Method for manufacturing grid line with high uniformity through double exposure

A gate line, double exposure technology, applied in microlithography exposure equipment, photolithography process exposure equipment, semiconductor/solid-state device manufacturing, etc., can solve the problems of limited uniformity, complex process, low production capacity, etc. cost, simplify the production process, and improve the effect of production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0049] Figure 4A to Figure 4G It schematically shows a method for manufacturing gate lines with high uniformity by double exposure according to the first preferred embodiment of the present invention.

[0050] Specifically, as Figure 4A to Figure 4G As shown, the method for making gate lines with high uniformity by double exposure according to a preferred embodiment of the present invention includes:

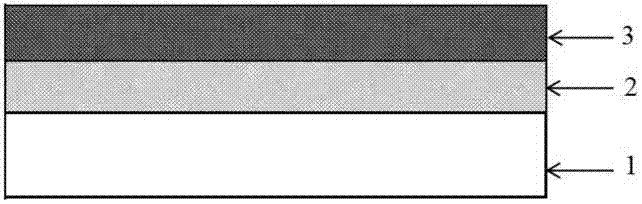

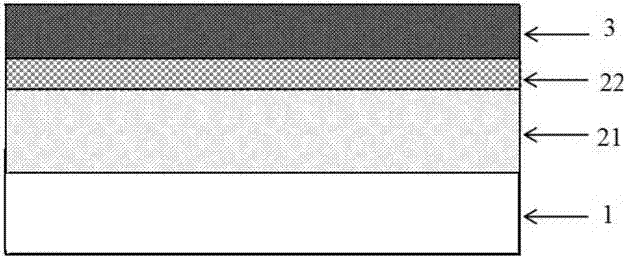

[0051] The first step: deposit polysilicon film 4, amorphous carbon film 21, and carbon-containing silicon oxide film 22 successively on substrate silicon wafer 1, and then coat the first photoresist 3 of formable hard film, such as Figure 4A shown;

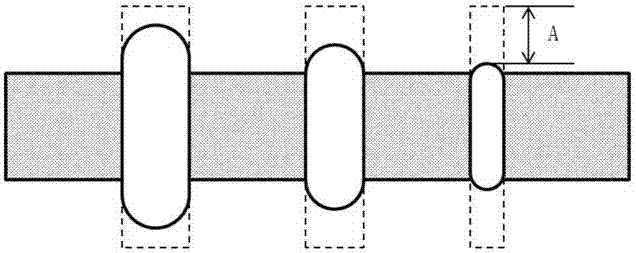

[0052] The second step: finish exposing and developing so as to form the structure of the first gate lines 31 in the first photoresist 3 film, such as Figure 4B shown;

[0053] The third step: in the same development machine as the development of the second step, the silicon wafer with the first gate line 31 structure in th...

no. 2 example

[0059] Figure 4A to Figure 4G It schematically shows a method for fabricating gate lines with high uniformity by double exposure according to the second preferred embodiment of the present invention.

[0060] Specifically, as Figure 4A to Figure 4G As shown, the method for making gate lines with high uniformity by double exposure according to a preferred embodiment of the present invention includes:

[0061] The first step: deposit polysilicon film 4, amorphous carbon film 21, and carbon-containing silicon oxide film 22 successively on substrate silicon wafer 1, and then coat the first photoresist 3 of formable hard film, such as Figure 4A shown;

[0062] The second step: finish exposing and developing so as to form the structure of the first gate lines 31 in the first photoresist 3 film, such as Figure 4B shown;

[0063] The third step: in the same development machine as the development of the second step, apply a silylation material liquid on the first photoresist 3 ...

Embodiment approach

[0069] Preferably, the first photoresist 3 capable of forming the hard film is a photoresist containing one or more of silyl, siloxyl and silsesquioxane.

[0070] Preferably, the etching resistance ratio of the first photoresist 3 and the second photoresist 5 is greater than or equal to 1.5:1.

[0071] Preferably, the silylating material is hexamethyldisilazine (HMDS, hexamethyldisilazine), trimethylchlorosilane (TMCS, trimethylchlorosilane), hexamethyldisilazane (HMDSZ, hexamethyldisilazane), or other applicable silylating materials one or more of.

[0072] Preferably, the heating temperature in the third step ranges from 80°C to 300°C. Further preferably, the heating temperature in the third step ranges from 90°C to 200°C.

[0073] Preferably, the thickness of the amorphous carbon thin film 21 is 20 nm to 300 nm. Further preferably, the thickness of the amorphous carbon film 21 is 50 nm to 250 nm.

[0074] Preferably, the carbon-containing silicon oxide film 22 has a thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com