Grid for radiography, radiation image detector, radiation imaging system, and method for manufacturing grid

A technology of an image detector and an imaging system, which is applied to instruments for radiological diagnosis, material analysis using radiation diffraction, diffraction gratings, etc. High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

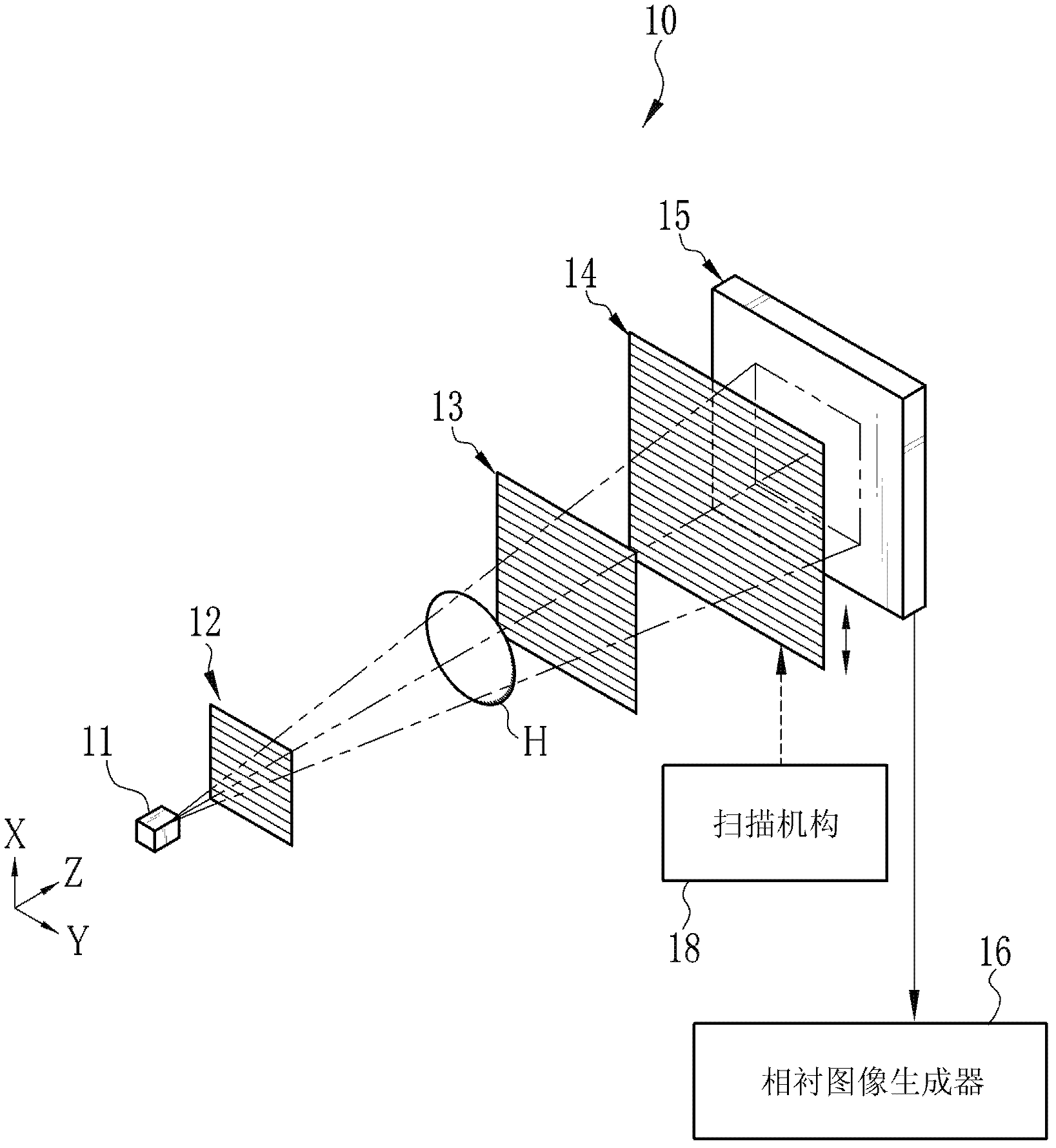

[0041] Such as figure 1 As shown in , the X-ray imaging system 10 is composed of the following items: X-ray source 11, source grid 12, first grid 13, second grid 14 and X-ray image detector 15, which are arranged as X-ray in the Z direction of the propagation direction. The X-ray source 11 has, for example, a rotating anode type X-ray tube, and a collimator for confining a radiation field of X-rays and applying an X-ray cone beam to the sample H. The X-ray image detector 15 is a flat panel detector (FPD) composed of, for example, a semiconductor circuit, and is disposed behind the second grid 14 . A phase-contrast image generator 16 is connected to the X-ray image detector 15 to generate a phase-contrast image from image data detected by the X-ray image detector 15 .

[0042] A source grid 12 , a first grid 13 , and a second grid 14 , which are X-ray absorption grids, are opposed to the X-ray source 11 in the Z direction. The sample H is arranged between the source grid 12 ...

no. 2 approach

[0071] In a second embodiment, a phosphor-doped nonlinear single-crystal substrate is integrated in an X-ray image detector and used as a second grid and scintillator. Such as Figure 12 As shown in , before or after filling the X-ray absorbing material 48 into the groove 40e of the nonlinear single crystal substrate 40, the inversion portion 40c may be doped with phosphor. In another case, a phosphor-doped nonlinear single crystal substrate may be prepared, and then the X-ray absorbing material 48 may be filled into the trench 40e. After that, the seed layer 22 is removed to take out the nonlinear single crystal substrate 40 . Such as Figure 13 As shown in , the nonlinear single crystal substrate 40 emits light when X-rays are applied. After that, if Figure 14 As shown in , the nonlinear single crystal substrate 40 is included in the X-ray image detector 60, so the nonlinear single crystal substrate 40 functions as a second grid and a scintillator. In the case of using...

no. 3 approach

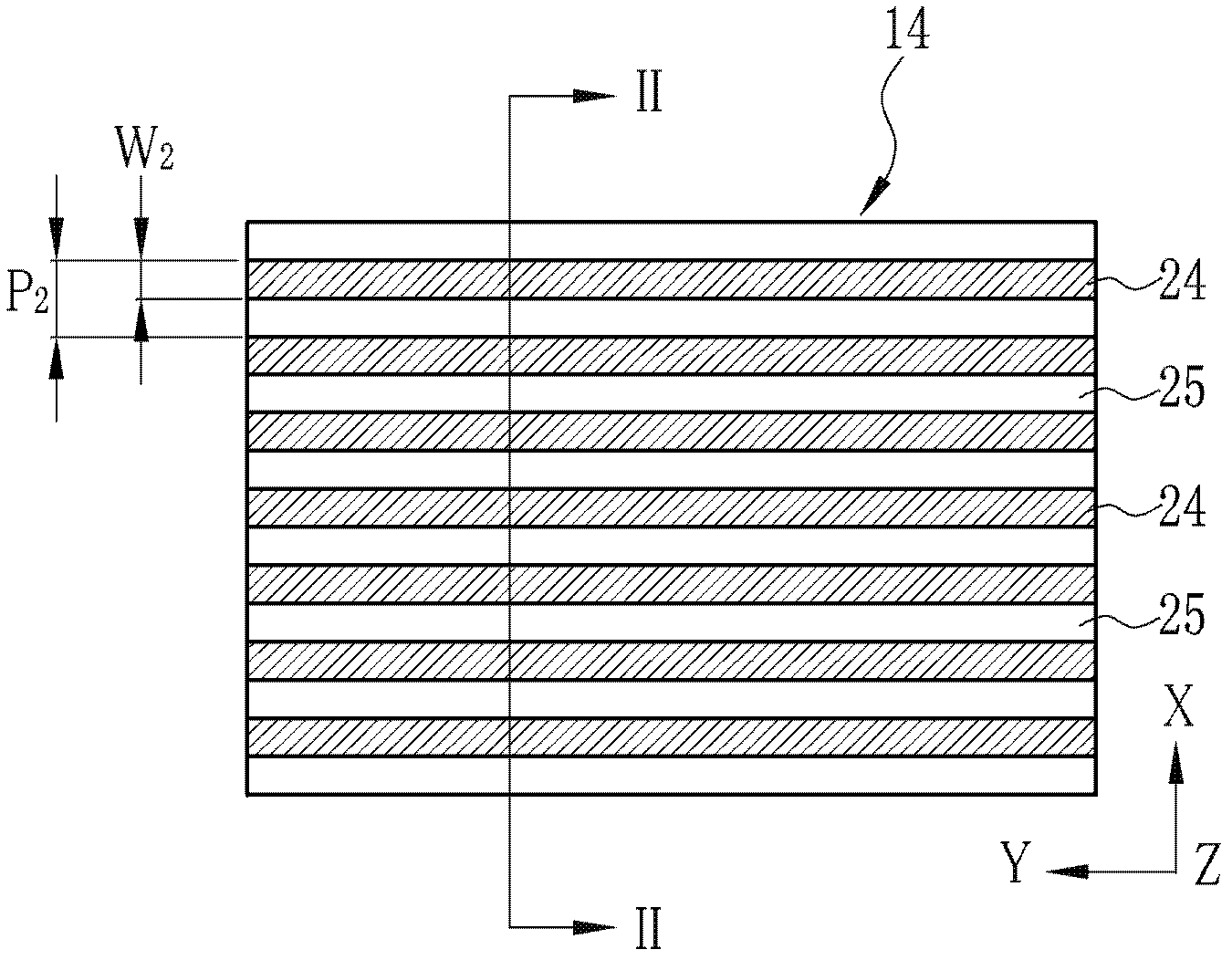

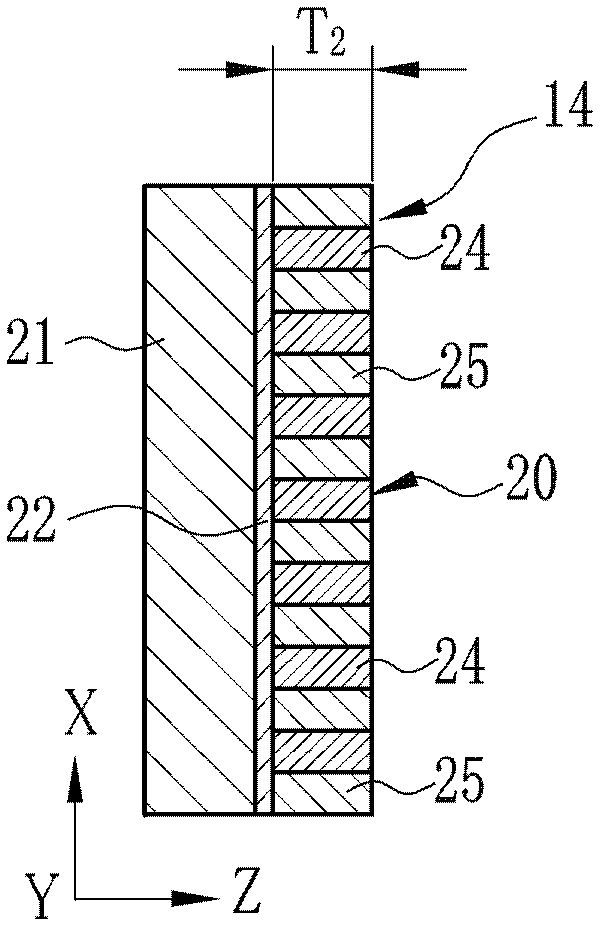

[0074] In the above embodiments, the polarization inversion is performed straight along the thickness direction of the nonlinear single crystal substrate 40 . However, if Figure 16 As shown in , a second periodic electrode 70 having a periodicity different from that of the periodic electrode 41 of the first surface 40 a may be formed in the second surface 40 b of the nonlinear single crystal substrate 40 . After that, a voltage is applied from the high voltage source 46 to the second periodic electrode 70 so that a polarization inversion occurs between the periodic electrode 41 and the second periodic electrode 70 . According to this embodiment, as in Figure 17 As shown in the grid 75 of , the X-ray absorbing portion 24 and the X-ray transmitting portion 25 may be inclined in the grid surface, so that the X-ray emitted from behind the grid 75 and passing through the X-ray transmitting portion 25 The rays converge to an X-ray focal point 11 a which is an X-ray generating po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com