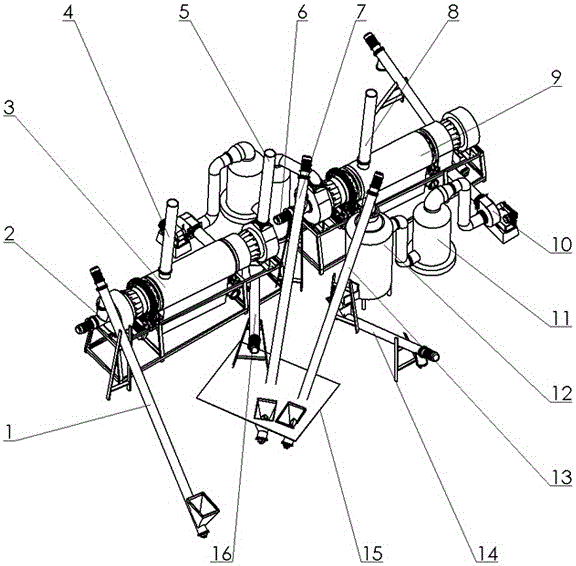

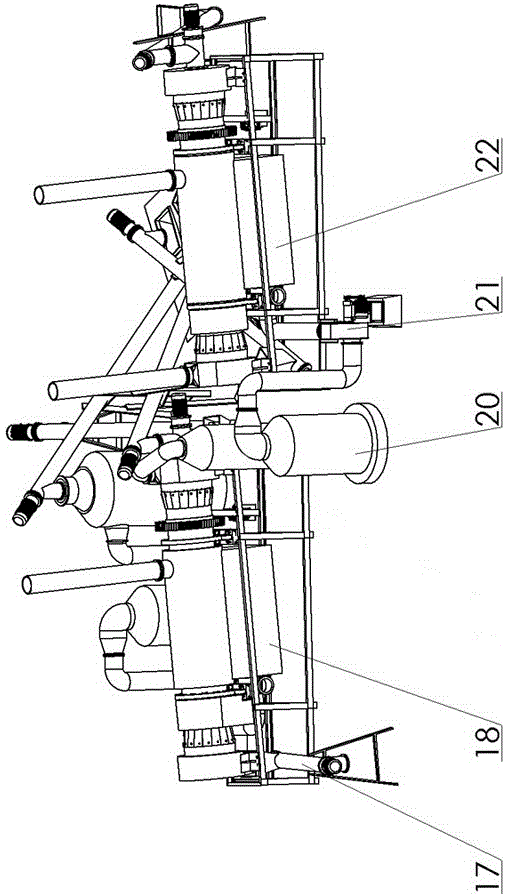

Carbonization device and technology for preparing biochar at low temperature

A technology of low-temperature carbonization and biochar, applied in biofuel, petroleum industry, indirect heating and dry distillation, etc., can solve the problems of difficult decomposition and utilization, reduce the rate of biomass charcoal production, energy waste, etc., achieve good surface activation performance, improve Fluidity, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

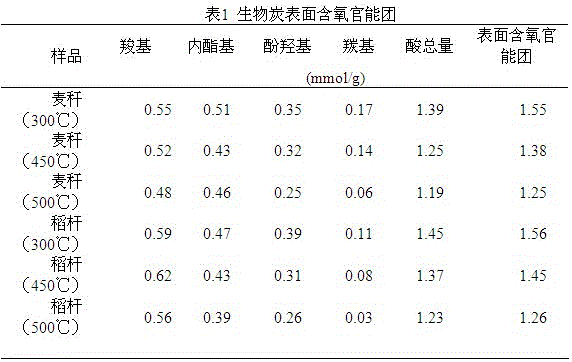

Embodiment 1

[0040] The process of preparing biochar at low temperature using the above-mentioned carbonization equipment, the steps are as follows:

[0041] 1) Drying:

[0042] Ignite the fuel reserved in the heating mechanism box under the drying device, and preheat the cylinder of the drying device to 80°C, and then the elevator will guide the biomass raw material into the cylinder from the inlet of the drying device, and convey it in the screw Driven by the machine, it moves and dries towards the discharge port. The moisture in the biomass raw material is discharged to the outside through the exhaust pipe. After the dehydration rate reaches 80%, the biomass raw material is discharged from the discharge port and enters the transfer bin through the pipeline to wait. use;

[0043] 2) Low-temperature carbonization: The dry biomass in the transfer bin is introduced into the low-temperature carbonization device and the high-temperature pyrolysis device through the elevator. The cylinder is...

Embodiment 2

[0047] The process of preparing biochar at low temperature using the above-mentioned carbonization equipment, the steps are as follows:

[0048] 1) Drying:

[0049] Ignite the fuel reserved in the heating mechanism box below the drying device, and preheat the cylinder of the drying device to 120°C, and then the elevator will guide the biomass raw material into the cylinder from the inlet of the drying device, and convey it in the screw The moisture in the biomass raw material is discharged to the outside through the exhaust pipe, and the biomass raw material after the dehydration rate reaches 90% is discharged from the discharge port, and enters the transfer bin through the pipeline to wait. use;

[0050] 2) Low-temperature carbonization: The dry biomass in the transfer bin is introduced into the low-temperature carbonization device and the high-temperature pyrolysis device through the elevator. The cylinder is heated to 500°C, and the biomass in the cylinder is pyrolyzed at...

Embodiment 3

[0054] The process of preparing biochar at low temperature using the above-mentioned carbonization equipment, the steps are as follows:

[0055] 1) Drying:

[0056] Ignite the fuel reserved in the heating mechanism box below the drying device, and preheat the cylinder of the drying device to 120°C, and then the elevator will guide the biomass raw material into the cylinder from the inlet of the drying device, and convey it in the screw The moisture in the biomass raw material is discharged to the outside through the exhaust pipe, and the biomass raw material after the dehydration rate reaches 85% is discharged from the discharge port, and enters the transfer bin through the pipeline to wait. use;

[0057] 2) Low-temperature carbonization: The dry biomass in the transfer bin is introduced into the low-temperature carbonization device and the high-temperature pyrolysis device through the elevator. The cylinder is heated to 350°C, and the biomass in the cylinder is pyrolyzed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com