Preparation method and preparation device of marble tiles with entire-body textures

A technology for preparing device and textured stone, applied in the field of decorative building materials, can solve problems such as lack of texture simulation and rigid effect, and achieve the effect of few operation steps and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing stone tiles with a whole body texture, comprising the following steps:

[0031] (1) Scan the selected natural marble stone to obtain a large-scale design drawing; the large-scale design drawing includes a line texture area and a background area, and the line texture area is distributed on the background area at intervals.

[0032] (2) According to the texture feature of design drawing described in step (1), make the grid that is used for the green body push material cloth; Horizontal bar; the grid sheet is a curved stainless steel cloth grille prepared according to the texture of the large-scale design drawing and has a consistent texture. Each area of the grid sheet is formed with different intervals of base material or colored line texture material, and these intervals are random distribution and the size, thickness and width of these intervals are not the same.

[0033] (3) After the material is distributed by the material distribution devic...

Embodiment 2

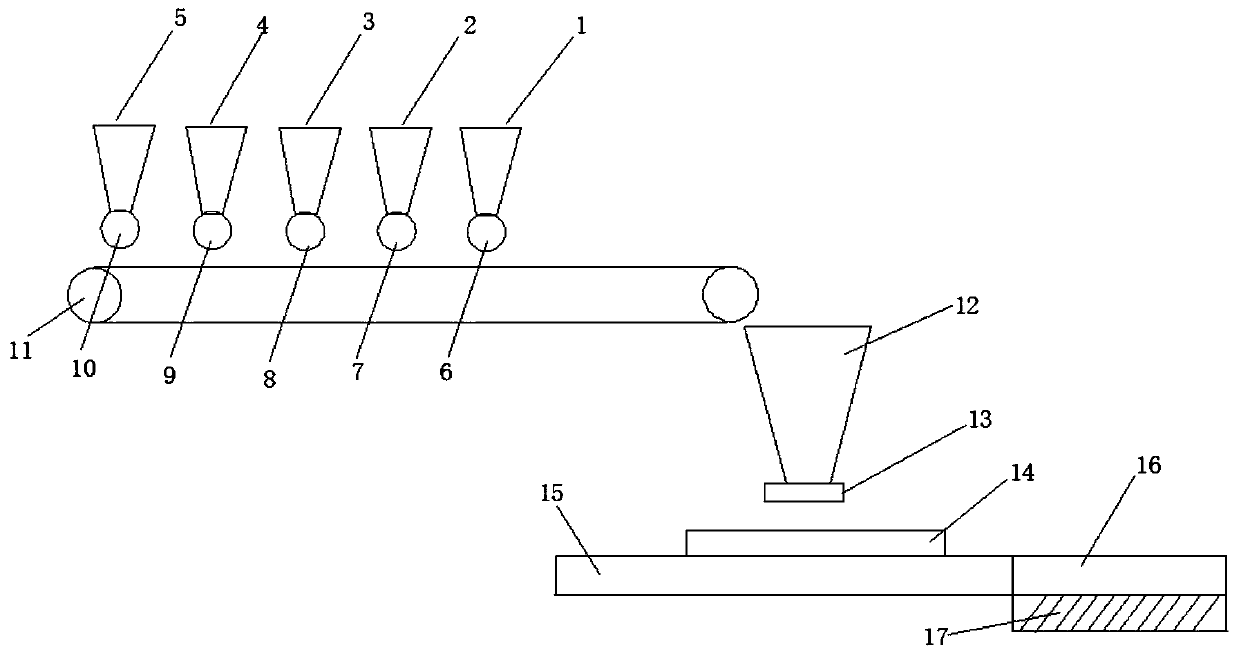

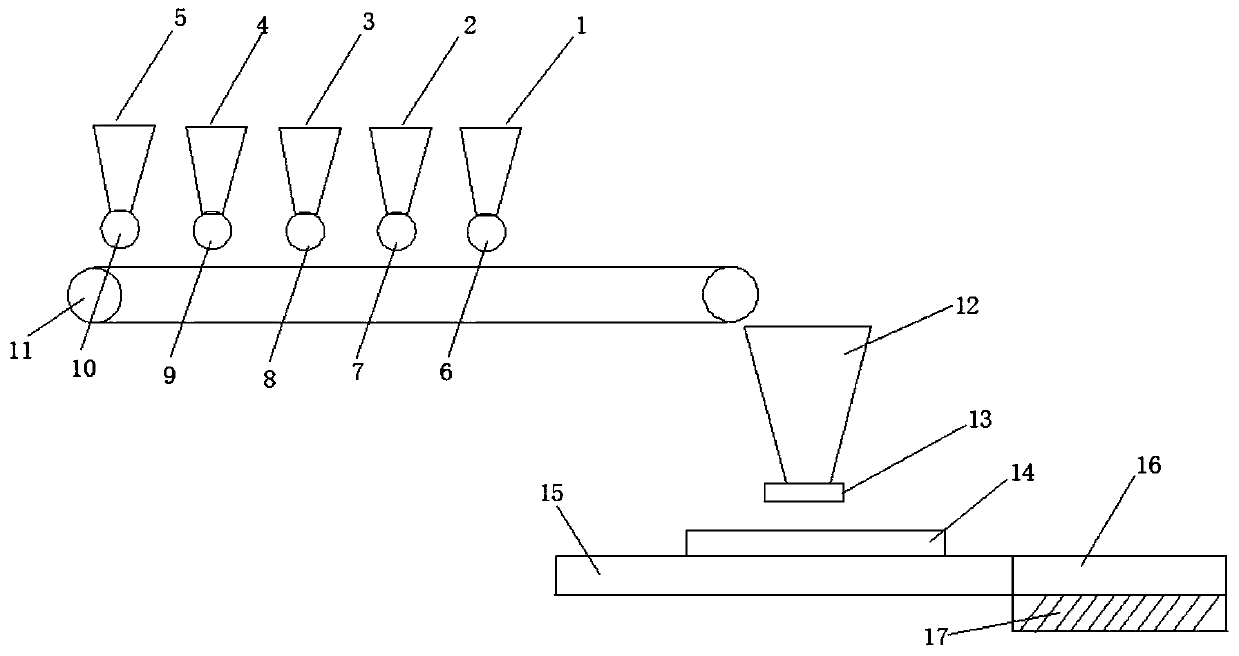

[0036] A preparation device for whole-body textured stone tiles, including a distribution hopper, a roller, a conveyor belt, a collection hopper, a cloth grid, a base plate and a press mold, and there are several distribution hoppers, each of which is connected with a A roller, the roller is arranged above the starting end of the conveying direction of the conveyor belt, the roller includes a full-body roller and a grooved roller, and the grooved roller is provided with grooves of different sizes and protruding outwards inside the roller , the bottom of the groove is provided with a groove roller outlet, and the whole body roller is uniformly provided with a whole body roller outlet; the collection hopper is installed below the end of the conveyor belt transmission direction, and can catch the conveyor belt to upload For the powder sent over, the lower end of the collecting hopper is provided with an on-off valve, the distribution grid is arranged under the collecting hopper, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com