Integrated adjustor, namely rectifier bridge of automobile alternating-current generator

A technology for alternators and regulators, applied in the direction of adjusting connections, electrical components, electromechanical devices, etc., can solve the problems of high production input costs, time-consuming installation, and large generator space, so as to reduce production input costs and reduce manufacturing costs. , the effect of simplifying the product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

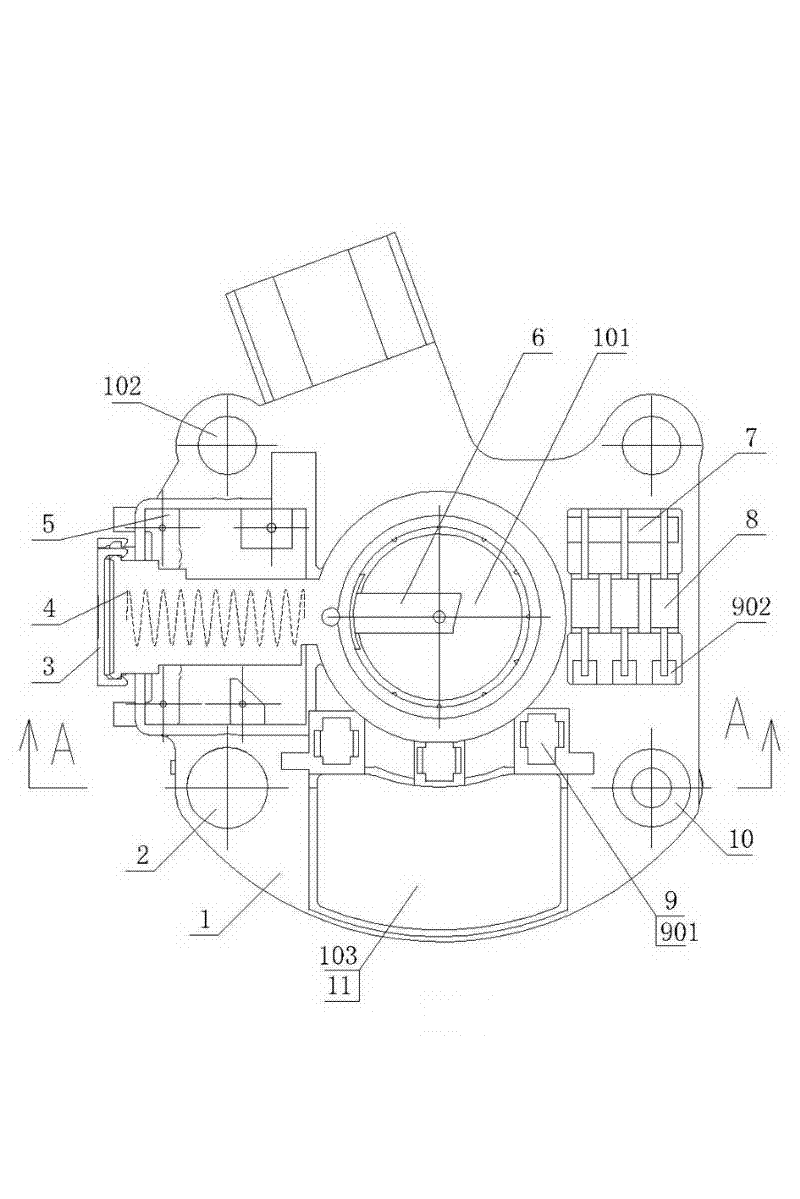

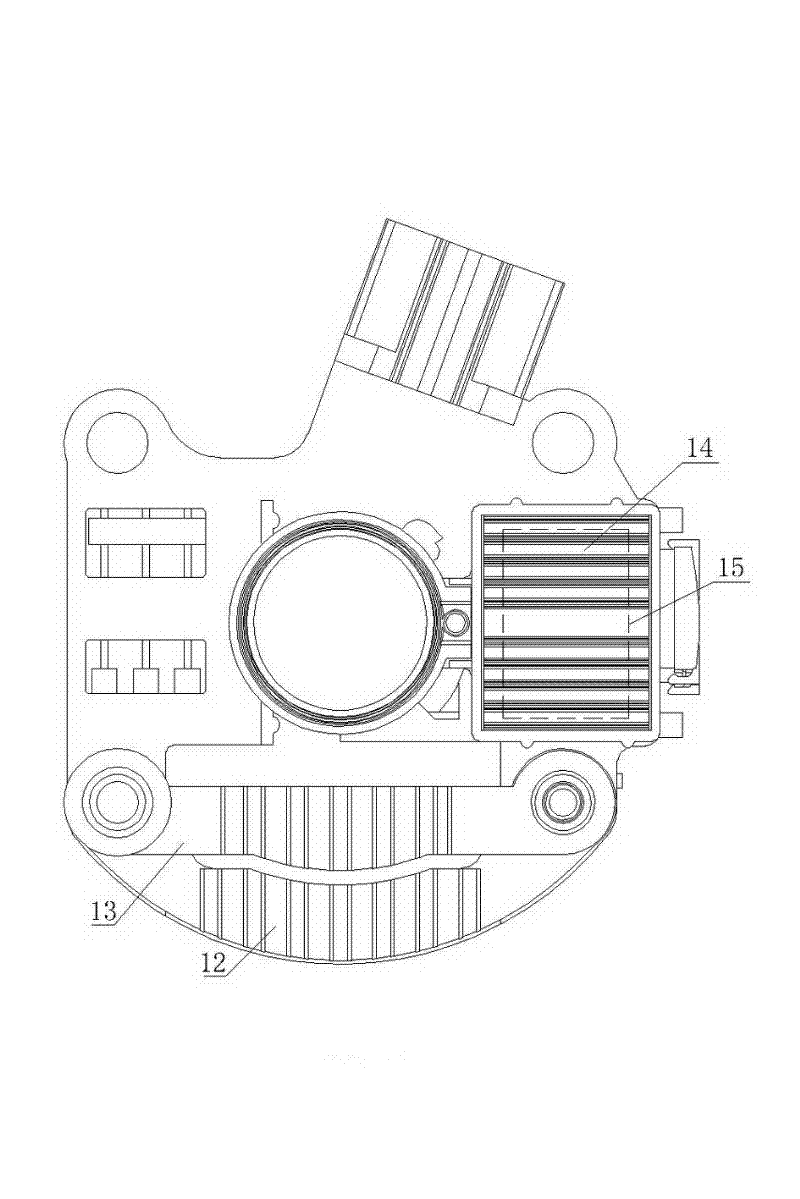

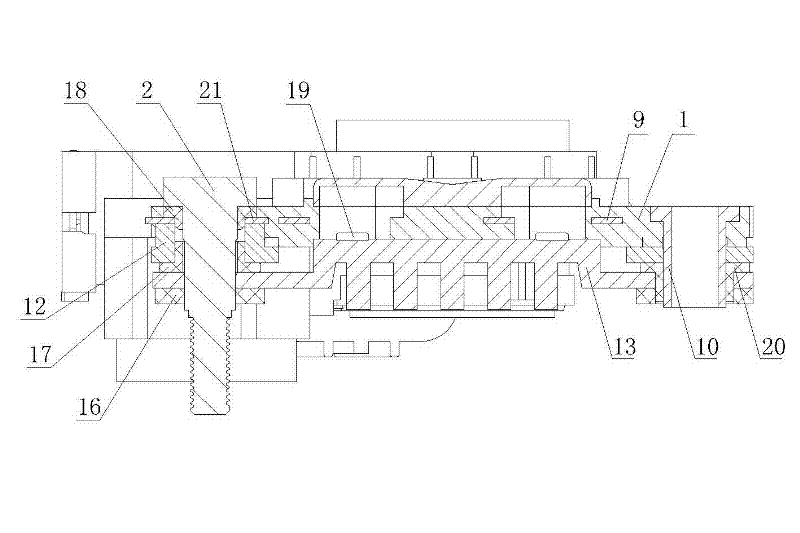

[0017] As shown in the figure, the automotive alternator integrated regulator-rectifier bridge has a regulator frame 1, a regulator cooling fin 14 is sealed and bonded in the notch on the regulator frame 1, and the regulator cooling fin 14 The inner surface is bonded with a regulator hybrid integrated circuit 15, and the regulator hybrid integrated circuit 15 has a carbon brush connection terminal F, a ground terminal G, an indicator lamp connection terminal L, an ignition terminal I, and four terminals of the regulator hybrid integrated circuit 15 The regulator frame 1 passes through and is respectively welded to a plurality of regulator embedded pieces pre-embedded in the regulator frame 1 . There are two carbon brush installation holes 104 in the regulator frame 1, and carbon brushes 6 and springs 4 are respectively installed in the two carbon brush installation holes 104, and the outer ends of the carbon brush installation holes 104 are located on the regulator frame 1. An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com