Slurry uniform filling system and slurry uniform filling method for testing flow sedimentation law of filling slurry

A technology for filling slurry and testing, which is applied in the direction of flow characteristics, preparation of test samples, and analysis of materials, etc. It can solve the problems of difficult control of the speed of slurry delivery, influence on the accuracy of test results, and instability of manual operation. Achieve the effect of saving manpower and material resources, avoiding instability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

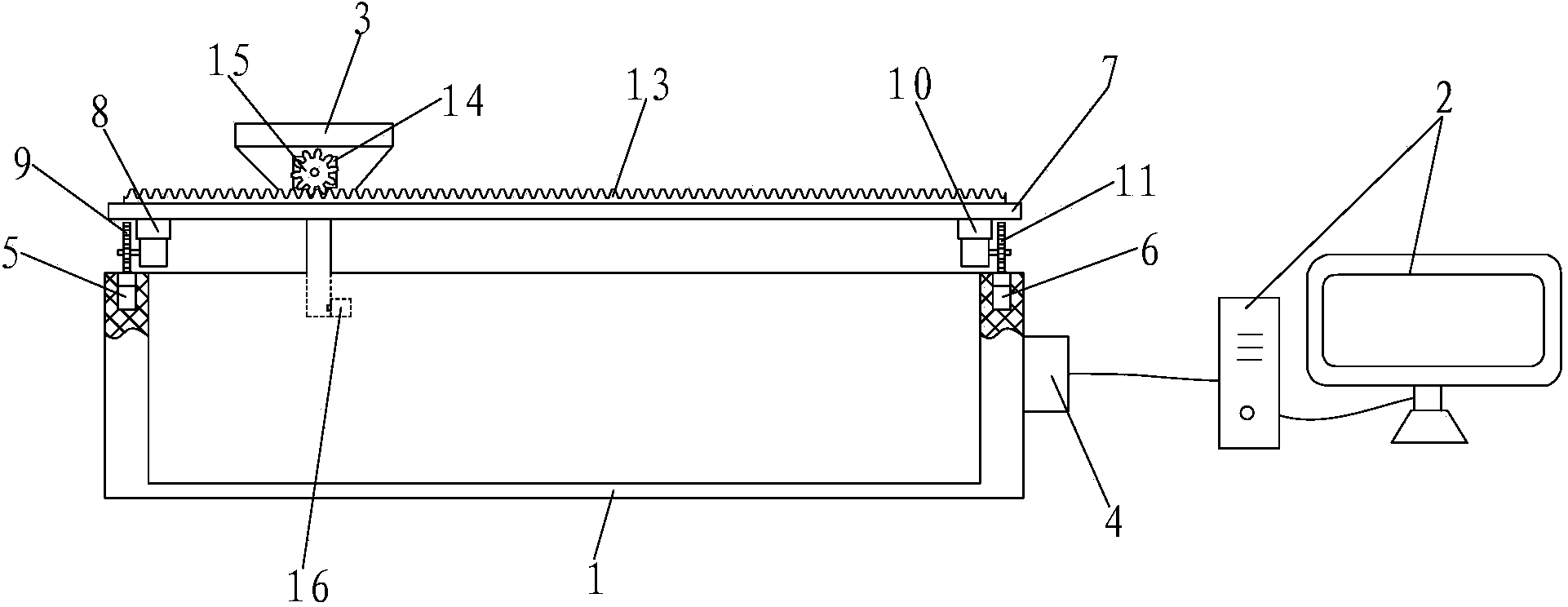

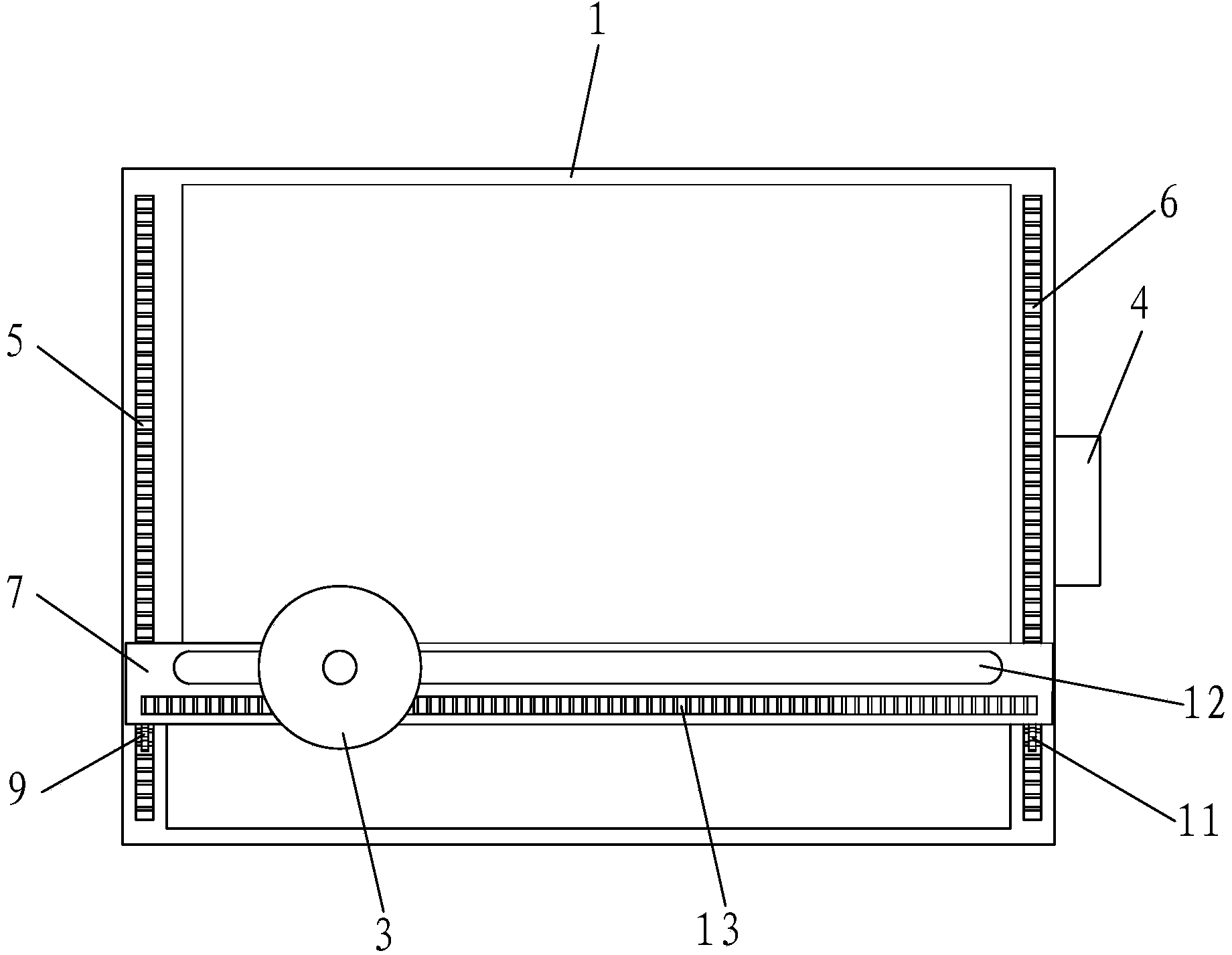

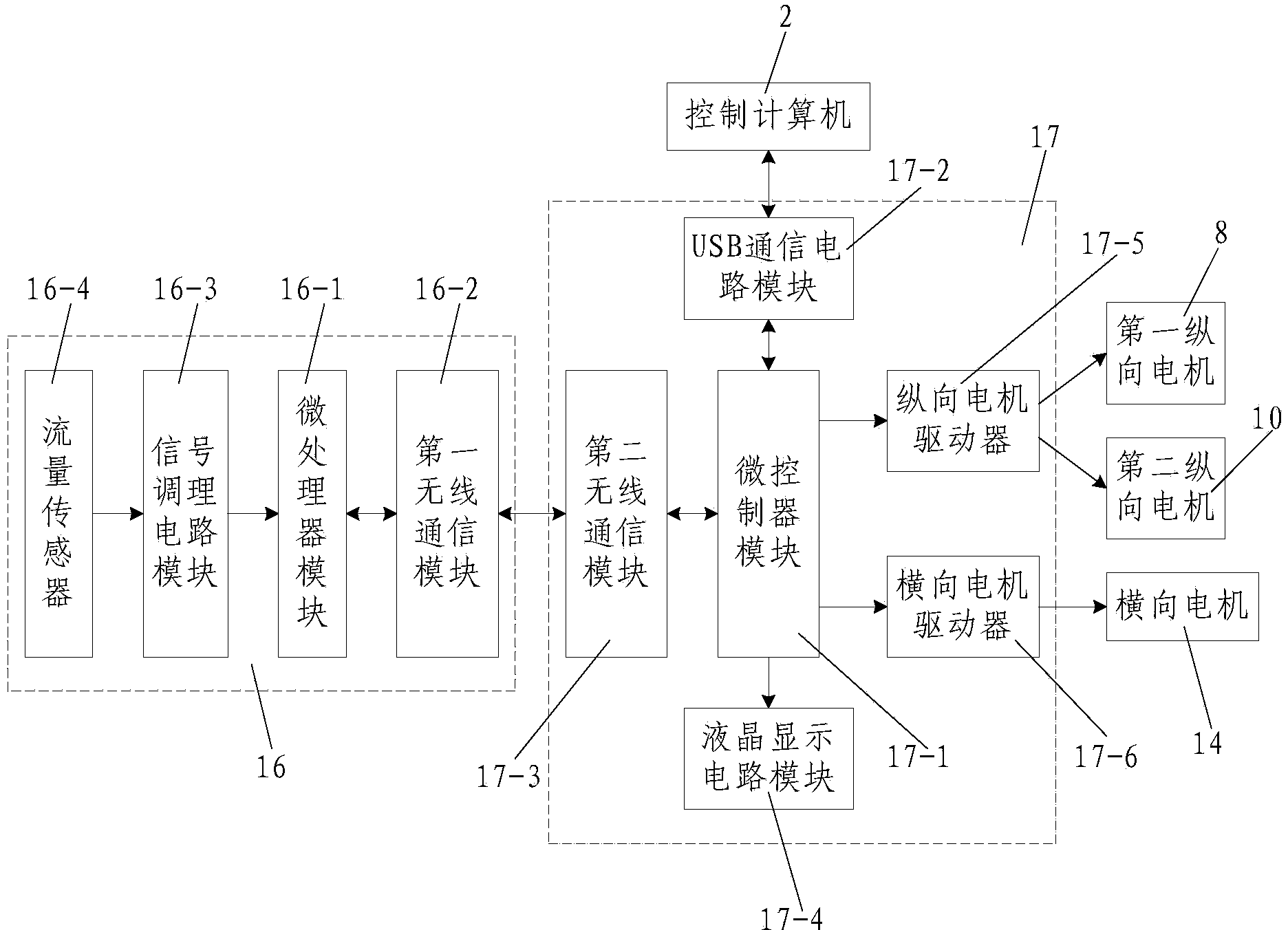

[0046] Such as figure 1 , figure 2 and image 3 As shown, the slurry uniform filling system for the flow deposition law test of the filling slurry of the present invention includes a cube-shaped test tank body 1 and a control computer 2, as well as a slurry funnel 3 arranged above the test tank body 1 and installed in the test tank body 1. The control box 4 on the outer wall of the tank body 1 is provided with a slurry uniform filling control system 17 inside; the top of the test tank body 1 in the width direction is respectively embedded with a first longitudinal rack 5 and a second longitudinal rack. The rack 6 is provided with a movable track beam 7 that can move along the first longitudinal rack 5 and the second longitudinal rack 6 along the length direction of the test cell 1, and the lower part of one end of the movable track beam 7 is equipped with a first A longitudinal motor 8, the output shaft of the first longitudinal motor 8 is fixedly connected with the first l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com