Long-distance coal injection system

A long-distance, tank-injection technology, applied in tuyere, furnace, blast furnace details, etc., can solve problems such as injection pulsation pipeline, blast furnace temperature fluctuation, blockage, etc., achieve long-distance uniform injection, reduce impact, and reduce pipeline Effect of wear and gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

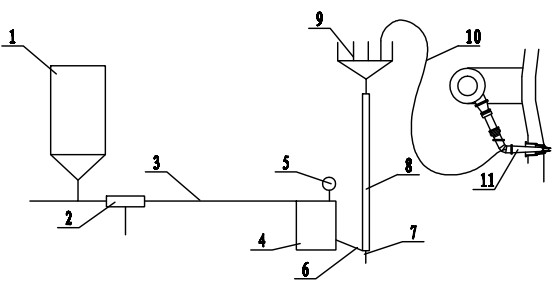

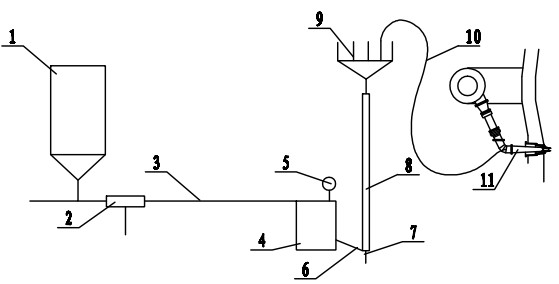

[0015] Such as figure 1 As shown, a long-distance coal injection system uses compressed air to transport gas. The sending end of the system is the injection tank 1, the mass flow rate of pulverized coal at the outlet of the injection tank is 40 t / h, and the solid-gas ratio is 100:1. The pulverized coal main pipe 3 transports the pulverized coal to the buffer tank 4. The pulverized coal main pipe adopts double-tube turbulent flow dense-phase conveying with a length of 1000 m. The pulverized coal and air are separated in the buffer tank 4, and the air is released through the pressure control valve 5. The pulverized coal settles to the buffer tank 4 bottom.

[0016] The pulverized coal in the buffer tank 4 flows into the vertical riser 8 through the inclined descending pipe 6. Under the action of the air nozzle 7, the pulverized coal begins to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com