Monolithic integrated manufacturing method for indium phosphide-based resonant tunneling diodes and high-electron-mobility transistors

A technology with high electron mobility and manufacturing method, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems affecting production and application, and achieve high yield, good practicability, and strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

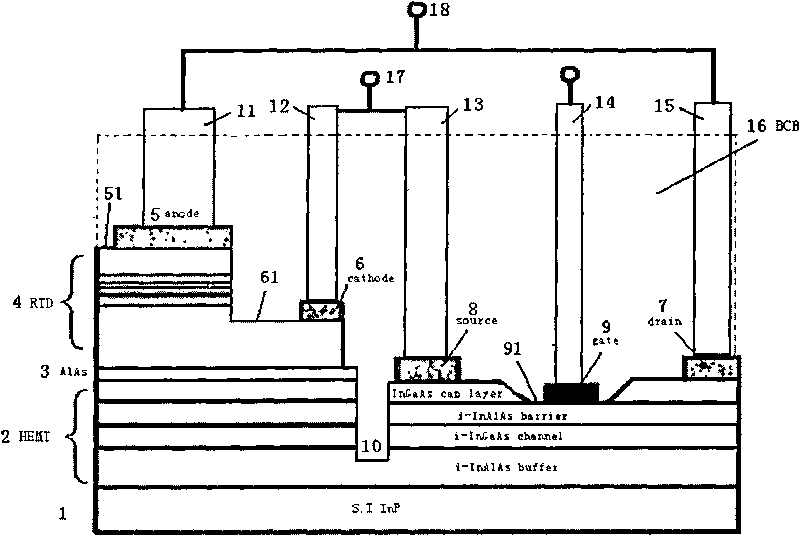

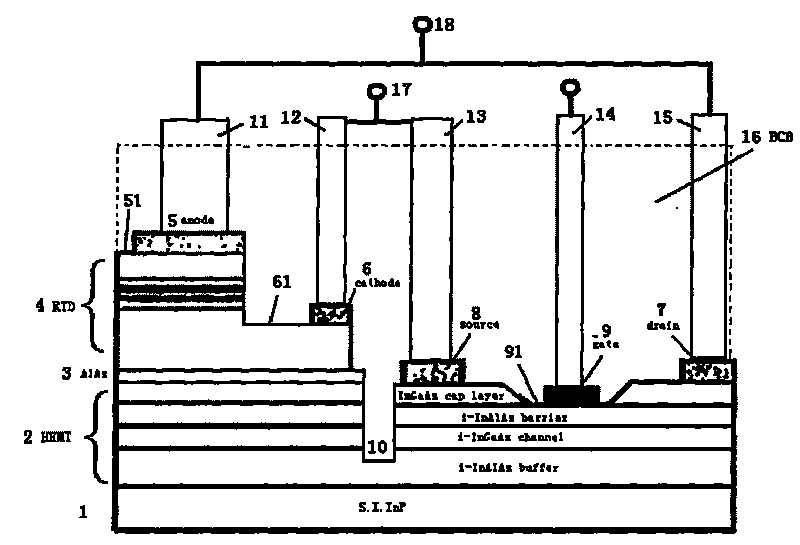

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0034] Such as figure 1 shown.

[0035] A method for monolithically integrating an indium phosphide-based resonant tunneling diode and a high electron mobility transistor, comprising the following steps:

[0036] Step 1: On the semiconductor material indium phosphide (InP) substrate 1, use molecular beam epitaxy (MBE) equipment to grow high electron mobility transistor (HEMT) material layer 2, aluminum arsenic (AlAs) isolation self-stop layer 3 and resonance in sequence Tunneling diode (RTD) material layer 4 structure; wherein aluminum arsenic (AlAs) isolates the self-stop layer 3 to realize the corrosion self-stopping of succinic acid (SA) etching solution, and simultaneously realizes the resonant tunneling diode material 4 and high electron mobility transistor Isolation of material 2;

[0037] Step 2: On the resonant tunneling diode (RTD) material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com