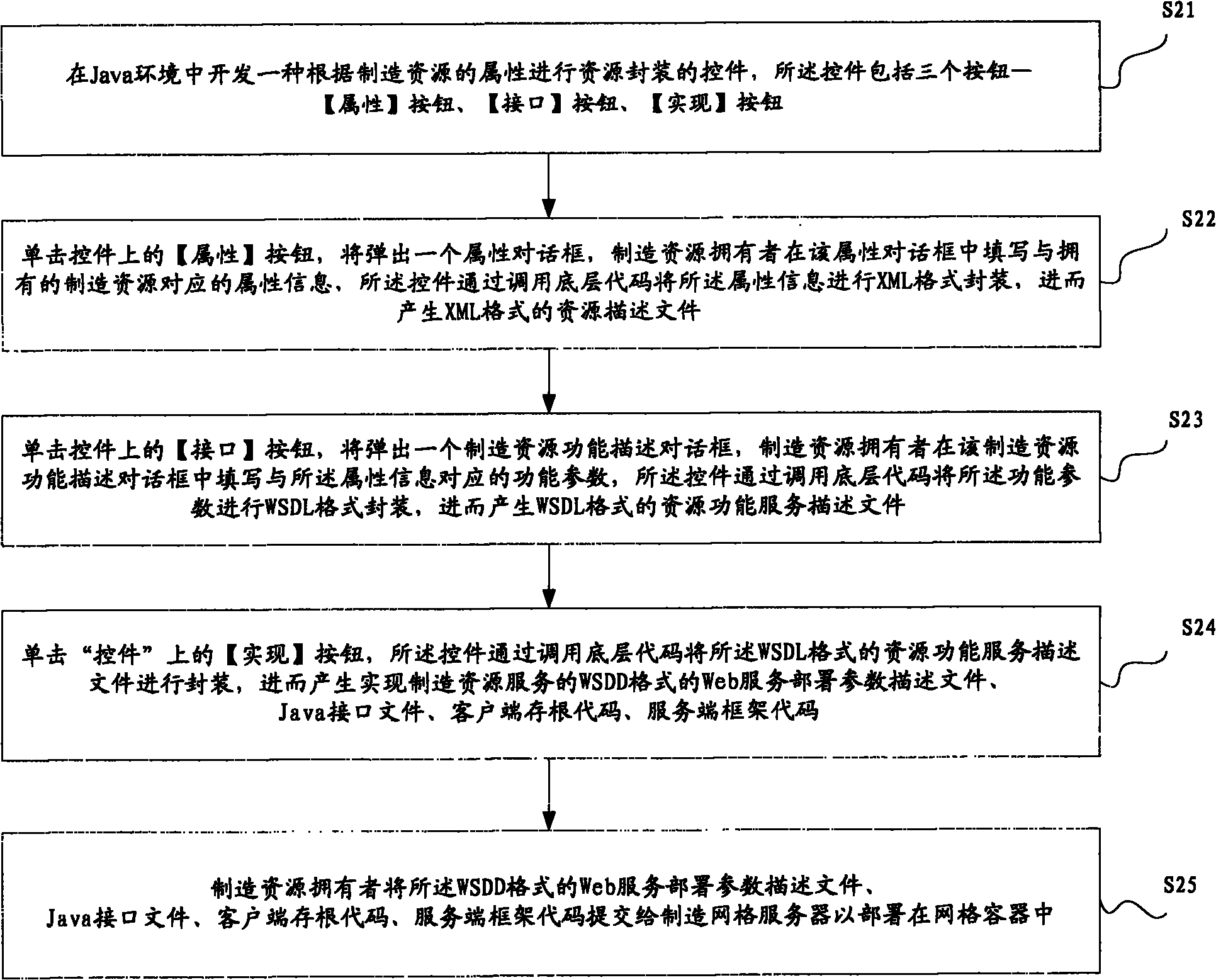

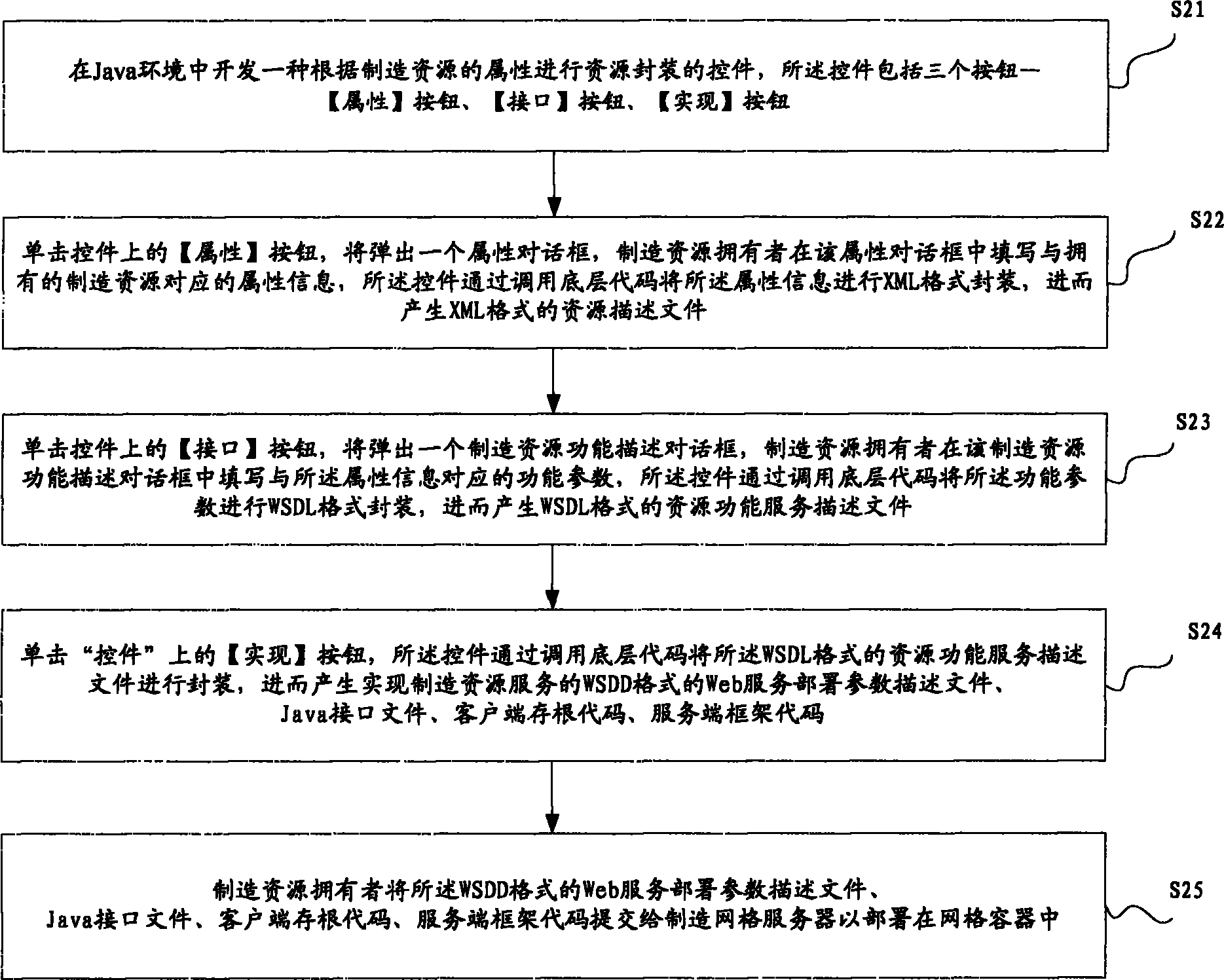

Manufacturing grid resource encapsulation method based on control

InactiveCN101882076ASimplify the packaging processEasy to operateSpecific program execution arrangementsSTUNWeb service

The invention discloses a manufacturing grid resource encapsulation method based on a control, which comprises the following steps that a control for carrying out resource encapsulation is developed in a Java environment according to the attribute of a manufacturing resource; the control generates a resource description file with an XML (Extensive Markeup Language) format according to input attribute information which corresponds to the owned manufacturing resource; the control generates a resource function service description file with a WSDL (Web Services Description Language) format according to input function parameter information which corresponds to the attribute information; according to the resource function service description file with the WSDL format, the control generates a resource function service description file with a WSDD (Web Service Deployment Descriptor) format, a Java interface file, a client stun code and a server frame code which realize manufacturing resource service; and a manufacturing resource owner submits all files for realizing the manufacturing resource service to a manufacturing grid server so as to deploy the files in a grid container. In the method, the manufacturing resource owner does not need to know the steps and the details of the resource encapsulation method when the manufacturing resource is encapsulated, and the manufacturing grid resource encapsulation method has simple operation, easy implementation and convenient use.

Owner:WUHAN UNIV OF TECH

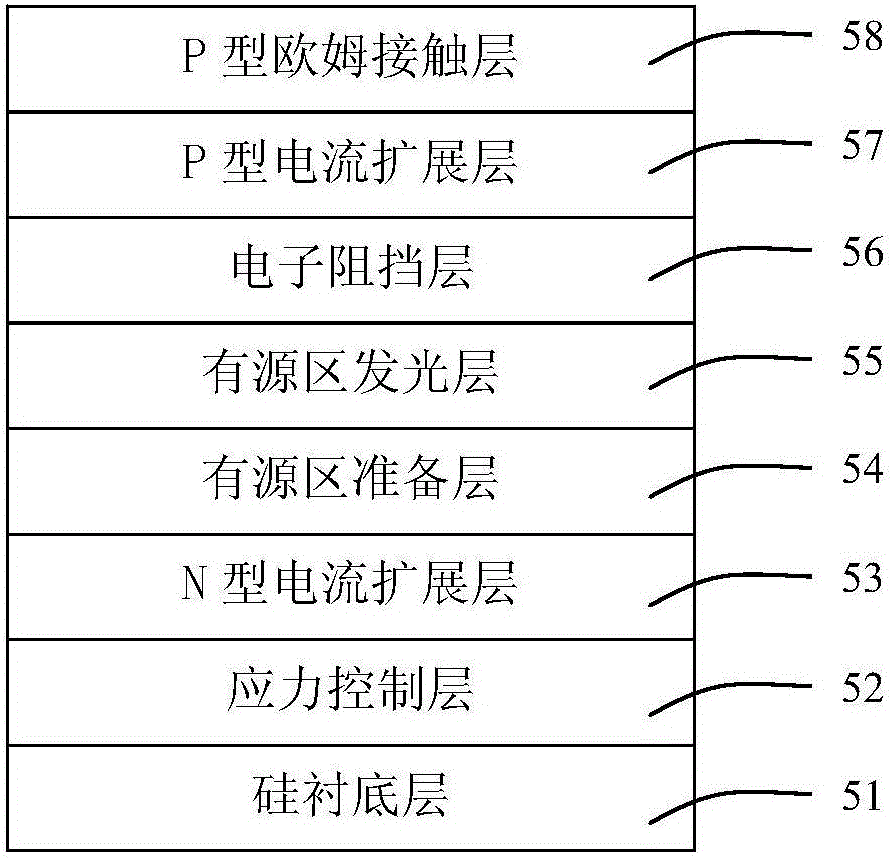

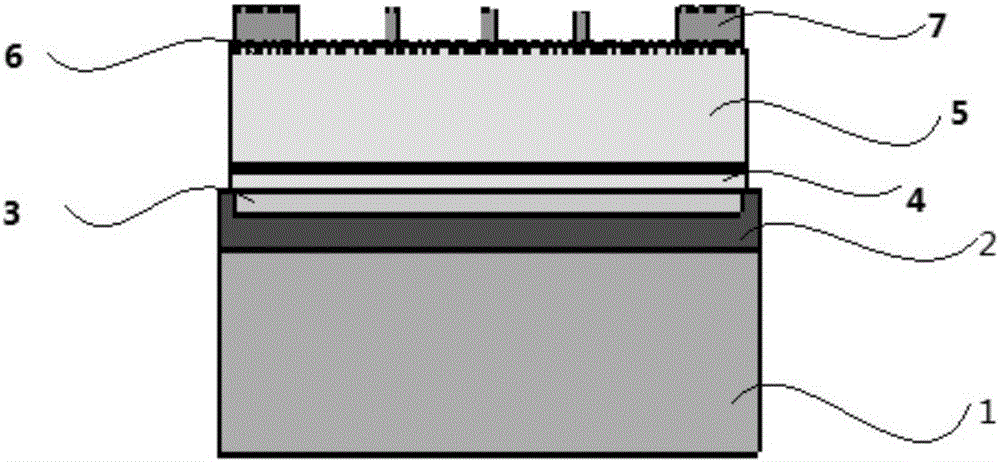

Silicon substrate nitride ultraviolet LED chip structure and implementation method therefor

ActiveCN105720144AIncrease the turn-on voltageImprove conductivitySemiconductor devicesManufacturing gridUltraviolet

The invention provides a silicon substrate nitride ultraviolet LED chip structure and an implementation method therefor. The preparation method for the LED chip comprises the steps of preparing an epitaxial structure, wherein the epitaxial structure comprises a growth substrate and a stress control layer; performing surface treatment on the epitaxial structure; depositing a reflective layer on the epitaxial structure and performing patterning treatment on the reflective layer; depositing a bonding layer on the patterned reflective layer; enabling the epitaxial structure after the bonding layer is deposited to be bonded with a supporting substrate through a bonding technology; removing the growth substrate and the stress control layer; roughening the stress control layer to form a roughened layer; and manufacturing grids used for electric conduction and a negative electrode bonding pad on the surface of the roughened layer to finish the preparation of the silicon substrate nitride ultraviolet LED chip structure. The ultraviolet LED epitaxial structure is growing on the high-thermal-conductivity silicon substrate, and the silicon substrate ultraviolet LED perpendicular structured chip is prepared, so that the LED chip structure has the advantages of high thermal dissipation, high chip yield and low cost.

Owner:晶能光電股份有限公司

Manufacturing method for gate and semi-conductor device

InactiveCN101459069AReduced execution timeStrong ability to remove residues and defectsSemiconductor/solid-state device manufacturingSemiconductor devicesManufacturing gridPhotoresist

A method of manufacturing grids includes steps of sequentially forming a grid layer, an anti-reflection layer and grid photoresist patterns on a semiconductor substrate, etching for removing the anti-reflection layer uncovered by the grid photoresist patterns, etching the grid layer uncovered by the anti-reflection layer, and forming grids, wherein a process of etching the anti-reflection layer includes steps of primarily etching the anti-reflection layer with plasma and over-etching the anti-reflection layer with plasma containing CF4 and O2. The invention further provides a method of manufacturing semiconductor devices. The method of manufacturing grids is capable of reducing residue defects of the anti-reflection layer materials or does not have any residue defects.

Owner:SEMICON MFG INT (SHANGHAI) CORP

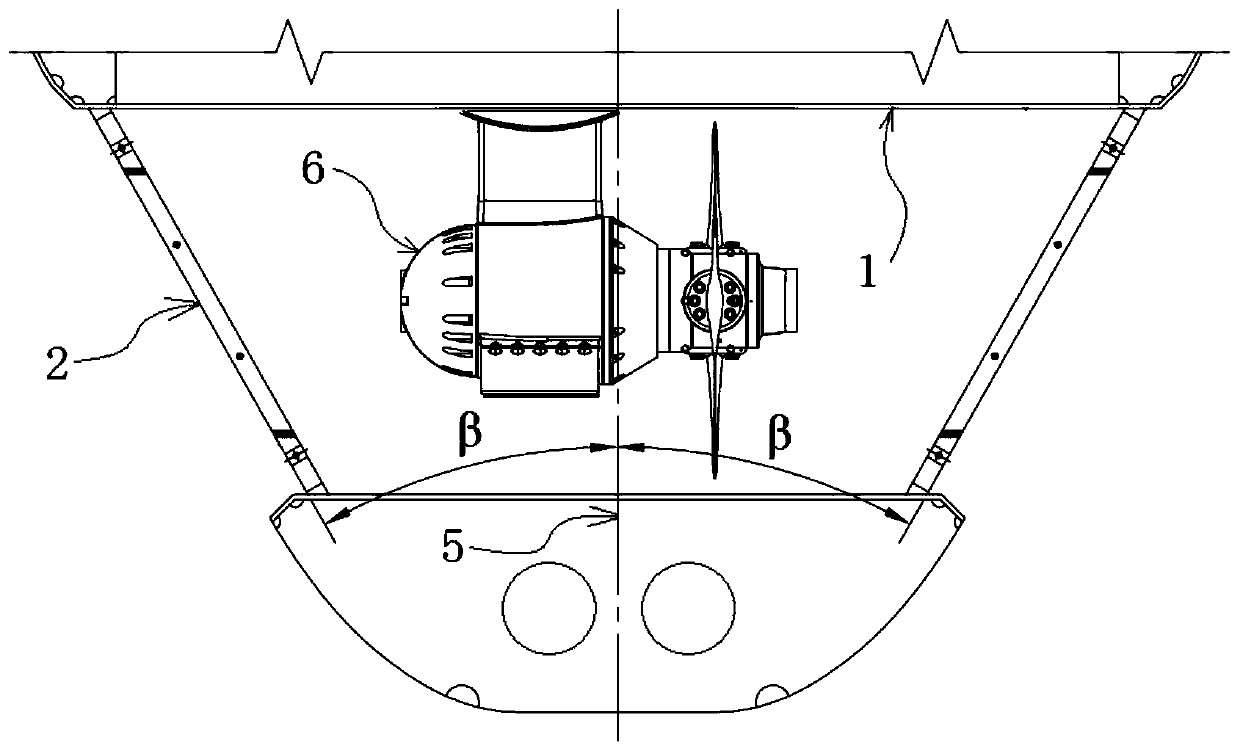

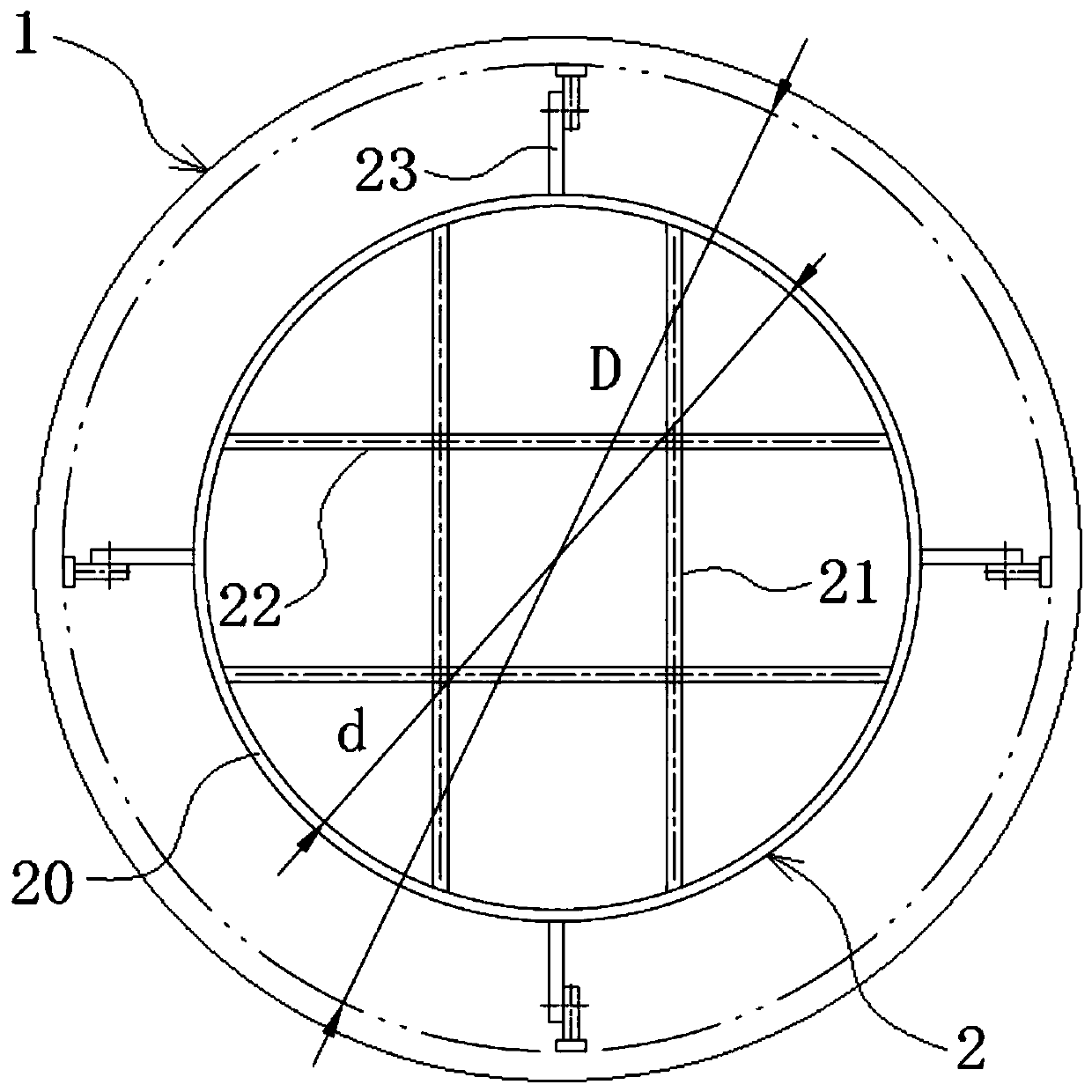

Side pushing grid manufacturing method

ActiveCN110254620AEfficient determinationEasy to manufactureVessel designingPlane figureManufacturing grid

The invention provides a side pushing grid manufacturing method, and relates to the technical field of ship side pushing devices. The side pushing grid manufacturing method comprises the following steps that firstly, the space position relation between a side pushing barrel and ship body outer boards is determined; secondly, in three-dimensional space of cartographic software, a cylinder and a plane figure corresponding to the position relation are drawn; thirdly, the cylinder is split according to the plane figure, and a split oval figure is obtained; and fourthly, a grid frame is manufactured according to the split oval figure. The split oval figure is utilized for conducting shape simulating on the grid frame, the grid frame is manufactured according to the split oval figure, the manufactured grid frame is matched with ports, in the positions of the ship body outer boards on the two sides, of the actual side pushing barrel in shape, parameters of the grid frame can be effectively determined according to the method, repeated testing and shape parameter adjusting are avoided, and the whole side pushing grid manufacturing process is more convenient and accurate.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

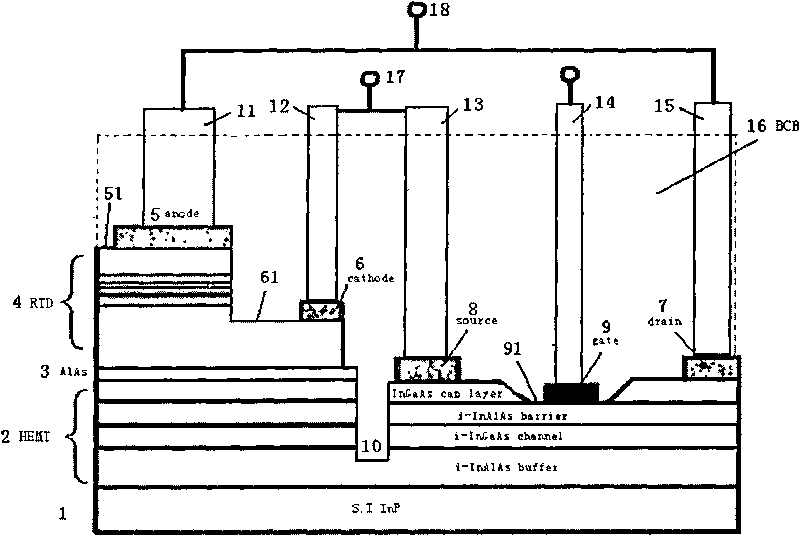

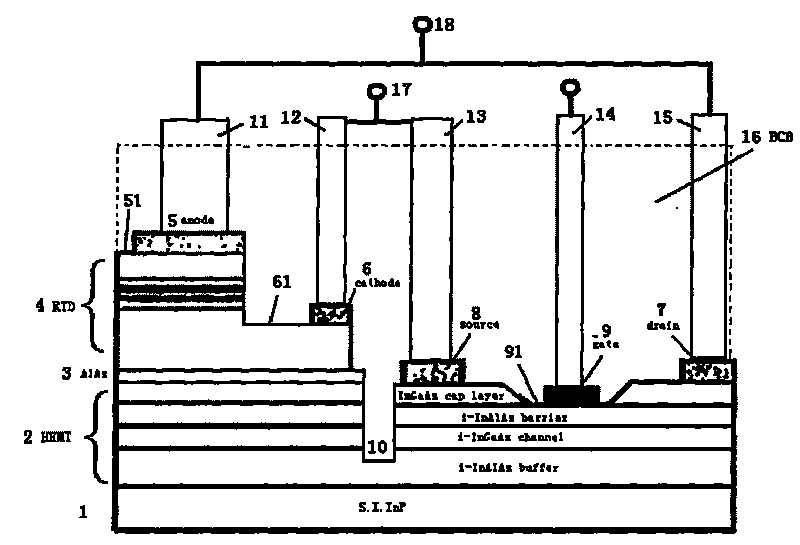

Monolithic integrated manufacturing method for indium phosphide-based resonant tunneling diodes and high-electron-mobility transistors

InactiveCN101692438ASimple processEasy to operateSemiconductor/solid-state device manufacturingSemiconductor materialsEvaporation

The invention provides a monolithic integrated manufacturing method for indium phosphide-based resonant tunneling diodes and high-electron-mobility transistors, which comprises the following basic steps: orderly growing high-electron-mobility transistor and resonant tunneling diode materials on a semiconductor material indium phosphide (InP) substrate with molecular beam epitaxial equipment; etching the surface of an epitaxial wafer with electron beams, and forming the mesa of the resonant tunneling diodes through optical lithography and wet etching; realizing the isolation between devices through the optical lithography and the wet etching to form isolated channels; manufacturing upper and lower electrodes of the resonant tunneling diodes and source electrodes and drain electrodes of the high-electron-mobility transistors through metal ohmic contact, and then annealing; manufacturing grid electrodes through electron beam lithography, dry etching and wet etching; manufacturing metal terminals through dry etching, optical lithography and electron beam evaporation; and finally, interconnecting the resonant tunneling diodes and the high-electron-mobility transistors through a benzocyclobutene flatness process and metal wiring. The method has the characteristics of simple process, strong operability, high finished product ratio and the like, and has good practicability.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Method for manufacturing grid line with high uniformity through double exposure

ActiveCN103488058ASimple manufacturing processMeet the requirements of uniformitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusManufacturing gridMetallurgy

The invention provides a method for manufacturing a grid line with high uniformity through double exposure. The method comprises the following steps: sequentially depositing a polycrystalline silicon thin film, an amorphous carbon thin film and a silicon oxide thin film containing carbon, and then coating, so as to form a first photoresist for a hard film; performing exposure and development to form a first grid line structure in a first photoresist film; curing the first grid line structure, and heating, so as to enable a silanization material to react with the surface of the first photoresist to form an isolating film which is insoluble in a second photoresist; coating the second photoresist on the cured first photoresist; performing exposure and development to form a first line end cutting figure in a second photoresist film; etching the isolating film and a first line by using the second photoresist film as a mask, so as to form a second line end cutting figure; sequentially etching all films by using the rest isolating film and the first grid line as the mask, and finally forming a second grid line structure in the polycrystalline silicon thin film.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

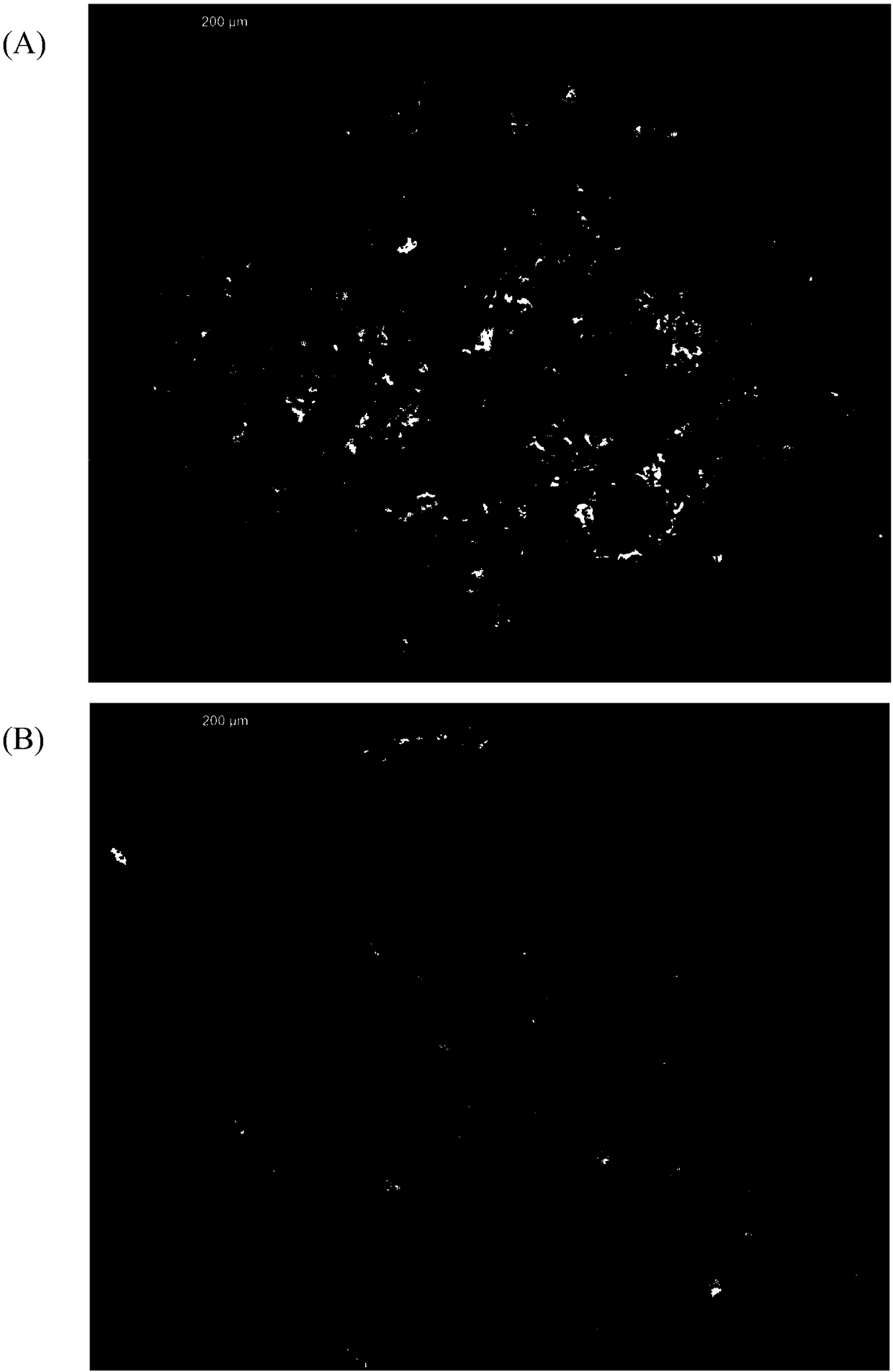

Storage battery grid with refined alloy grains and manufacturing method thereof

ActiveCN108396171AImprove performanceImprove corrosion resistanceElectrode carriers/collectorsIngot castingManufacturing grid

The invention discloses a storage battery grid with refined alloy grains and a manufacturing method thereof, and belongs to the technical field of storage battery manufacturing. The storage battery grid adopts a lead-tin-silver-lanthanum-cerium alloy, furthermore, an antimonide is added, and the grains are refined, so that the corrosion resistance and strength of the alloy are improved, and the performance of a storage battery is improved. The manufacturing method comprises the steps that firstly, mutual melting is carried out on grain-changing agents which cannot be easily molten in combination with ultrasonic waves under the conditions of high temperature and high shearing and stirring, and then the mixture is mixed with a large amount of molten lead, so that the uniform mixing of the grain-changing agents is guaranteed, and segregation is avoided in the solidification process; an alternating magnetic field is applied in the ingot casting process, the changed magnetic field damages the solidification structure of the grains, and the grains are refined; and when the grid is cast, the magnetic field and the ultrasonic vibration are adopted at the same time, and the grains are further refined under the double action of the magnetic field and the vibration energy. By adopting the grain refining method, the high-temperature corrosion resistance of the manufactured grid is improvedby 60%, the capacity, the low temperature performance and the charging acceptance performance of the storage battery are improved and the service life of the storage battery is prolonged correspondingly to different degrees, and the service life is prolonged by 30% or more.

Owner:浙江天能汽车电池有限公司

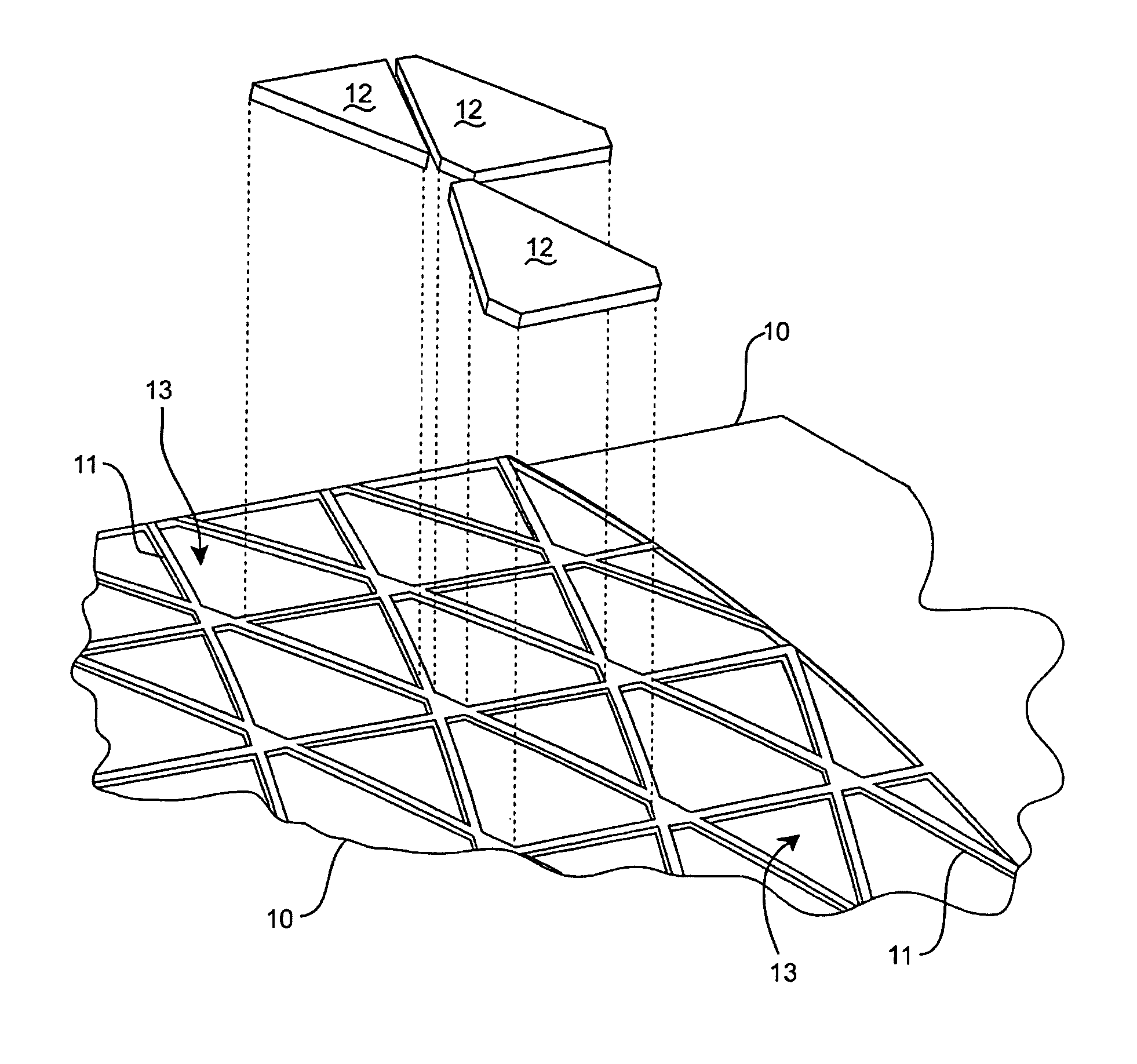

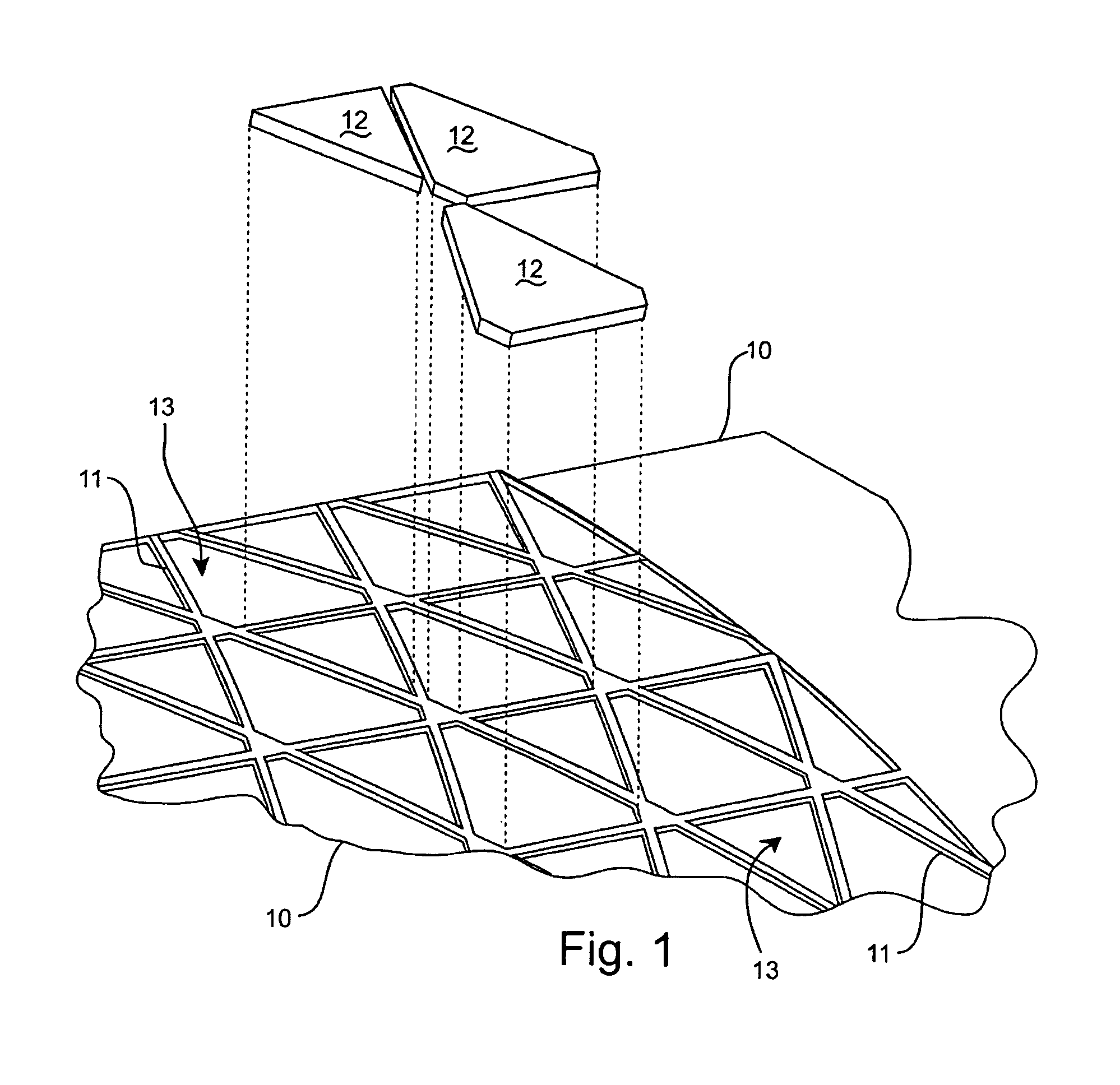

Method for fabricating grid-stiffened composite structures

InactiveUS7871487B1Minimizing any differential in pressureMouldsSynthetic resin layered productsManufacturing gridSubject matter

A method for fabricating a grid-stiffened structure from fiber-reinforced composite materials. Ribs are formed on a smooth hard base tool. Expansion blocks are placed in the shallow cavities formed by the ribs and the base tool, and held in place by one of several means while a skin is placed over the ribs, expansion blocks, and base tool. The assembly is then placed in a vacuum bag and autoclave cured. After cooling, the formed structure is separated from the base tool and the expansion blocks are removed from the cavities. This abstract is provided to comply with the rules requiring an abstract, and is intended to allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com