Nonlinear correction system used for box-type heating furnace temperature field thermocouple

A non-linear correction, temperature-controlled thermocouple technology, used in lighting and heating equipment, furnaces, furnace types, etc., can solve the problems of temperature-controlled thermocouple errors, temperature field offset, etc., to ensure uniformity and improve uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

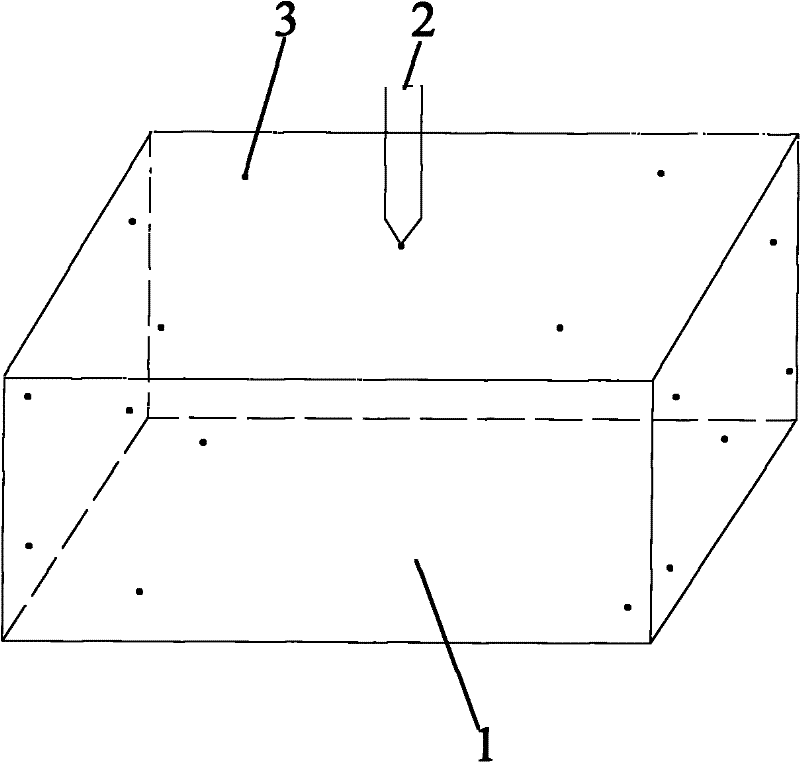

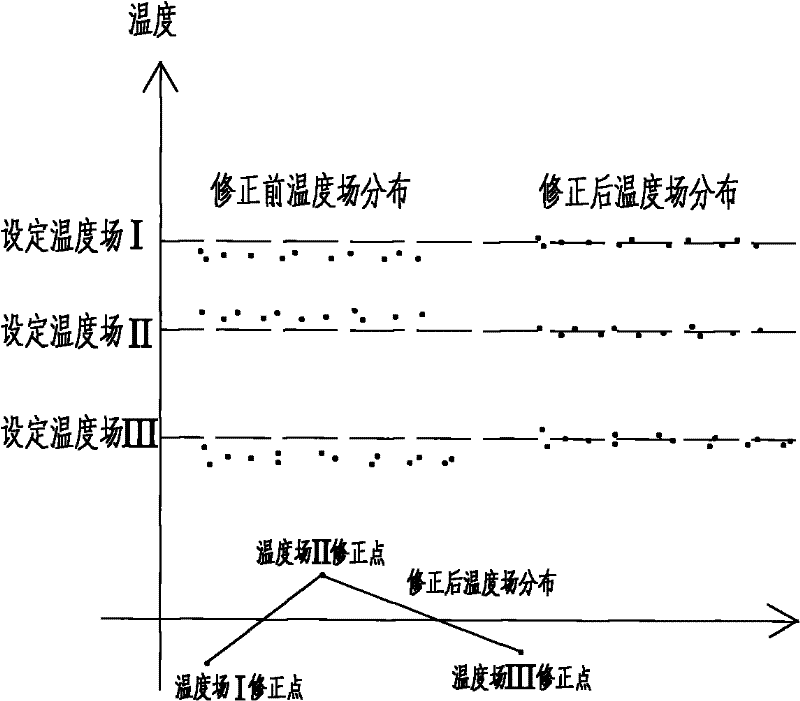

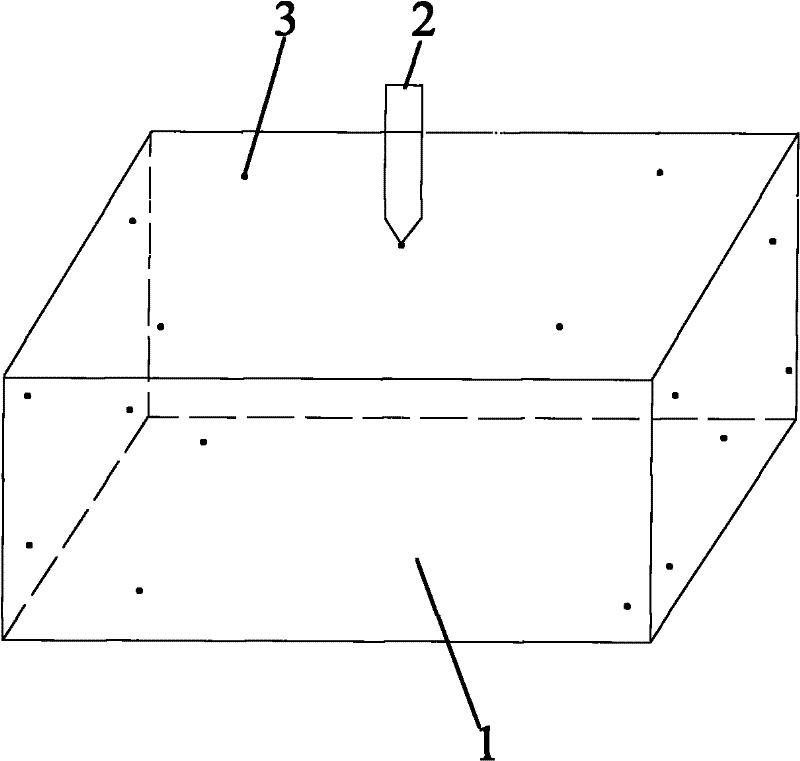

[0014] The heating furnace generally adopts a hot air circulation system. The heating furnace is divided into multiple temperature zones according to the requirements of the furnace load. One circulation fan corresponds to one temperature zone, such as figure 1 As shown, a plurality of thermocouples 2 are arranged within the effective distribution range of the temperature zone 1 to form a plurality of detection points 3, and the thermocouples 2 are temperature-controlling thermocouples.

[0015] In order to ensure the performance of the material, it has uniformity within the corresponding required range in each temperature zone. A temperature control thermocouple is installed in each temperature zone, and the feedback signal of the thermocouple and the heating control installed on the furnace are used. The system forms a closed-loop control to ensure the accuracy of temperature control. Although the temperature control thermocouple meets the requirements of the design level, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com