Patents

Literature

142results about How to "Meet uniformity requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

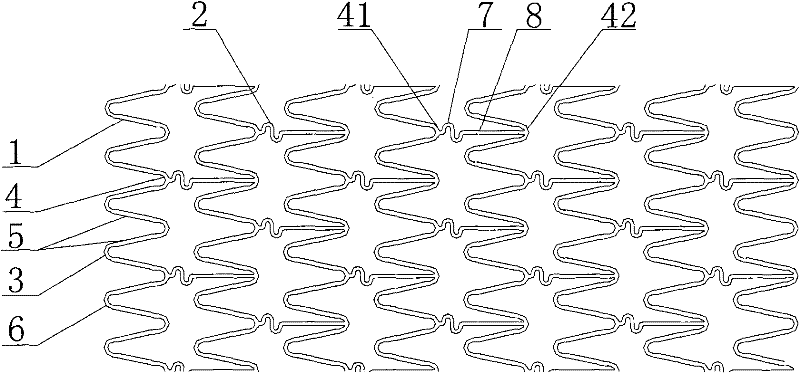

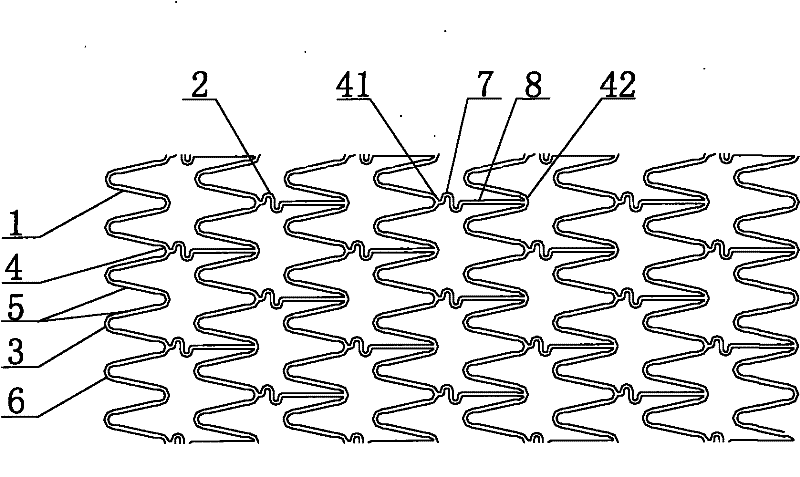

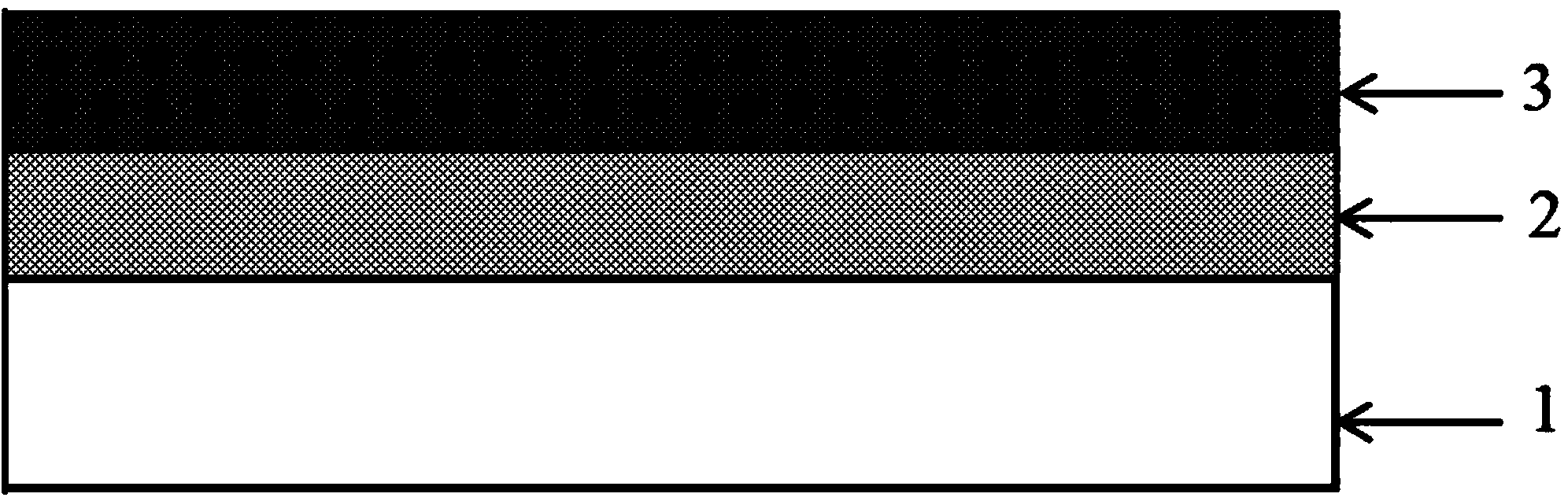

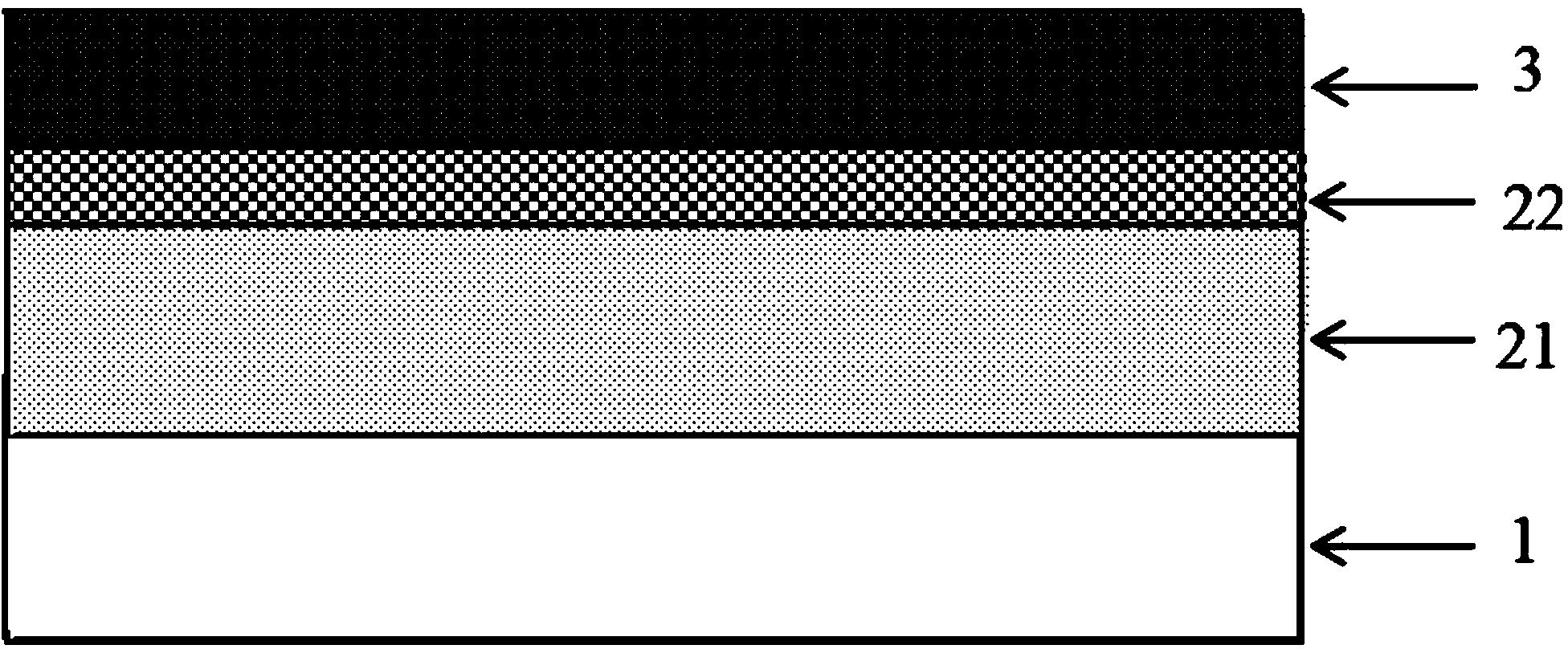

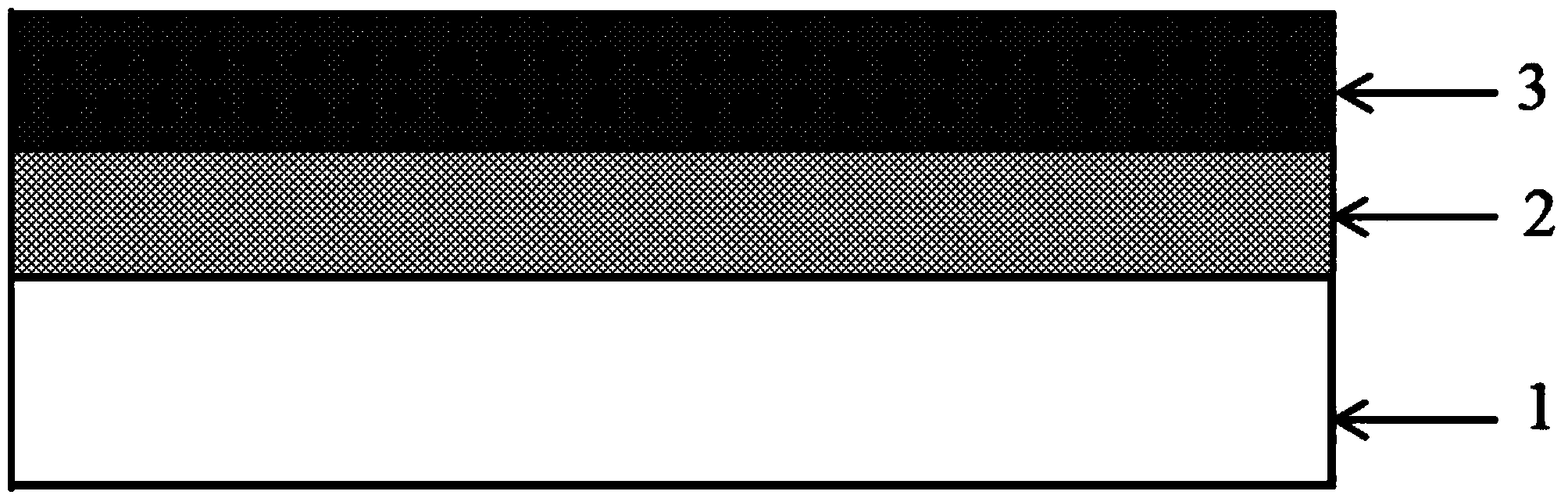

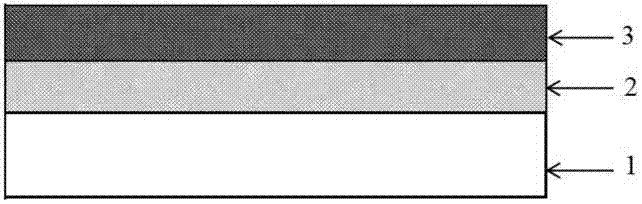

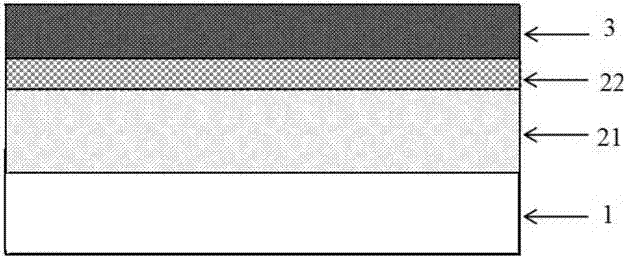

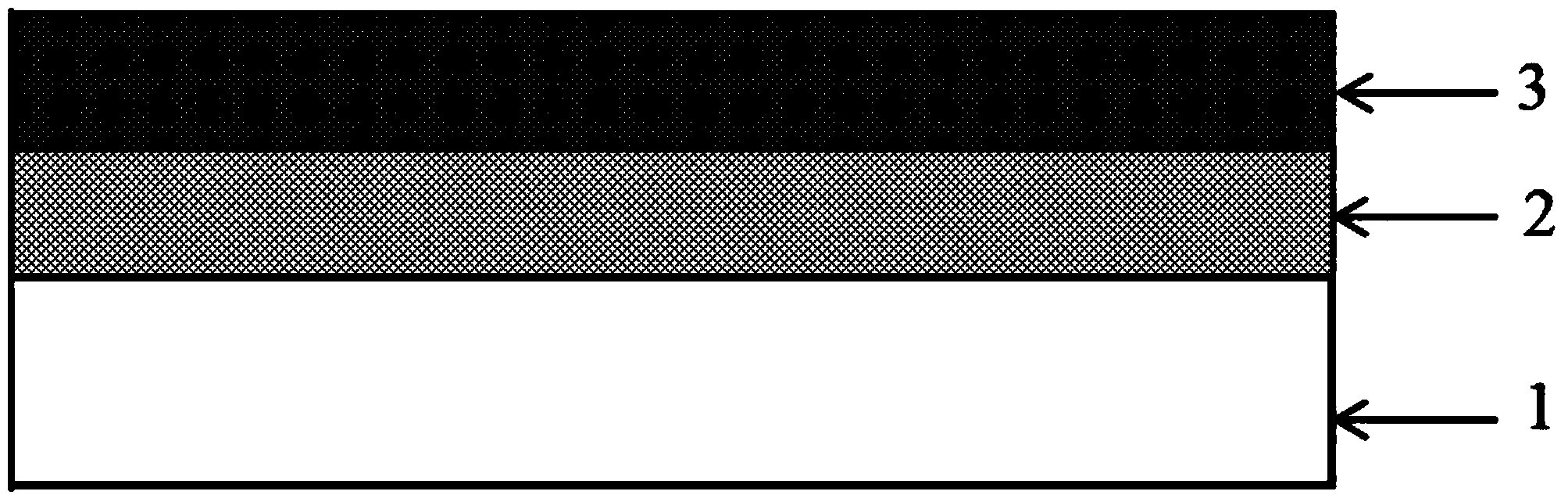

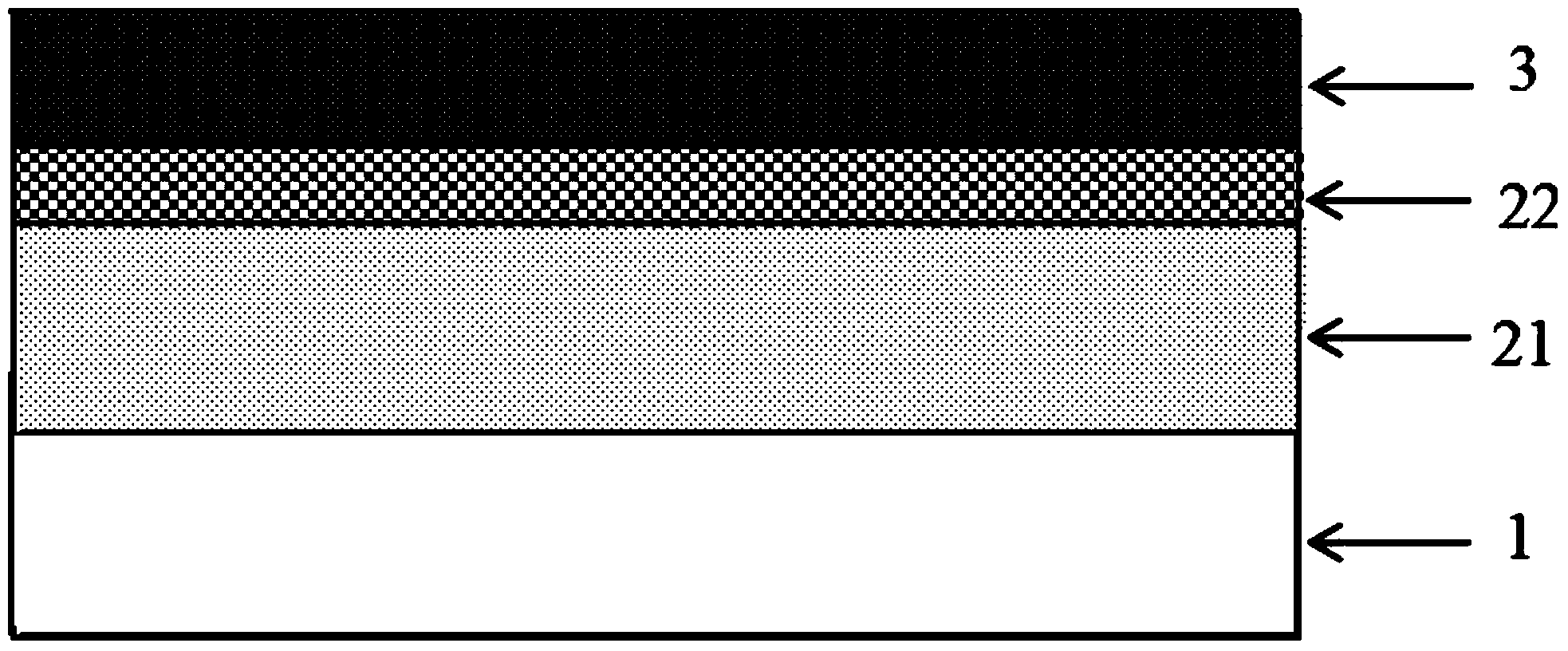

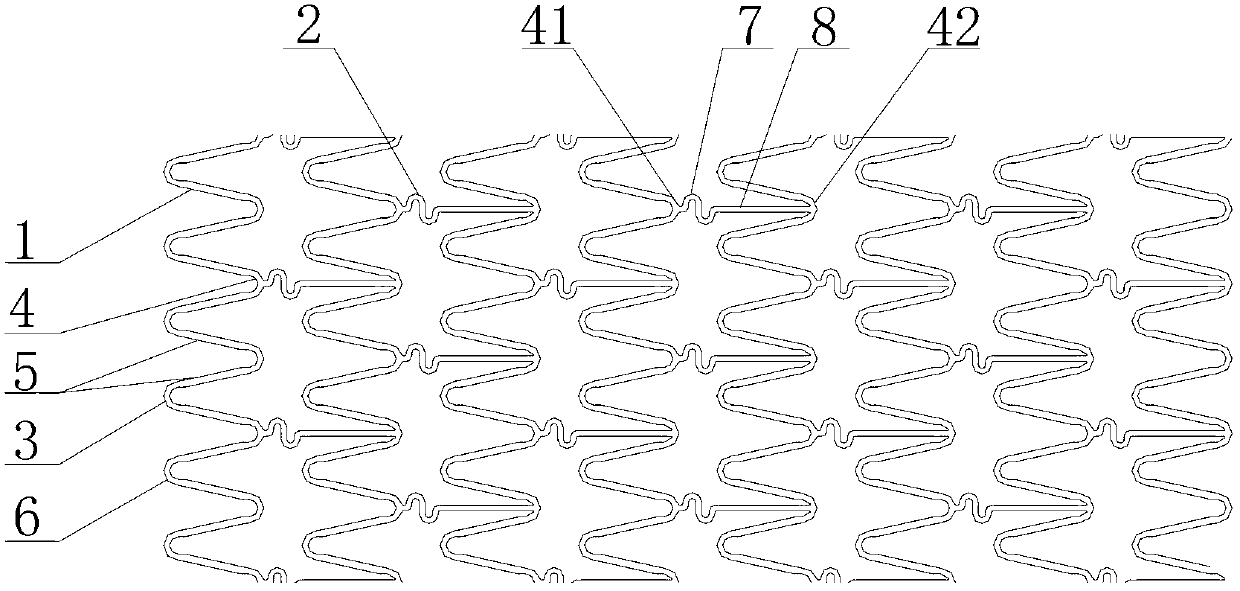

Cobalt-chromium alloy artery stent with full-biodegradation medicine coating, stent system and preparation method thereof

ActiveCN101745153AImprove flexibilityShorten repair timeStentsSurgeryPercent Diameter StenosisCvd risk

The invention provides a cobalt-chromium alloy artery stent with full-biodegradation medicine coating; the full-biodegradation coating of the stent has good stent flexibility, pathological change permeability and radial bearing force; the invention further provides a preparation method of the stent; multi-level coating applying technology, metallic support surface inert gas processing process and the like are adopted, the firmness of the stent surface coating, the toughness and tensile strength thereof are greatly improved, thereby being beneficial to keeping the integrity of the coating; in addition, the invention provides a cobalt-chromium alloy artery stent with full-biodegradation medicine coating, which is prepared by radial grading squeezing process, the damage of the coating can be avoided to the greatest extent, the retention force between the stent and a conveying system is greatly improved, the possibility that the stent is migrated in the conveying process is avoided, the clinical using risk is reduced, and the problems of coronary artery stenosis and restenosis are effectively solved.

Owner:万瑞飞鸿(北京)医疗器材有限公司

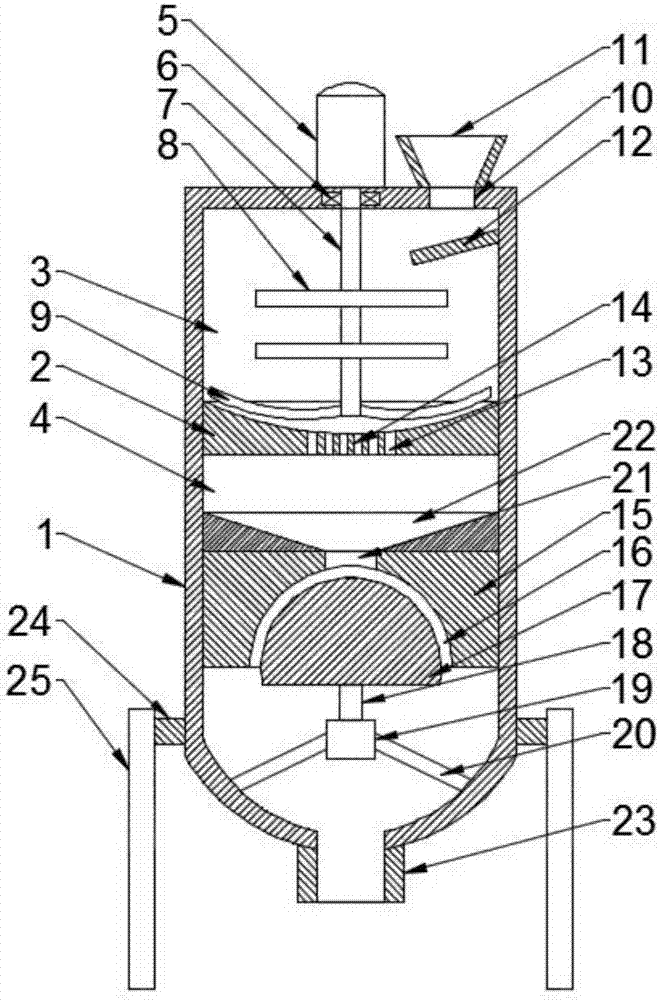

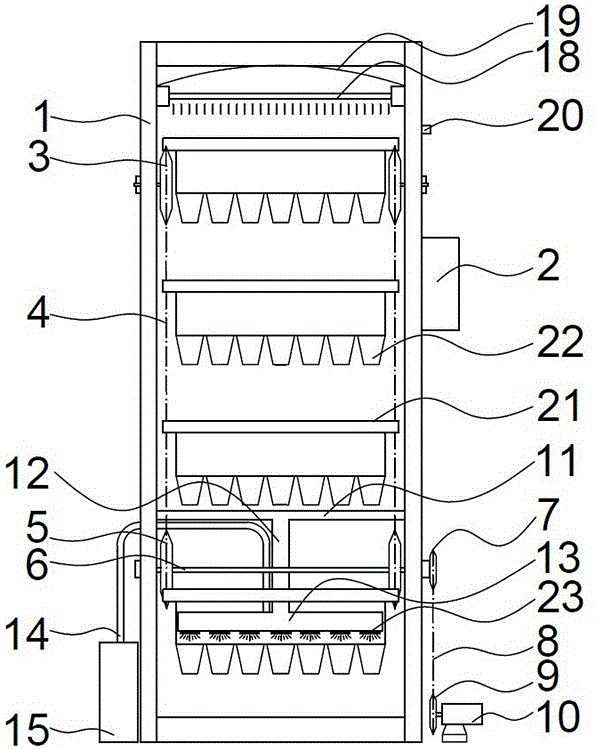

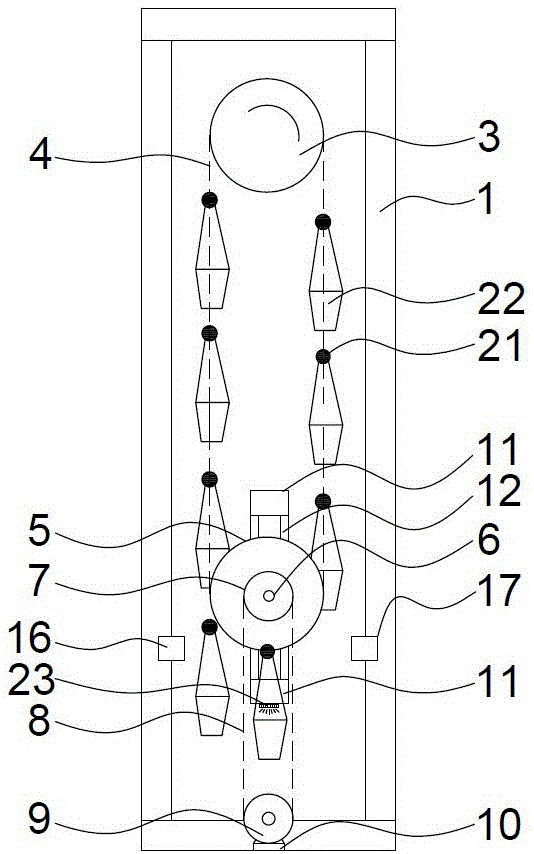

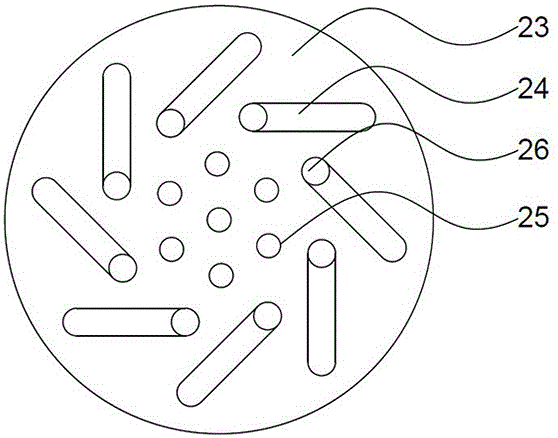

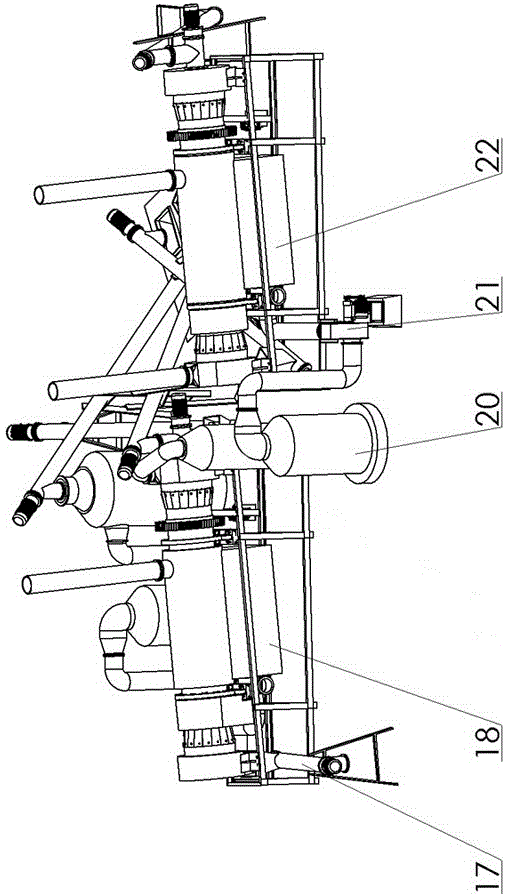

Graded traditional Chinese medicine smashing device

InactiveCN106925395AMeet uniformity requirementsImprove crushing effectGrain treatmentsElectric machineryEngineering

The invention discloses a graded traditional Chinese medicine crushing device, which comprises a tower body. The inner chamber of the tower is provided with a partition crushing plate. The partition crushing plate divides the tower body cavity into a crushing chamber and a grinding chamber. The top of the rod passes through the tower body and is fixedly connected to the motor shaft of the crushing motor. The middle part of the crushing rod is uniformly equipped with a number of first crushing blades, and the bottom end of the crushing rod is uniformly equipped with a number of second crushing blades in the circumferential direction. The grinding chamber is provided with a grinding plate body, the bottom end of the grinding plate body is provided with a grinding chamber, the grinding chamber is provided with a grinding body, and the grinding body is fixed on the motor shaft of the grinding motor through a rotating shaft; The crushing device grinds and pulverizes the traditional Chinese medicine, and under the screening of the filter screen, it meets the uniformity requirements; the primary pulverized Chinese medicine particles are ground and pulverized under the joint action of the grinding chamber and the grinding body, so that the Chinese medicine particles are further finely crushed, Improve the crushing effect and ensure the crushing quality.

Owner:合肥九州龙腾科技成果转化有限公司

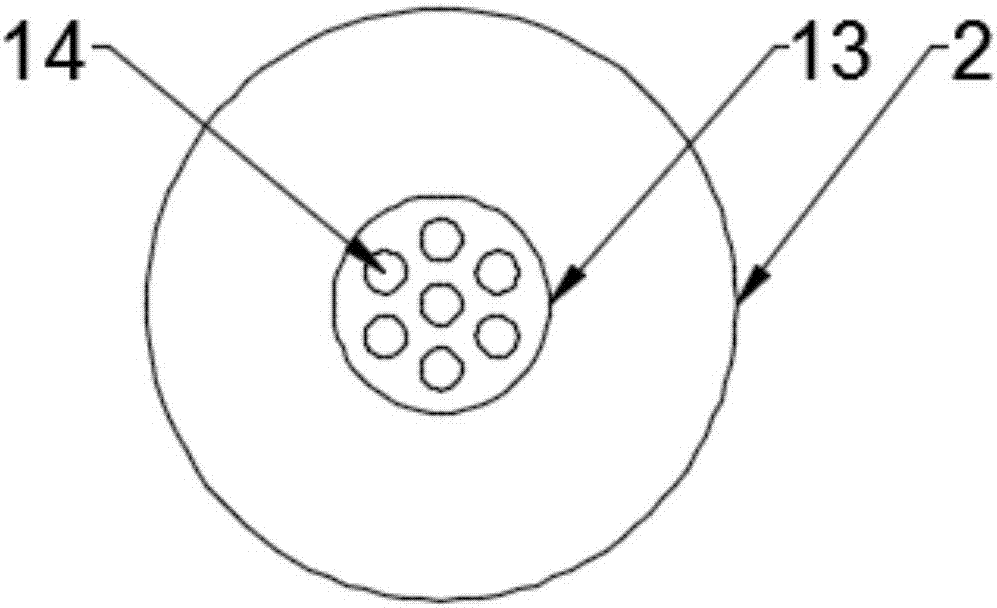

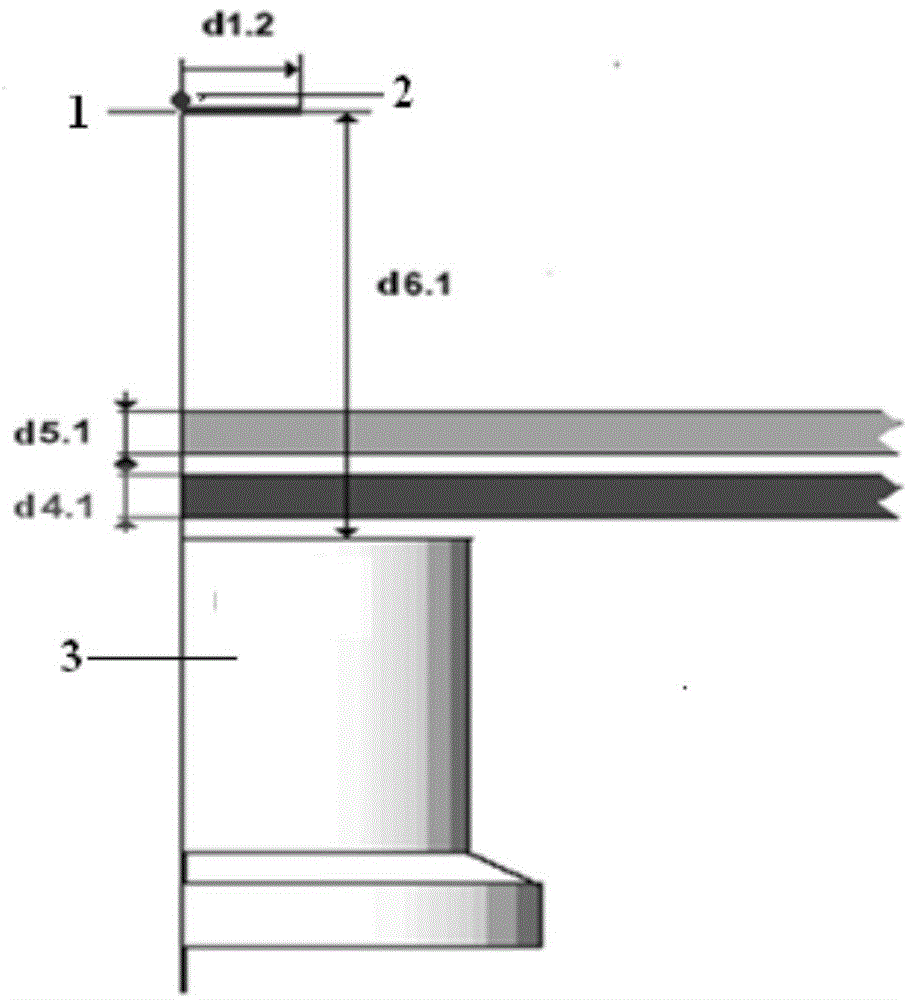

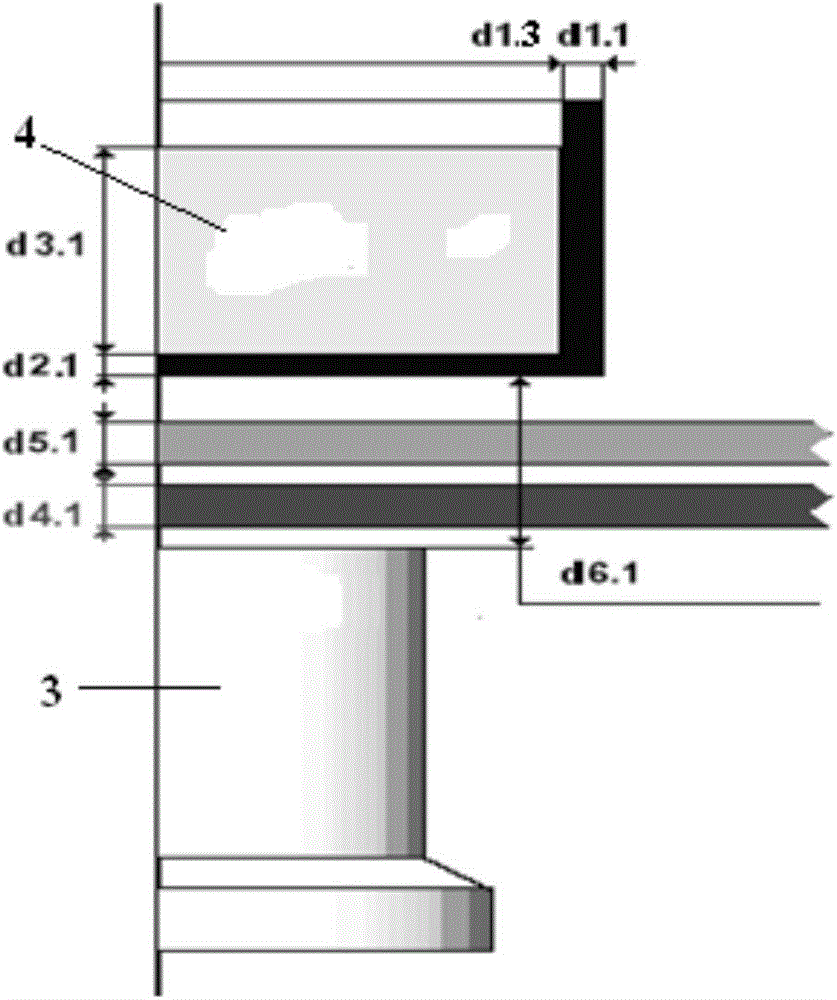

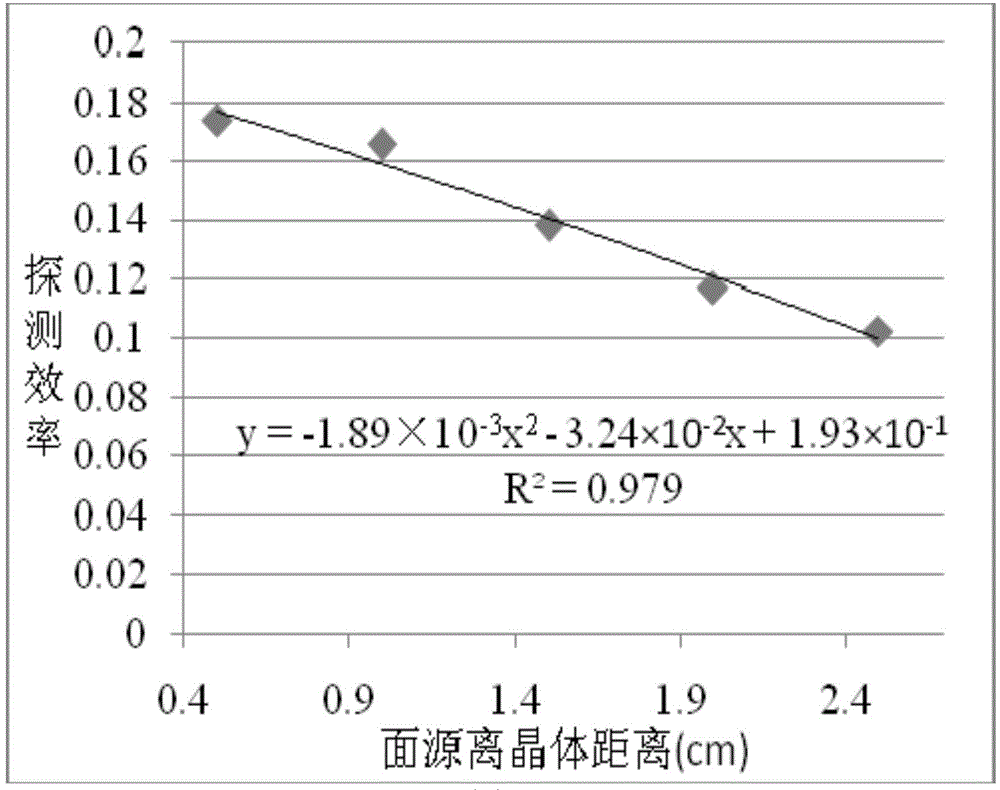

Device and method for detection efficiency calibration of xenon sample HPGe

ActiveCN103605149AShort half-lifeMeet uniformity requirementsX-ray spectral distribution measurementAir sampleSelf-absorption

The invention discloses a device and method for detection efficiency calibration of a xenon sample HPGe. The device comprises a radioactive source, a plurality of polyethylene boxes and a detector, wherein the polyethylene boxes are different in height and contain air samples. The radioactive source comprises a 133Ba surface source and a 137Cs point source. A surface area aluminum substrate is used as an upper absorption layer. The 137Cs point source is located in the central position on the upper surface of the 133Ba surface source. The 133Ba surface source is located above the polyethylene boxes containing the air samples. The upper surface and the lower surface of each polyethylene box are used as lower absorption layers. The detector comprises a crystal, an aluminum outer shell and a carbon material window, wherein the aluminum outer shell is located outside the crystal, and the carbon material window is located on the aluminum outer shell and located above the crystal. The polyethylene boxes are placed above the window of the detector. According to the device and method for detection efficiency calibration of the xenon sample HPGe, the height of the adopted radioactive source is increased in an evenly-spaced mode, the 133Ba surface source is used for replacing a 133Xe sample to conduct efficiency calibration, the peak efficiency of the 137Cs point source is used for correcting correction factors conforming to the addition of the peak efficiency of the 133Ba surface source, and the technical problems that an existing detection efficiency calibration method is quite high in requirement for activity of the source, the self-absorption problem exists in rays, and larger uncertainty exists are solved.

Owner:NORTHWEST INST OF NUCLEAR TECH

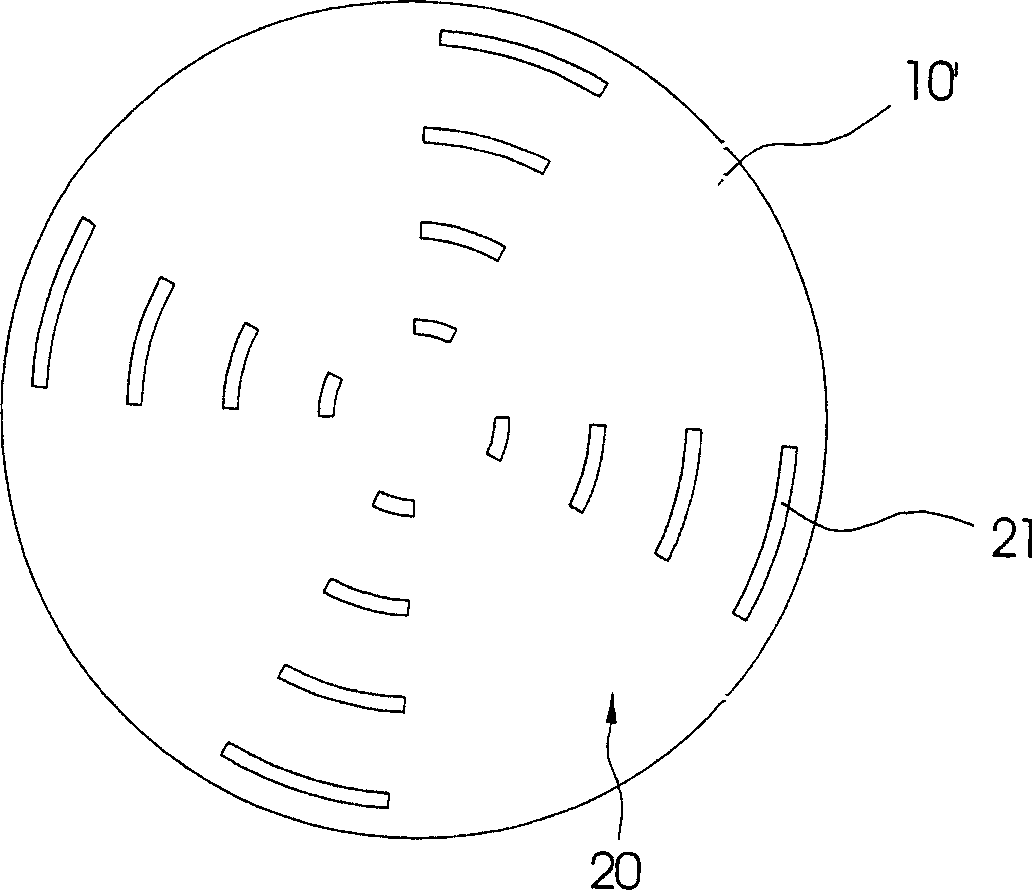

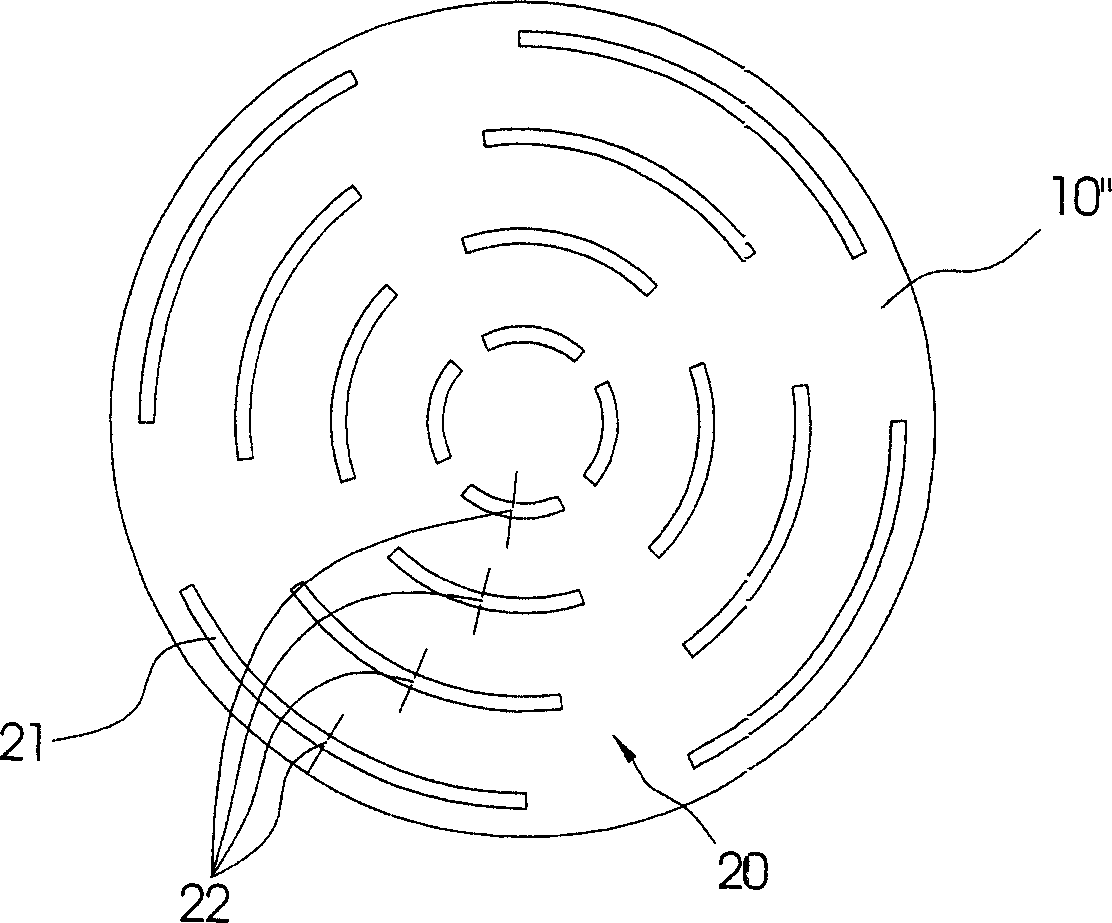

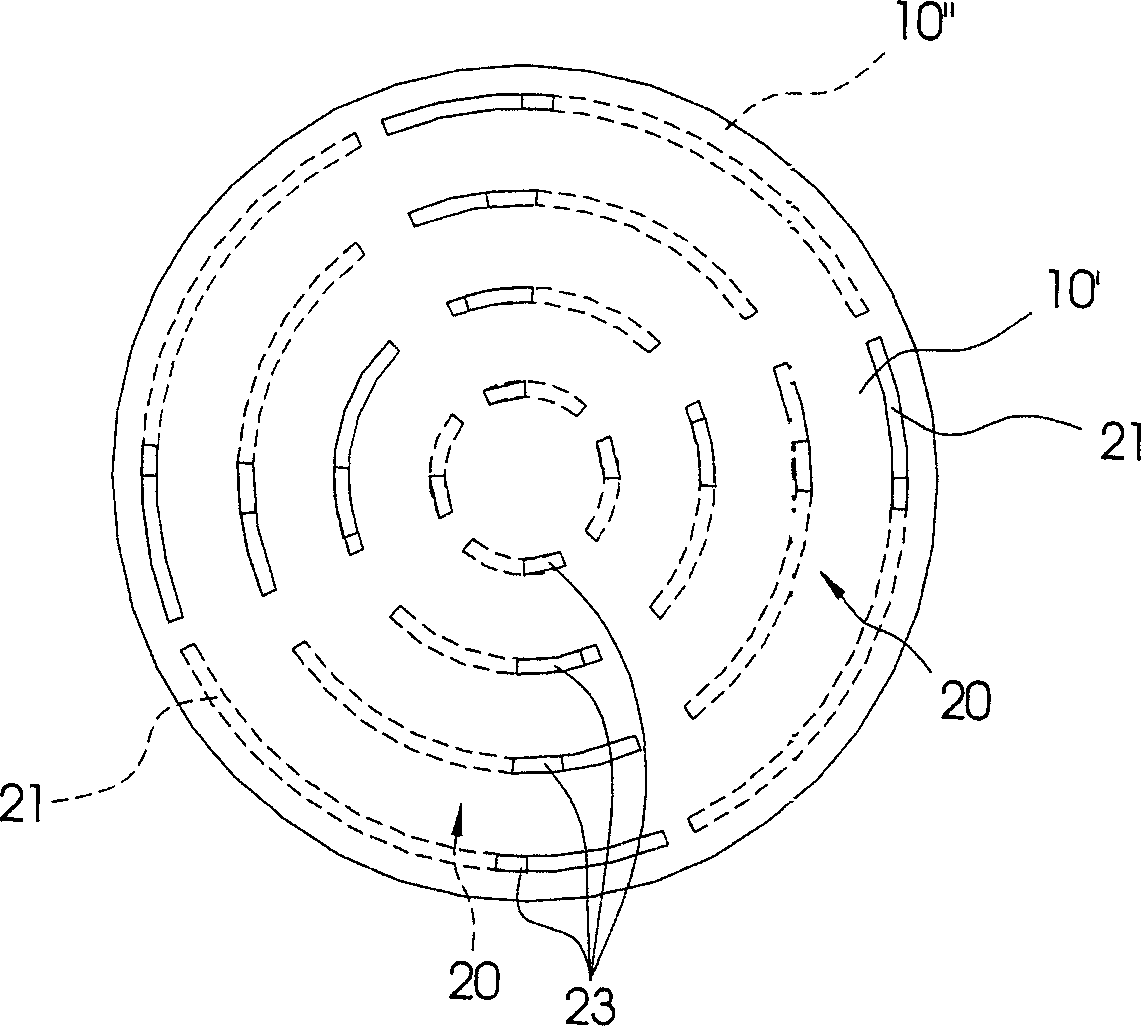

Rotary device for regulating flow of spray head

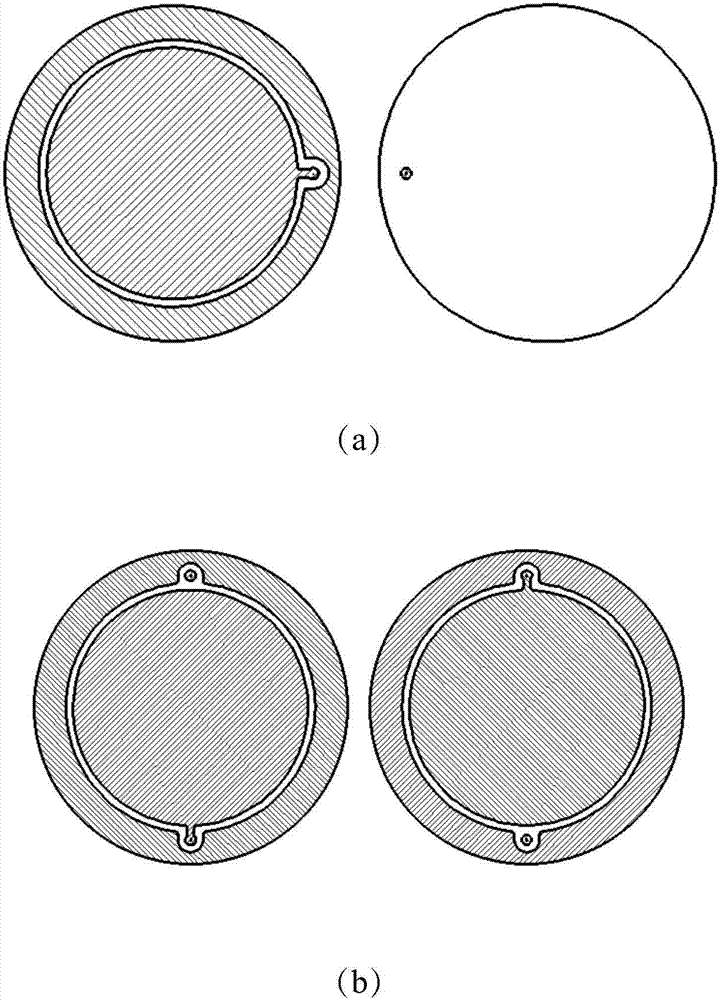

InactiveCN1634666AMeet uniformity requirementsAdd processing parametersMovable spraying apparatusSpray nozzlesEngineeringCircular disc

This invention relates to rotary spray flow adjusting device, which comprises at least two round discs and several relative groove sets, wherein the said two round discs are overlapped together and the groove sets are separately formed on the round discs located on the spray head. The groove sets are connected to the exit mouth of the spray to control the groove connection area and to control flow volume through the spray.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A sealing and pressing method of organic illuminant part and encapsulation device for this method

InactiveCN101086973AEasy to operateMeet uniformity requirementsSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceGlue line

The invention relates to organic electroluminescence technique filed, especially a encapsulation method of organic electroluminescence element and encapsulation equipment with the method. Back cover is superposed with base piece and then placed in a encapsulated cavity, thereinto surface of back cover which is smeared with gluewater faces the surface of base piece plating film; then, encapsulated cavity is vacuumized, and vacuum degree of encapsulated cavity is maintained within a fixed range, positioning framework of back cover or base piece is released, the two is joint under function of gravity; then, encapsulated cavity is charged, the back cover and base piece are pressed together under pressure, the gluewater is pressed evenly; at last, the gluewater is solidified, the encapsulated cavity is open, and element encapsulated is pick out. The invention can resolve problem that equality of width of glue line is poor, and affect of smoothness of clamp surface to encapsulation can be eliminated.

Owner:东莞彩显有机发光科技有限公司 +1

Planting equipment with multicolor supplementing lamps

InactiveCN107517753AExtend the lifespanHigh hardnessSelf-acting watering devicesSaving energy measuresGrowth plantWater resources

The invention provides planting equipment with multicolor supplementing lamps, and belongs to the field of planting equipment. The planting equipment with the multicolor supplementing lamp comprises a support and a controller arranged on the outer side wall of the support, large driven sprockets are arranged at the upper end of the support, large driving sprockets are arranged at the lower end of the support, the corresponding large driven sprocket and large driving sprocket on each side are connected through a transmission chain, multiple suspending rods are horizontally arranged in the support, wherein the two ends of each suspending rod are suspended to the two transmission chains, and multiple cultivation containers are arranged on the suspending rods through suspending ropes in a suspended mode; the equipment is further provided with the long-strip four-color supplementing lamps, and the colors are red, yellow, blue and white respectively; the equipment is further provided with a water supplementing system which can supplement water for cultivated plants; by means of the water supplementing system, the evenness and the stability of plant water supplementing can be achieved, so that not only are water resources saved, but water can be precisely supplemented; the supplementing lamps are capable of evenly supplementing required light for the plants, so that synthesis of chlorophyll and biological enzyme of the plants is accelerated, differentiation of plant cells is promoted, plant growth is accelerated, and the requirements of nighttime even illumination of the plants can be met.

Owner:兰溪市拜瑞珂科技服务有限公司

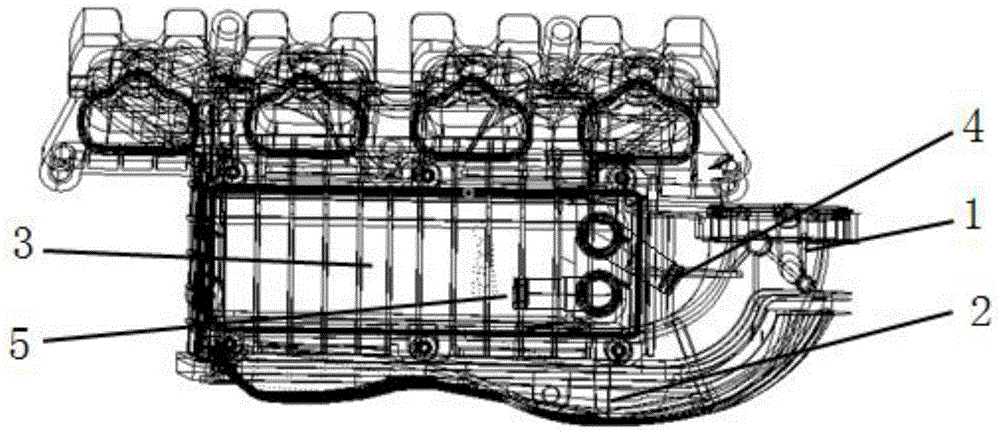

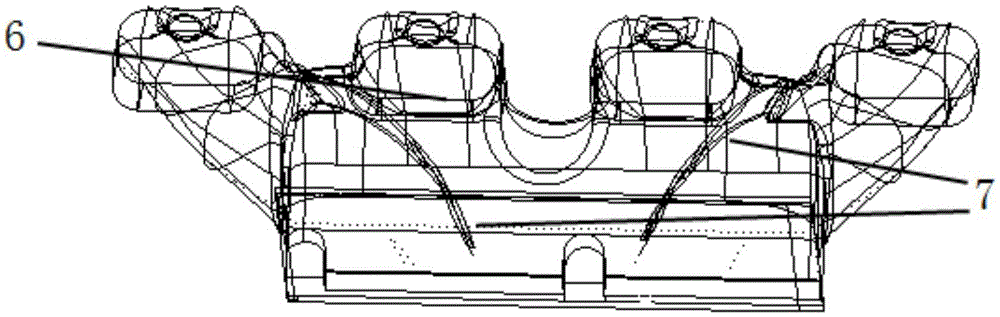

Inlet manifold integrated with intercooler

ActiveCN105673185AImprove cooling efficiencySpeed up the flowInternal combustion piston enginesCombustion-air/fuel-air treatmentEngineeringIntercooler

The invention discloses an inlet manifold integrated with an intercooler. The inlet manifold comprises an inlet manifold body and the intercooler; a pressure stabilizing cavity is arranged on the inlet manifold body; the intercooler is integrated in the pressure stabilizing cavity; and the inlet manifold body further comprises an air inlet cavity communicating with the bottom face of the pressure stabilizing cavity and used for adjusting the air inlet direction and the boundary air space of the intercooler. As the appearance of the air inlet cavity of the inlet manifold integrated with the intercooler is optimized and the space of air of an edge and corner area of the intercooler is enlarged, air entering the air inlet cavity is prevented from being unevenly cooled when the boundary area space of the intercooler is small, the flowing direction of the air inlet face of the intercooler is adjusted, and accordingly flowing on the air inlet face of the intercooler is more even, and the temperature distribution evenness of the air outlet face of the intercooler is improved.

Owner:CHERY AUTOMOBILE CO LTD

Galanthamine hydrobromide compound as well as preparation method and medicine compositions thereof

ActiveCN104177368AHigh chemical purityImprove stabilityNervous disorderOrganic chemistryPharmaceutical drugCombinatorial chemistry

The invention discloses a galanthamine hydrobromide compound as well as a preparation method and medicine compositions thereof. The galanthamine hydrobromide compound disclosed by the invention has the advantages of high chemical purity and good stability, wherein the maximum content of single impurity is below 0.1%; and the stability to light and heat is particularly good. The medicine compositions of the galanthamine hydrobromide compound, prepared by adopting special auxiliary materials, have the following more obvious advantages of being good in stability, easy to implement and remarkable in economic benefit, meeting the clinical needs, reducing the production cost and realizing the industrialization.

Owner:天津梅花生物医药科技有限公司

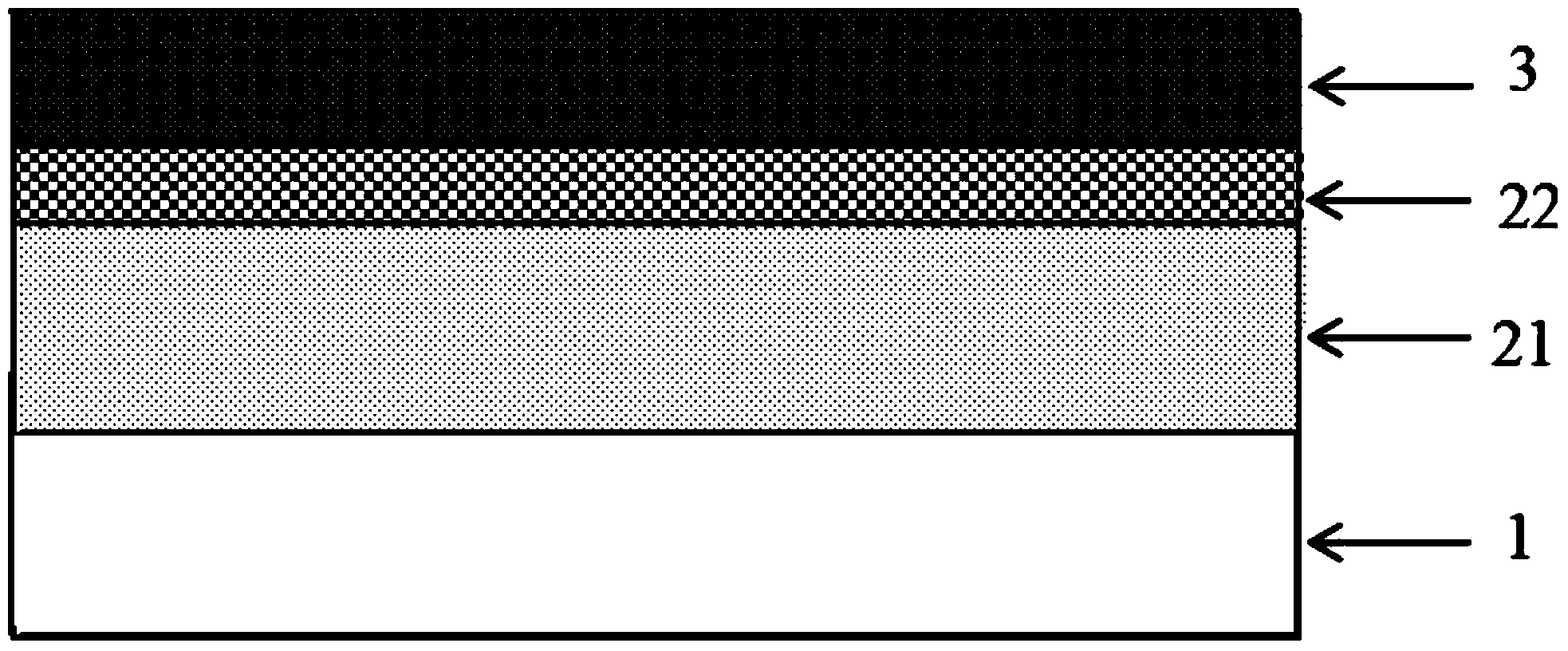

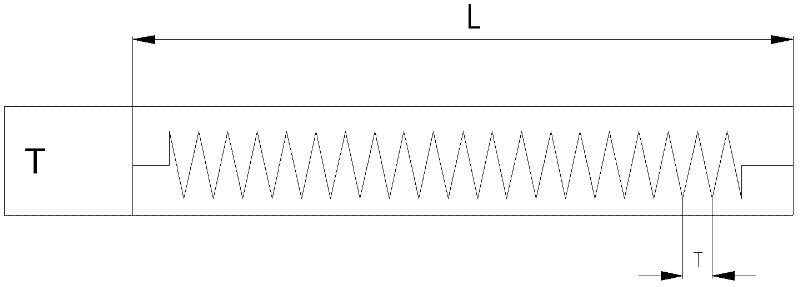

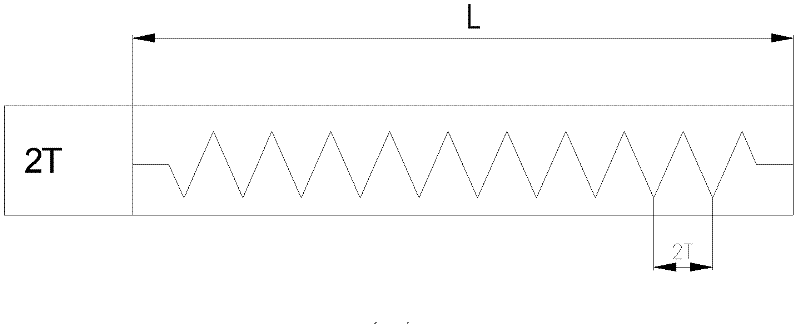

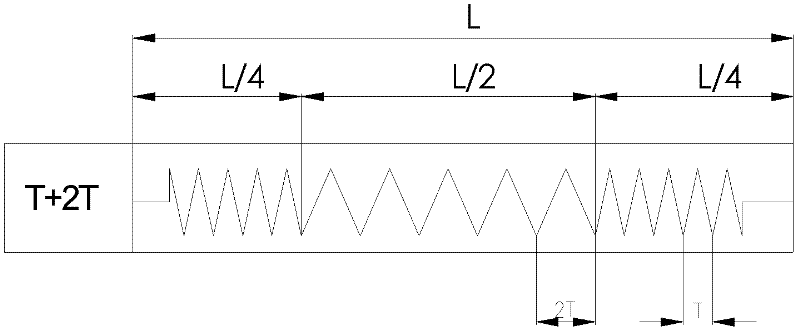

Method for manufacturing grid lines with high uniformity through double exposure

ActiveCN103400753ASimple manufacturing processMeet the requirements of structural uniformitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPhotoresistManufacturing grid

A method for manufacturing grid lines with high uniformity through double exposure comprises the following steps: depositing a polycrystalline silicon film, an amorphous carbon film and a carbonaceous silicon oxide film and coating a first photoresist; carrying out exposure and development to form a first grid line structure in the films of the first photoresist; coating alkyl-amino solidification materials to solidify the first grid line structure in the first photoresist, heating to enable solidification materials and the surface of the first photoresist to react, so as to form isolation films undissolved in a second photoresist, and removing residual solidification materials; coating the second photoresist; forming a first line end cutting pattern in second photoresist films; etching the isolation films and first grid lines to form a second line end cutting pattern, and then removing the second photoresist; etching the carbonaceous silicon oxide film, the amorphous carbon film and the polycrystalline silicon film in sequence by taking the residual isolation films and the first grid lines as masks, and removing the residual carbonaceous silicon oxide film and the amorphous carbon film, so as to form a second grid line structure on a polycrystalline silicon film layer.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

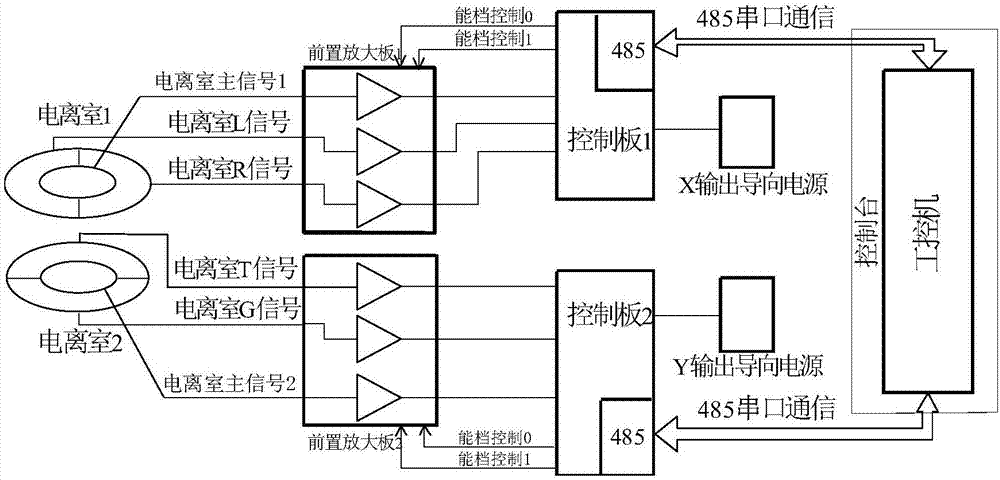

Medical accelerator beam automatic centring control system

ActiveCN106861054ADose rate symmetry error correctionMeet the requirements of uniformityX-ray/gamma-ray/particle-irradiation therapyControl systemIonization chamber

The invention discloses a medical accelerator beam automatic centring control system. The centring of the medical accelerator beam can be rapidly and effectively realized, the uniformity of treatment filed dosage can be improved, and the reliability is good. An ionization chamber is divided into a main ionization chamber and symmetrical branch ionization chambers, the deviation beam signal in the X or Y direction of the medical accelerator ray beam is detected by the branch ionization chambers, the deviation beam signal is amplified and rectified, and then the error value of the dosage rate symmetry between the two symmetrical branch ionization chambers is calculated, By changing the medical accelerator output-oriented power supply, the dosage rate symmetry error is corrected, so that the medical accelerator beam can meet the uniformity requirement in the treatment filed.

Owner:江苏海明医疗器械有限公司

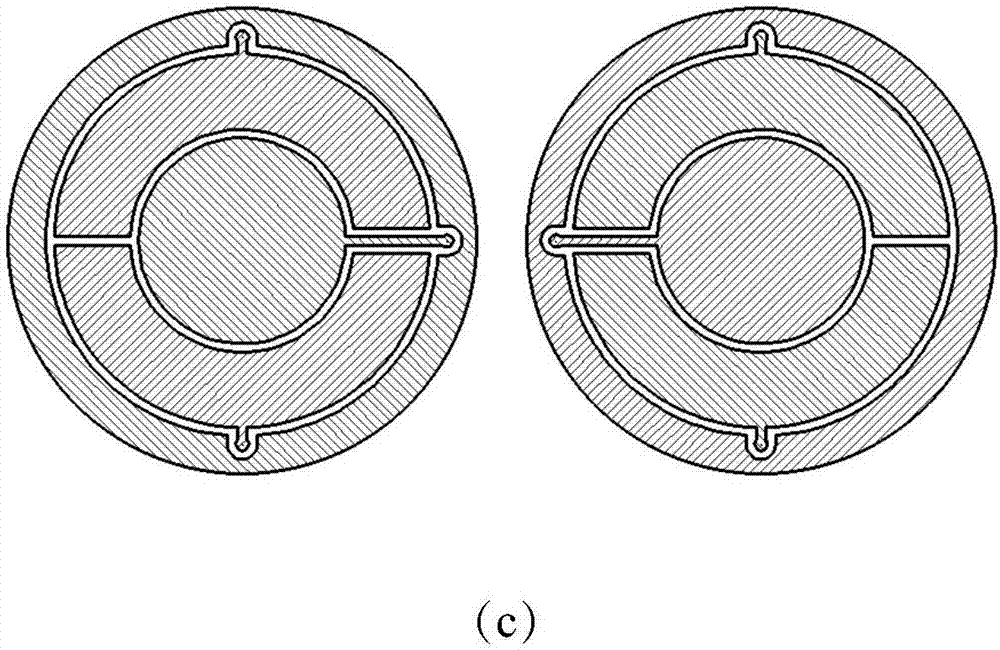

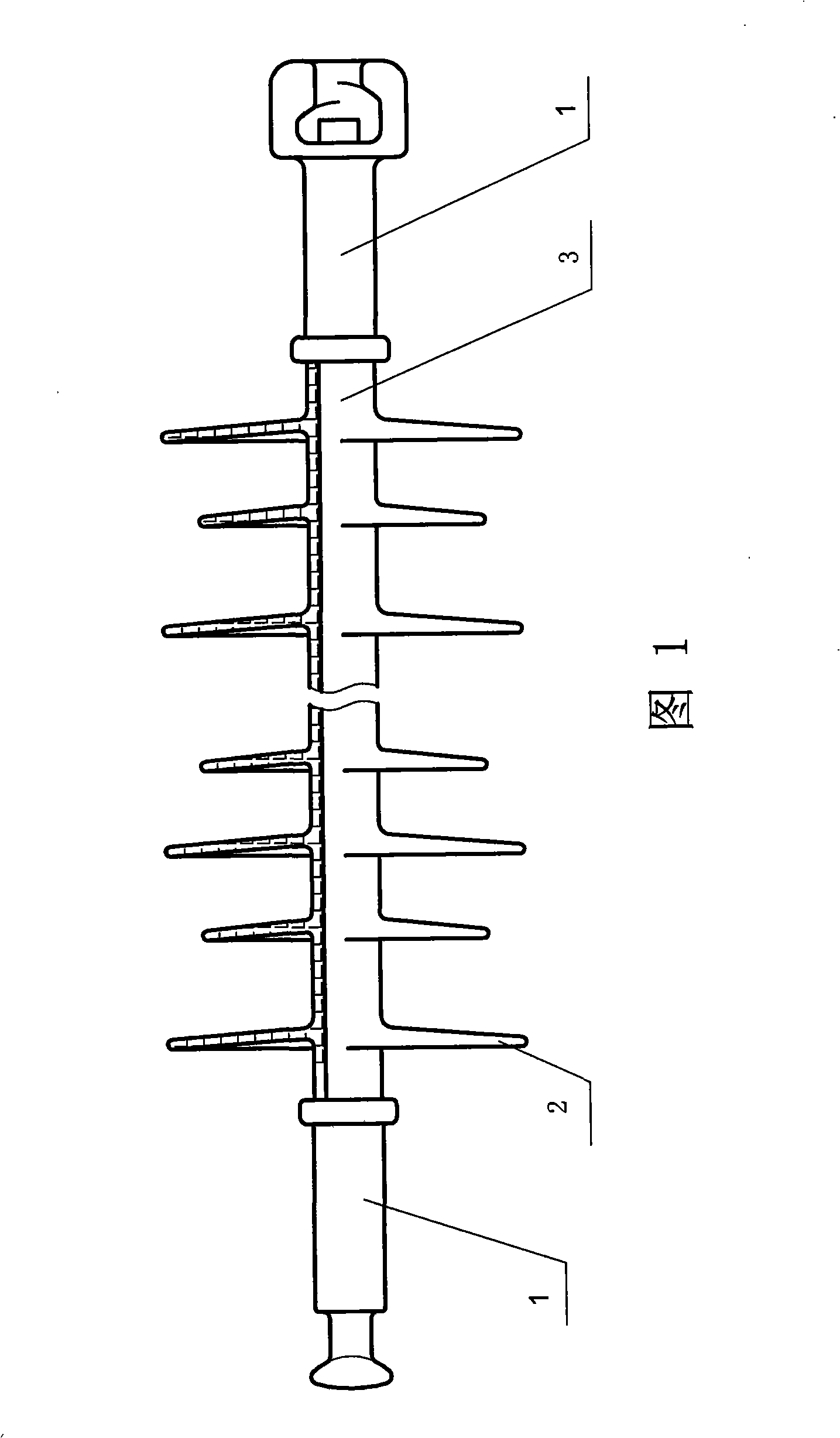

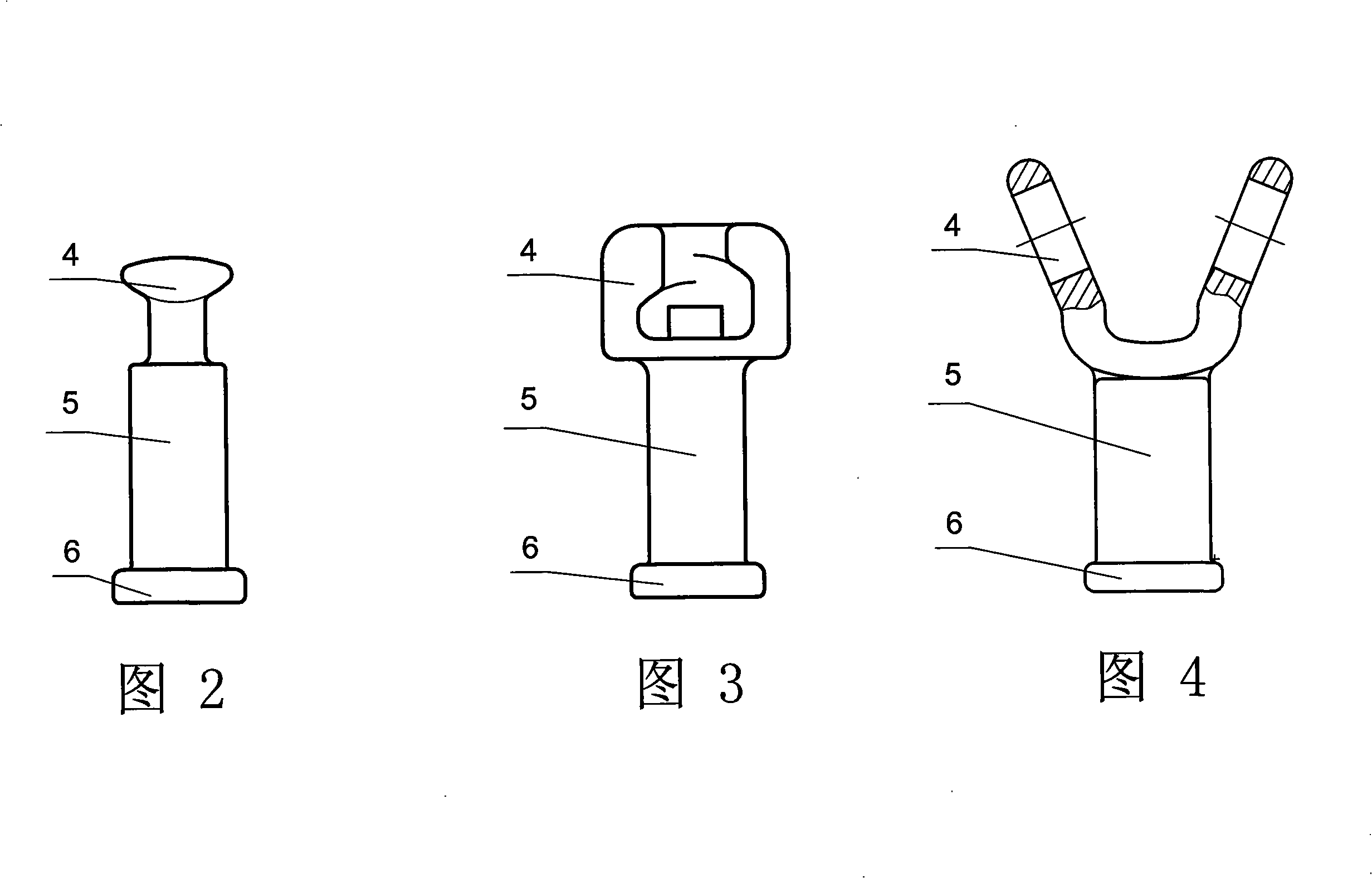

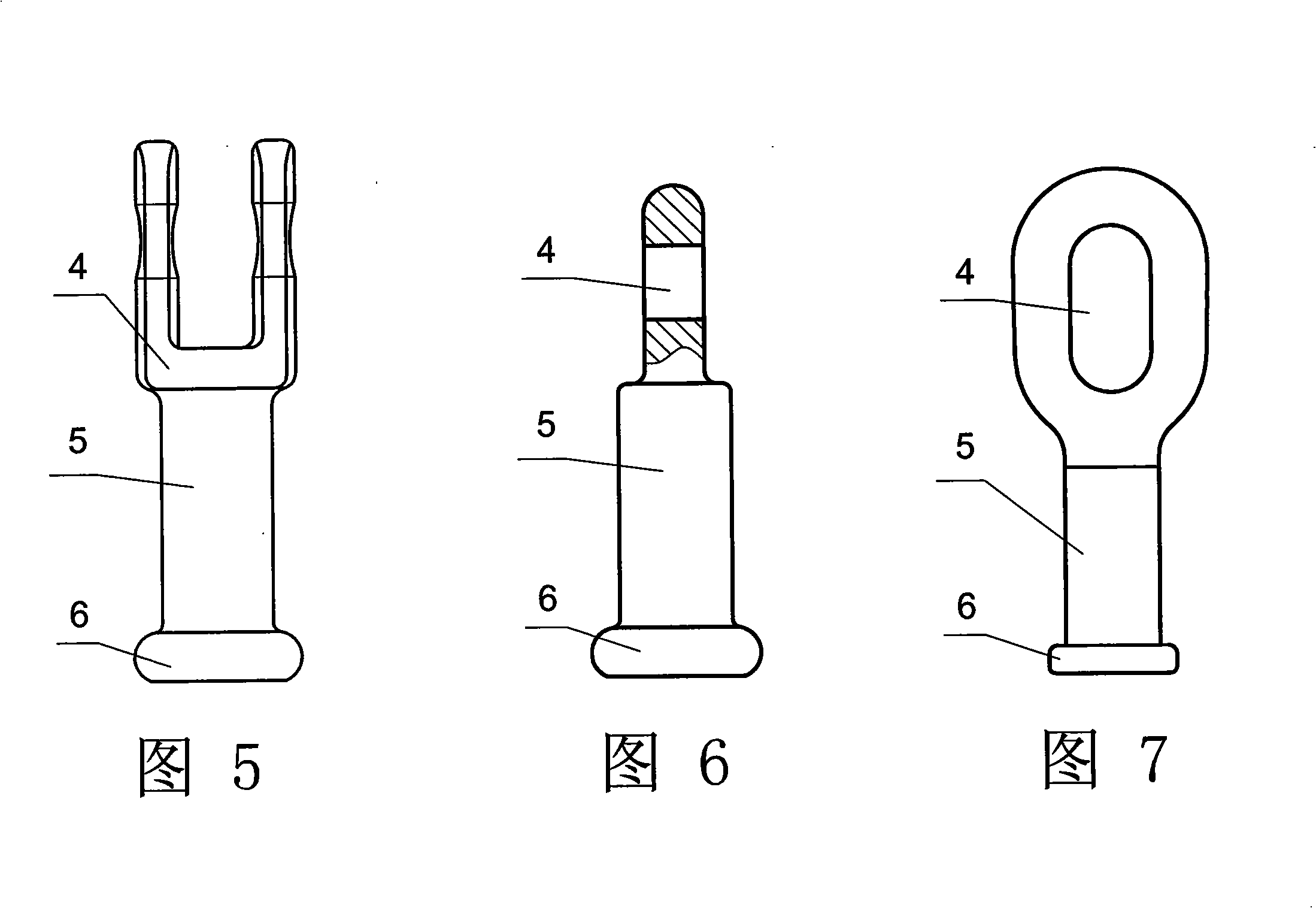

Combined insulator gold tool and method for manufacturing the same

InactiveCN101303925AEasy to industrializeImprove qualitySuspension/strain insulatorsFriction weldingEngineering

The invention discloses a piece of combined insulator hardware and a production method thereof. A standard joint of the combined insulator hardware and a connection bar adopt a split type structure and are fixed together by friction welding. The connection bar and a seal-adhesive seat of the insulator adopt an integrated structure or a split type structure; the connection bar and the seal-adhesive seat are fixed together by friction welding if the connection bar and the seal-adhesive seat adopt a split type structure. The standard joint is a Y-shaped double-ear or a ball head or a ball socket or a U-shaped double-ear or a straight line shaped single ear or a hanging ring-shaped single ear. The production method is that: according to the application characteristics of the specific parts of the hardware, a piece of hardware is divided into two or three parts and respectively produced to satisfy different strength and hardness requirements; then all the parts are fixedly welded together by friction welding technique. By adopting the invention, industrialization of the production of the insulator hardware can be easily realized, product quality and qualified rate in production are enhanced, the working efficiency is improved, the management difficulty in production is reduced and good social and economical benefits can be achieved.

Owner:ZHENGZHOU JINGWEI ELECTRIC POWER TECH

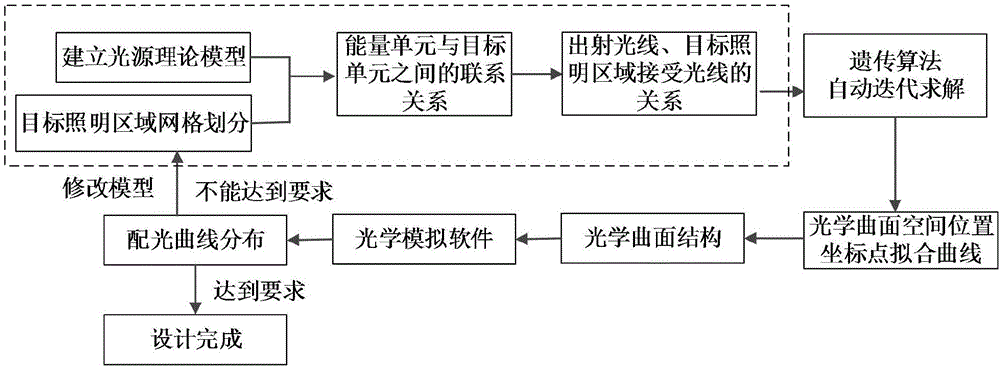

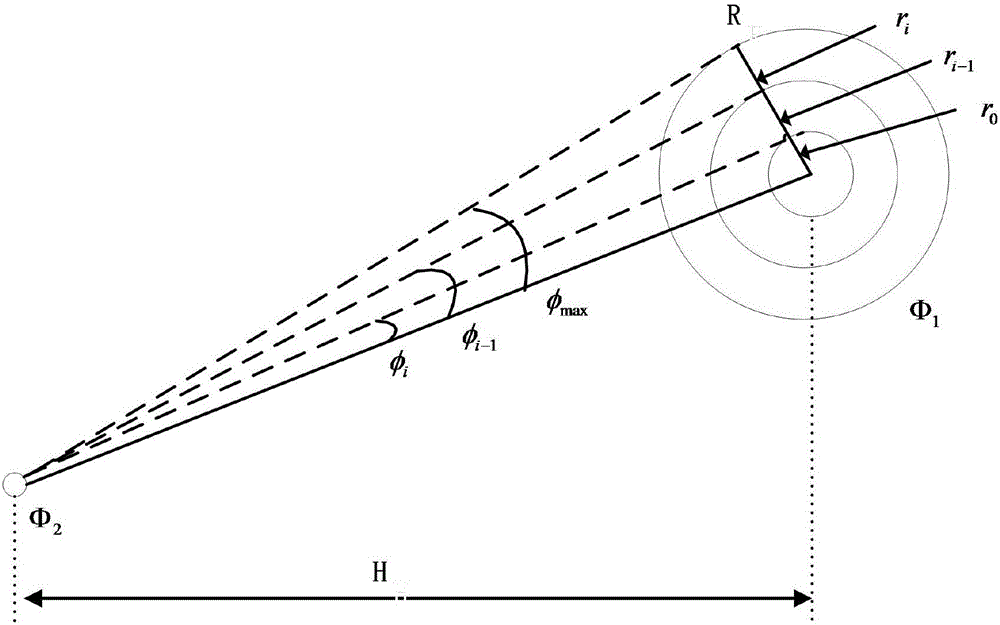

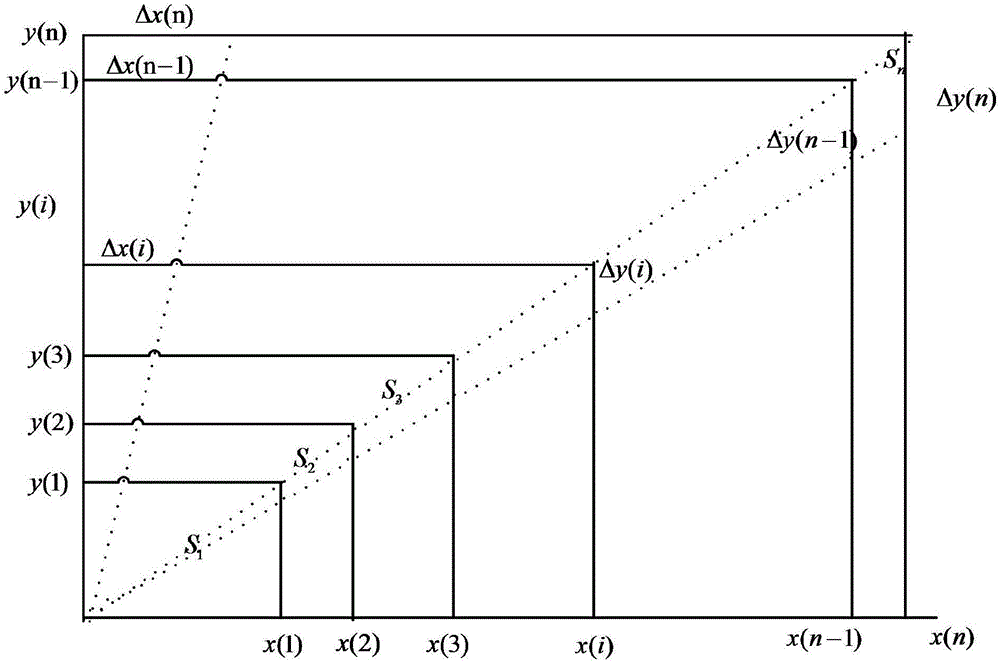

Light distribution method for power type LED integrated module

InactiveCN106402730AComply with lighting illuminanceMeet uniformity requirementsMechanical apparatusOutdoor lightingRelative distributionDistribution method

The invention relates to a light distribution method for a power type LED integrated module. A region segmentation method is adopted for achieving the purpose of even illumination of a target face, an illumination region projected to the road surface is lengthened, energy, projected to two regions, of emitted light is in asymmetrical distribution, in other words, the light projected to the sidewalk region is weak, and the light projected to the motor vehicle region is high. The light distribution method includes the steps that firstly, the emitted light of a light source is partitioned into a certain number of partition regions according to the angle, and a target face is correspondingly divided into multiple regions; secondly, the relation between the projection luminous flux in the adjacent angle ranges and the received light of the target illumination region is established; and thirdly, relative distribution of a light distribution curve at all angles is calculated according to the corresponding relation and the projection angle of the LED light source, finally, an integrated module lens curved surface is constructed according to the curve rate of the light distribution curve, and the space coordinate position of the optical curved surface of the lens module is solved. According to the light distribution method, uniformity of secondary light distribution of the LED integrated module is achieved, and therefore illumination and brightness distribution of the illumination region is uniform.

Owner:FUSHUN OPTOELECTRONICS TECH

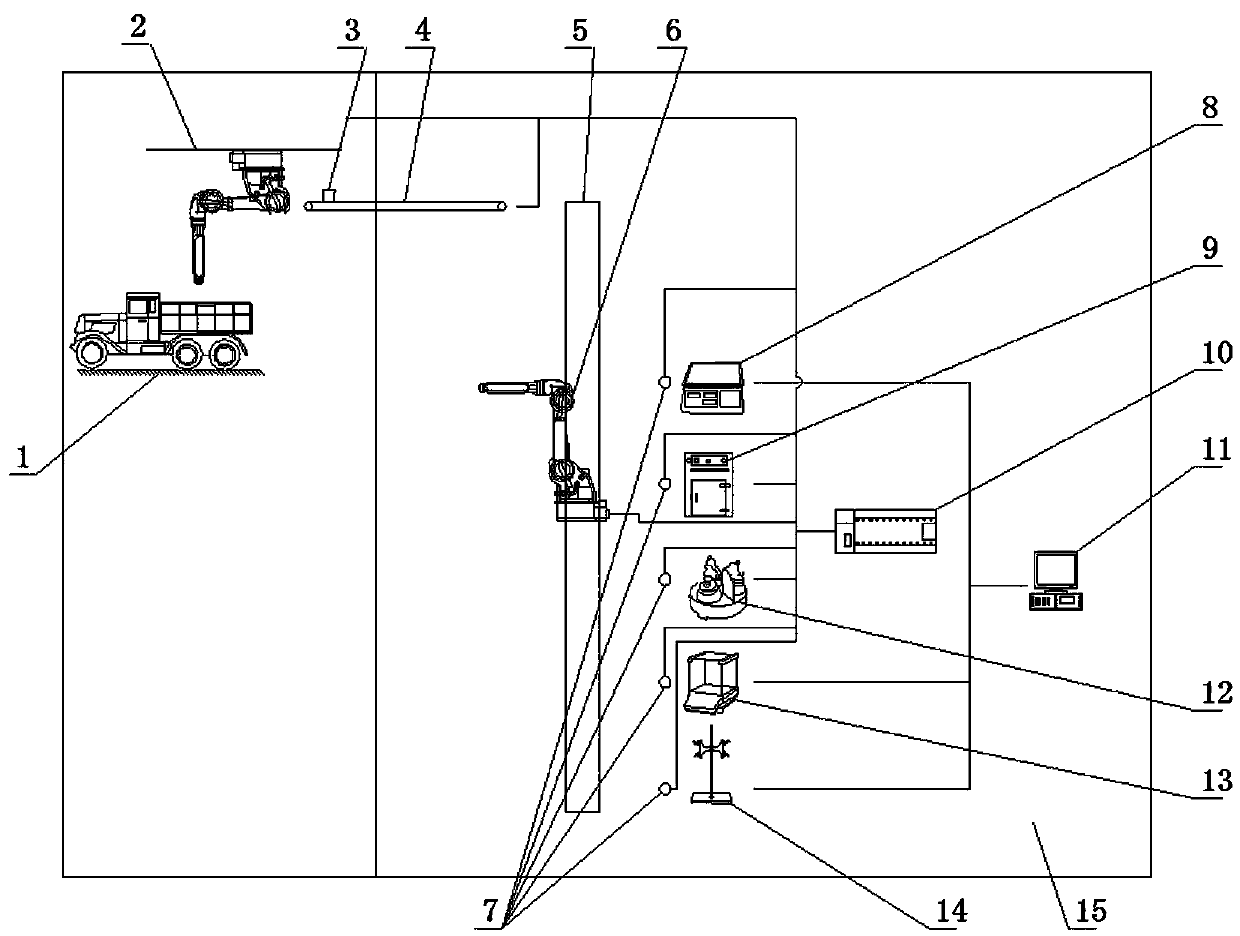

Iron powder testing laboratory unattended system and method for applying same

PendingCN107831323ATimely testEliminate safety hazards such as personal injuryProgramme-controlled manipulatorMaterial analysisMachineConveyor belt

The invention relates to an iron powder testing laboratory unattended system and a method for applying the same. The iron powder testing laboratory unattended system comprises a testing laboratory. Afixed parking space is arranged outside the testing laboratory, a sampling manipulator is arranged above the fixed parking space, a track, a PLC (programmable logic control) system and an upper computer are arranged in the testing laboratory, a movable intelligent manipulator is arranged on the track, samples can be conveyed between the sampling manipulator and the movable intelligent manipulatorvia a disposable sample accommodating container and a conveyor belt, a first scale, an oven, a grinding machine, a second scale, a titration apparatus are sequentially arranged in the testing laboratory along a side of the track, and corresponding sample in-place proximity switches are arranged in the testing laboratory along the side of the track. The iron powder testing laboratory unattended system and the method have the advantages that the samples can be automatically taken by the sampling manipulator, testing equipment can be controlled by the PLC system, the movable intelligent manipulator can be operated, computation can be carried out by software of the upper computer, accordingly, unattended testing can be carried out in the whole course without manual participation, unity requirements can be met by integral testing procedures, errors can be reduced, and testing results can be obtained in an accelerated manner and are accurate.

Owner:闫伟

Method for manufacturing high-evenness grid electrode lines

ActiveCN103474339ASimple manufacturing processMeet uniformity requirementsSemiconductor/solid-state device manufacturingSemiconductor devicesCarbon filmPhotoresist

A method for manufacturing high-evenness grid electrode lines comprises the steps that polycrystalline silicon films are directly deposited on a substrate silicon slice in sequence, then a spin coating carbon film and first photoresist are directly arranged in a coating mode in sequence; exposure and development are carried out, so that the structure of a first grid electrode line is formed in a first photoresist film; the first photoresist is coated with solidification materials with thiocyanic acid salt compounds, cross-linking and solidifying are carried out on the structure of the first grid electrode line in the first photoresist, heating is carried out, so that the solidification materials and the surface of the first photoresist react to form a partitioning film which cannot be dissolved in second photoresist; the first photoresist after solidification is coated with the second photoresist; a first line end cutting pattern is formed in a second photoresist film; the second photoresist film is used as a mask film, the partitioning film and the first grid electrode line are etched, a second line end cutting pattern is formed; the surplus partitioning film and the first grid electrode line are used as a mask film, the spin coating carbon film and the polycrystalline silicon films are etched in sequence continuously, and the structure of a second grid electrode line is formed.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

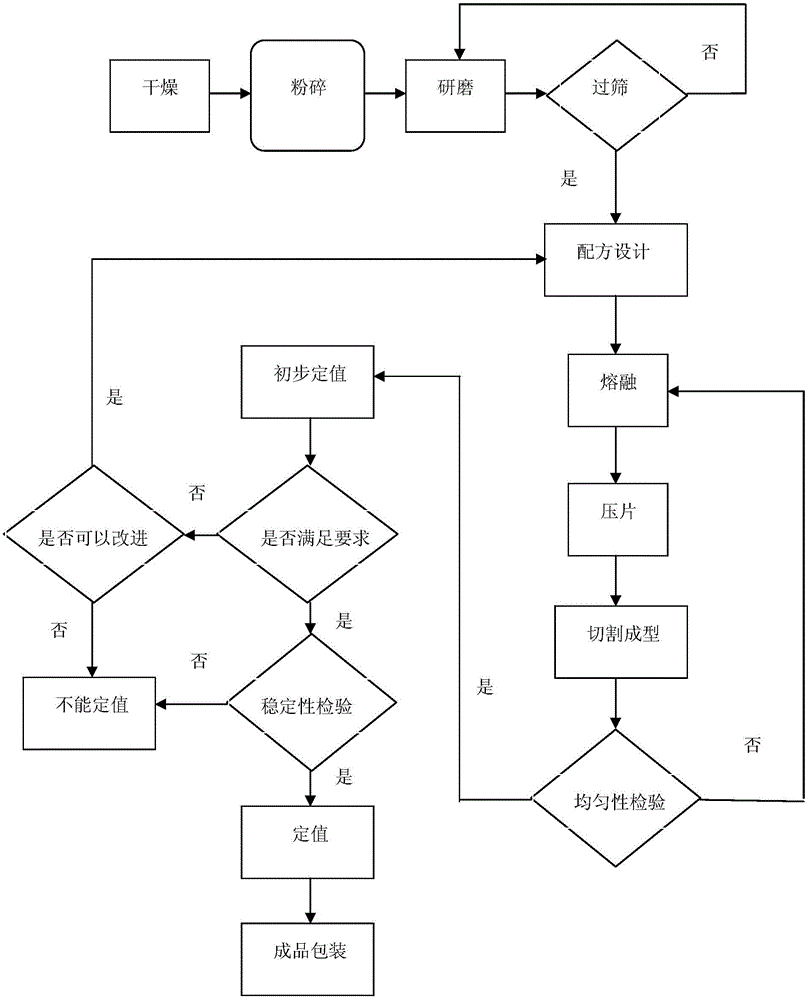

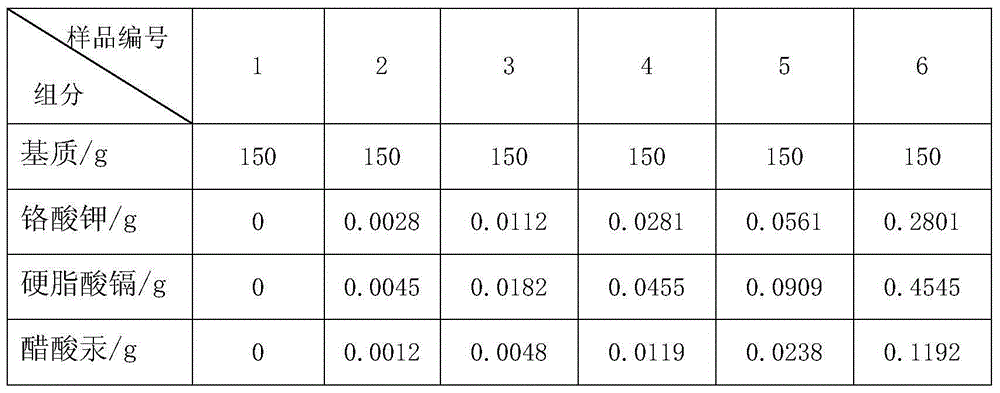

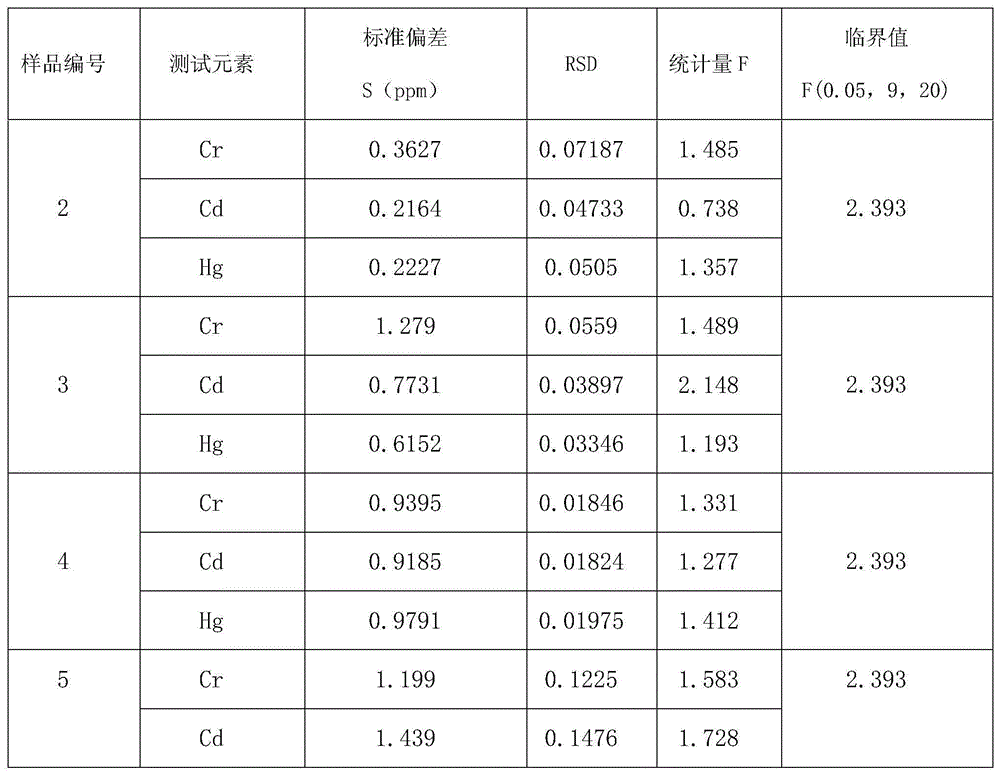

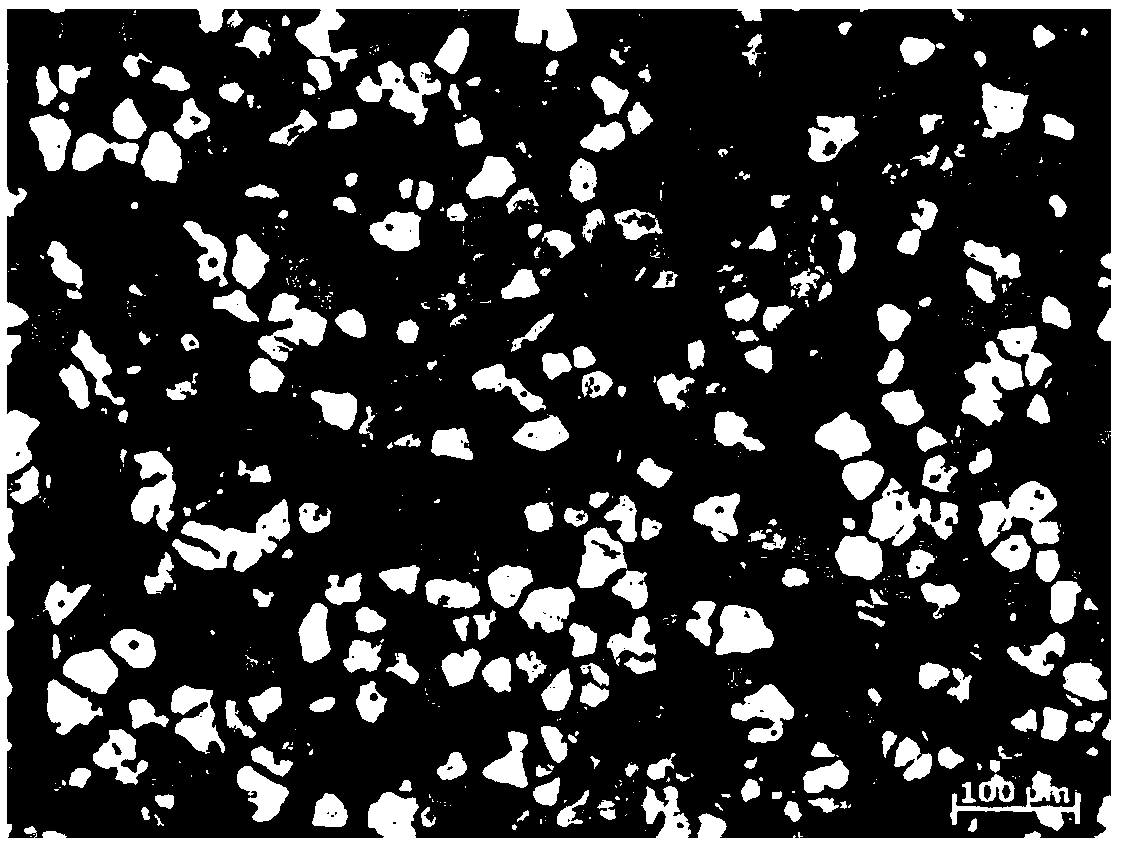

Sample preparation method for uniformly distributing trace components in solid block matrix

InactiveCN103604678AEvenly distributedAvoid problemsPreparing sample for investigationSolid massPrimary standard

The invention discloses a sample preparation method for uniformly distributing trace components in a solid block matrix. The method comprises the following steps: (1) sequentially drying, grinding and screening trace components to be measured; (2) accurately weighing a certain amount of trace components and a plastic matrix according to the formula design, heating to a melting temperature so as to melt the plastic matrix, adding the trace components into the melted plastic matrix under stirring condition, stirring and mixing for 2-3 hours, and thus preparing a molten mixture; (3) introducing the molten mixture in the step (2) into a mold, separating the molten mixture from the mold through diaphragm paper, and pressing for molding under the pressure of 70-120kg / cm<2> and at the melting temperature; (4) cooling and sizing the sample in the step (3) under the pressure of 100-150kg / cm<2> and at temperature which is 10-30 DEG C lower than the melting temperature, and cutting into samples with different sizes and shapes. The sample preparation process is simple, the trace components can be uniformly distributed in the sample, and the uniformity requirement of primary standard substances is met.

Owner:GUANGZHOU CEPREI CALIBRATION & TESTING CENT SERVICE

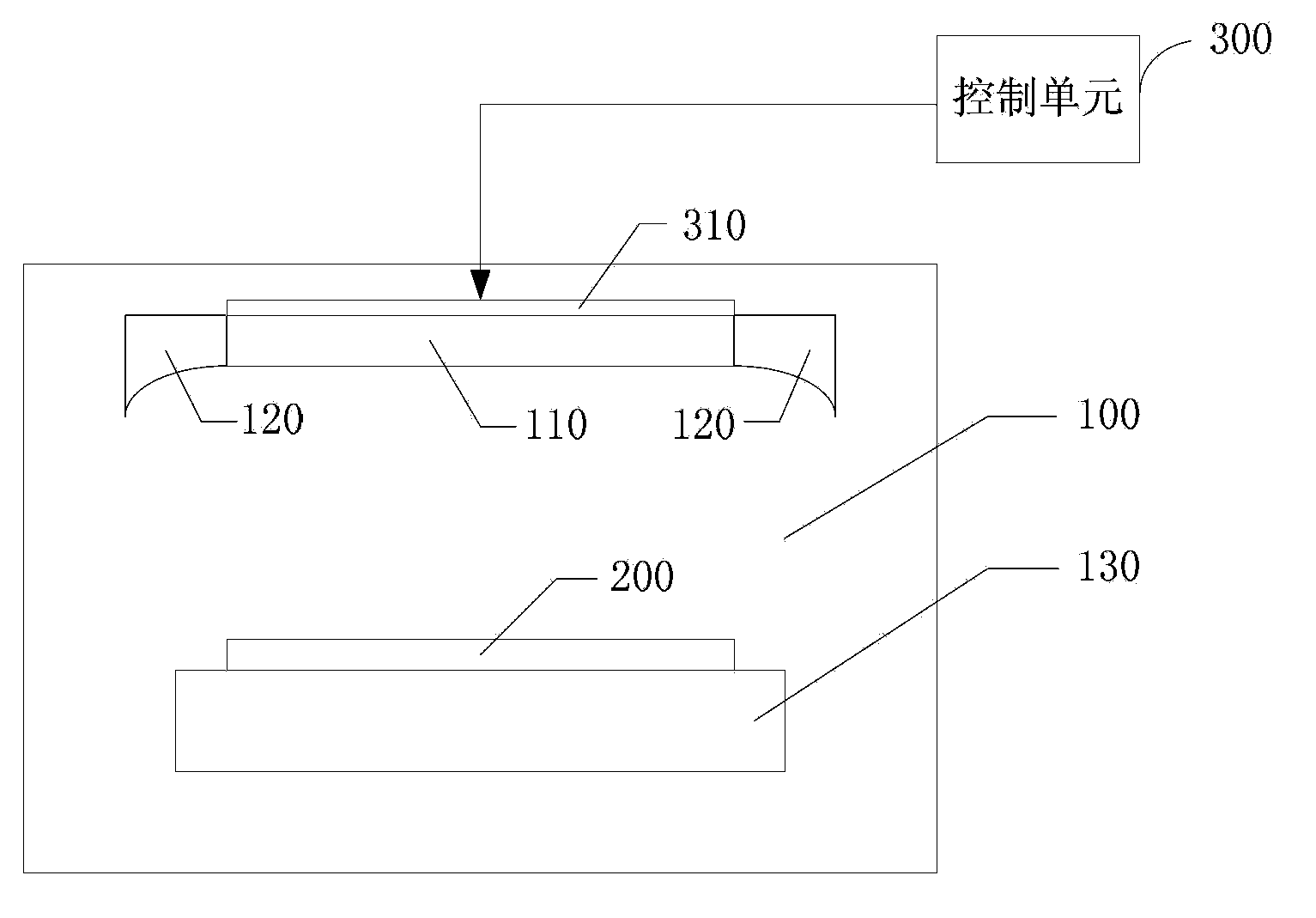

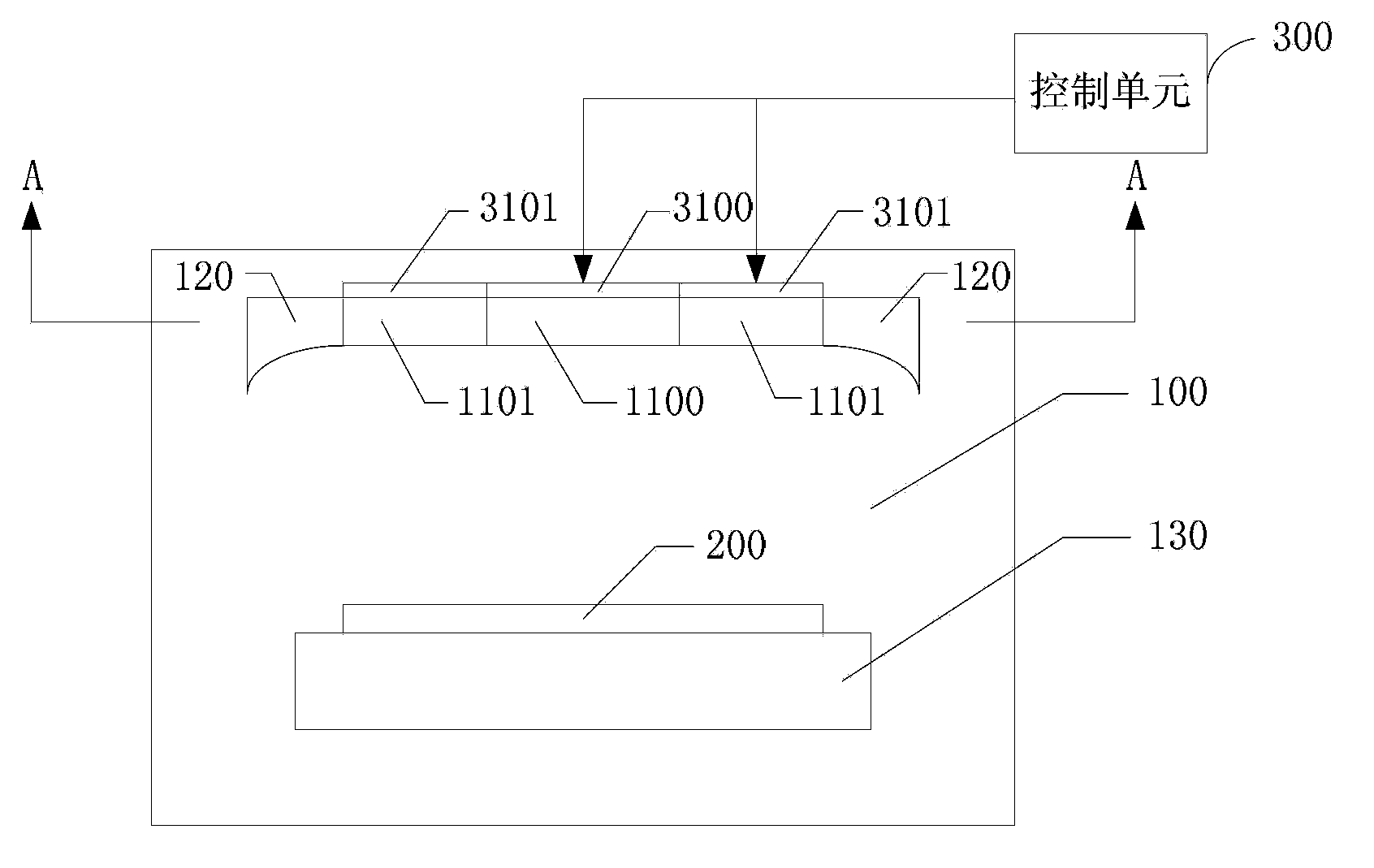

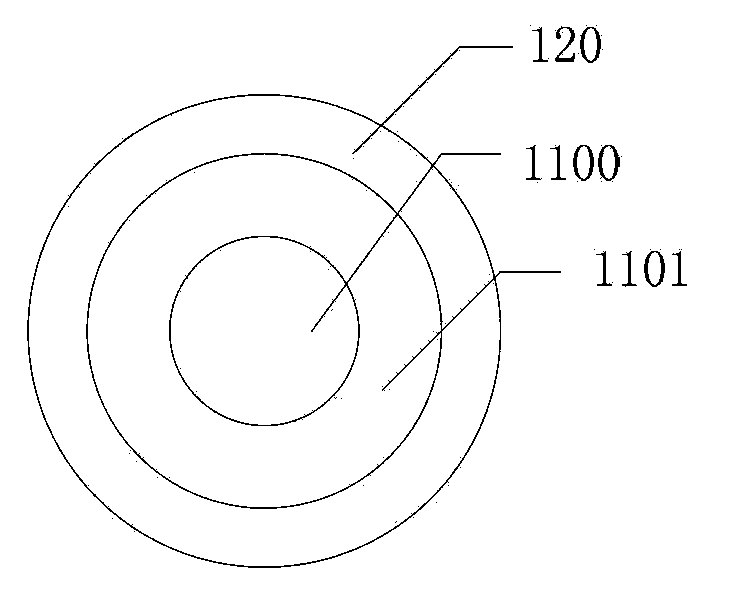

Critical size control system

ActiveCN103811296AMeet uniformity requirementsCutting costsElectric discharge tubesSemiconductor/solid-state device manufacturingTemperature controlControl signal

The invention relates to a critical size control system and a plasma processing device. The critical size control system comprises a first temperature control device and / or a second temperature control device and a control unit; the first temperature control device which is in contact with a gas spraying head is used for detecting, adjusting and controlling the temperature of the gas spraying head; the second temperature control device which is in contact with a grounding ring is used for detecting, adjusting and controlling the temperature of the grounding ring; the control unit which is corresponding to the first temperature device and / or the second temperature control device generates at least one type of the following control signals which comprise a first control signal which is used for controlling the first temperature control device to adjust the temperature of the gas spraying head and a second control signal which is used for controlling the second temperature device to adjust the temperature of the grounding ring. The critical size control system has the advantages of achieving adjusting and controlling of the critical size of different areas of wafers and being low in achieving costs and easy to expand and apply due to the temperature control of the gas spraying head and the grounding ring.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Method for manufacturing grid line with high uniformity through double exposure

ActiveCN103488058ASimple manufacturing processMeet the requirements of uniformitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusManufacturing gridMetallurgy

The invention provides a method for manufacturing a grid line with high uniformity through double exposure. The method comprises the following steps: sequentially depositing a polycrystalline silicon thin film, an amorphous carbon thin film and a silicon oxide thin film containing carbon, and then coating, so as to form a first photoresist for a hard film; performing exposure and development to form a first grid line structure in a first photoresist film; curing the first grid line structure, and heating, so as to enable a silanization material to react with the surface of the first photoresist to form an isolating film which is insoluble in a second photoresist; coating the second photoresist on the cured first photoresist; performing exposure and development to form a first line end cutting figure in a second photoresist film; etching the isolating film and a first line by using the second photoresist film as a mask, so as to form a second line end cutting figure; sequentially etching all films by using the rest isolating film and the first grid line as the mask, and finally forming a second grid line structure in the polycrystalline silicon thin film.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Method for manufacturing high-evenness grid electrode lines

ActiveCN103474337ASimple manufacturing processMeet uniformity requirementsSemiconductor devicesCarbon filmPolyamine Compound

A method for manufacturing high-evenness grid electrode lines comprises the steps that polycrystalline silicon films are directly deposited on a substrate silicon slice in sequence, then a spin coating carbon film and first photoresist are directly arranged in a coating mode in sequence; exposure and development are carried out, so that the structure of a first grid electrode line is formed in a first photoresist film; the first photoresist is coated with amine compounds and / or polyamine compounds, cross-linking and solidifying are carried out on the structure of the first grid electrode line in the first photoresist, heating is carried out, so that the solidification materials and the surface of the first photoresist react to form a partitioning film which cannot be dissolved in second photoresist; the first photoresist after solidification is coated with the second photoresist; exposure and development are completed, a first line end cutting pattern is formed in a second photoresist film; the second photoresist film is used as a mask film, the partitioning film and the first grid electrode line are etched, a second line end cutting pattern is formed; the surplus partitioning film and the first grid electrode line are used as a mask film, the spin coating carbon film and the polycrystalline silicon films are etched in sequence continuously, and the structure of a second grid electrode line is formed.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

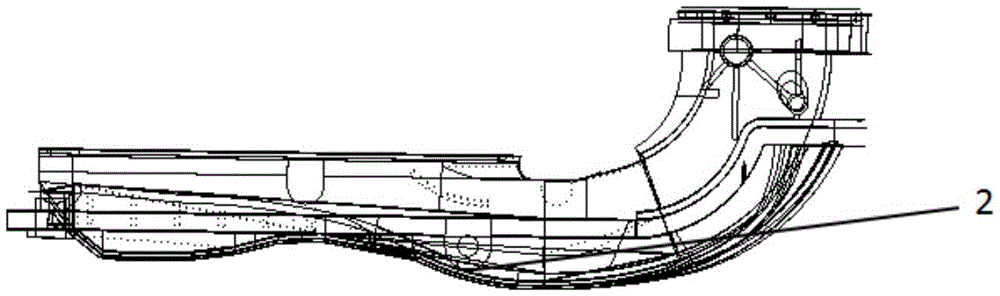

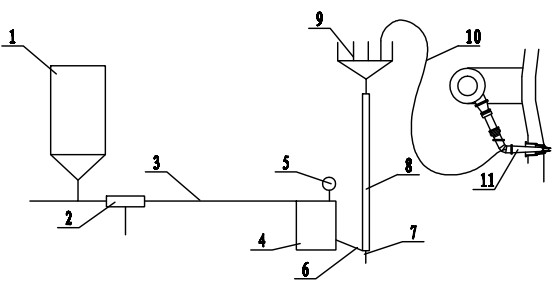

Long-distance coal injection system

ActiveCN102154532AEliminate fluctuationsMeet uniformity requirementsTuyeresBlast furnace detailsBuffer tankPressure controlled ventilation

The invention discloses a long-distance coal injection system which comprises an air supply device (2) connected with an injection tank (1), and has the key points that a buffer tank (4) provided with a pressure control valve (5) is also connected behind the air supply device (2); the buffer tank (4) is connected with a vertical raising pipe (8) by an inclined descent pipe (6); and an outlet of the vertical raising pipe (8) is connected with a blast-furnace tuyere (11) by a coal injection branch pipe (10). The vertical raising pipe (8) is provided with a gas nozzle (7), and compressed air or compressed inert gas is adopted for injection. As the buffer tank is arranged, the fluctuation of pulverized coal flow can be eliminated by the buffer tank after pulverized coal is conveyed into the buffer tank through the injection tank from a long distance, the requirement of a blast furnace for the uniformity of coal injection can be met, and the long-distance even injection of the blast furnace coal injection can be realized.

Owner:CISDI ENG CO LTD

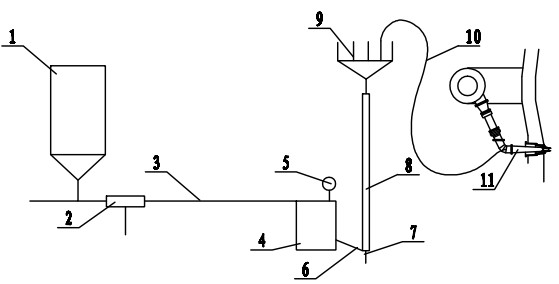

Production method of water-soluble iodine/selenium/cobalt premix agent

InactiveCN107801843AGood water solubilityImprove uniformityAccessory food factorsWorking-up animal fodderSolubilityIodine

The invention relates to a production method of a mixed type feed additive, and particularly discloses a production method of a water-soluble iodine / selenium / cobalt premix agent. The production methodcomprises the following steps of A, preparing an iodine / selenium / cobalt saturated solution; B, measuring carrier powder, wherein the carrier powder has water solubility and water absorption properties; and C, in the mixing process, uniformly spraying the iodine / selenium / cobalt clarified solution fog to sealed mixing equipment, enabling the fog to be adsorbed by carriers, and performing uniform mixing so as to obtain the water-soluble iodine / selenium / cobalt premix agent. The production method disclosed by the invention has the advantages that the production method of iodine / selenium / cobalt premix agent suitable for being added to a liquid feed is provided; a manner of preparing a saturated solution and enabling the saturated solution to be adsorbed on the carriers in a sealed material mixer is adopted, so that the mixing uniformity is increased; and fully water-soluble carriers are selected for adsorbing the saturated solution, so that the mixing uniformity is high, and the water-soluble iodine / selenium / cobalt premix agent wholly dissolves in water and is particularly suitable for producing the liquid feed.

Owner:GUANGHAN LONGDA FEED

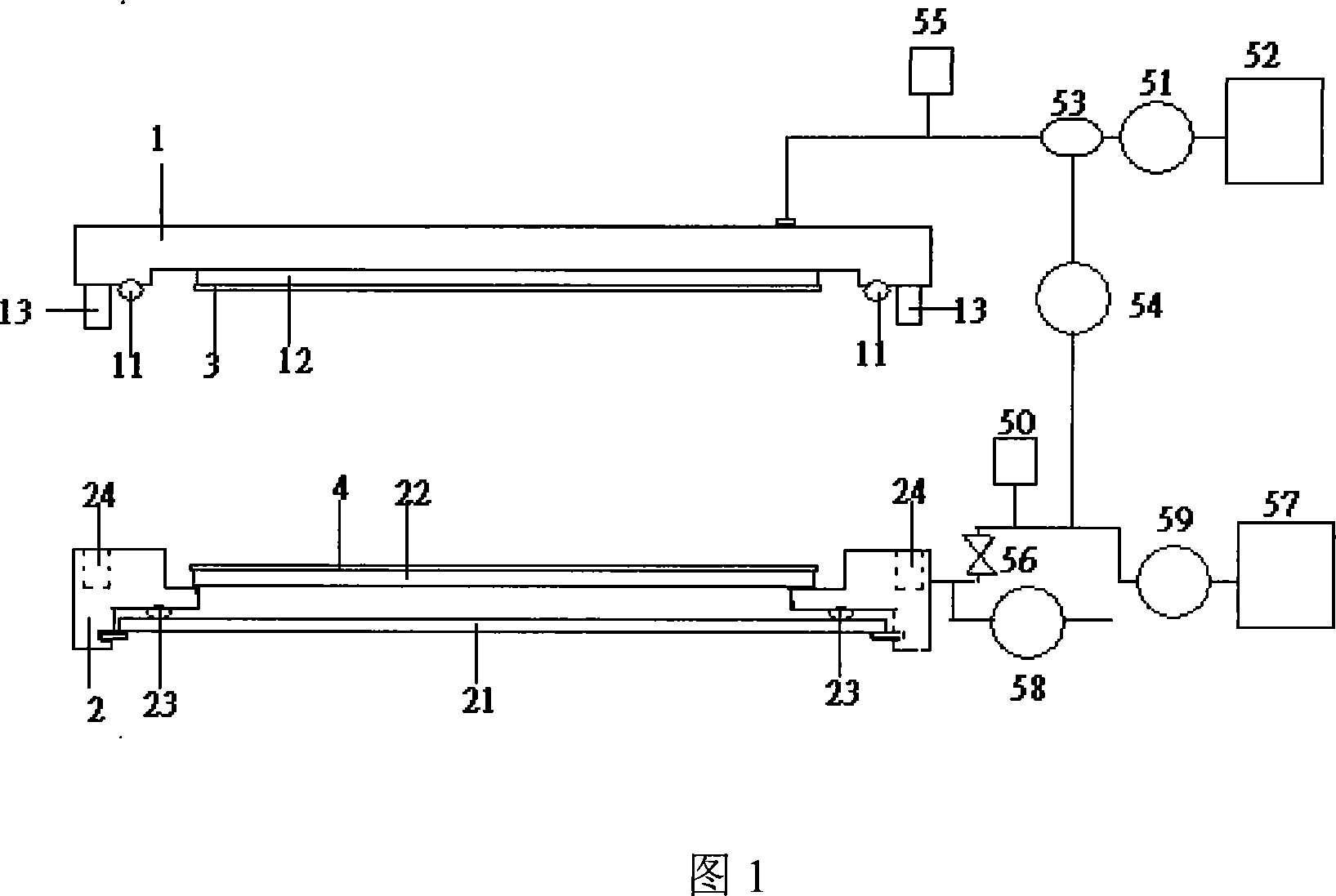

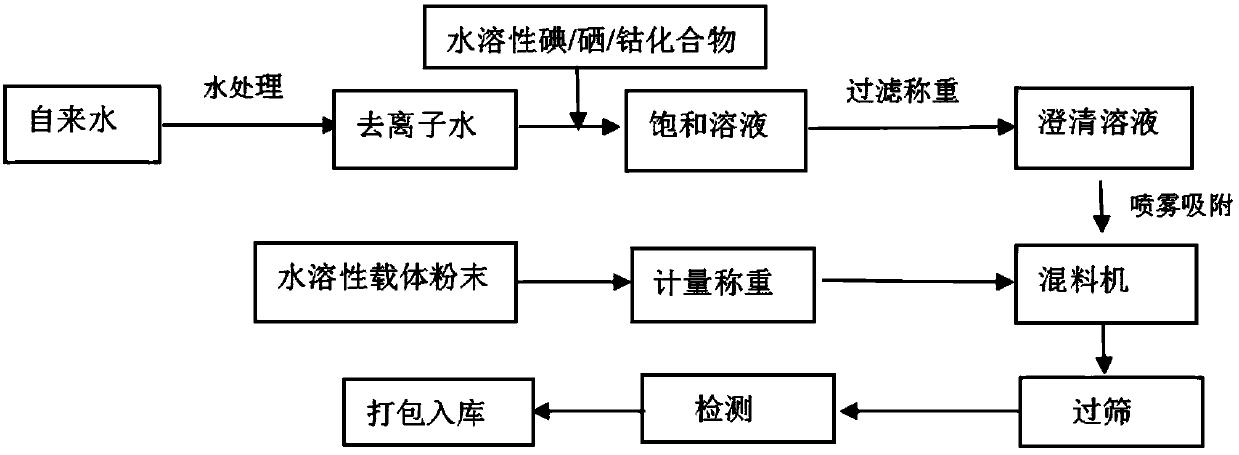

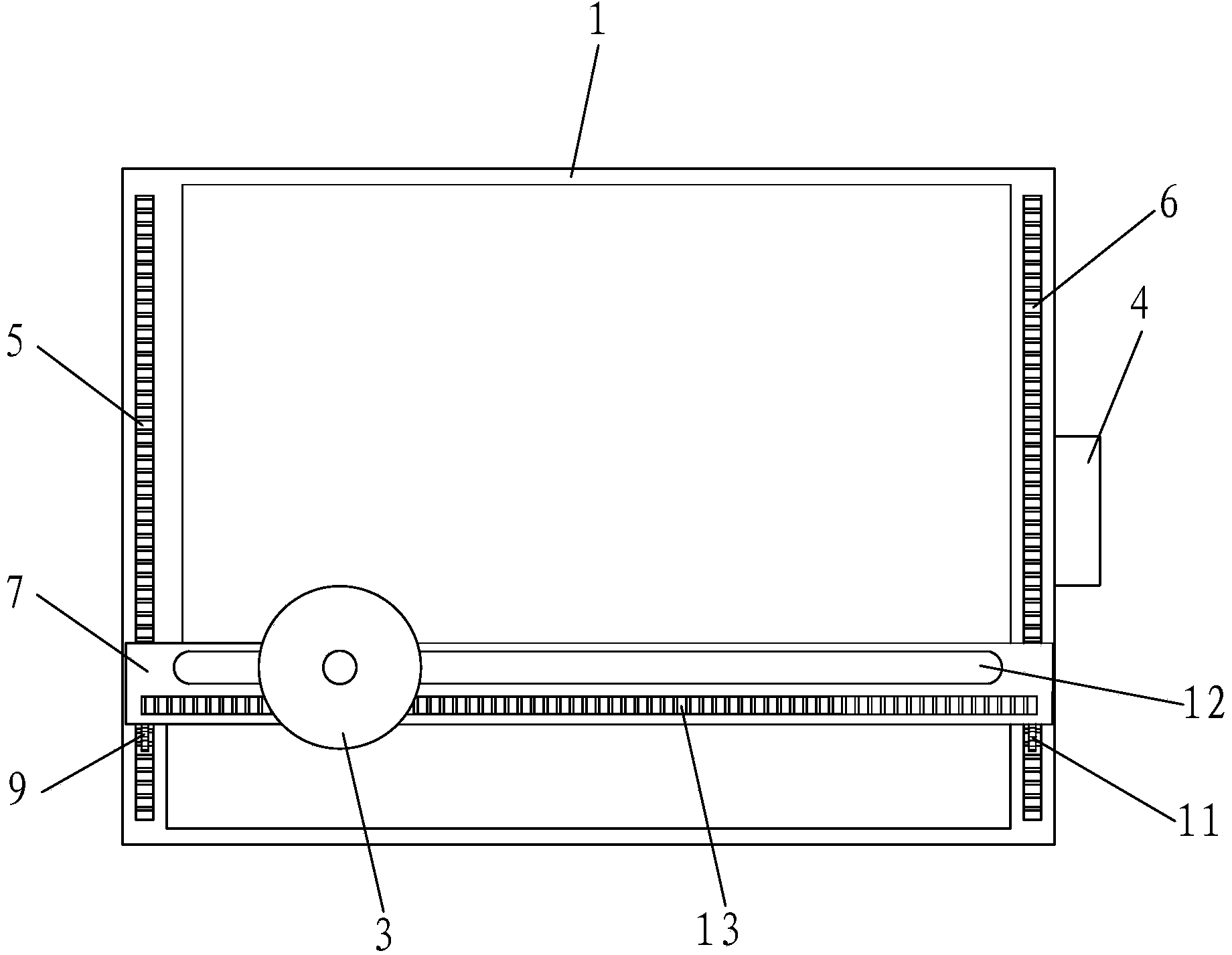

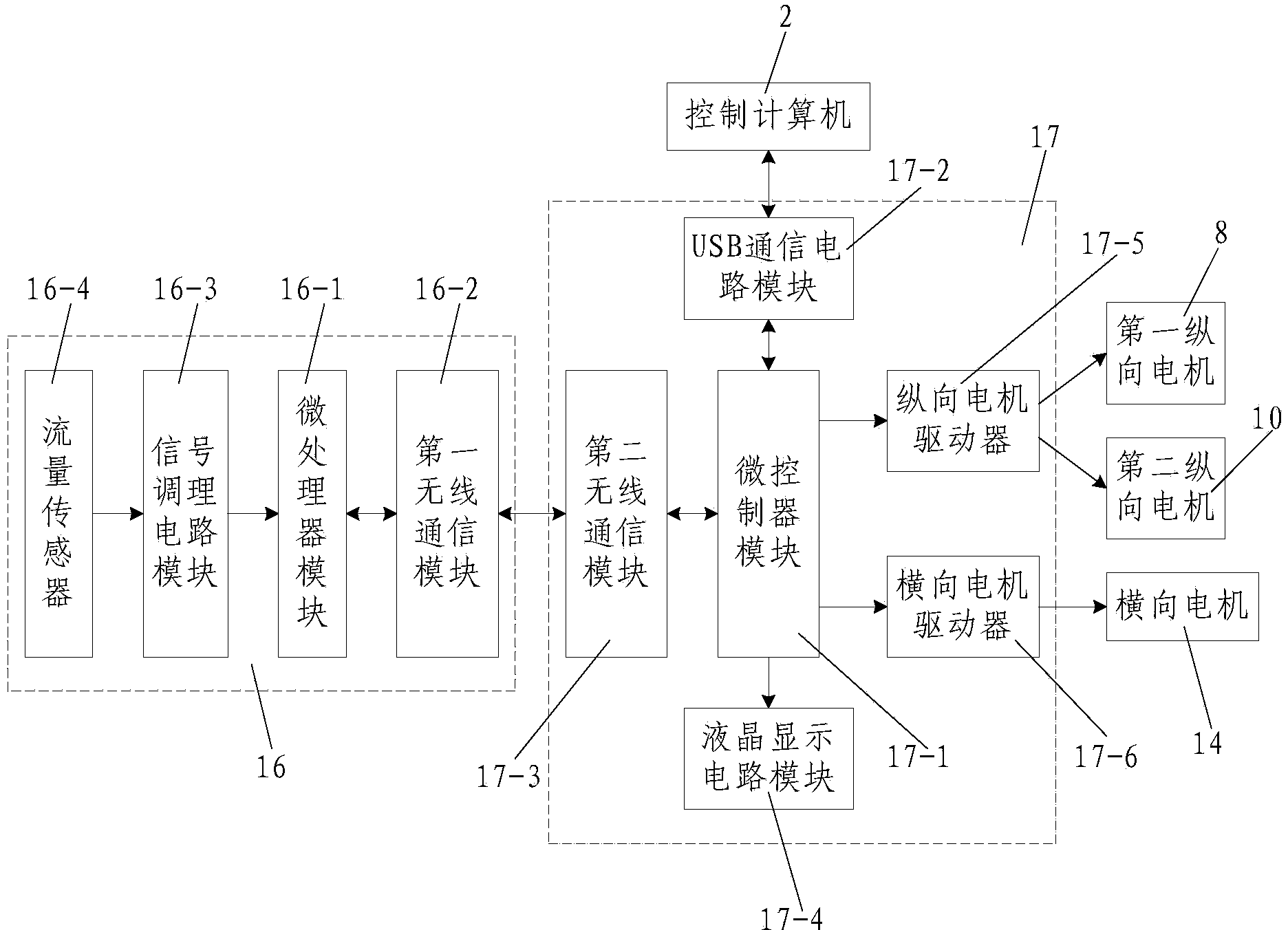

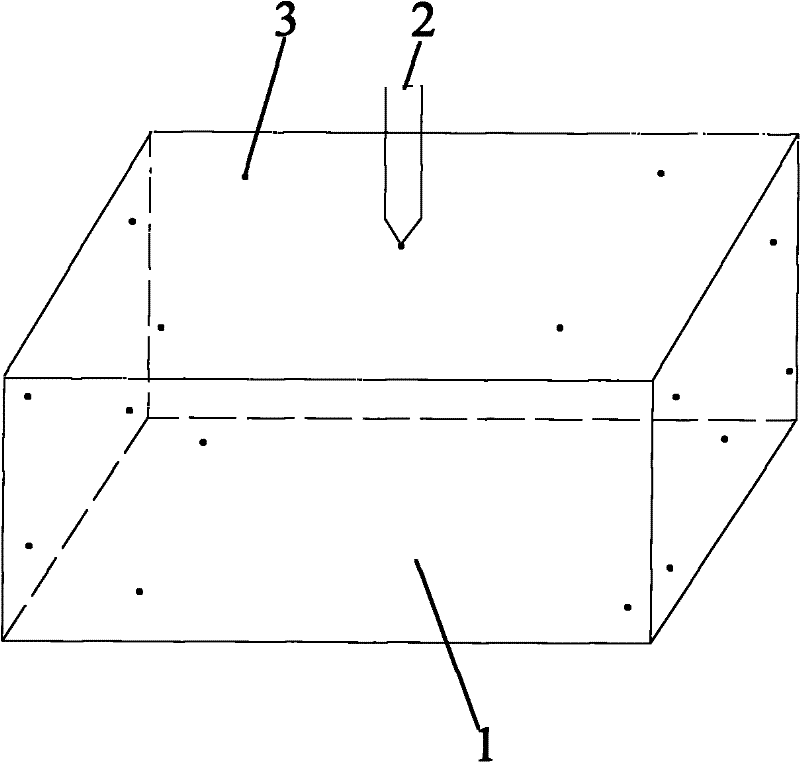

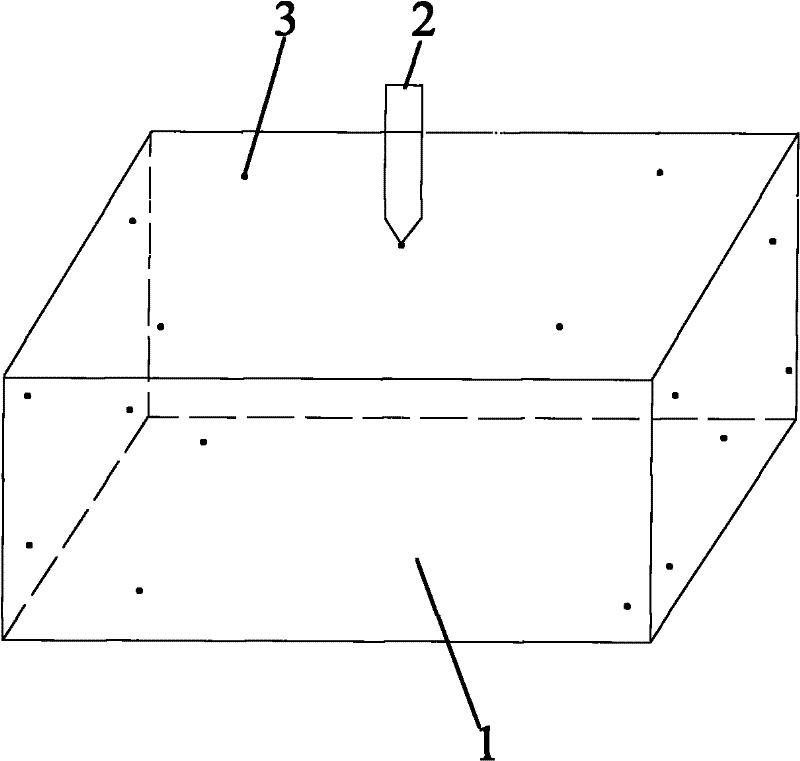

Slurry uniform filling system and slurry uniform filling method for testing flow sedimentation law of filling slurry

ActiveCN103900886ASimple structureNovel and reasonable designFlow propertiesPreparing sample for investigationMotor driveTest efficiency

The invention discloses a slurry uniform filling system and a slurry uniform filling method for testing flow sedimentation law of filling slurry. The system comprises a test trough body, a control computer, a flow slurry funnel and a flurry uniform filling control system; the test trough body is provided with a first longitudinal rack and a second longitudinal rack, and a movable track beam is arranged along the length direction of the test trough body; the lower part of a lower filling pipe of the flow slurry funnel is provided with a wireless flow rate collector, and the wireless flow rate collector comprises a microprocessor module, a first wireless communication module, a signal conditioning circuit module and a flow rate sensor; the slurry uniform filling control system comprises a microcontroller module, a USB (universal serial bus) communication circuit module, a second wireless communication module, a liquid crystal display circuit module, a longitudinal motor drive device and a transverse motor drive device. The slurry uniform filling method comprises the following steps of I. formulating a blanking track of the flow slurry funnel; II. setting and transmitting blanking parameters; and III. Uniformly carrying out blanking on each blanking point through the flow slurry funnel. By adopting the slurry uniform filling system and the slurry uniform filling method, the test efficiency can be improved, and the filling uniformity of the slurry can be guaranteed.

Owner:陕西嘉墨能源科技有限公司

Cutting ring specimen maker and use method thereof

ActiveCN106989971ASave soil samplesAccurate Penetration PerformancePreparing sample for investigationBiomedical engineeringEngineering

Owner:CHANGAN UNIV

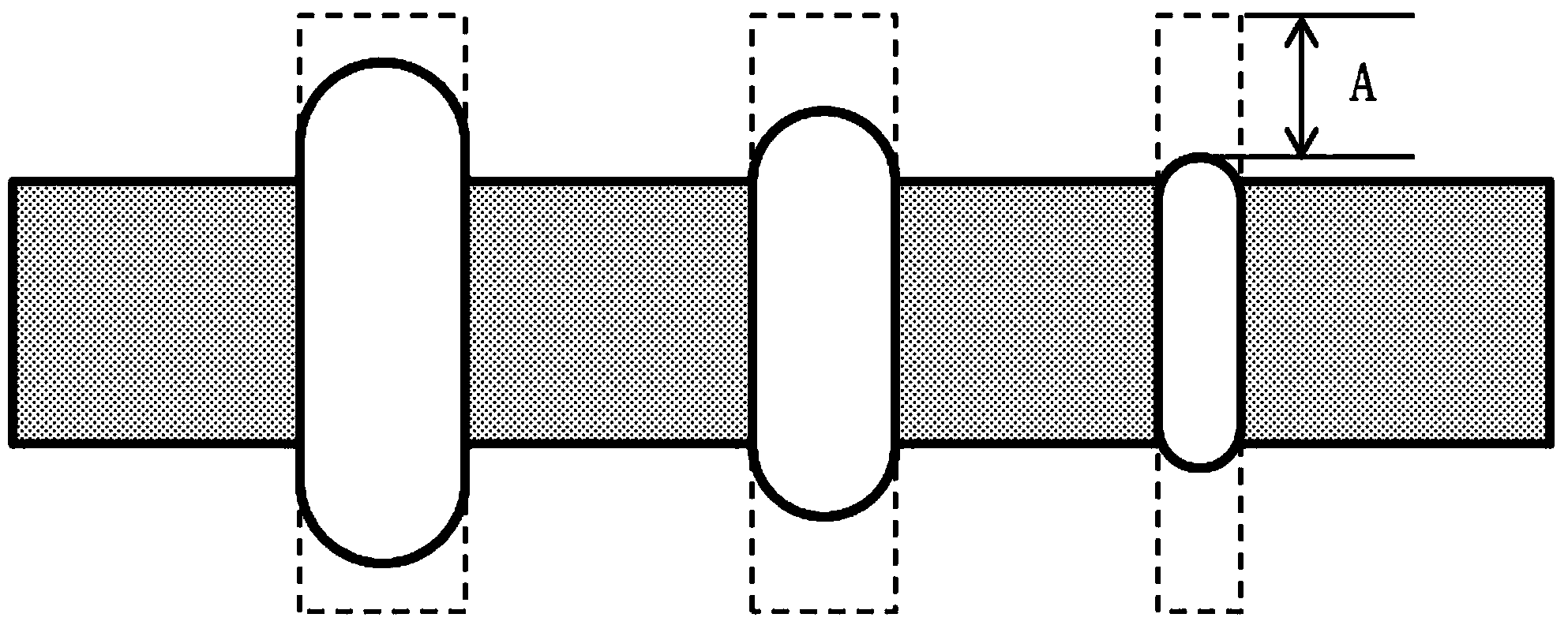

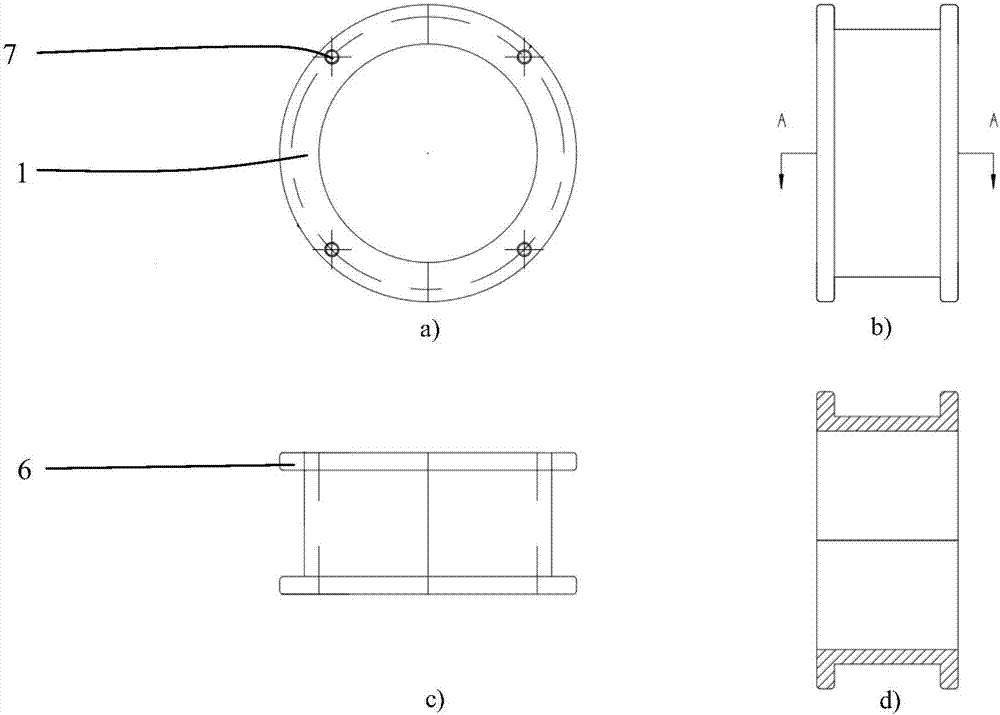

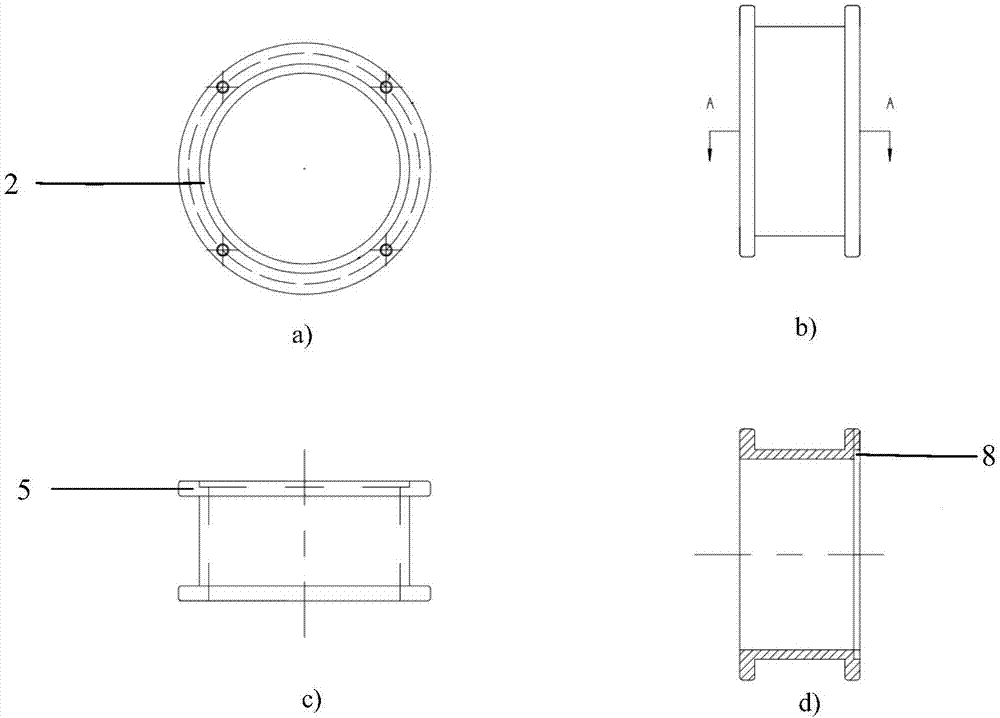

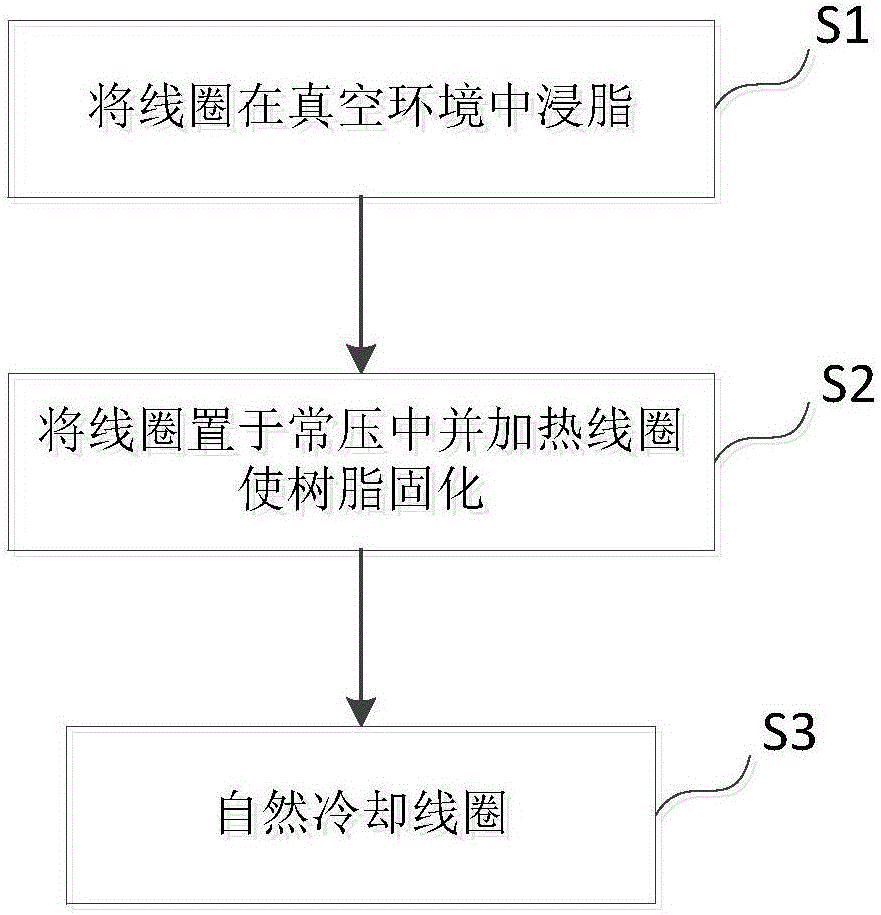

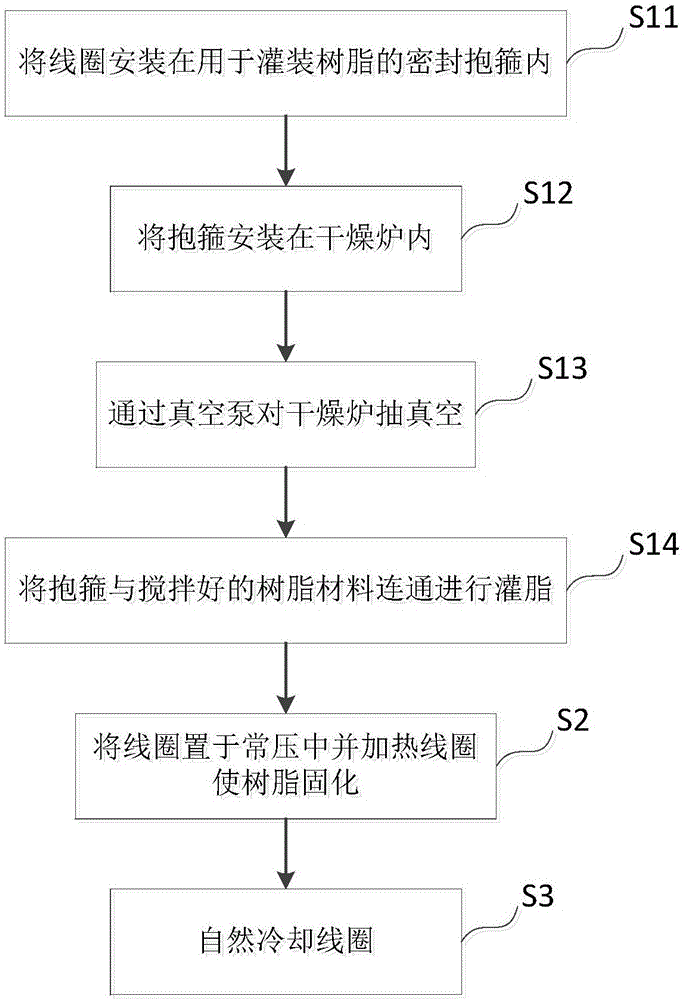

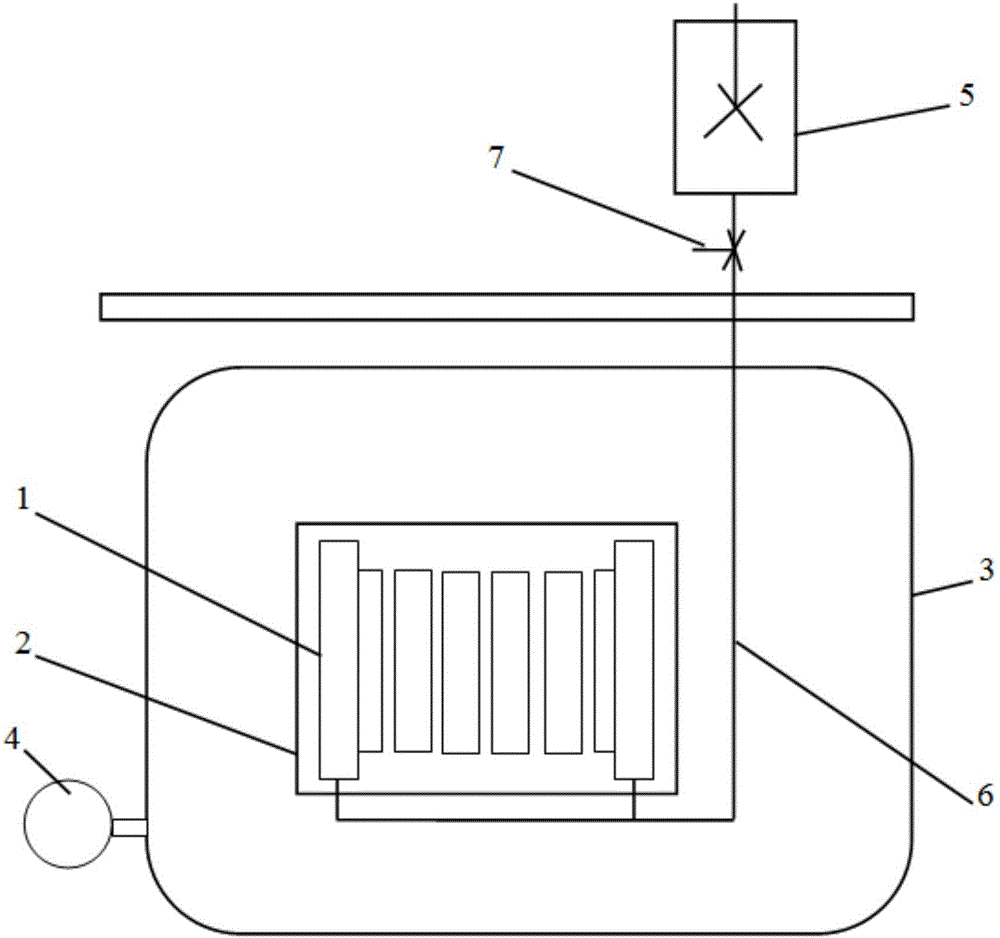

Superconducting coil and manufacturing method thereof

ActiveCN106782997AEvenly distributedMeet the requirements of basic magnetic field uniformityMagnetic measurementsSuperconducting magnets/coilsResonanceSuperconducting Coils

The invention discloses a superconducting coil and a manufacturing method thereof. The method comprises the steps of integrally performing resin immersion on the superconducting coil, wherein certain gaps are arranged between each circle and layer of wound superconducting wires; and heating and solidifying resin to fix positions of the superconducting wires. According to the method, the resin immersion is performed on the superconducting coil in a vacuum environment, so that the resin can be distributed uniformly, and a resin immersion success rate can be raised. Distances between each circle of superconducting wires and between each layer of superconducting wires are preset distances during winding of the superconducting wires, so that the distances are controlled, and a requirement of magnetic resonance imaging for the uniformity of a basic magnetic field of the superconducting coil can be met.

Owner:WEIFANG XINLI SUPERCONDUCTING MAGNETIC TECHCO

A knob switch for vehicle

ActiveCN109256294AAchieve diffusionLight transmission loss rate is smallElectric switchesScattered lightEngineering

The invention relates to a knob switch for a vehicle, include a housing and a knob, A PCB with a light emitter and a knob light transmission device are arranged in the housing, A light guide structureis arrange in that housing corresponding to the position of the light emit body, the light guide structure comprises a first light guide ring and a second light guide ring positioned below the firstlight guide ring, the bottom of the second diaphragm is provided with a plurality of diffusion portions along the circumferential direction of the bottom of the second diaphragm so as to diffuse the light emitted by the light emitter onto the second diaphragm, The upper surface of the second diaphragm is also provided with a saw tooth capable of uniformly scattering light to the lower bottom surface of the first diaphragm, and the first diaphragm is provided with a refractive part capable of refracting the upward transmitted light to the outer peripheral surface of a knob mounted on the firstdiaphragm. By adopting the technical proposal, the invention provides a vehicle knob switch which not only meets the requirement of uniformity, but also has high light source utilization ratio.

Owner:浙江长江汽车电子有限公司

Flow-induced vortex amplification frequency experiment apparatus

ActiveCN106644332AMeet uniformity requirementsSimple structureHydrodynamic testingVibration testingAxial-flow pumpAccelerometer

The invention provides a flow-induced vortex amplification frequency experiment apparatus comprising a flow-induced test pipeline, a honeycomb device, an axial-flow pump motor 5, a flow velocity measuring instrument, a water density cover plate, a water filling opening, an air exhaust opening, a water density piston, a pressure gauge and a vibration accelerometer, wherein the pressure gauge and the vibration accelerometer are arranged on a test piece; the flow-induced test pipeline comprises a non-test zone pipeline and a test zone pipeline; the water filling opening and the air exhaust opening are arranged above the non-test zone pipeline, one face of the test zone pipeline is provided with a square hole, a detachable water density cover plate is mounted on the square hole, the flow velocity measuring instrument is arranged on a front end of an upper wall face of the test zone pipeline, the axial-flow pump motor is arranged on an outer part of the flow-induced test pipeline, an output end of the axial-flow pump motor is connected with a water density axial tube, and an end part of the water density axial tube extends into the non-test zone pipeline and is provided with an axial-flow pump blade; the honeycomb device is arranged on a part, positioned between the axial-flow pump blade and a sudden contraction segment, of the non-test zone pipeline. The flow-induced vortex amplification frequency experiment apparatus can be used for testing flow-induced vortex amplification frequency of the test piece; the flow-induced vortex amplification frequency experiment apparatus is low in cost, wide in application range, simple in structure and convenient in operation.

Owner:HARBIN ENG UNIV

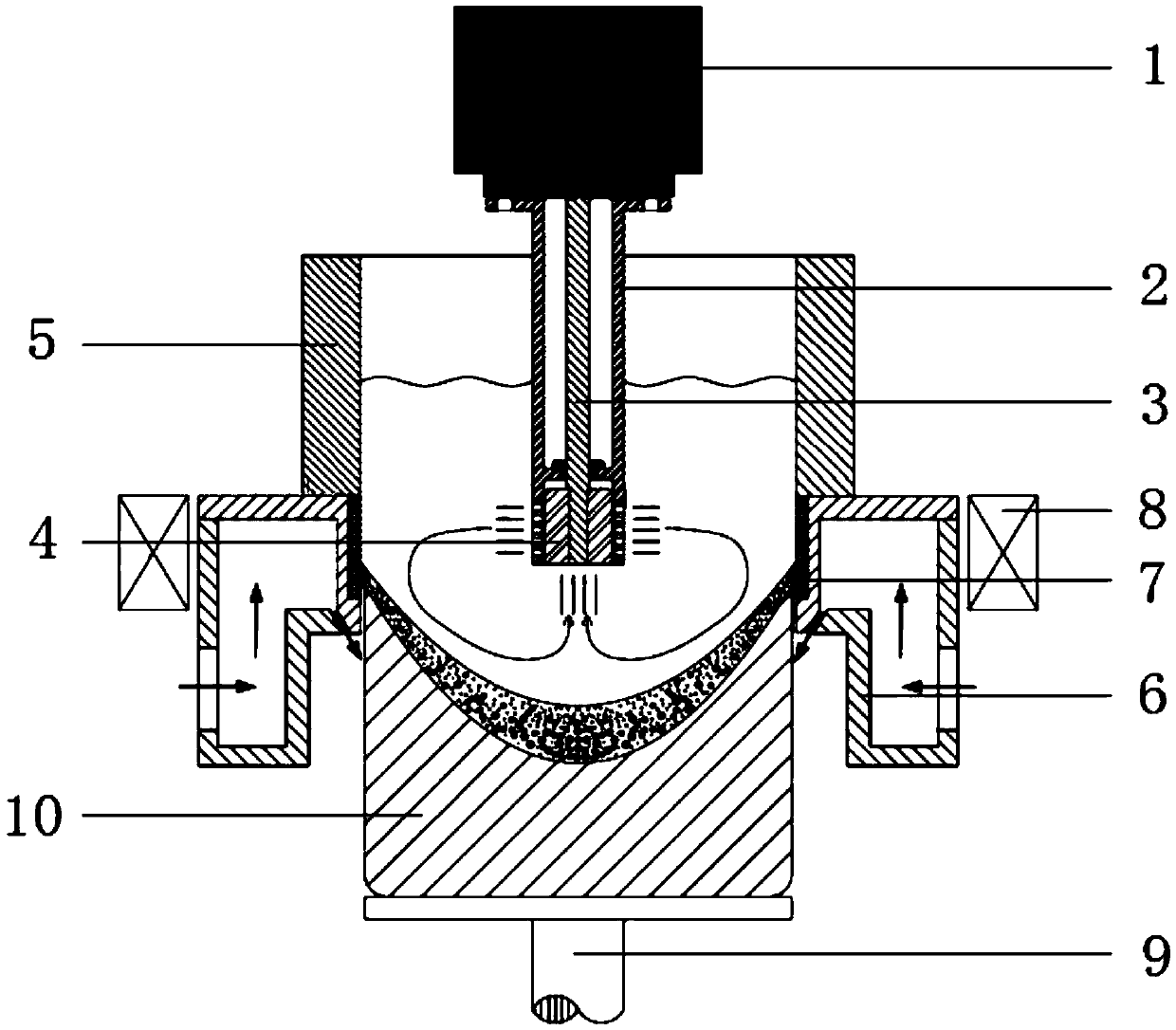

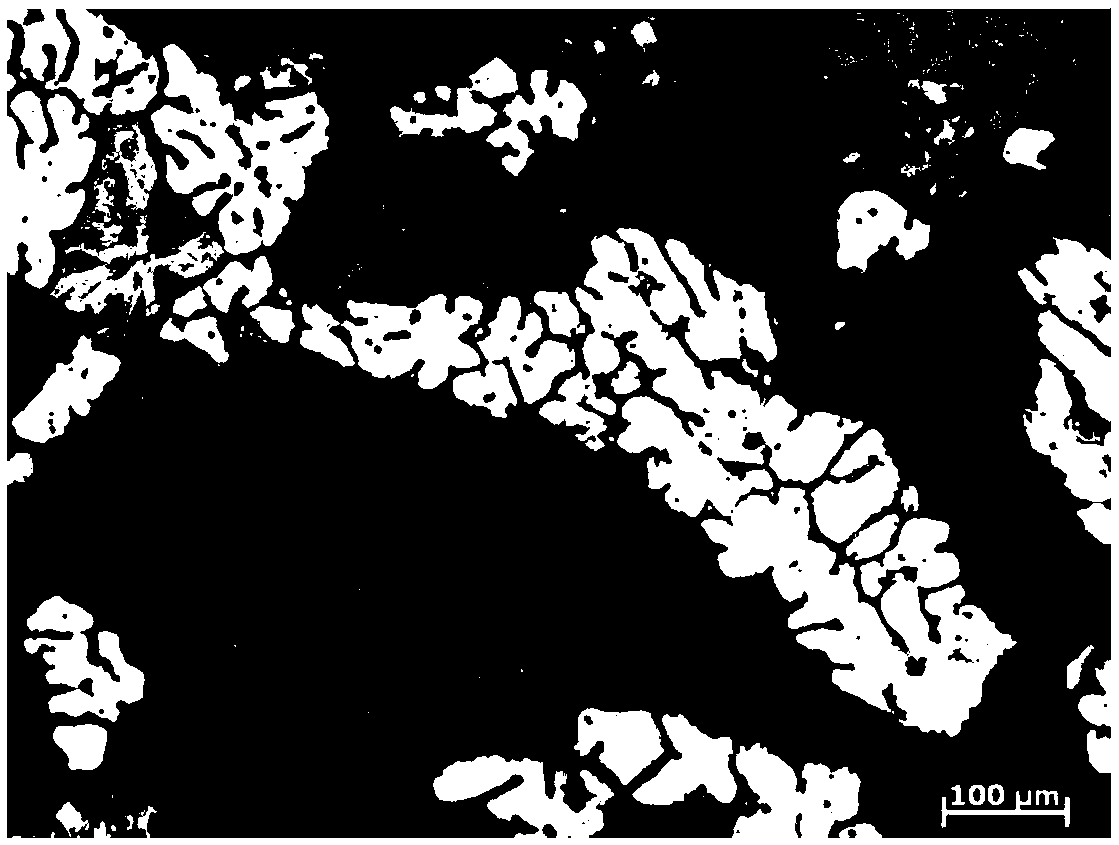

Light alloy semi-continuous casting device and method under composite action of shear and magnetic field

A light alloy semi-continuous casting device and method under the combined action of shearing and magnetic field, belonging to the technical field of light alloy semi-continuous casting. Compared with the existing technology, the present invention combines the use of magnetic field and melt shear on the basis of conventional semi-continuous casting. Its melt shear unit has the characteristics of strong shear and weak convection, which makes up for the weak shear and weak convection of the electromagnetic field. The shortcomings of strong convection are that strong shear and strong convection can be generated in the melt at the same time during semi-continuous casting; the present invention can fully meet the uniformity requirements of the temperature field, promote the fragmentation of dendrites, and reduce the film-like structure in the melt. The oxides are dispersed and broken into individually distributed fine particles, which can effectively refine the alloy structure. It not only increases the effective nucleation particles, but also weakens the damage of defects such as filmy oxides in the melt to the performance of the ingot, and improves the resistance of the ingot. The ability to crack cracks improves the yield of ingots.

Owner:NORTHEASTERN UNIV LIAONING

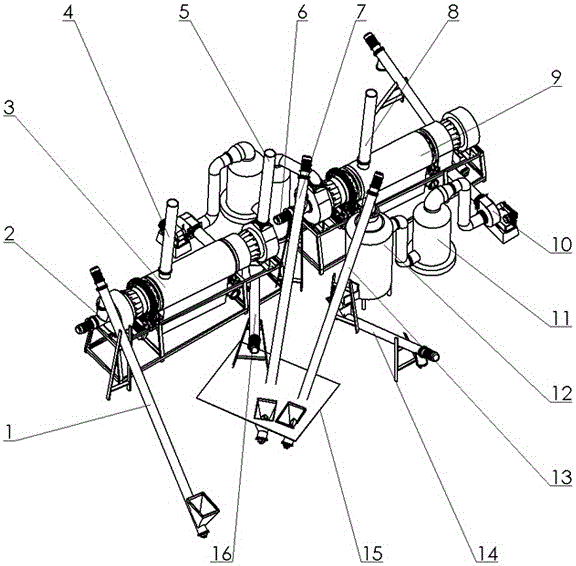

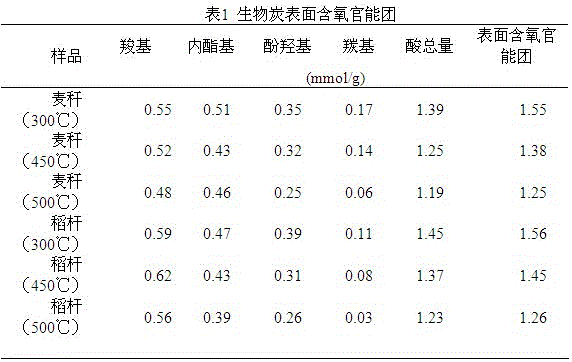

Carbonization device and technology for preparing biochar at low temperature

ActiveCN106635093AImprove biological activityImprove liquidityBiofuelsIndirect heating destructive distillationCarbonizationEngineering

The invention belongs to the technical field of biochar preparation, and particularly relates to a carbonization device and technology for preparing biochar at low temperature. The carbonization device comprises a drying device, a low-temperature carbonization device and a high-temperature pyrolysis device which are separately arranged; a discharge outlet of the drying device is connected with a feed inlet of the low-temperature carbonization device and a feed inlet of the high-temperature pyrolysis device through a feeding mechanism, an exhaust port of the high-temperature pyrolysis device is connected with a fuel inlet of the low-temperature carbonization device, and an exhaust port of the low-temperature carbonization device is connected with a fuel inlet of the drying device. According to the device and technology, by conducting two-stage carbonization operation on biomass, the biomass carbonization temperature and time can be effectively controlled, the biomass liquidity can be improved, the biochar yield can be increased, and the biochar quality can be improved.

Owner:HENAN AGRICULTURAL UNIVERSITY +1

Combination method for aviation heater

ActiveCN102538482AMeet uniformity requirementsElectric heating for furnacesAviationTemperature control

The invention relates to a combination method for an aviation heater, which is characterized in that a plurality of heating unit areas (3) are arranged on refractory supporting bricks in a hearth of a furnace, a spatial area (5) capable of holding heating element units (4) is arranged in each heating unit area (3) and divided into spatial positions capable of holding more than three heating element units (4), the heater can be formed by combining a plurality of heating unit areas (3) of the same structure or of different structures, and the heating element units (4) placed in the same heating unit area (3) are connected to a power supply after series connection. According to different spatial environments, different hearth sizes and different requirements on heat, combination forms can meet different requirements. As each spatial area (5) is divided into the spatial positions capable of holding six heating element units in various distribution modes, the combination method is even in heating and precise in temperature control.

Owner:XI AN AOJIE ELECTRIC HEATING EQUIP ENG CO LTD

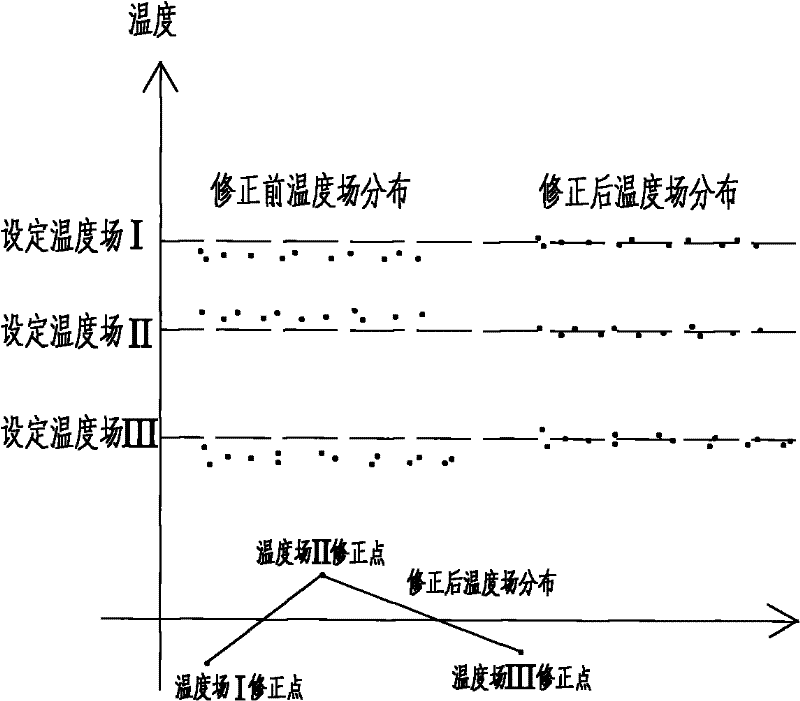

Nonlinear correction system used for box-type heating furnace temperature field thermocouple

InactiveCN102175082AImprove uniformityGuaranteed uniformityFurnace typesControl devices for furnacesEngineeringHeating furnace

The invention provides a nonlinear correction system used for a box-type heating furnace temperature field thermocouple. The heating furnace is divided into a plurality of temperature zones, wherein one circulating fan corresponds to one temperature zone, and multiple thermocouples are arranged in the effective distribution range of each temperature zone. By carrying out nonlinear correction on the thermocouples for temperature controlling, the requirement of temperature field uniformity for products in a production technology can be satisfied. The uniformity of the furnace temperature zones can be greatly improved after correction, which can meet the requirements of multiple alloy products to the temperature zones. As for the furnace with the plurality of temperature zones, the uniformity between the temperature zones can be ensured.

Owner:SUZHOU LONGRAY THERMAL TECH

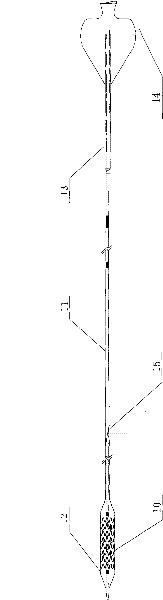

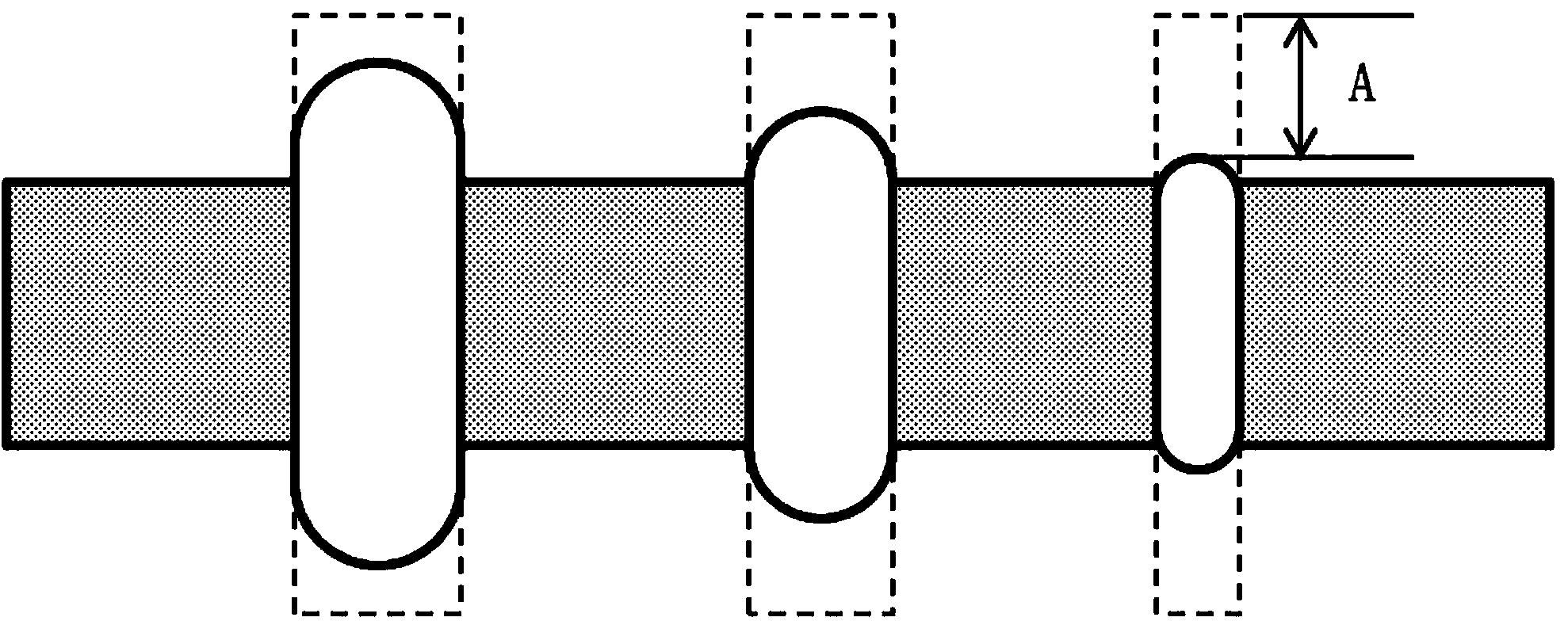

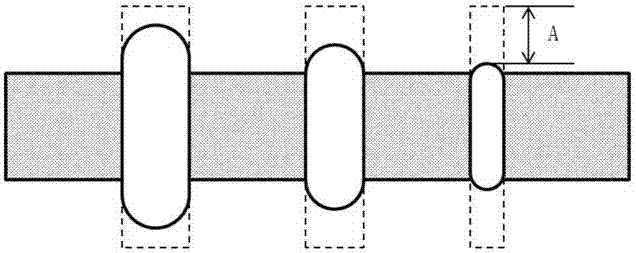

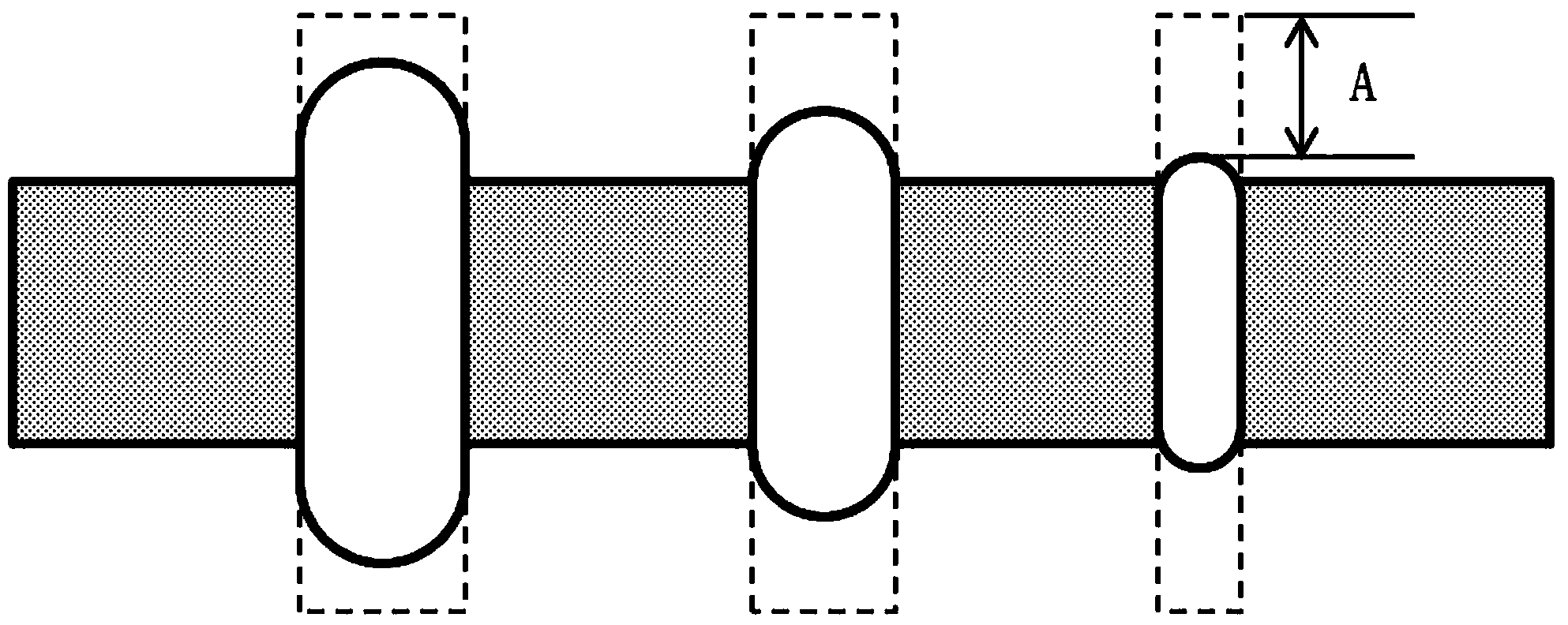

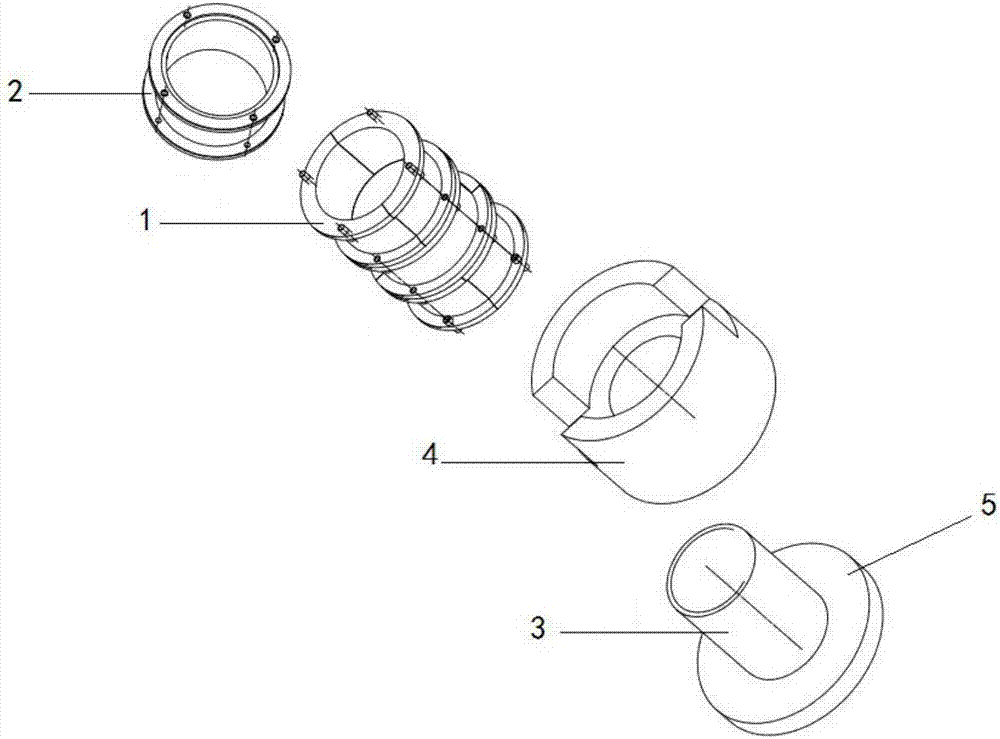

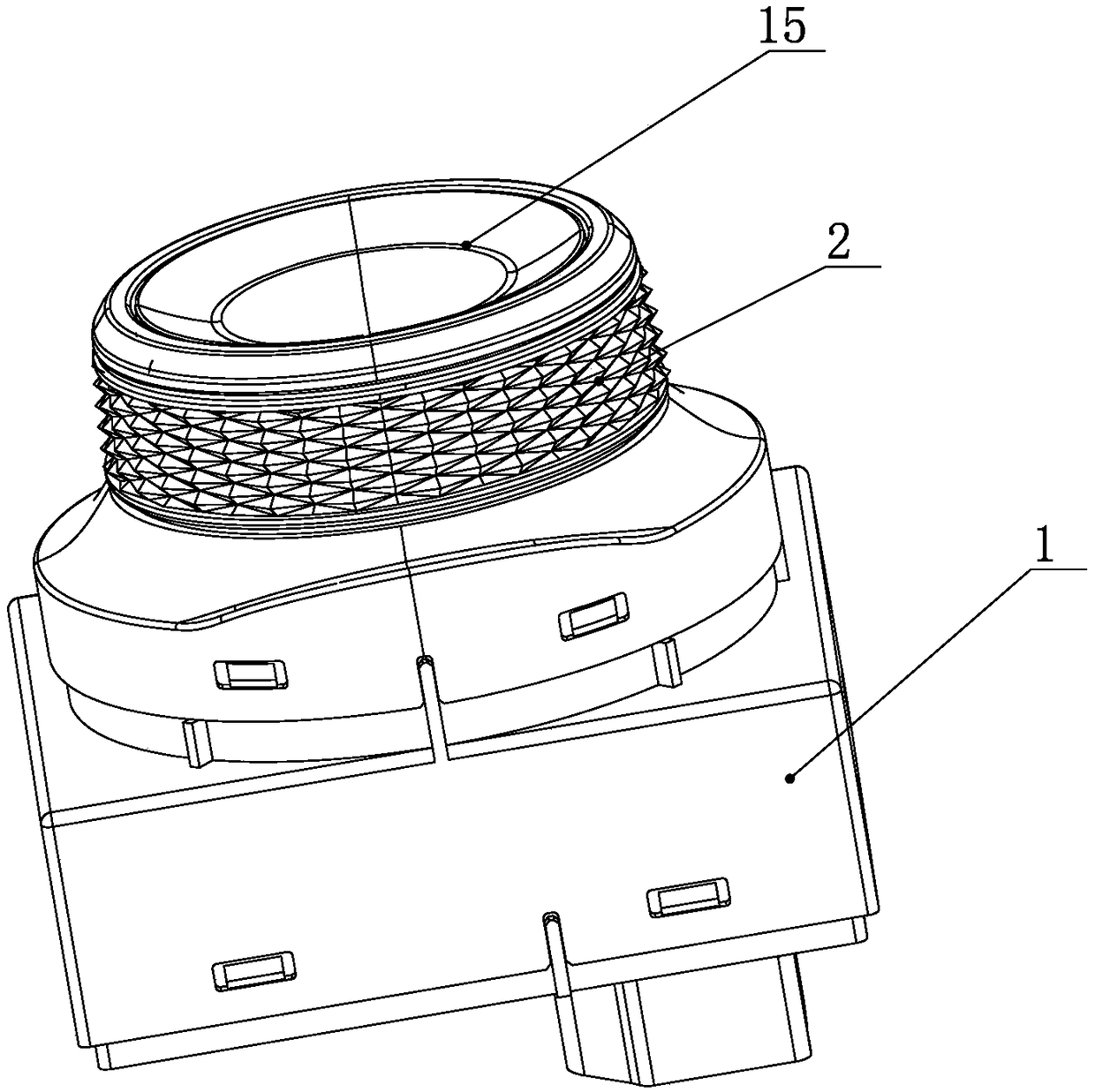

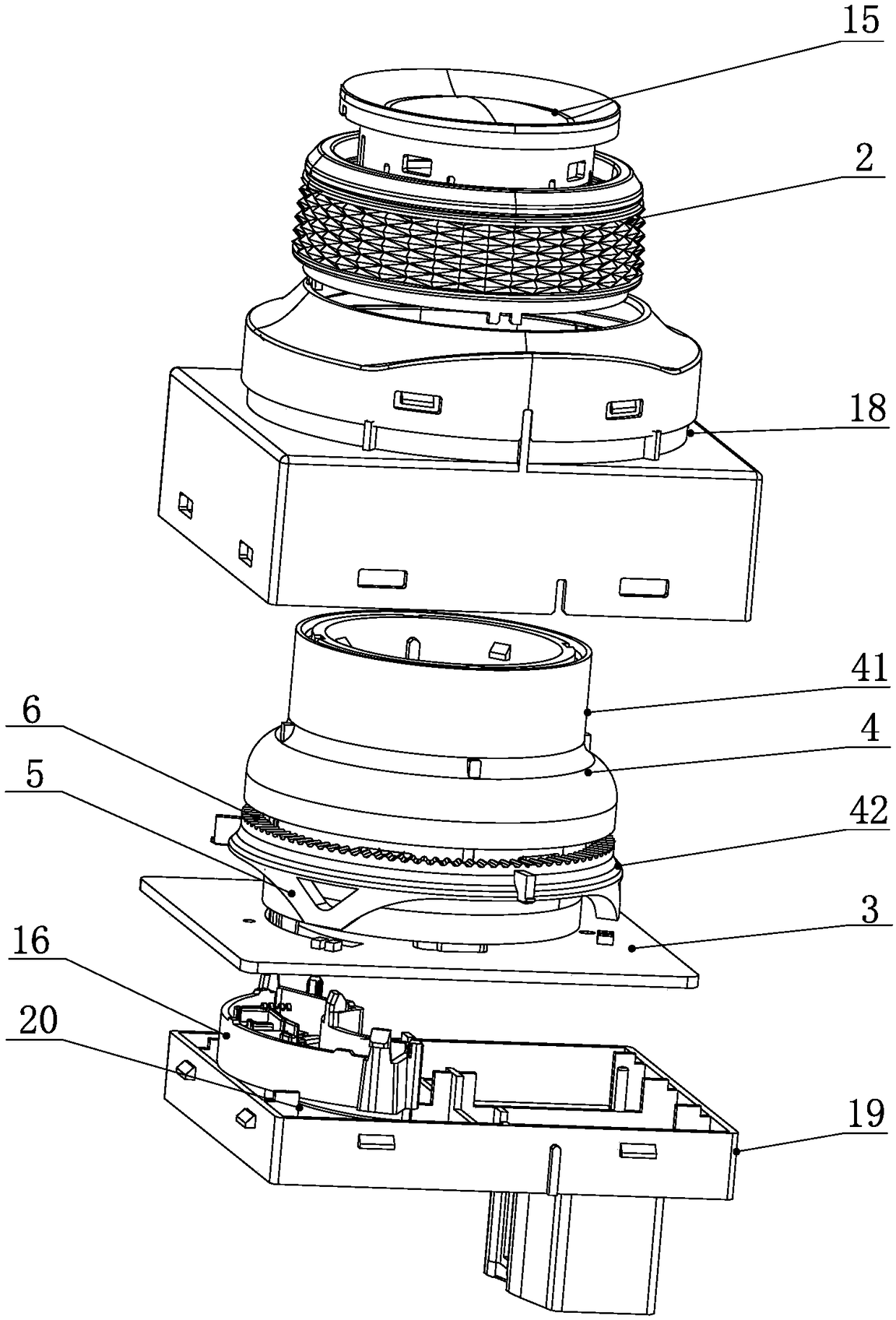

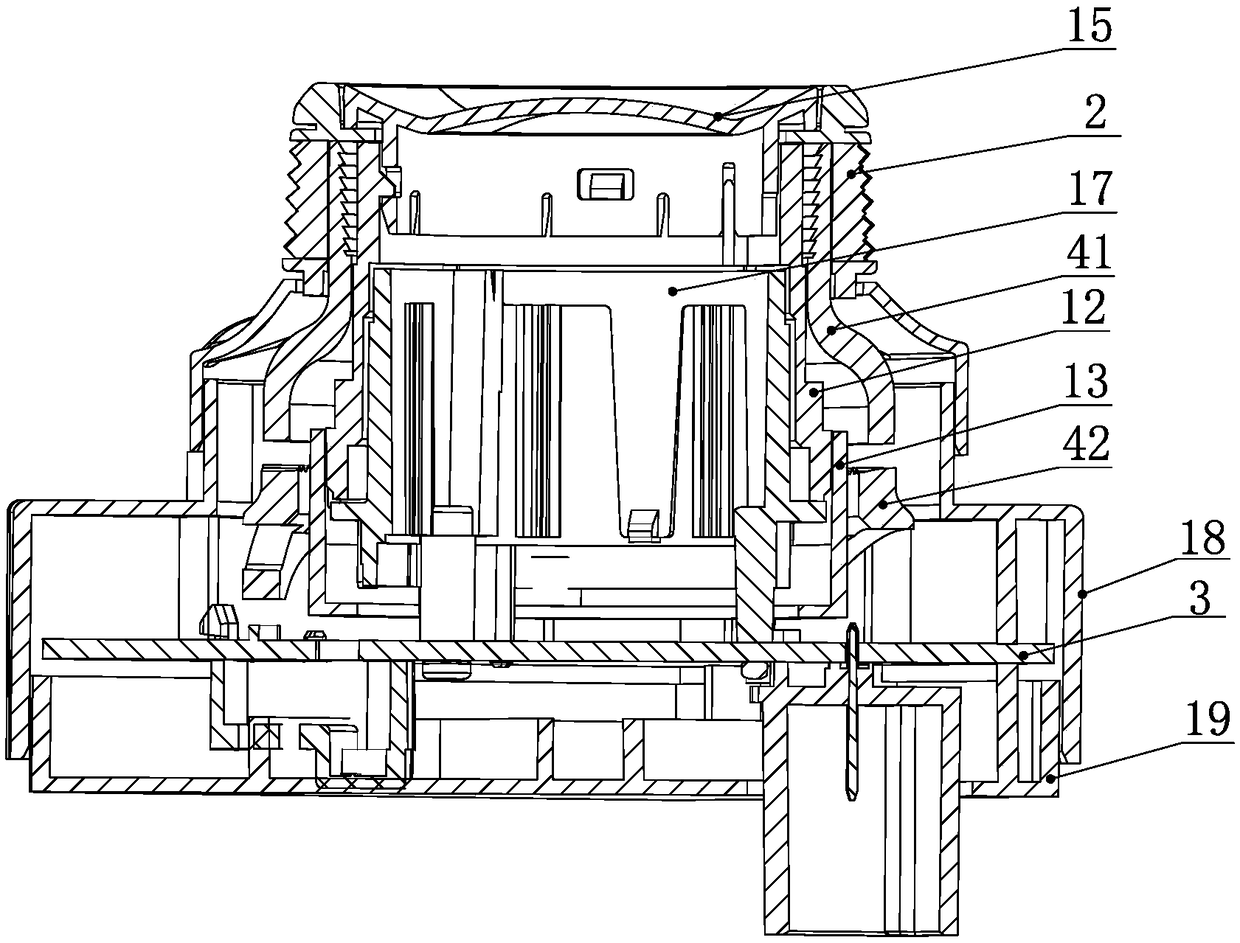

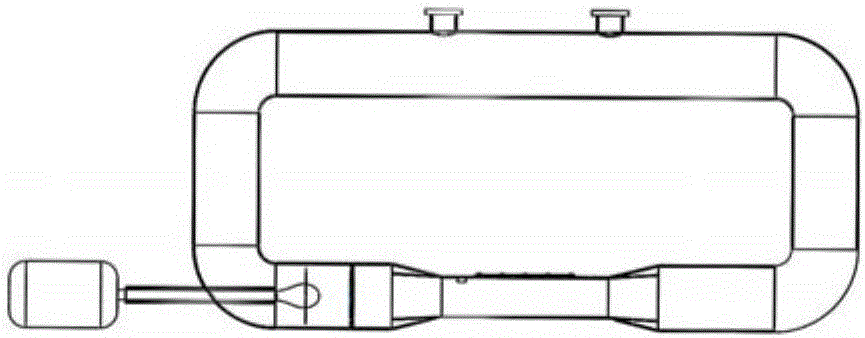

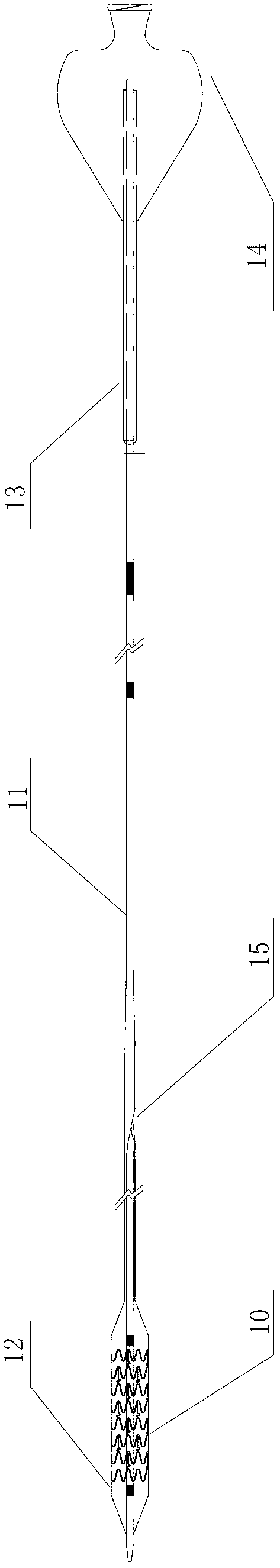

Cobalt-chromium alloy arterial stent system with full biodegrade medical coating

ActiveCN103212117AImprove mechanical propertiesGood biocompatibilityStentsSurgeryCoronary arteriesTransport system

The invention provides a cobalt-chromium alloy arterial stent system with a full biodegrade medical coating. The system comprises a transport system and a cobalt-chromium alloy arterial stent which has a full biodegrade medical coating and is sleeved on the transport system. The transport system comprises a push rod, a sacculus and a jacket respectively fixedly connected to both ends of the push rod, and a handle with a Luer joint. A cone-shaped hardened guide wire is arranged at the sacculus end of the push rod. The cobalt-chromium alloy arterial stent with the full biodegrade medical coating is sleeved on the sacculus. The system can avoid damage of the coating to the maximum extent, improve the retaining force between the bracket and the transport system greatly, prevent the probability that the bracket is out of load in the transport process, and reduce the clinical use risk, so that the problems of coronary artery stenosis and restenosis are effectively solved.

Owner:万瑞飞鸿(北京)医疗器材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com