Inlet manifold integrated with intercooler

A technology of intake manifold and intercooler, applied in machine/engine, combustion air/combustion-air treatment, internal combustion piston engine, etc. Unreasonable design of air cavity, unreasonable arrangement of cooling water flow, etc., to optimize the uniformity of intake air flow, meet the requirements of the uniformity of intake air flow of each cylinder, and improve the uniformity of intake air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

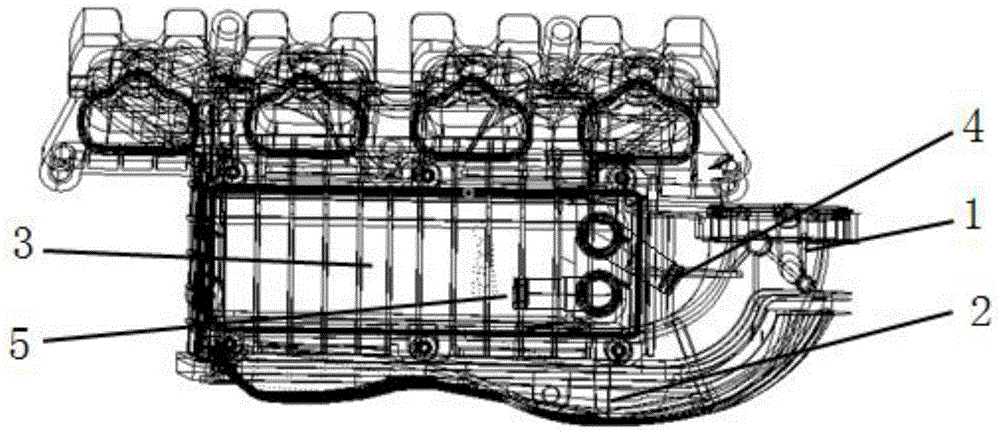

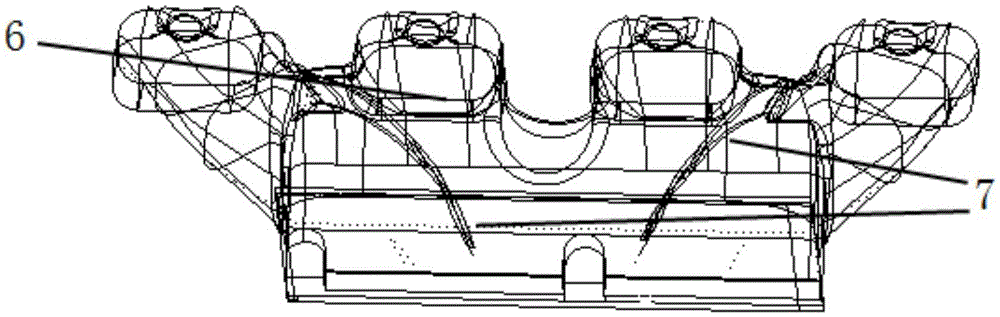

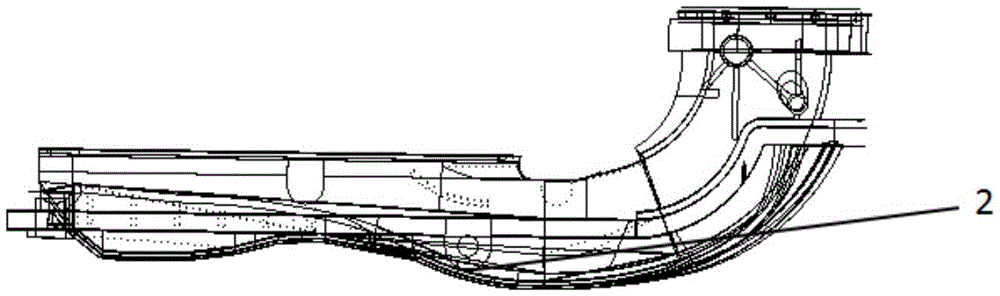

[0024] like Figure 1 to Figure 4 As shown, the present invention specifically relates to an intake manifold integrating an intercooler, including an intake manifold body and an intercooler 3, the intake manifold body is provided with a pressure stabilizing chamber 6, and the intercooler 3 is integrated in the stabilizing In the plenum 6 , the body of the intake pipe also includes an air intake chamber 2 which communicates with the bottom surface of the plenum chamber 6 and is used to adjust the flow direction of the intake air and the boundary gas space of the intercooler. An air intake pipe 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com