Method for manufacturing grid artificial board core strip

A manufacturing method and technology of wood-based panels, applied in the field of wood product manufacturing, can solve the problems of high density of wood-based panels, large growth stress, narrow range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

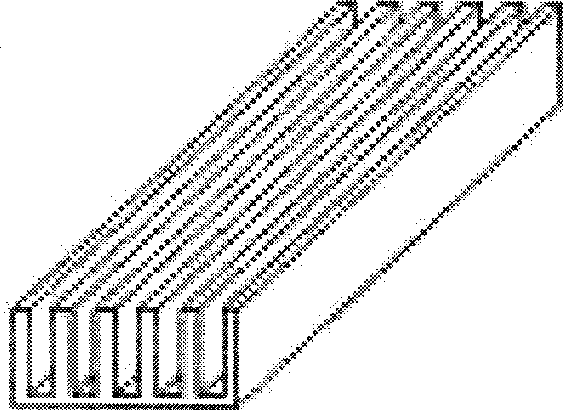

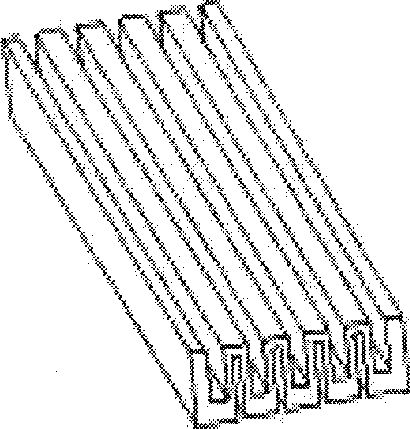

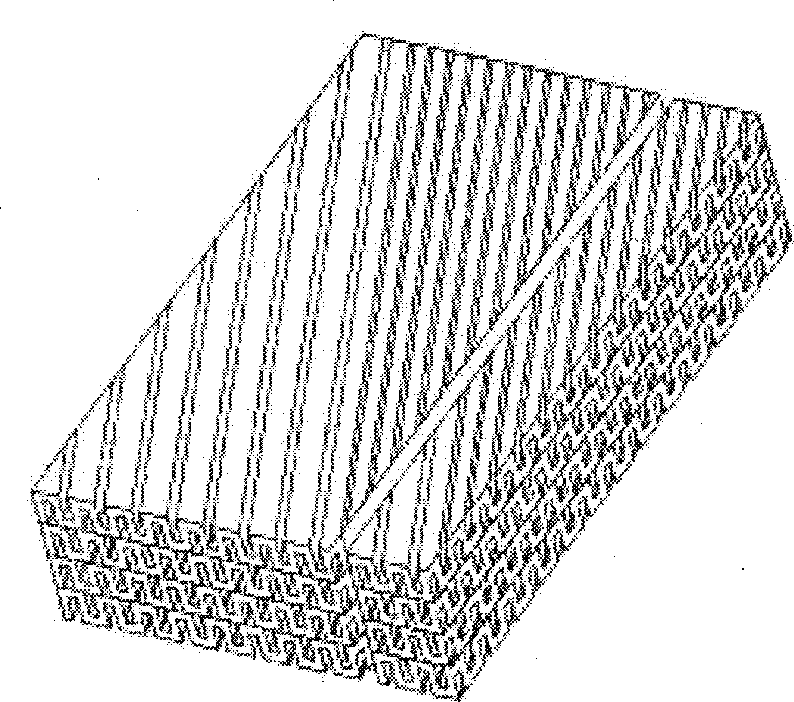

[0007] A best embodiment of the present invention, a manufacturing method of grid-based wood-based board core strips: small-diameter fast-growing forest wood boards are used as raw materials, the moisture content is 8%-12%, the length is less than 4000mm, the width meets the requirements of planing equipment, and the thickness is 15mm -70mm; special-shaped laminate processing: processing parallel to the length direction of the plate, making the plate into a special-shaped plate, such as figure 1 Comb plate as shown or as figure 2 For the bow-shaped plate shown, the groove width is 2mm-8mm, the groove shoulder width is 3mm-10mm, the groove bottom thickness is 3mm-10mm, the ratio of groove width to groove shoulder width is 0.5-1.5, and the ratio of groove shoulder width to groove bottom thickness is 0.5- 1.5; Special-shaped board gluing: The special-shaped board is glued, pressurized, and the adhesive is cured and glued. The grooves of adjacent two layers of special-shaped pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com