Manufacturing method for grid and semiconductor device, construction for manufacturing grid

A manufacturing method and semiconductor technology, applied in the manufacture of gates and semiconductor devices, and in the field of gate structure, can solve the problems of poor profile of gate 104a, influence on gate switching characteristics, large sidewall roughness, etc., and achieve reduction Small roughness, improved opening sensitivity, and the effect of protecting the side wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

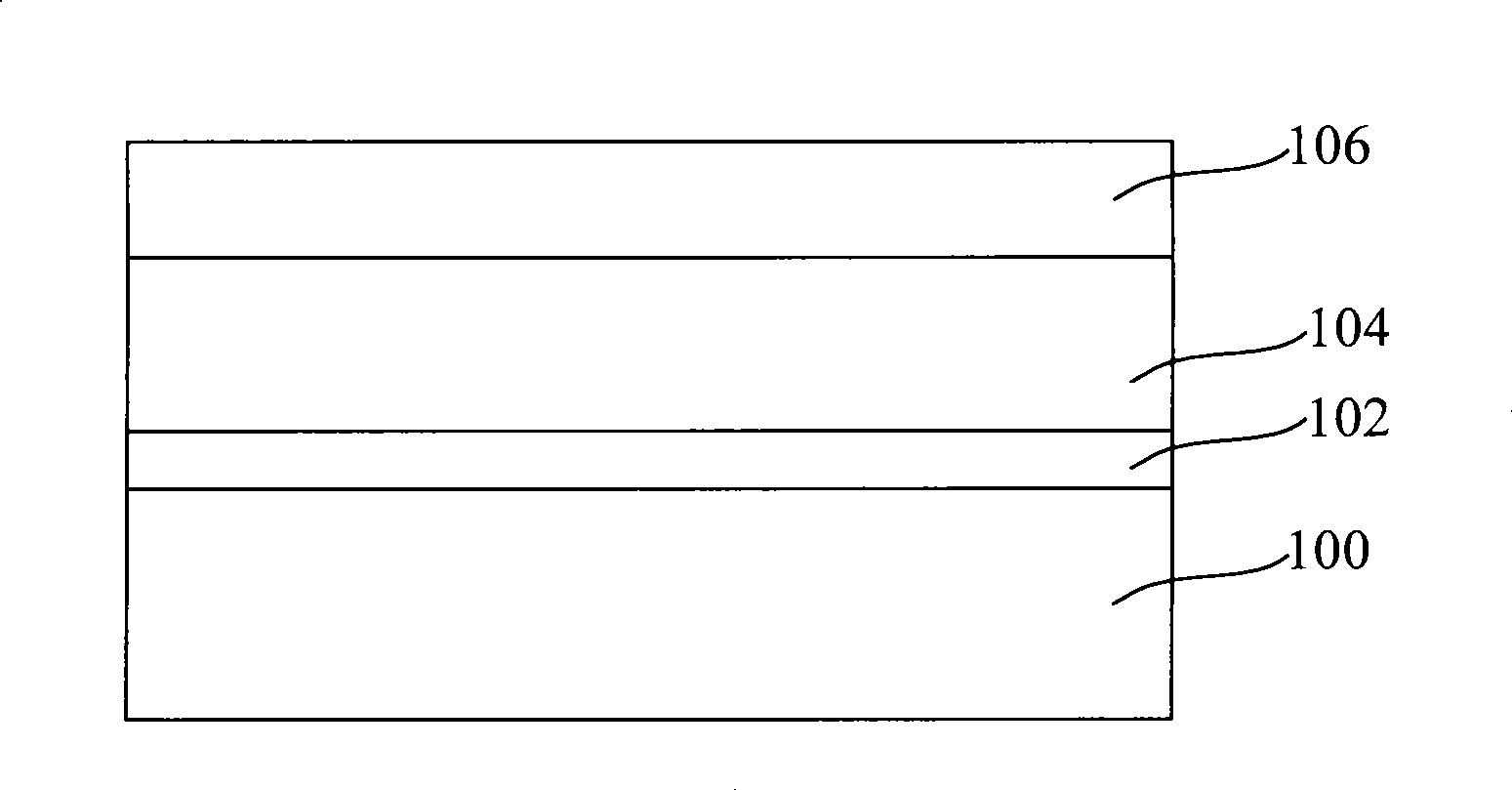

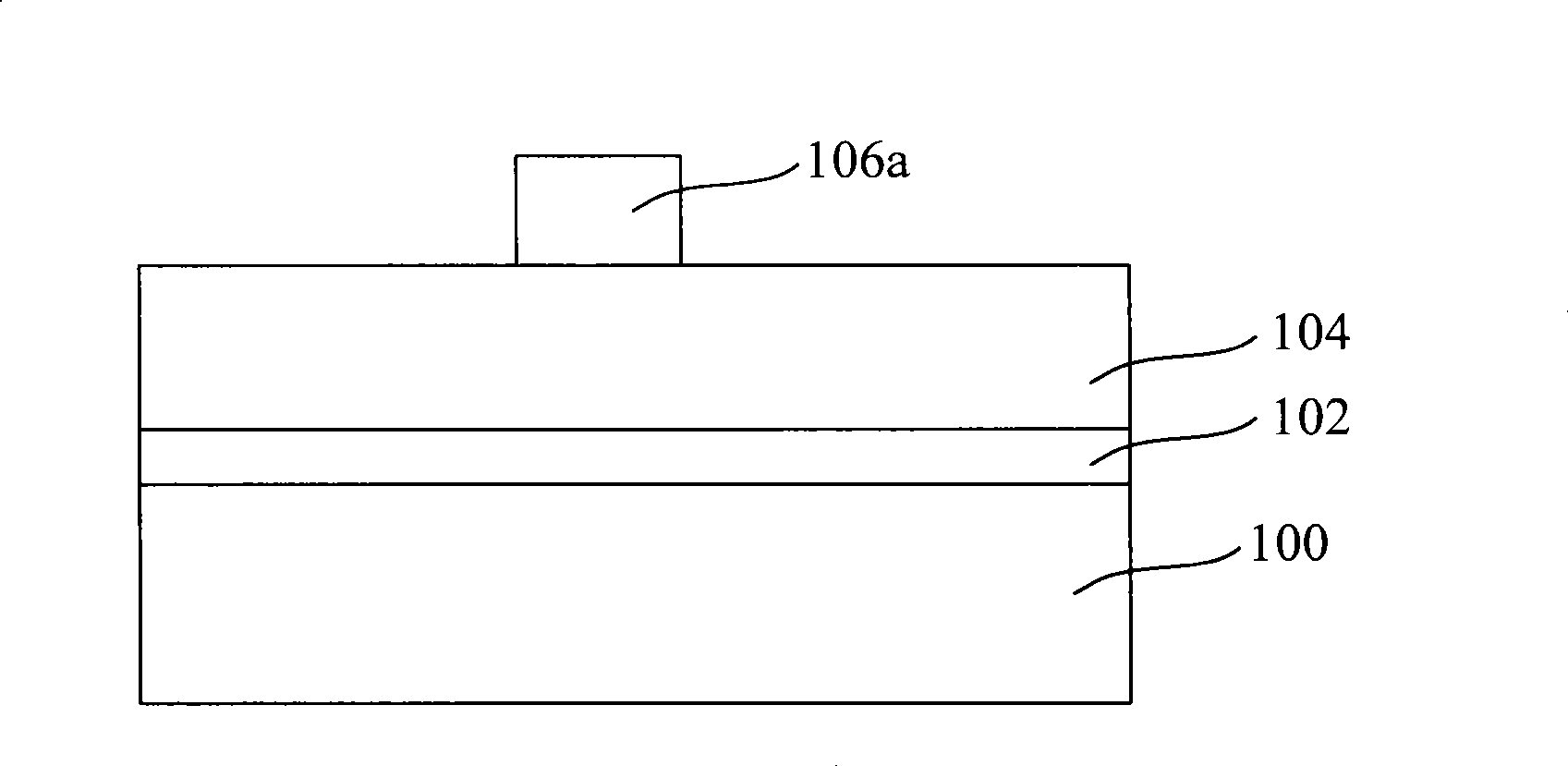

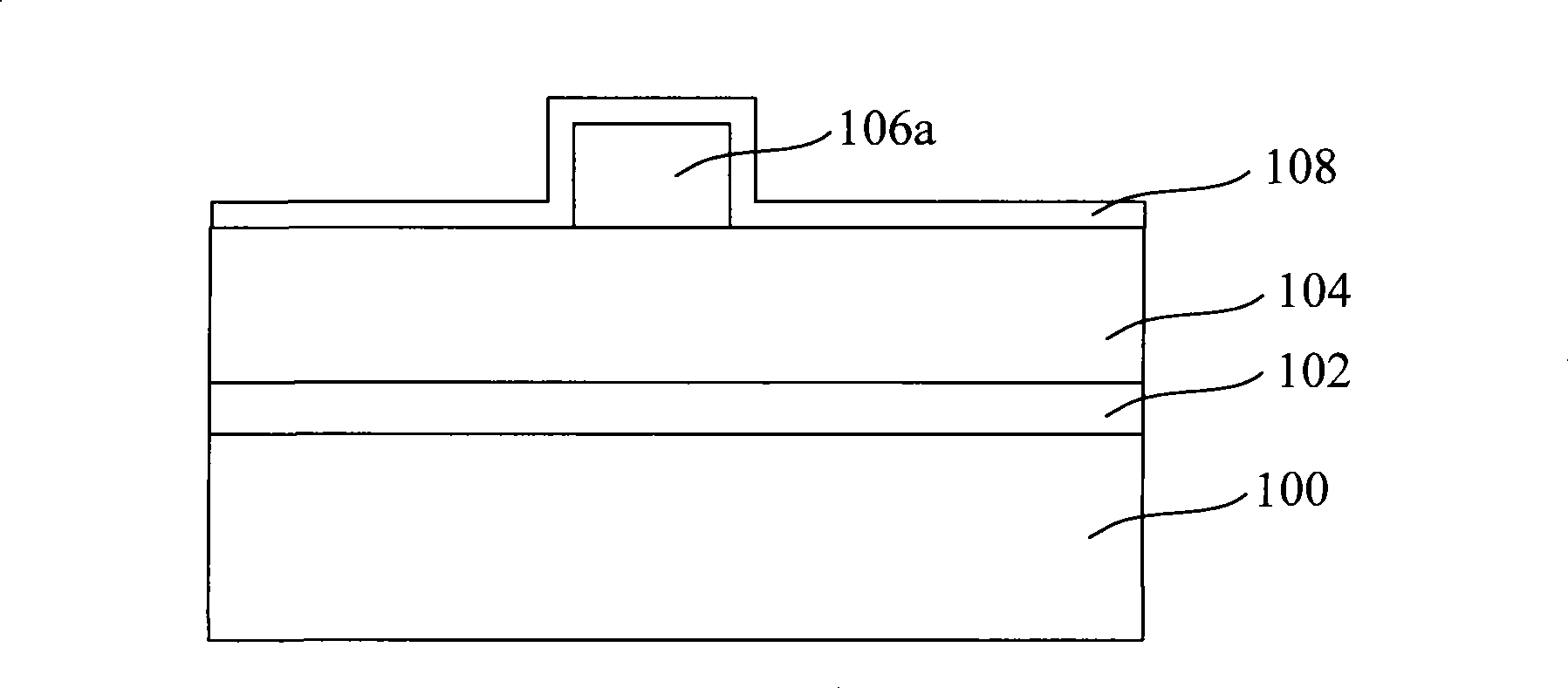

[0054] Figure 7 to Figure 17 It is a schematic cross-sectional view of the structure corresponding to each step of the embodiment of the method for manufacturing the gate of the present invention.

[0055] Such as Figure 7 As shown, a semiconductor substrate 10 is provided. The material of the semiconductor substrate 10 may be one of monocrystalline silicon, polycrystalline silicon, and amorphous silicon. The material of the semiconductor substrate 10 may also be a silicon germanium compound. The semiconductor substrate 10 may also have a silicon on insulator (SOI) structure or an epitaxial layer on silicon structure (not shown). The semiconductor substrate 10 may be doped with N-type impurities or P-type impurities to form an N-well or a P-well.

[0056] A gate dielectric layer 11 is formed on the semiconductor substrate 10. The gate dielect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com