Rotary device for regulating flow of spray head

A flow adjustment device, a rotary technology, applied in the field of nozzle flow adjustment devices to adjust the flow of nozzles, can solve the problems of time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

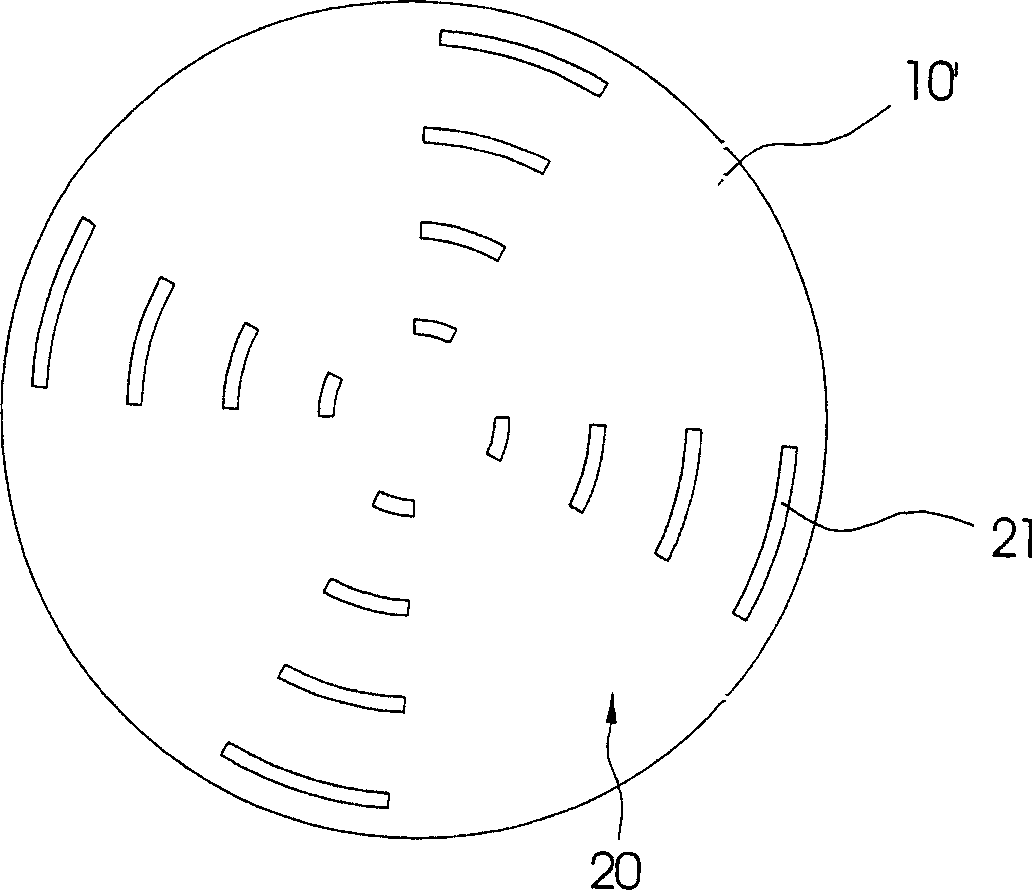

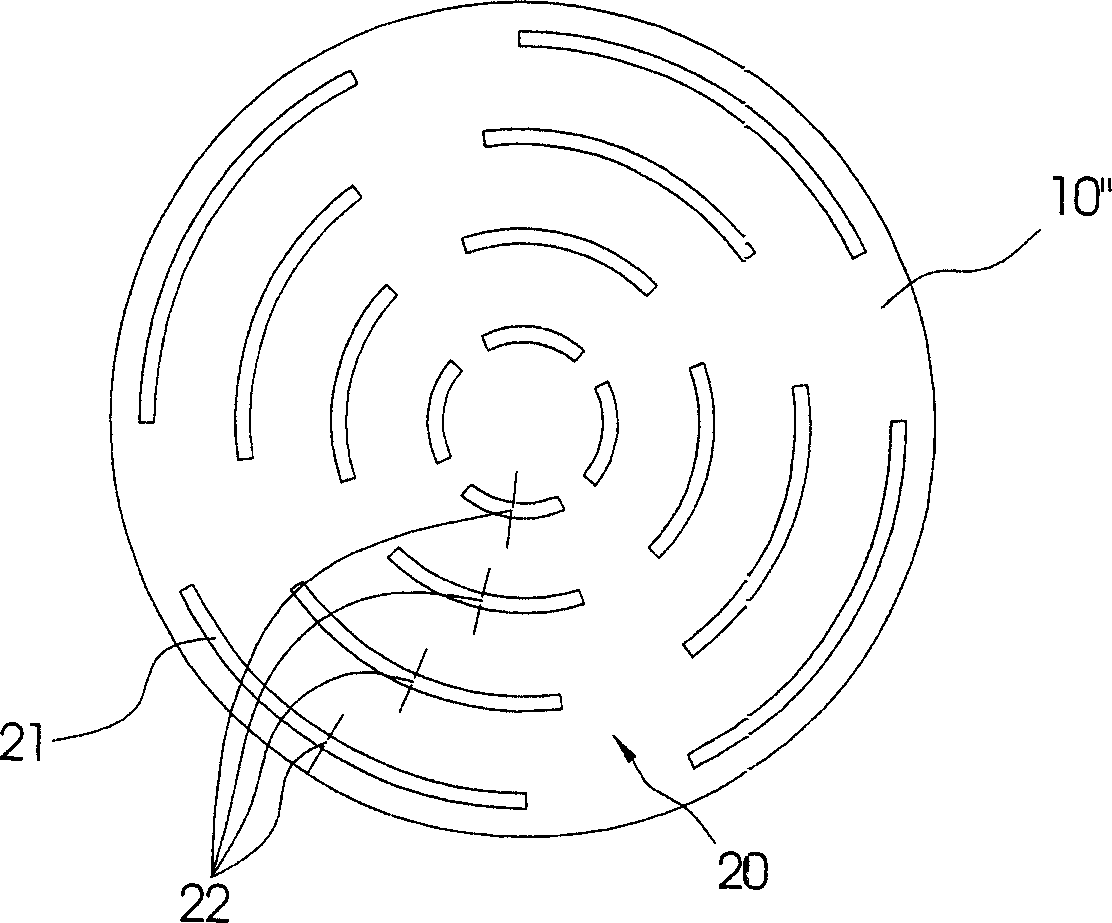

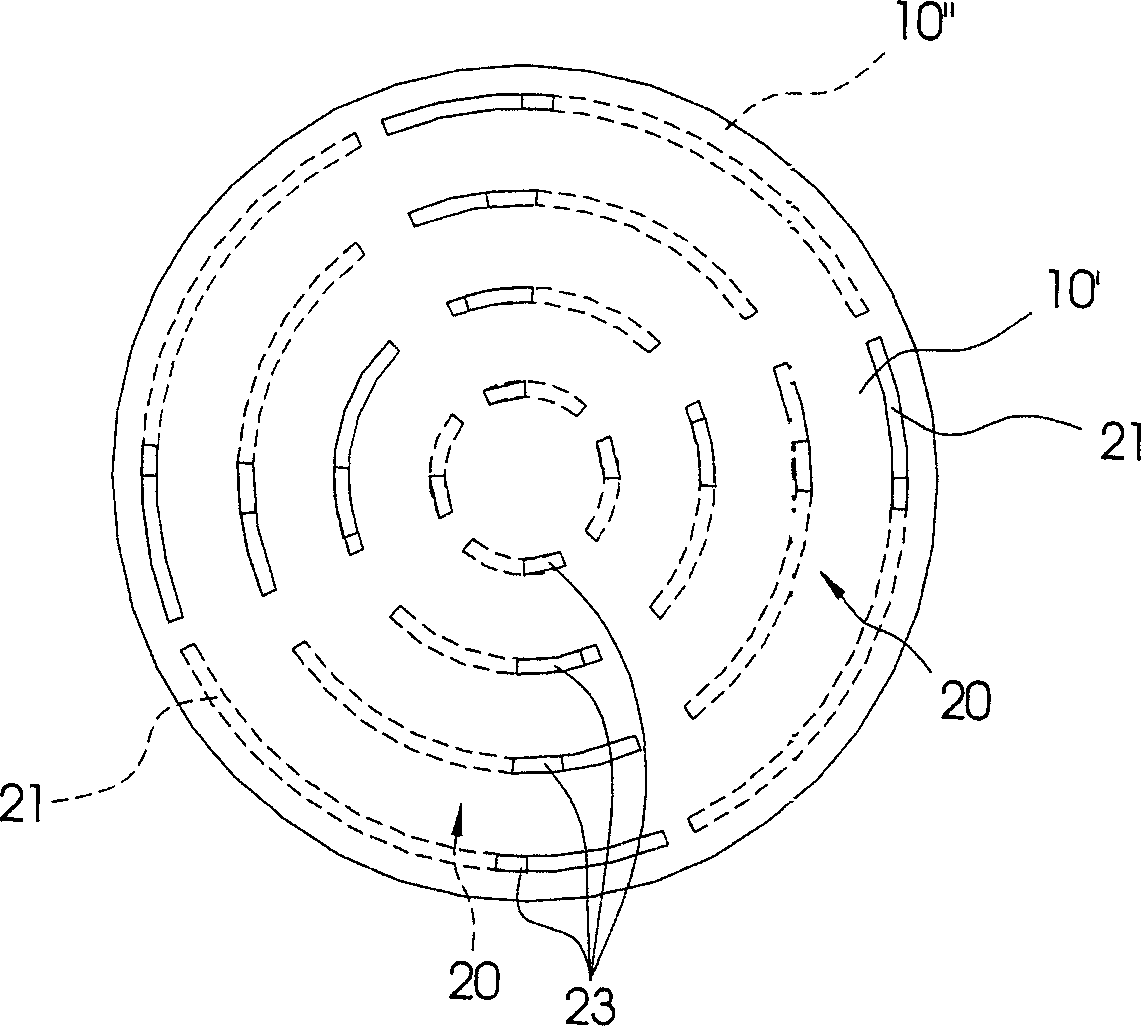

[0019] see Figure 1 to Figure 4 Shown, the present invention is a kind of rotary sprinkler head flow adjustment device, and it comprises two disc bodies 10 and several piercing groove groups 20 on it, and two disk bodies 10 are piled up together, and described piercing groove group 20 are arranged oppositely on the disc body 10 respectively, and the disc body 10 is assembled on a shower head, and the outlet of the shower head is communicated with the through-groove group 20, and through the disc body 10 is relatively rotated to control the size of the communication area of the opposite through-groove group 20, so as to control the flow rate of the fluid flowing out of the spray head through the connected through-groove group 20.

[0020] see figure 1 and figure 2 As shown, there are four through-groove groups 20 which respectively have four concentric arc-shaped through-grooves 21, and are arranged on the disc body 10 with different radii. Please refer to figure 1 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com