Silicon substrate nitride ultraviolet LED chip structure and implementation method therefor

A technology of LED chips and implementation methods, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of poor heat dissipation of ultraviolet LED chips, expensive AlN substrates, and difficult to achieve commercialization, and achieves suitable for large-scale production. Good electrical and thermal conductivity, the effect of reducing absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

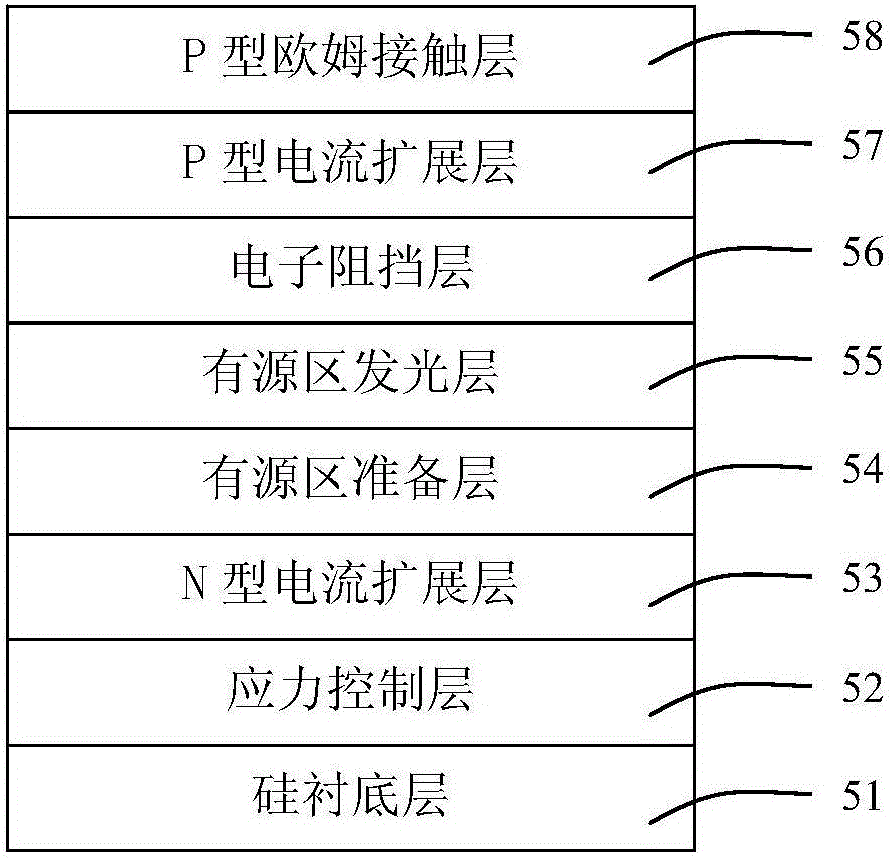

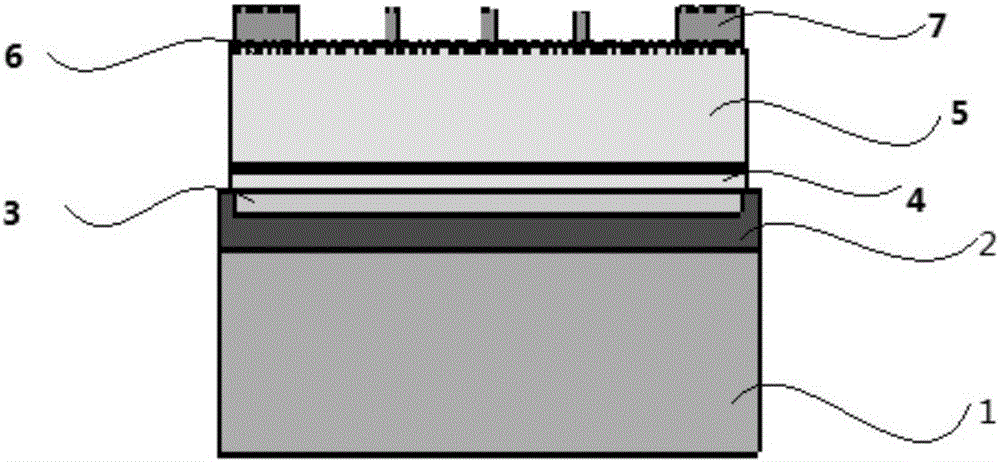

[0059] Based on the silicon-substrate ultraviolet LED epitaxial structure provided by the present invention, a silicon-substrate ultraviolet light-emitting diode chip structure is prepared in this embodiment. The structure is shown in FIG. 3 , and the preparation process includes the following steps: as shown in FIG. 3 .

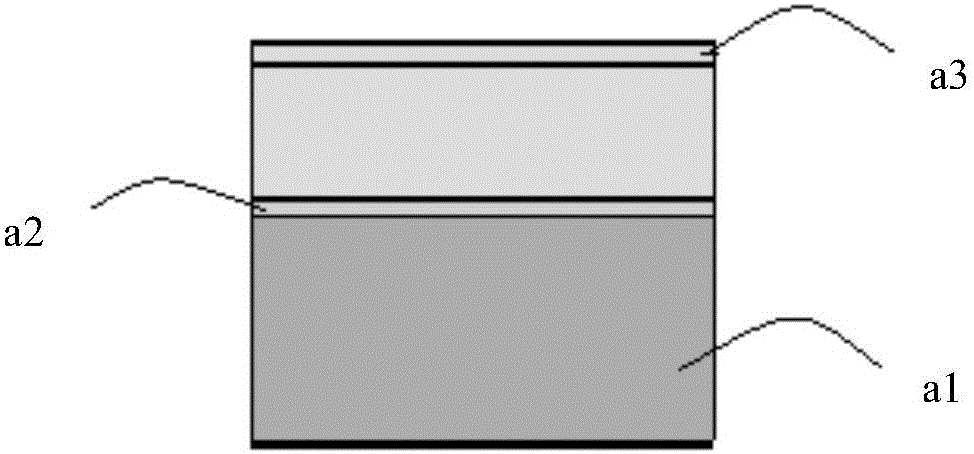

[0060] Such as Figure 3a First, the surface layer of the silicon substrate ultraviolet LED epitaxial structure, that is, the p-type ohmic contact layer a3, is surface-cleaned with acetone and alcohol, and then it is surface-treated with sulfuric acid: hydrogen peroxide: water = 1:1:3 to ensure that the surface is free of any impurities. Next, Mg activation annealing is carried out on the epitaxial structure whose surface has been cleaned. The annealing conditions are: at 550°C, N 2 :O 2 Anneal for 3 minutes (minutes) in an environment with a ratio of 4:1. In addition, in Figure 3a Among them, a1 is the silicon substrate layer, a2 is the stress control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com