Iron powder testing laboratory unattended system and method for applying same

A laboratory and control system technology, applied in the field of iron powder testing, can solve the problems of manual errors, equipment errors, loss of accuracy of test results, and difficulty in sampling by sampling personnel, and achieve accurate storage, timely testing, and error reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

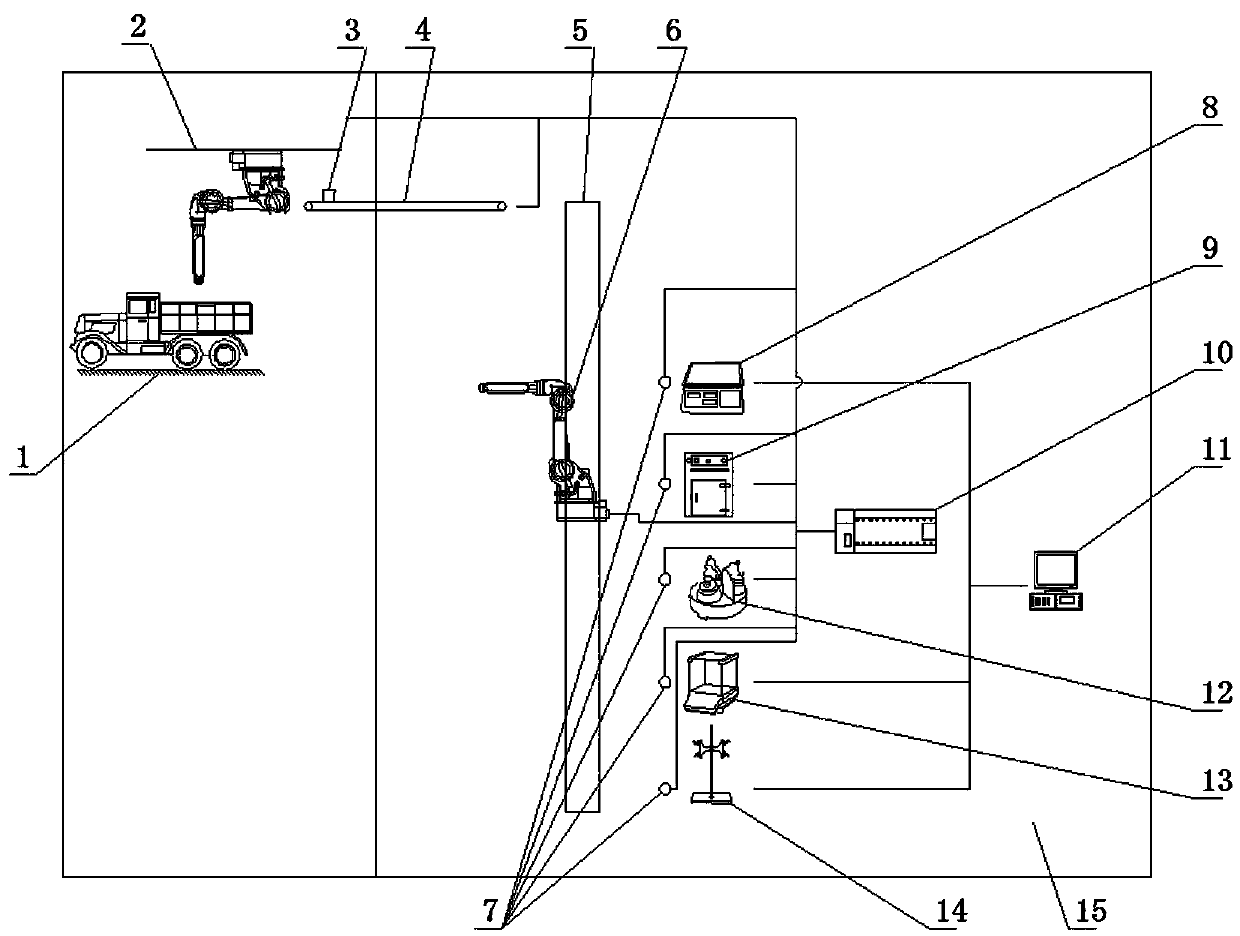

[0020] see figure 1 , an iron powder laboratory unattended system, including a laboratory 15, a fixed parking space 1 is arranged around the laboratory 15, a sampling manipulator 2 is arranged above the fixed parking space 1, and rails 5 are respectively arranged in the laboratory 1 , a PLC control system 10, a host computer 11, a movable intelligent manipulator 6 is arranged on the track 5, and the sample taken out by the sampling manipulator 2 from the vehicle on the fixed parking space 1 is sent to the laboratory through a disposable sample container 3 and a conveyor belt 4 The movable intelligent manipulator 6 in the chamber 15, the first balance 8, the oven 9, the grinder 12, the second balance 13, the titrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com