Patents

Literature

109results about How to "Shorten the horizontal length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

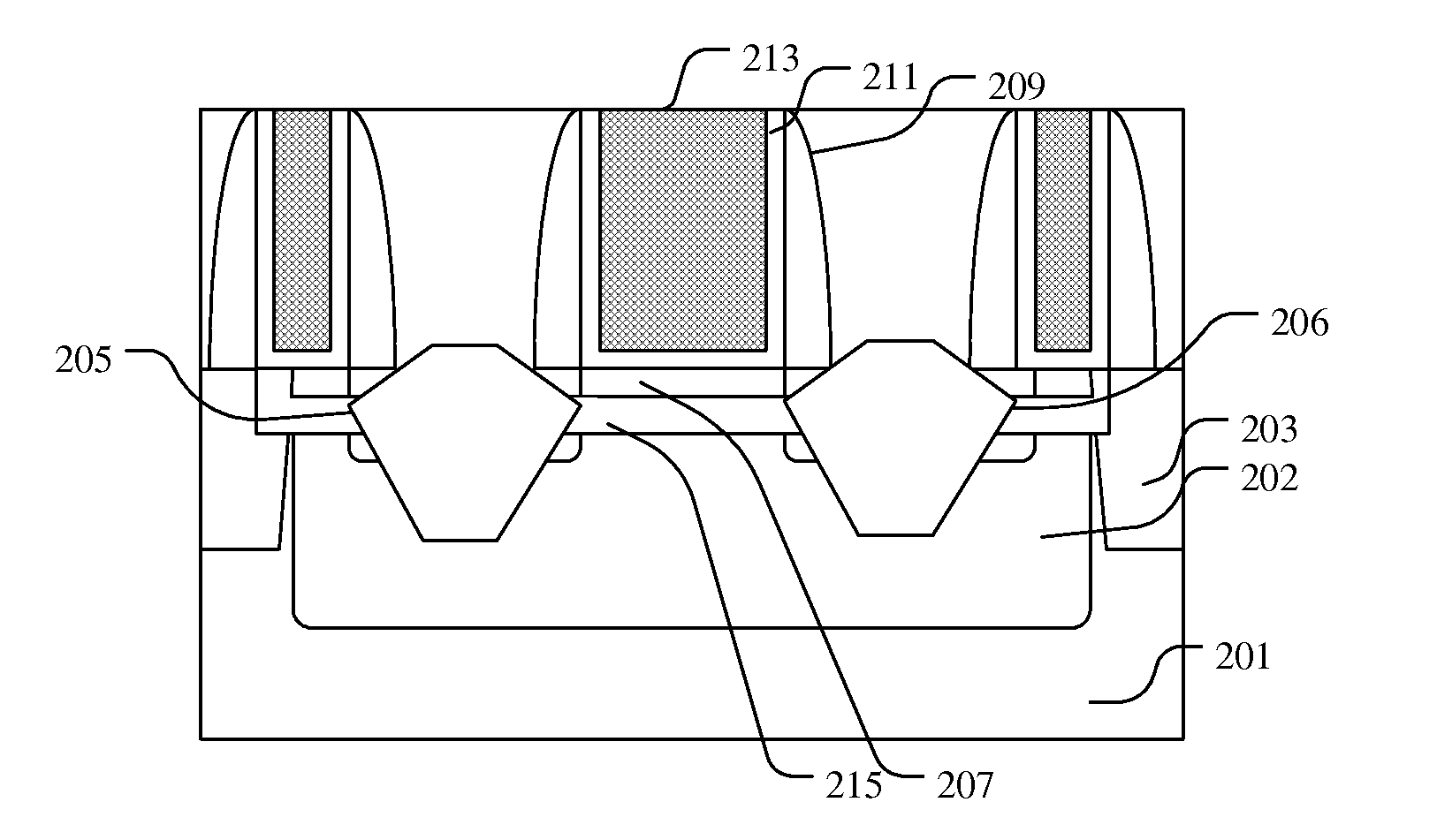

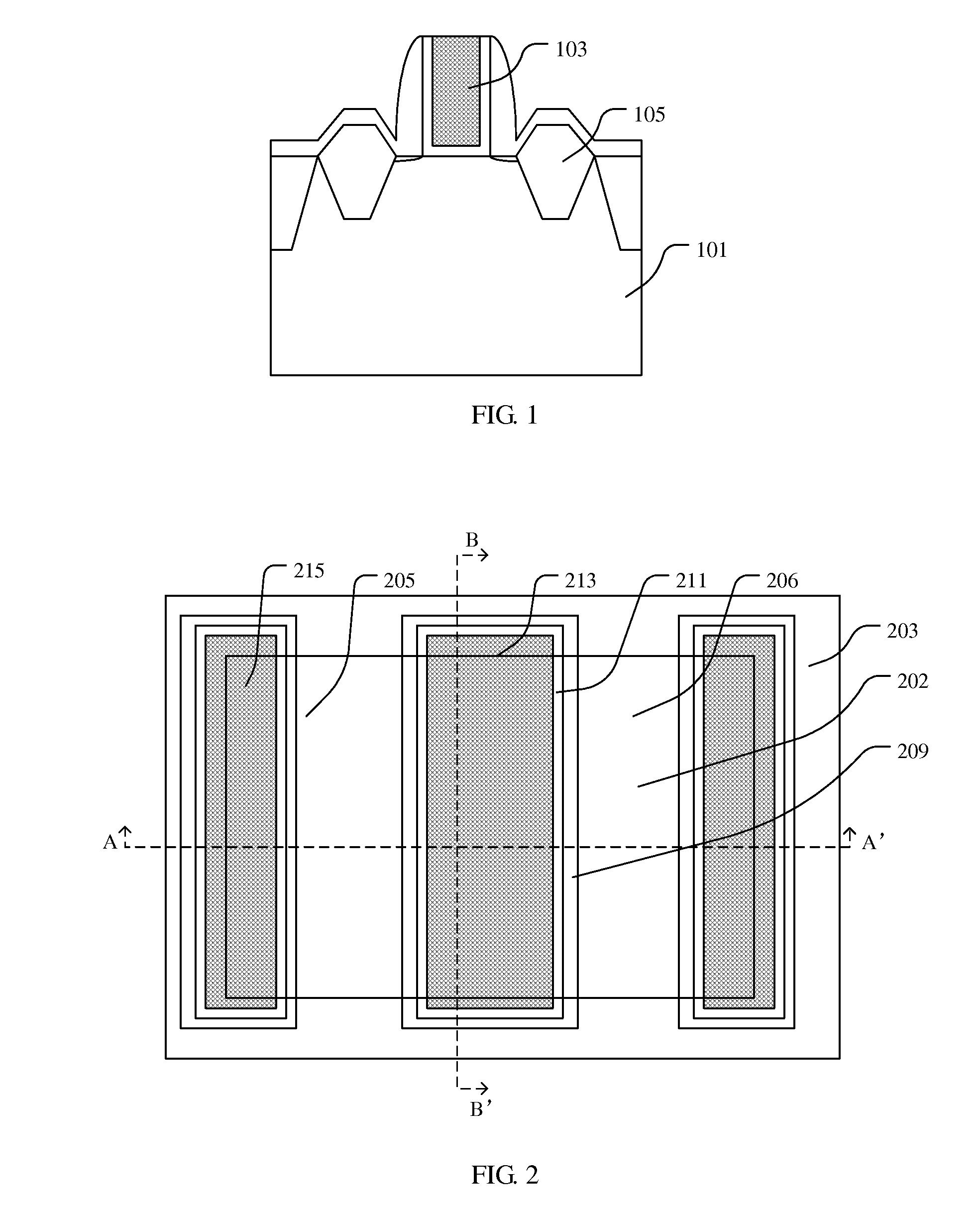

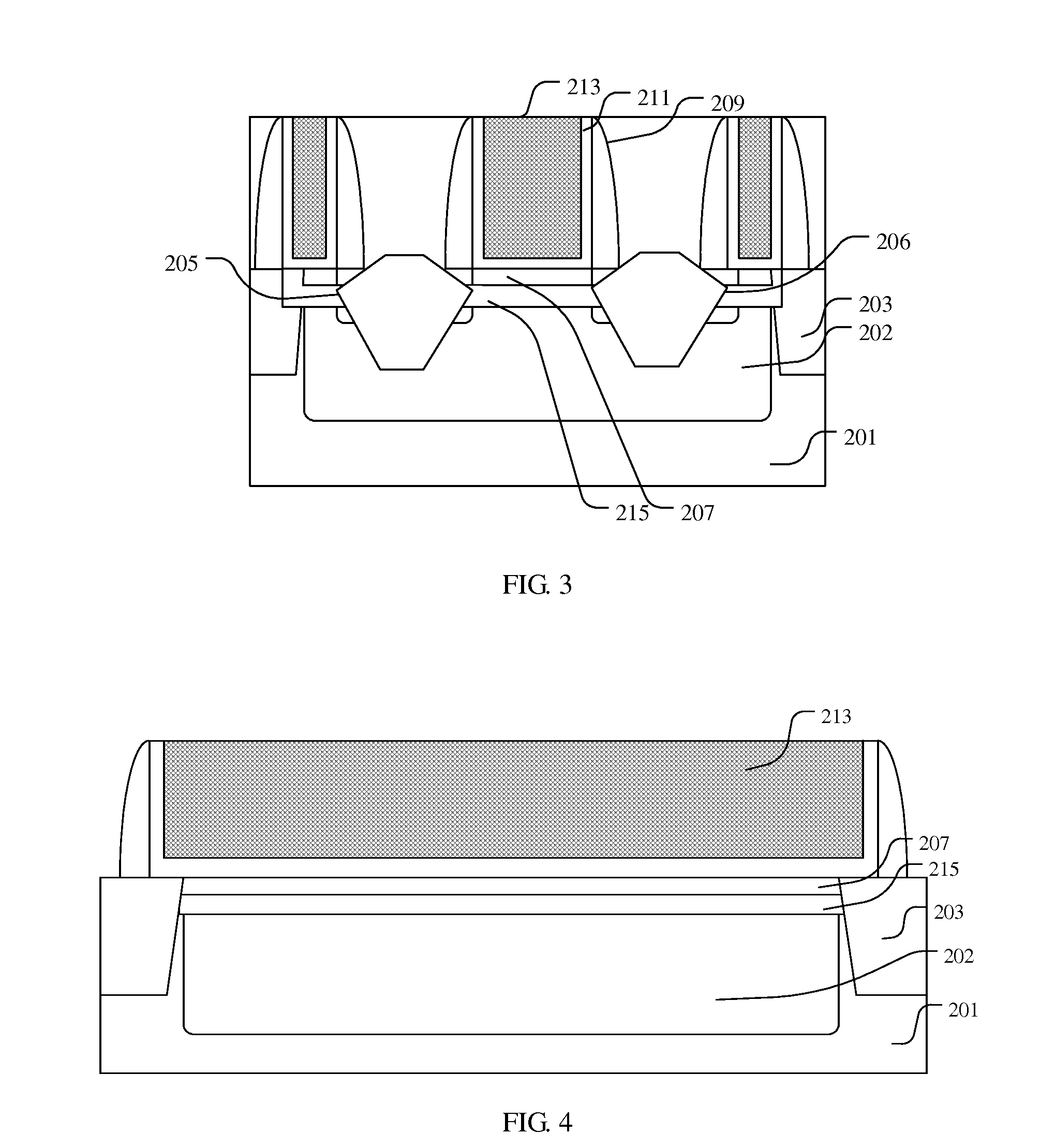

Ultra-thin body transistor and method for manufcturing the same

InactiveUS20120043624A1Decreases effect to effective lengthRegion of becomes thinSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricUltra thin body

An ultra-thin body transistor and a method for manufacturing an ultra-thin body transistor are disclosed. The ultra-thin body transistor comprises: a semiconductor substrate; a gate structure on the semiconductor substrate; and a source region and a drain region in the semiconductor substrate and on either side of the gate structure; in which the gate structure comprises a gate dielectric layer, a gate embedded in the gate dielectric layer, and a spacer on both sides of the gate; the ultra-thin body transistor further comprises: a body region and a buried insulated region located sequentially under the gate structure and in a well region; two ends of the body region and the buried insulated region are connected with the source region and the drain region respectively; and the body region is isolated from other regions in the well region by the buried insulated region under the body region. The ultra-thin body transistor has a thinner body region, which decreases the short channel effect. In the method for manufacturing an ultra-thin body transistor together with the replacement-gate process, the forming of the buried insulated region is self-aligned with the gate, which reduces the parasitic resistance under the spacer.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

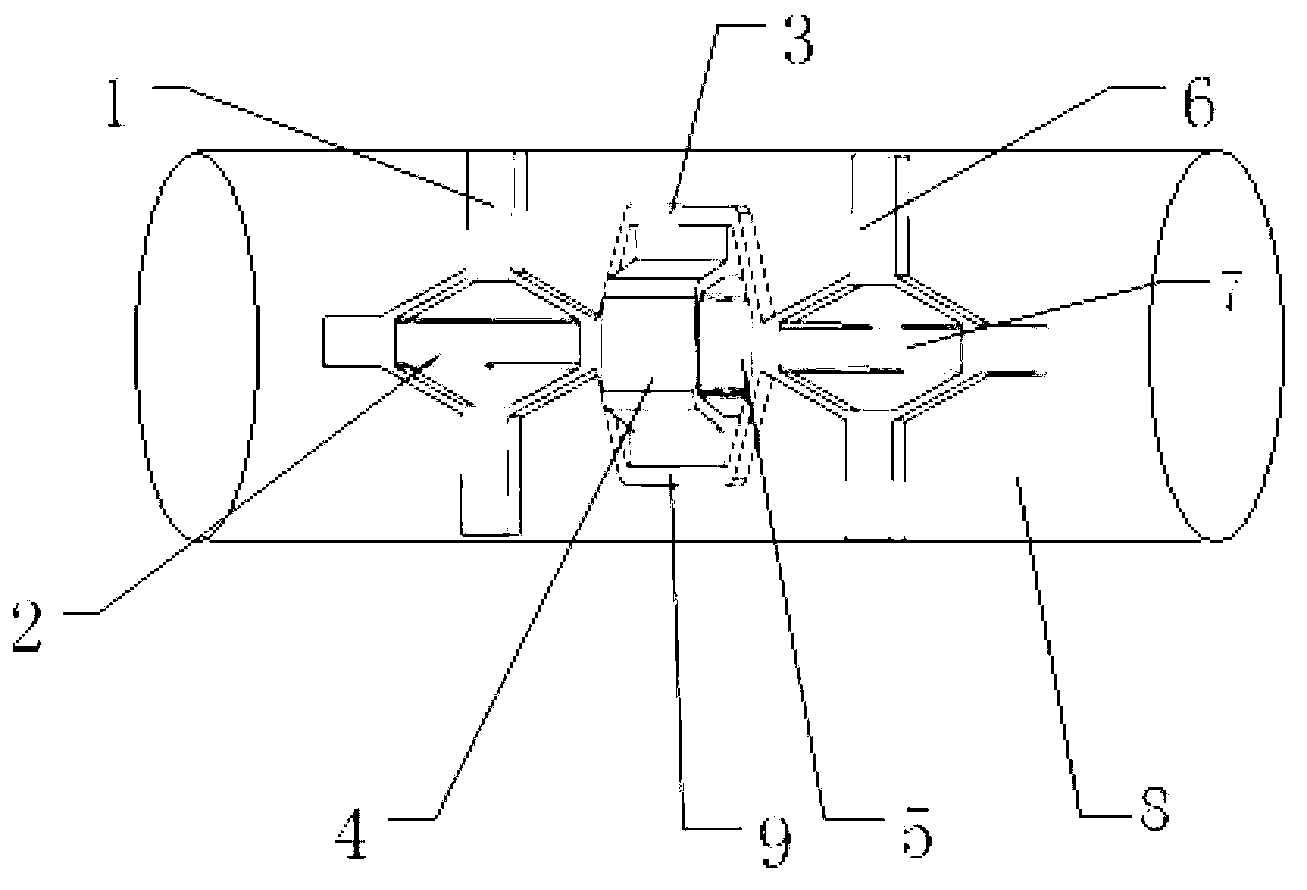

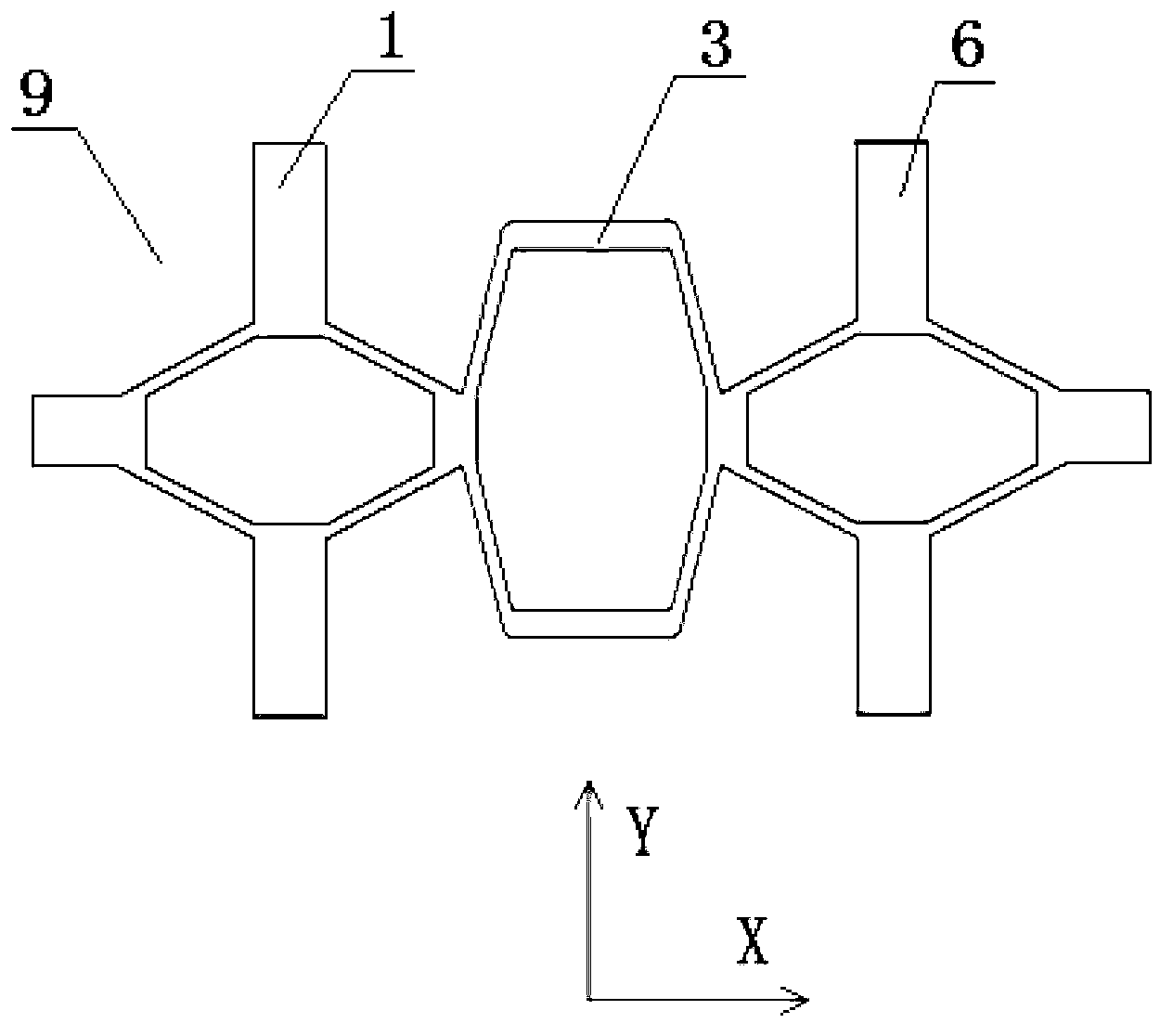

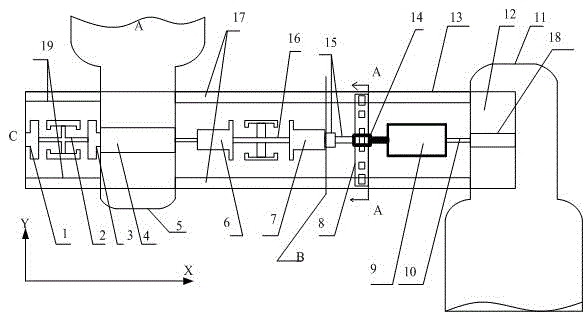

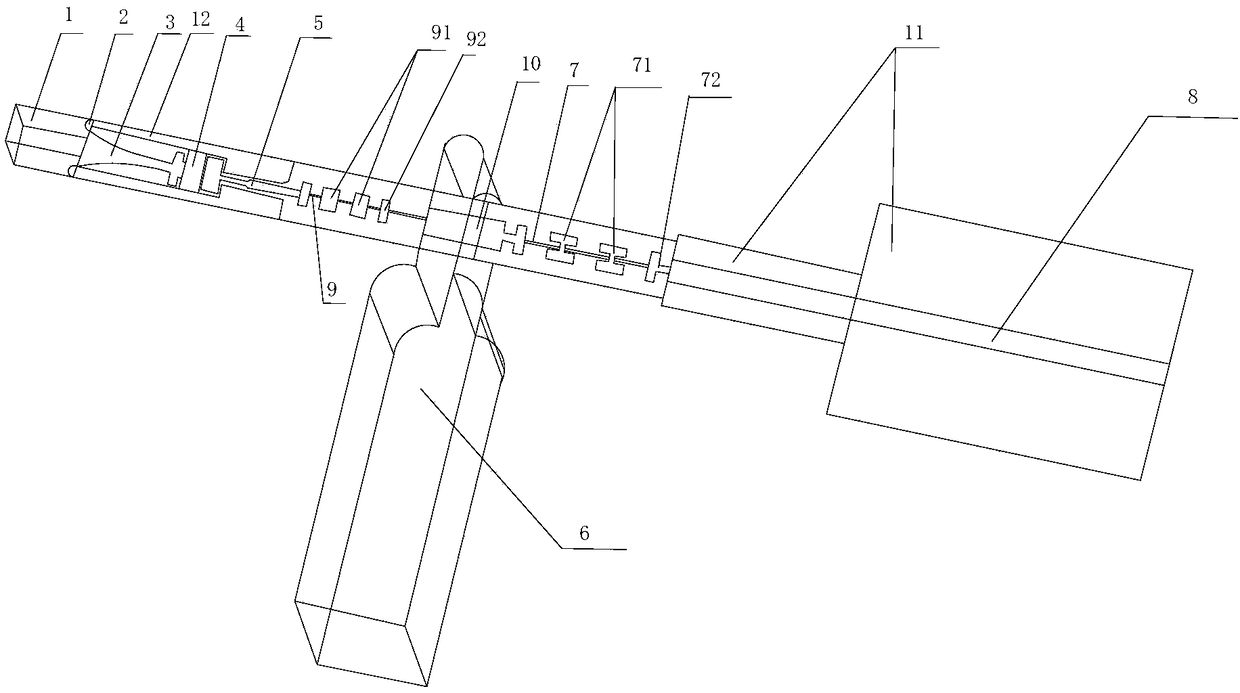

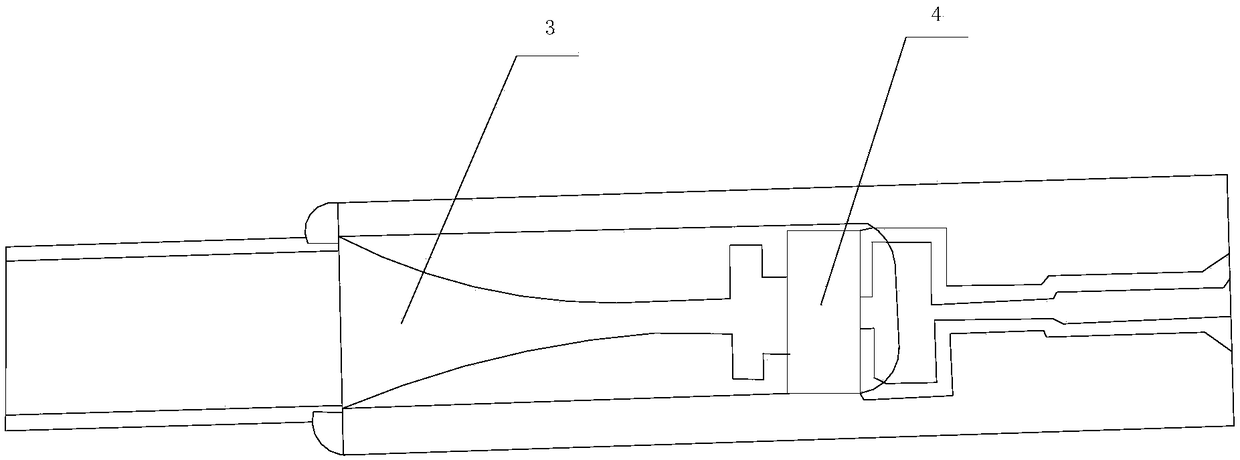

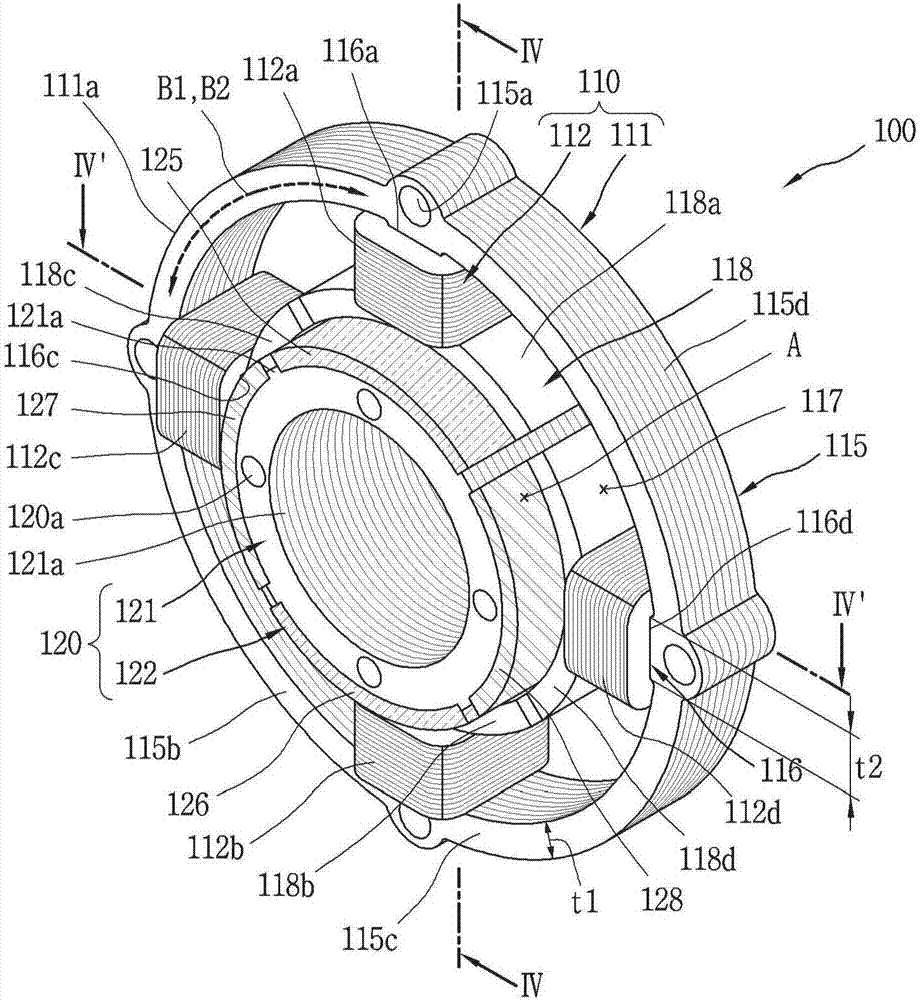

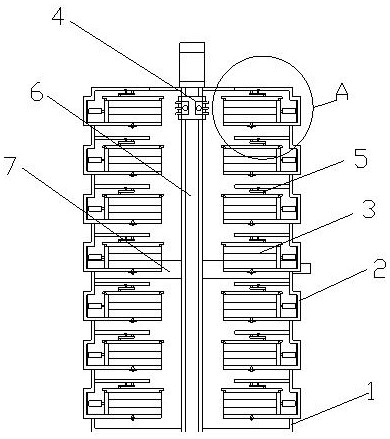

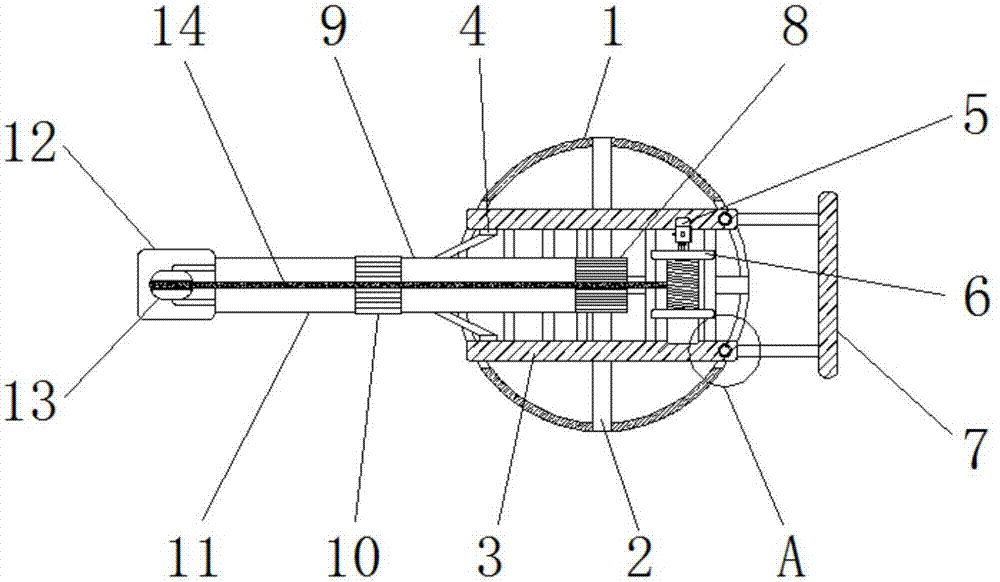

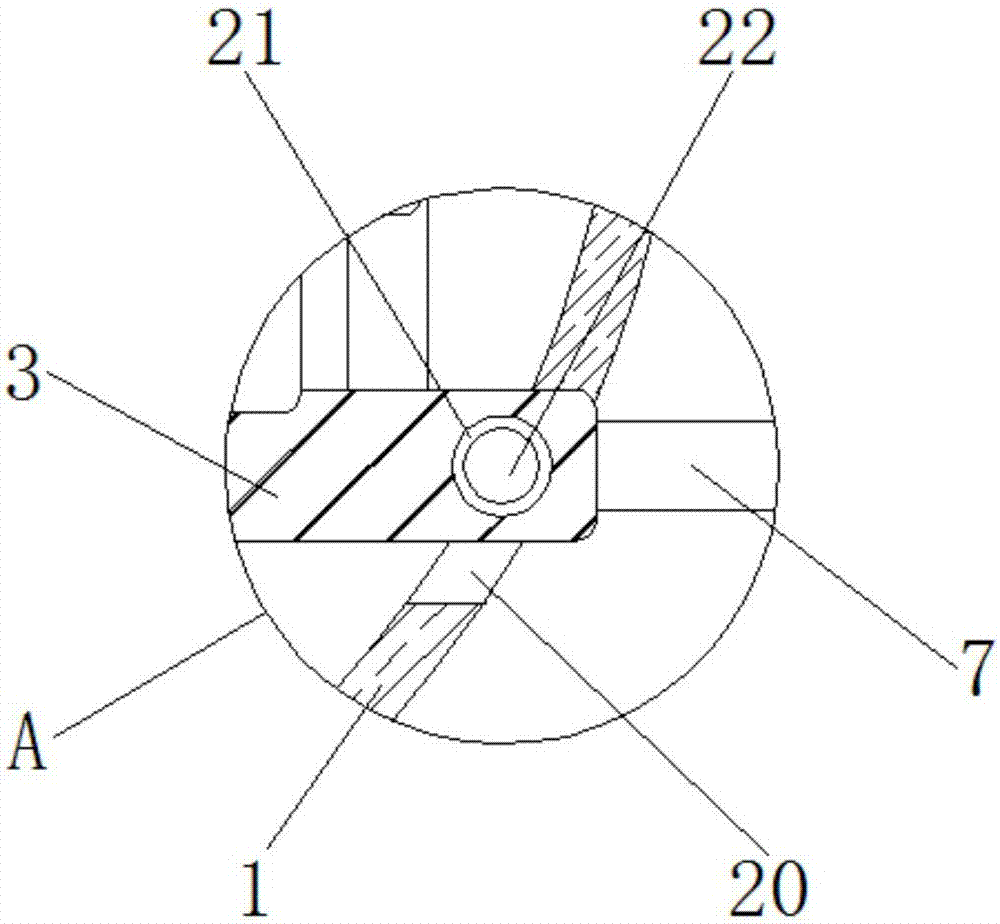

Large-step long-inchworm-type actuator

ActiveCN103326616AIncrease vertical lengthImplement power-down clampingPiezoelectric/electrostriction/magnetostriction machinesBridge typeWire cutting

Disclosed is a large-step long-inchworm-type actuator. The actuator is installed inside a sliding rail. The actuator comprises a connecting ring, a first clamping mechanism and a second clamping mechanism which are fixedly connected to the connecting ring, and an actuating ring which is fixedly connected to the middle portion of the connecting ring. A stretching piezoelectric stack is installed inside the actuating ring, a first clamping piezoelectric stack is installed inside the first clamping mechanism, a second clamping piezoelectric stack is installed inside the second clamping mechanism, and the first clamping mechanism, the connecting ring and the second clamping mechanism form an outer framework of the actuator. The outer framework is integrally machined by the adoption of a slow wire feeding wire cutting machine tool. Bridge-type displacement amplifying mechanisms are adopted in the first clamping mechanism, the second clamping mechanism, the connecting ring and the actuating ring. The large-step long-inchworm-type actuator is large in step size, high in running speed and capable of realizing outage clamping, and meanwhile, has the advantages of being compact in structure, small in size and low in weight.

Owner:XI AN JIAOTONG UNIV

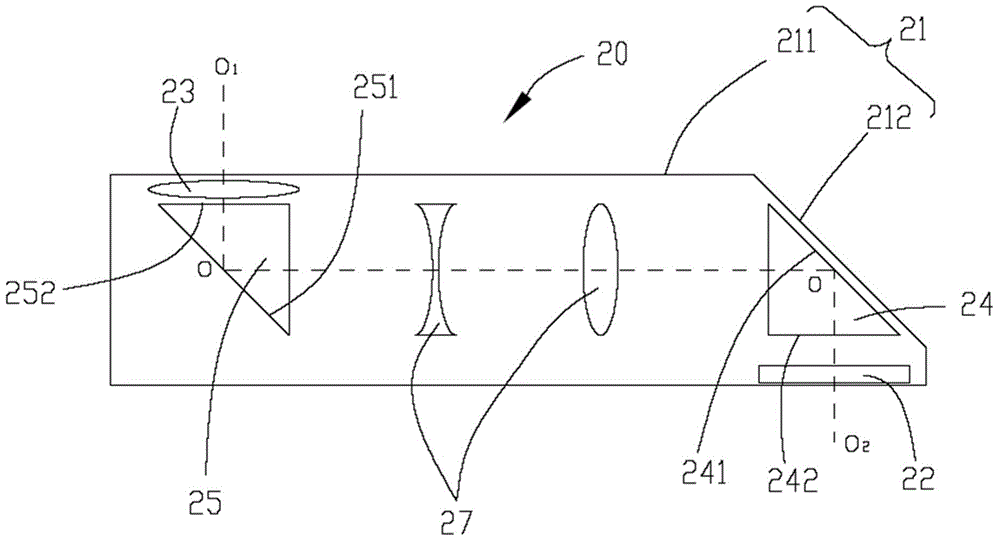

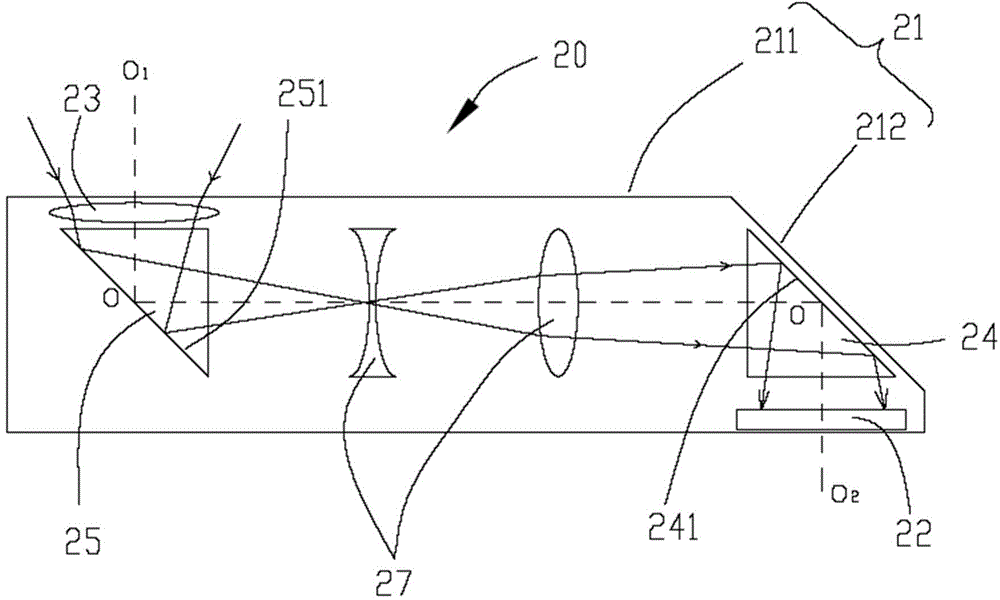

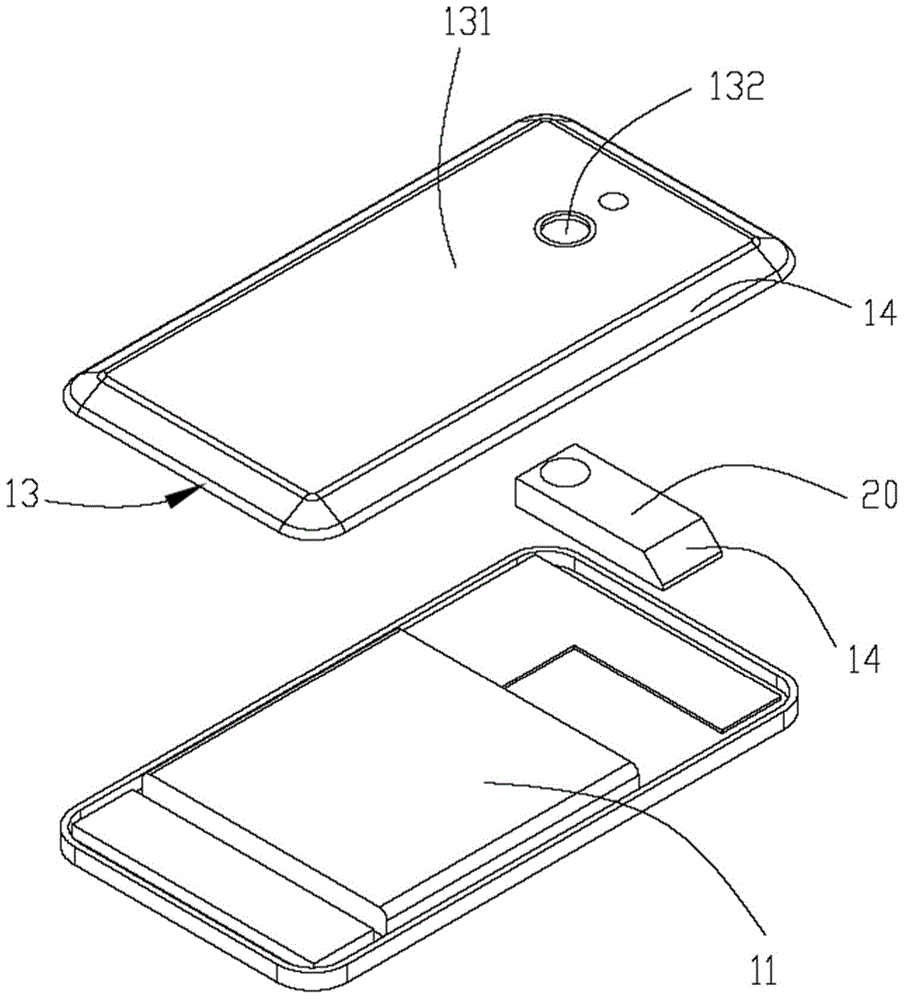

Optical zooming camera module and mobile terminal provided with optical zooming camera module

InactiveCN104635404AShorten the lengthSimple designTelevision system detailsColor television detailsOptoelectronicsCamera module

The invention provides an optical zooming camera module. The optical zooming camera module comprises an optical zooming lens group and an image sensor, and is characterized in that the optical zooming lens group comprises a light incidence lens, a light converting lens and a reflective mirror, wherein the reflective mirror is provided with a reflective slope; the light converting lens and the reflective mirror are positioned at the two ends of the optical zooming lens group; the center line of the light incidence lens is vertical to a center connecting line between the light-converting lens and the reflective mirror; the image sensor and the light incidence lens are positioned on both sides of the center connection line between the light converting lens and the reflective mirror, and are arranged oppositely; the reflective slope faces the image sensor, and is used for receiving light rays entering through the light incidence lens and reflecting the light rays to the image sensor. The invention further provides a mobile terminal.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

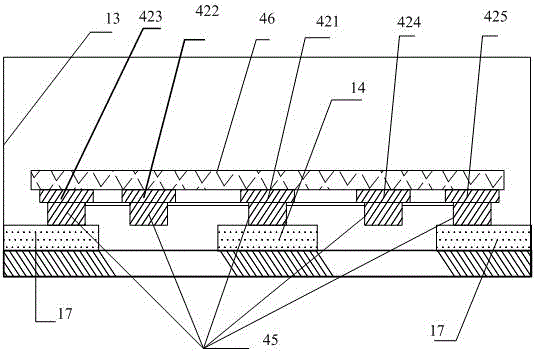

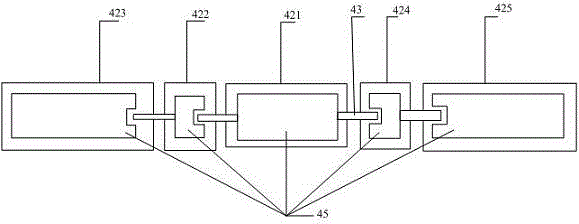

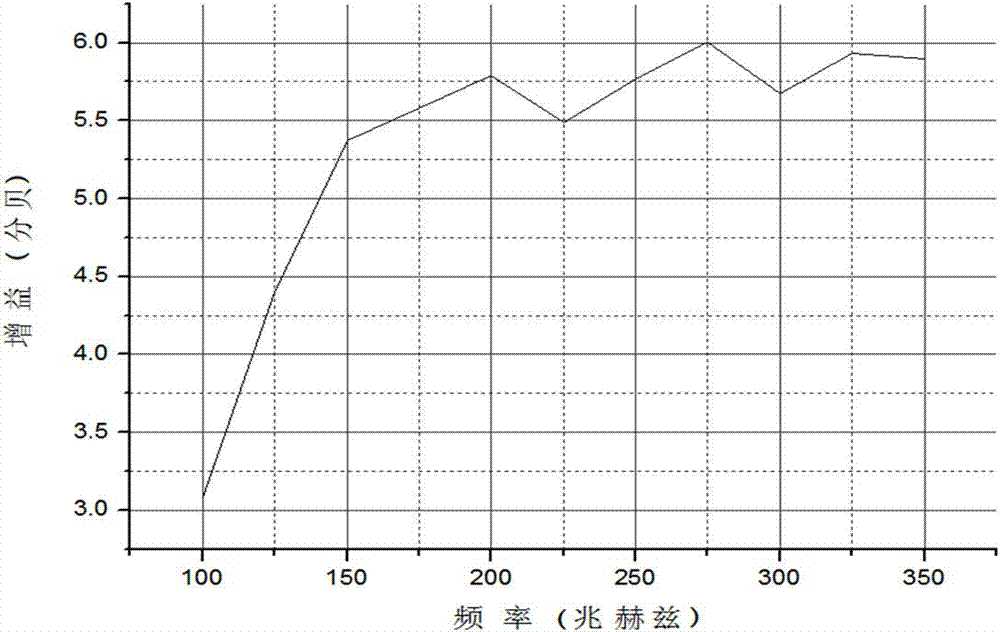

Terahertz frequency tripler based on coplanar waveguide transmission wires

ActiveCN104600403AReduced assembly stepsReduced processing performanceWaveguide type devicesLow-pass filterCoplanar waveguide

The invention discloses a terahertz frequency tripler based on coplanar waveguide transmission wires. The terahertz frequency tripler based on the coplanar waveguide transmission wires comprises three waveguides, including a fundamental wave input wave guide, an output waveguide and a main body waveguide, a dielectric substrate inside the main body waveguide, and electrical structures arranged on the dielectric substrate through the coplanar waveguide transmission wires in an integrated mode, wherein the electrical structures are composed of a DC (direct current) bias low-pass filter, an input matching transmission wire, a fundamental wave low-pass filter, a fundamental wave matching transmission wire, a triple-harmonic matching transmission wire, a three-stage matching transmission wire, a four-stage matching transmission wire and an output matching transmission wire from left to right and takes the coplanar waveguide transmission wires as a ground wire. The coplanar waveguide transmission wires substitute traditional microstrip wires and traditional suspended microstrip wires for designing the peripheral passive circuit of the frequency tripler; the inside of the circuit is directly connected with a cavity wall to achieve a radio frequency grounding and DC circuit; by means of a fundamental wave input duplexer, DC bias and other circuits can be designed simultaneously, subsequent assembling steps can be reduced, and the circuit structure is easy to process and assemble.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

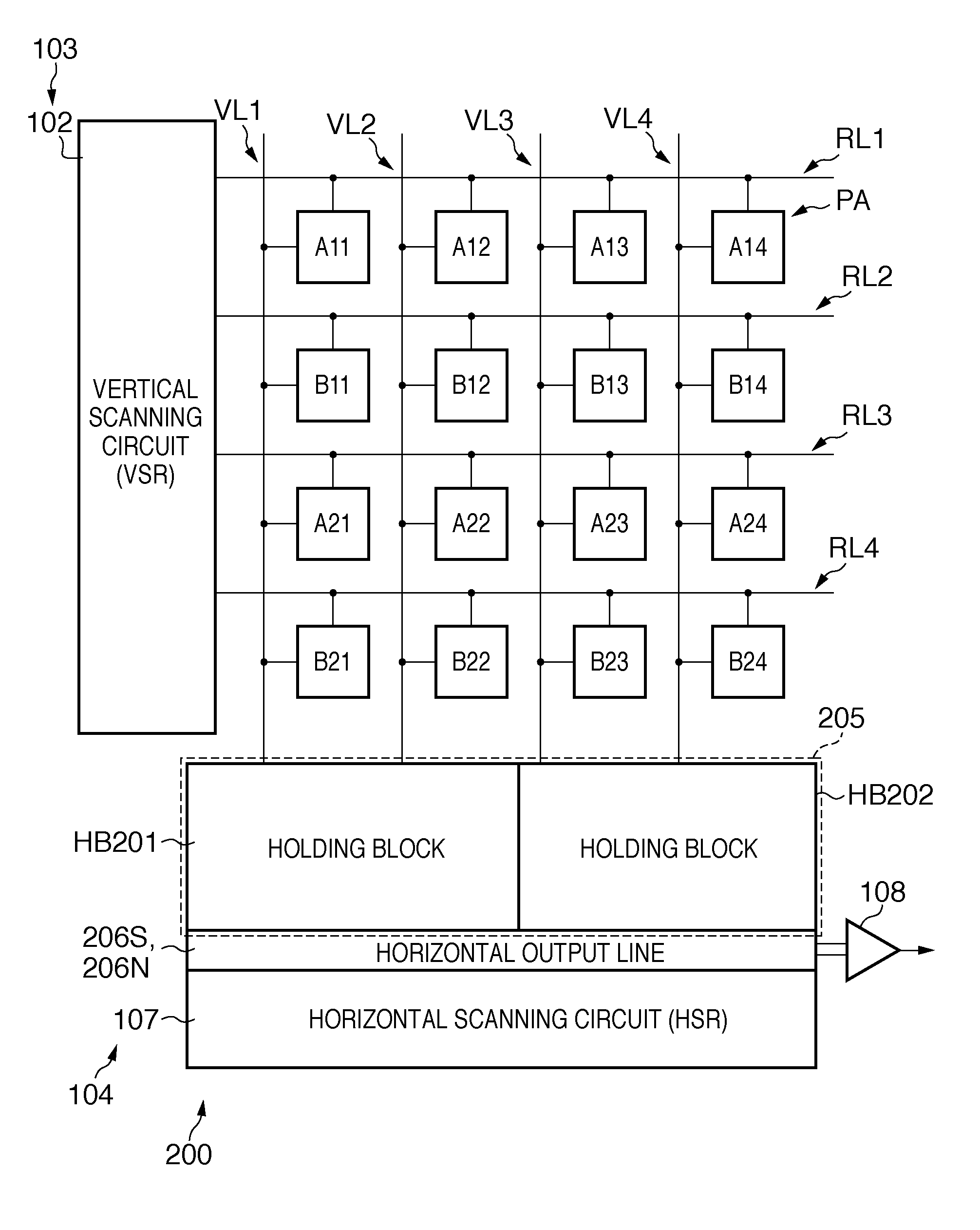

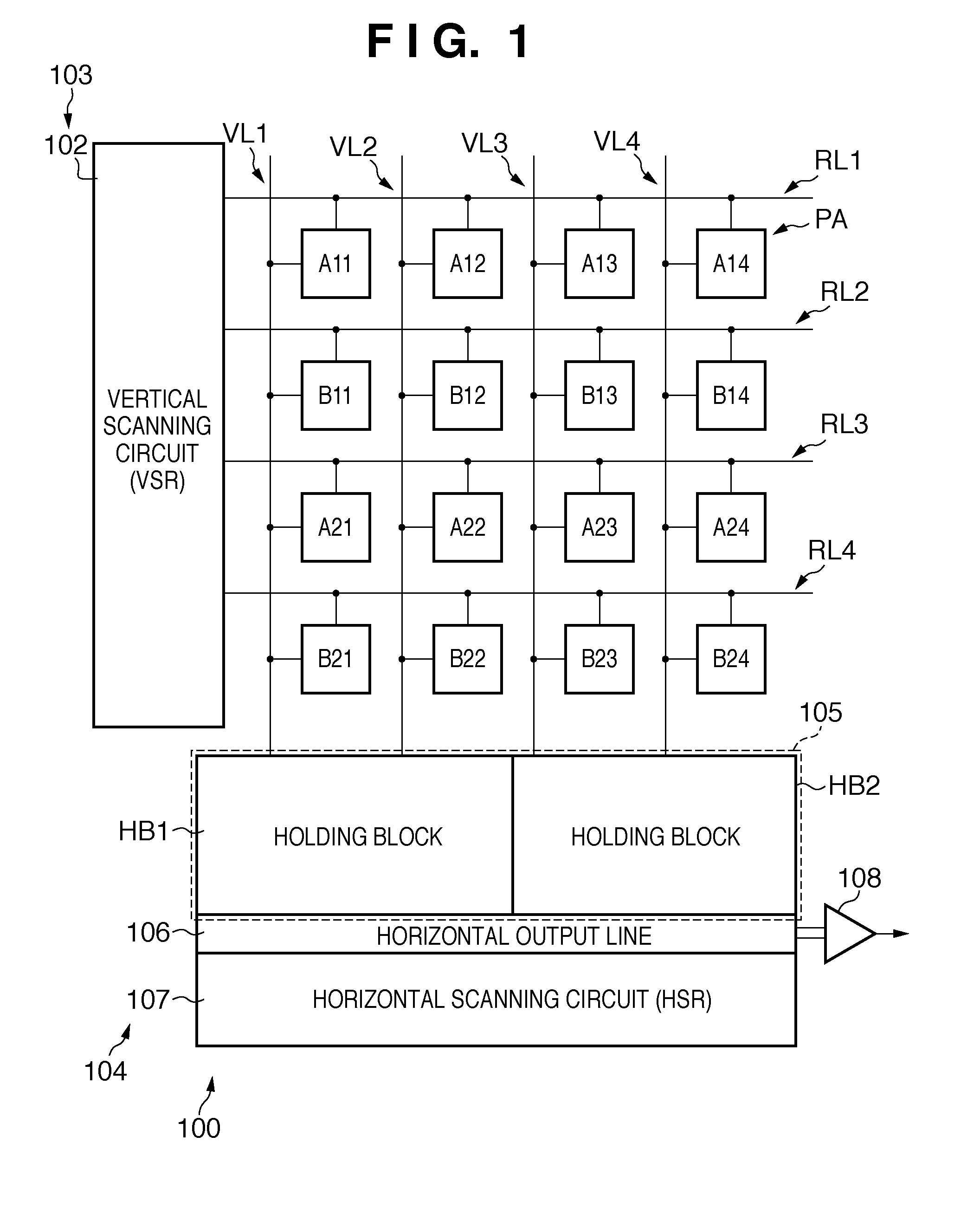

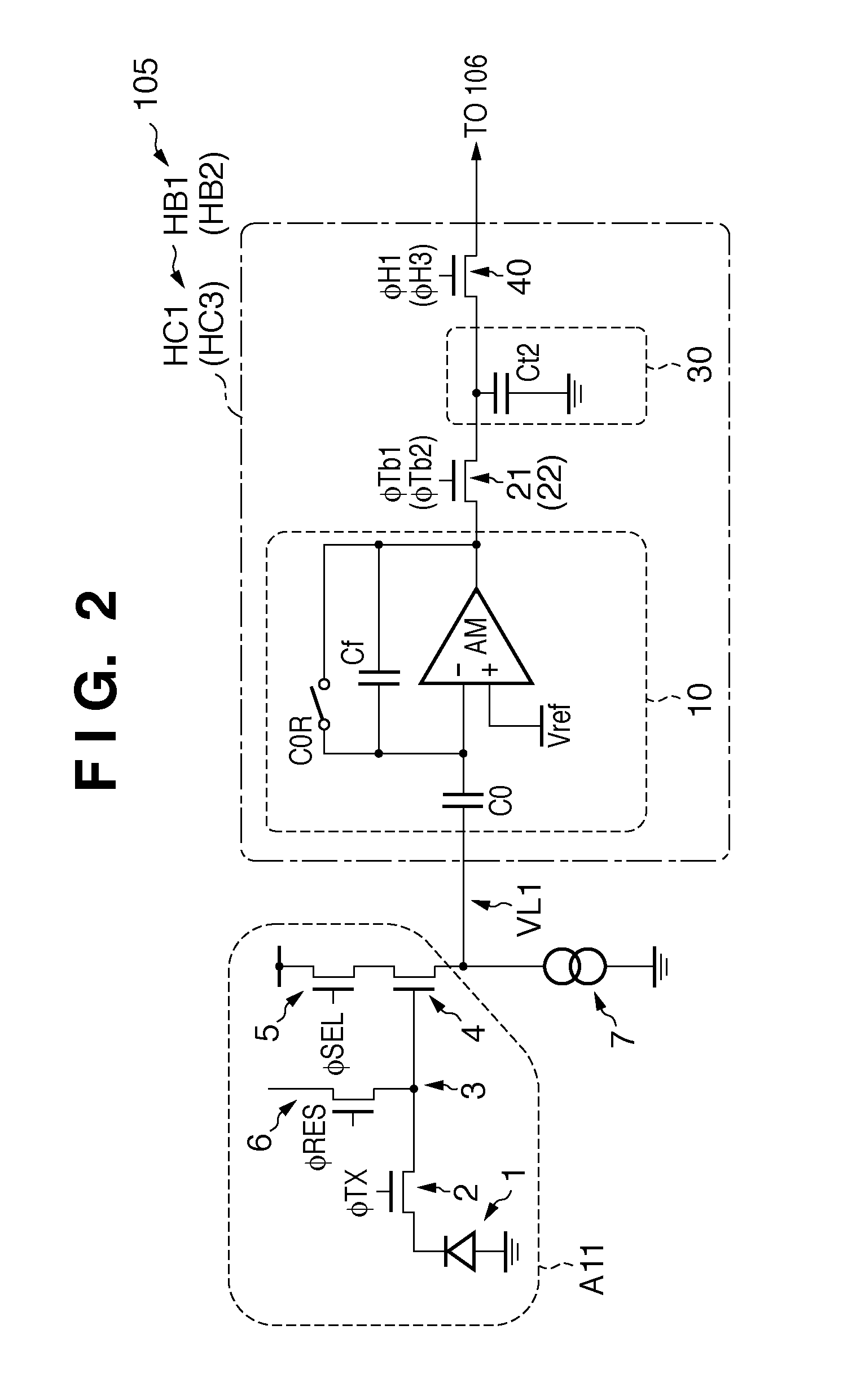

Image sensing device and image sensing system

InactiveUS8169525B2Shorten the horizontal lengthShorten the lengthTelevision system detailsTelevision system scanning detailsAudio power amplifierTransfer switch

An image sensing device comprises a readout unit, an output amplifier, and a horizontal scanning unit, wherein the horizontal scanning unit scans a plurality of column signal holding circuits in a plurality of holding blocks in the readout unit in a direction along a row, in each holding block, a first operation in which the signal held in a first holding unit is transferred to a second holding unit via a transfer switch is performed, and subsequently, a second operation in which the signal held in the second holding unit is transferred to the output amplifier, and a third operation in which a signal output from a pixel is read out to the first holding unit are performed in parallel, and the second operation and the first operation are performed in parallel between different holding blocks in the plurality of holding blocks.

Owner:CANON KK

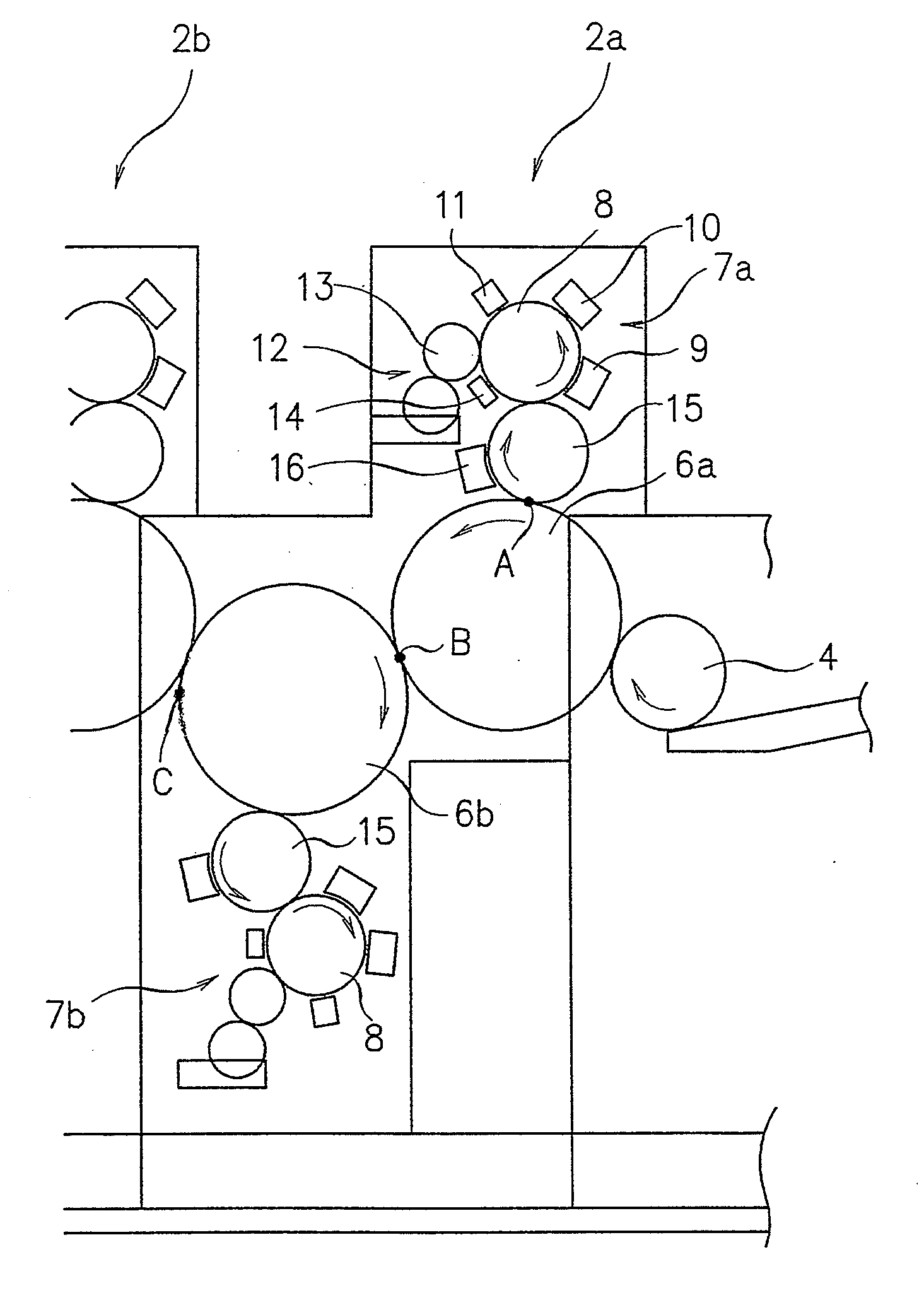

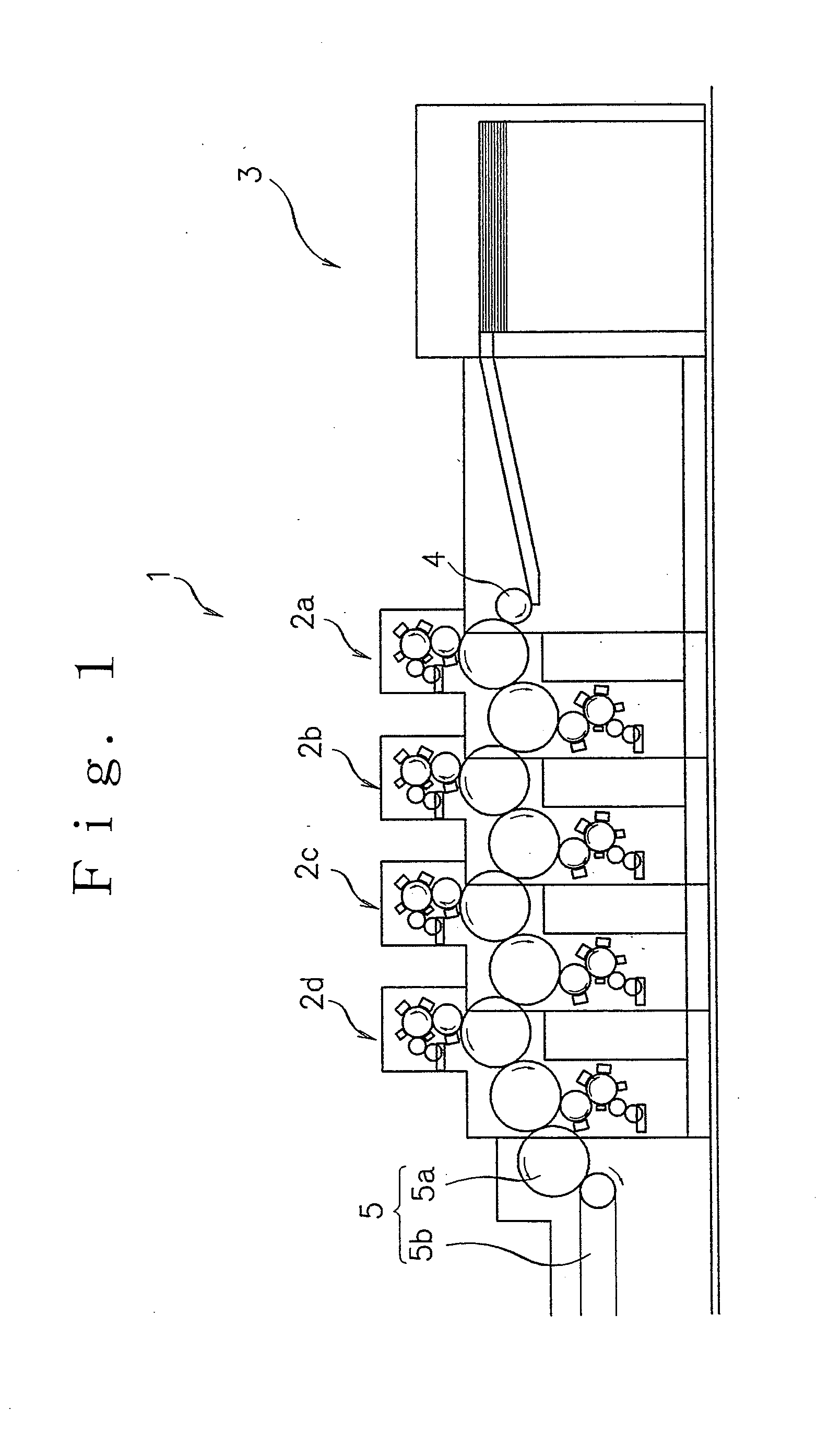

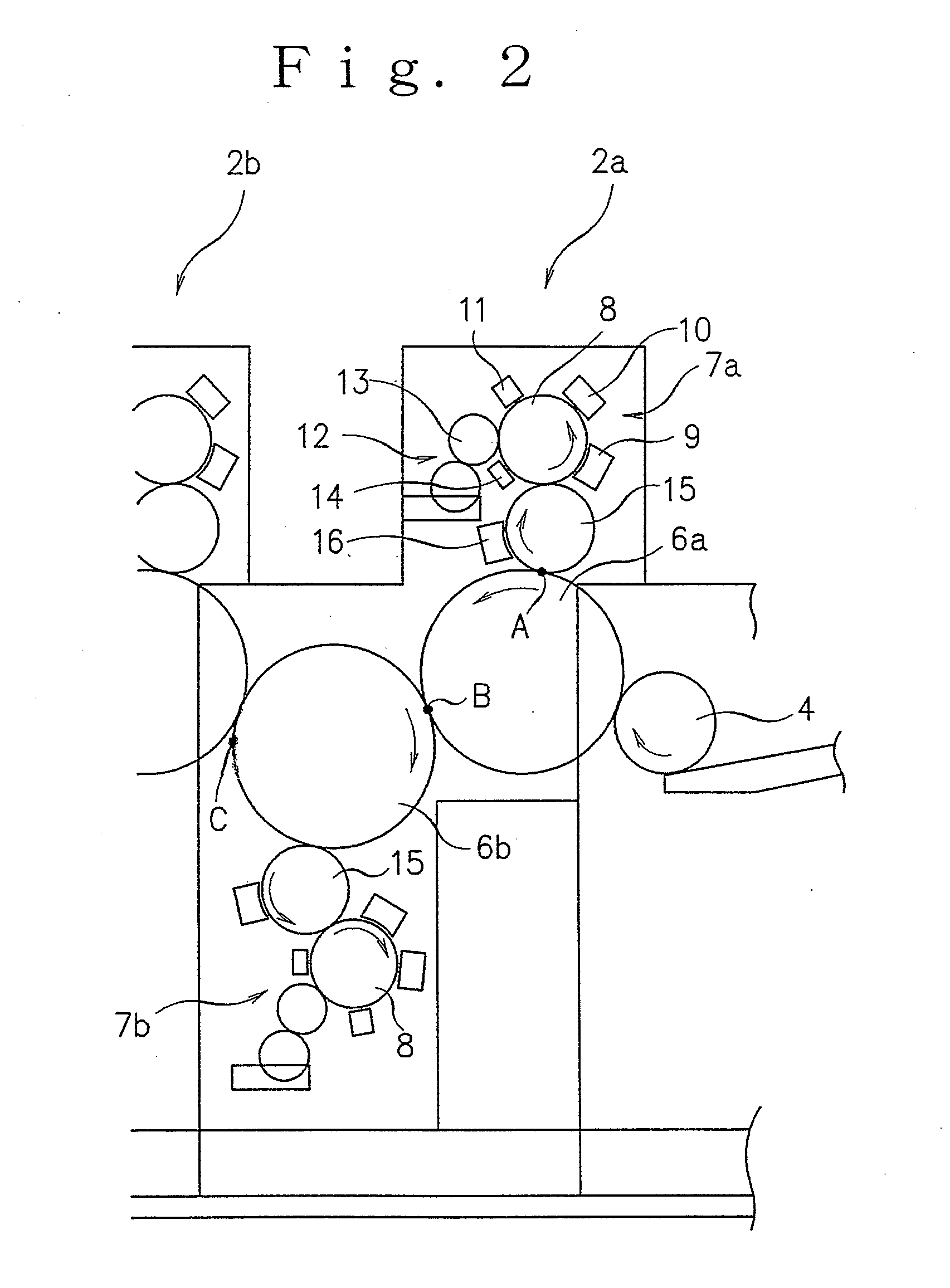

Sheet-Fed Duplex and Sheet-Fed Duplex Multi-Color Printers

InactiveUS20120128395A1Shorten the horizontal lengthBehavioral stabilityElectrographic process apparatusEngineeringMechanical engineering

A sheet-fed duplex printer comprises a pair of impression cylinders 6a, 6b and first and second electrophotographic printing units 7a and 7b. Each of the cylinders is provided on a peripheral surface thereof with a paper gripper for gripping a sheet of paper. The cylinders and printing units are so disposed relative to each other and suitably operated for printing on one face of the sheet of paper as it is conveyed following the peripheral surface of one cylinder, and for printing on the other face of the sheet of paper as it is conveyed following the peripheral surface of the other cylinder. This arrangement allows high precision and high speed printing of a sheet of paper large in size without increasing the entire apparatus length.

Owner:MIYAKOSHI PRINTING MACHINERY

Fin line structure-based terahertz third-harmonic mixer

ActiveCN108134168AEasy to GrindSolve common problemsWaveguide type devicesFrequency mixerThird harmonic

The invention discloses a fin line structure-based terahertz third-harmonic mixer. The fin line structure-based terahertz third-harmonic mixer comprises a metal cavity used for placing circuits, a substrate, a radio frequency input circuit and a local oscillation transitional circuit; the substrate is positioned in the metal cavity; the radio frequency input circuit and the local oscillation transitional circuit are positioned on the substrate; the radio frequency input circuit and the local oscillation transitional circuit are connected through local oscillation matching branches; the input end of the radio frequency input circuit is connected with radio frequency transitional waveguide; the fin line branch structure arranged on the radio frequency input circuit is directly connected withthe metal cavity; a Schottky diode pair on the radio frequency input circuit is mounted on the fin line; the fin line branch structure is also in grounding connection with a direct current; and the direct current grounding is positioned at the radio frequency input end of the radio frequency input circuit. By adoption of the structure, and by adopting the fin line structure in the radio frequencyport, high grounding of the direct current component in the Schottky diode can be ensured, so that the universality problem of the existing old harmonic mixer can be solved; and the terahertz third-harmonic mixer has less spurious signals and high compression point.

Owner:四川众为创通科技有限公司

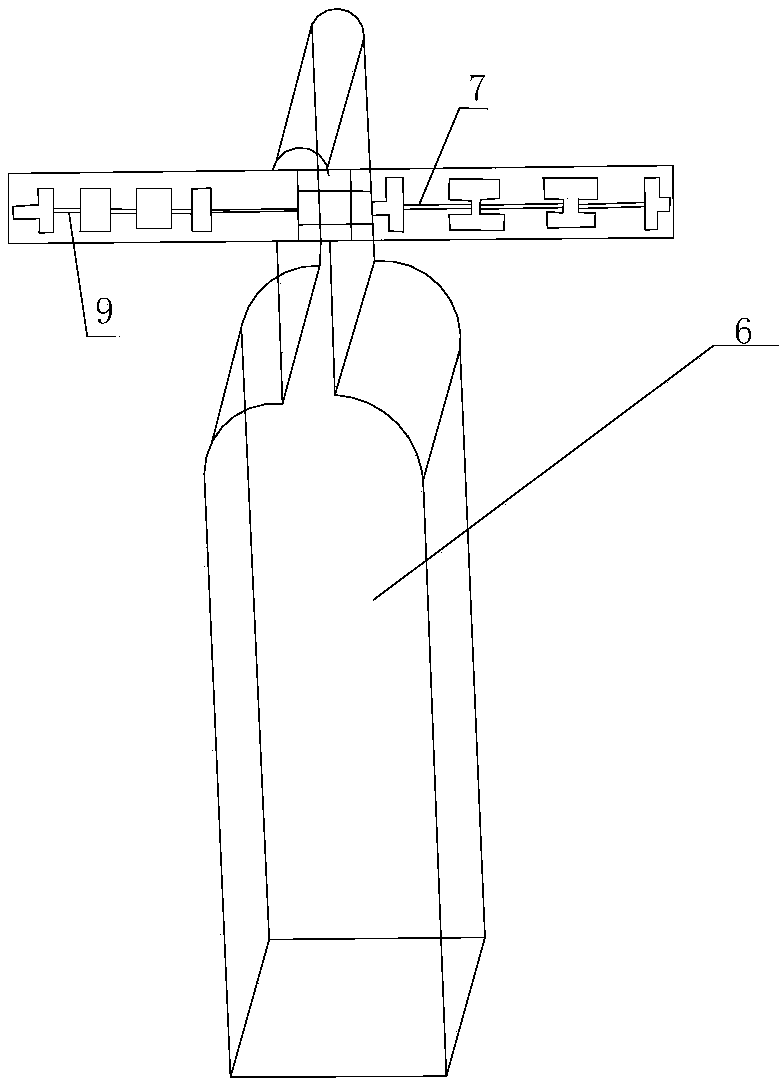

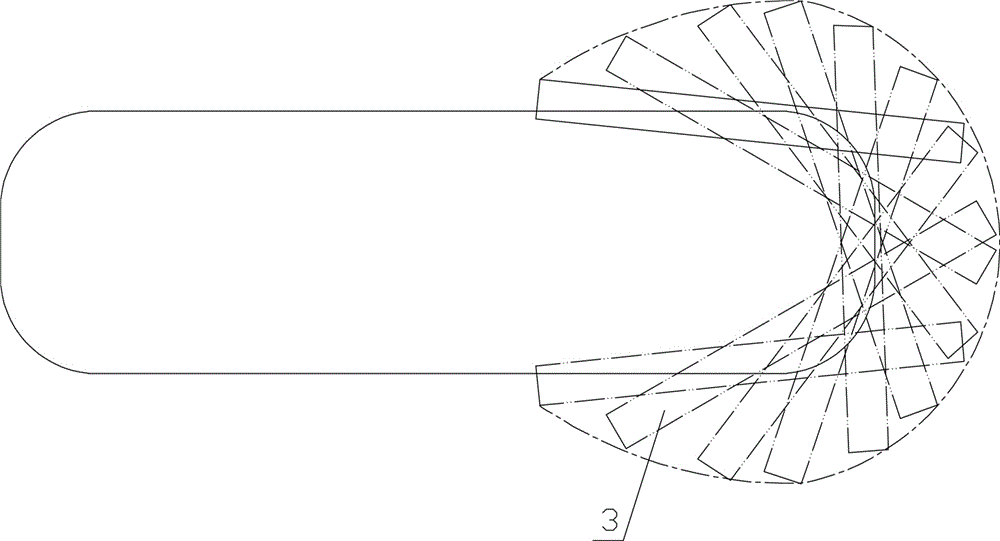

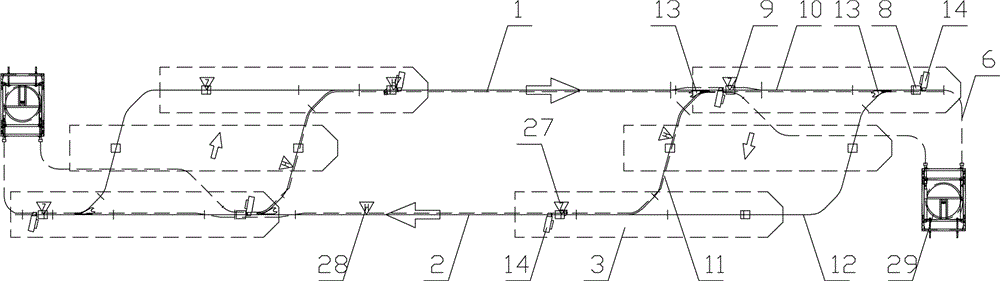

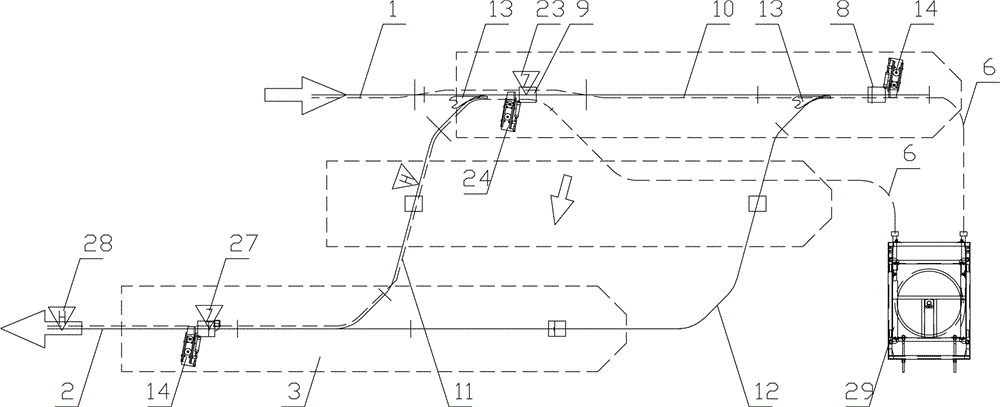

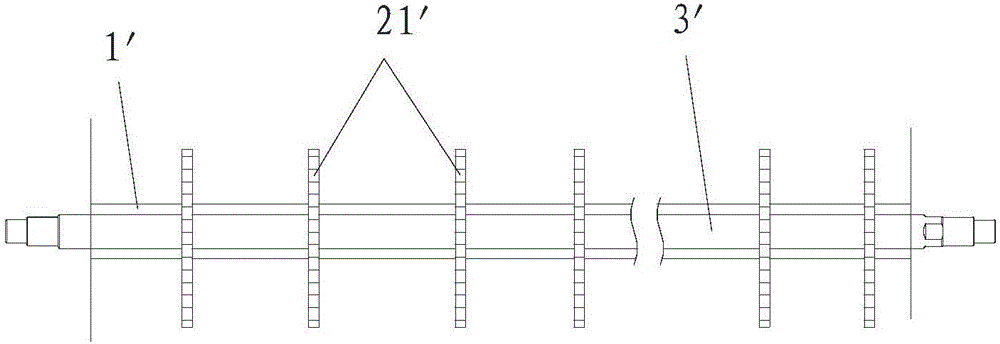

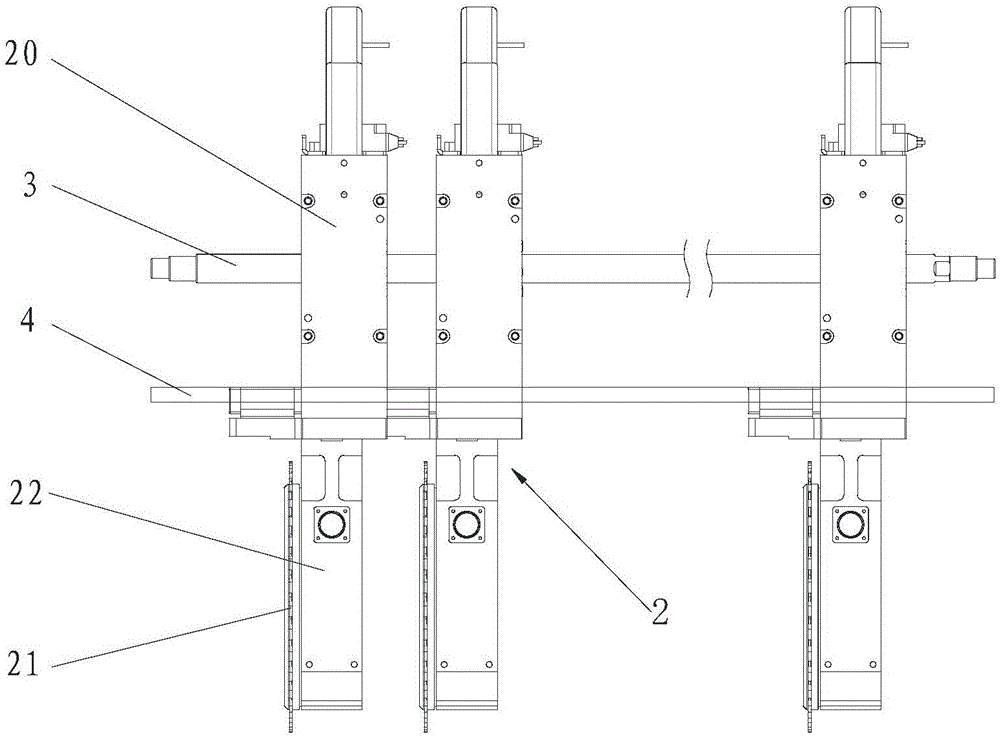

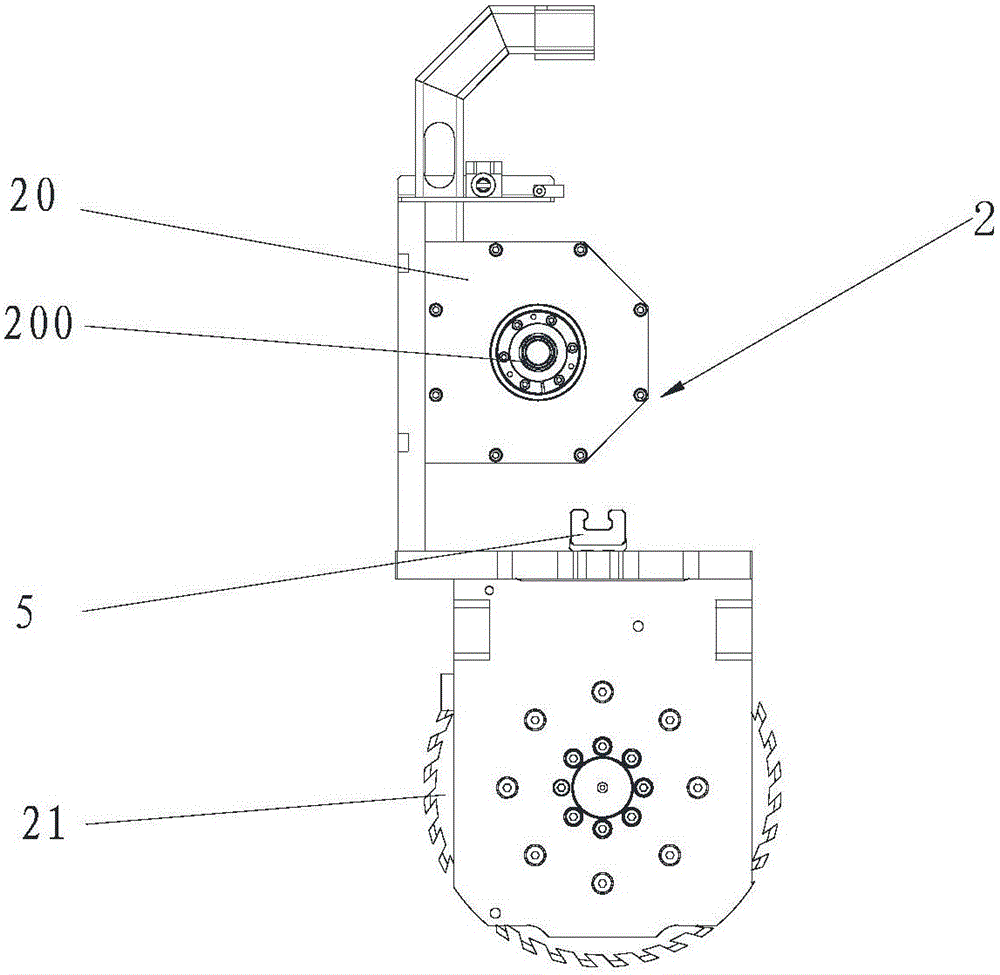

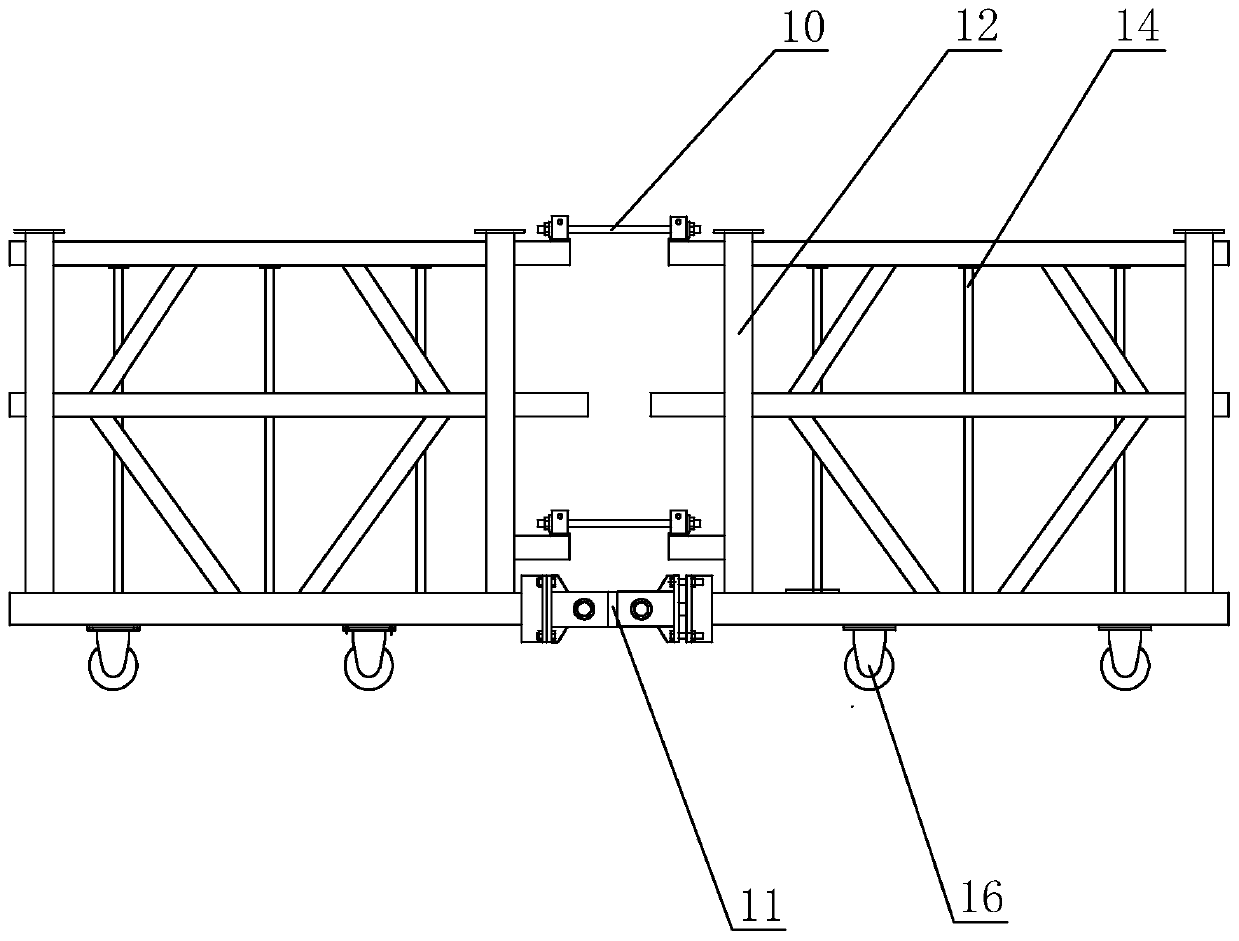

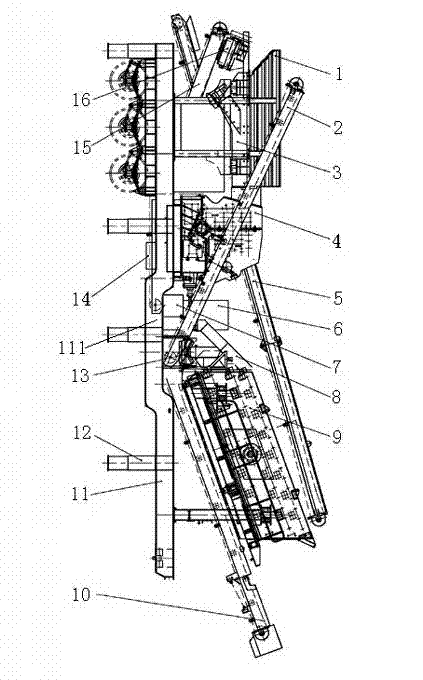

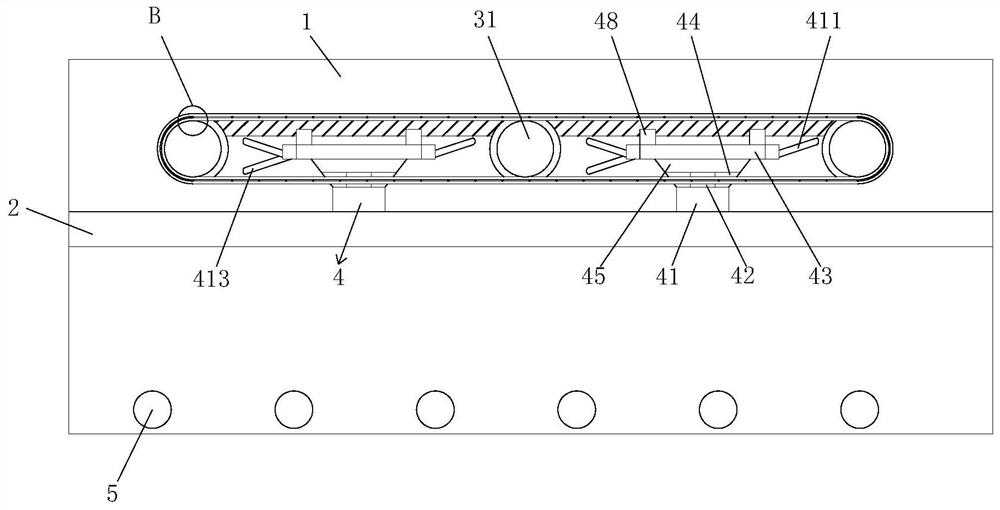

Heavy-load power and free chain conveying system used for conveying big long workpieces

ActiveCN106516612ASmall footprintShorten the horizontal lengthMechanical conveyorsButt jointEngineering

A heavy-load power and free chain conveying system used for conveying big long workpieces comprises a conveying track and multiple heavy-load vehicle groups. The conveying track comprises at least two conveying track bodies arranged in parallel in a linear manner and transverse translation track groups arranged at the ends of the adjacent conveying track bodies arranged in the linear manner. Each transverse translation track group is of a square structure formed by a reversing rail, a cross traction rail, a turnout and a cross traction-free rail. The reversing rail is in butt joint with one of the conveying rail bodies arranged in the linear manner. Each turnout is formed by the corresponding reversing rail, one end of the corresponding transverse traction rail and one end of the corresponding traction-free rail. A turnout tongue is mounted at each of the two turnouts. The other end of the corresponding transverse traction rail and the other end of the transverse traction-free rail are in butt joint with the other adjacent conveying rail body arranged in the linear manner. By the adoption of the heavy-load power and free chain conveying system, the purpose that a heavy-load vehicle group conducts transverse translation between the two adjacent linear conveying track bodies is achieved, and the space occupied when the big long workpieces turn around and rotate is reduced, so that the transverse length of an industrial plant is reduced, and the production input cost is lowered.

Owner:HUBEI SANFENG INTELLIGENT CONVEYING EQUIP

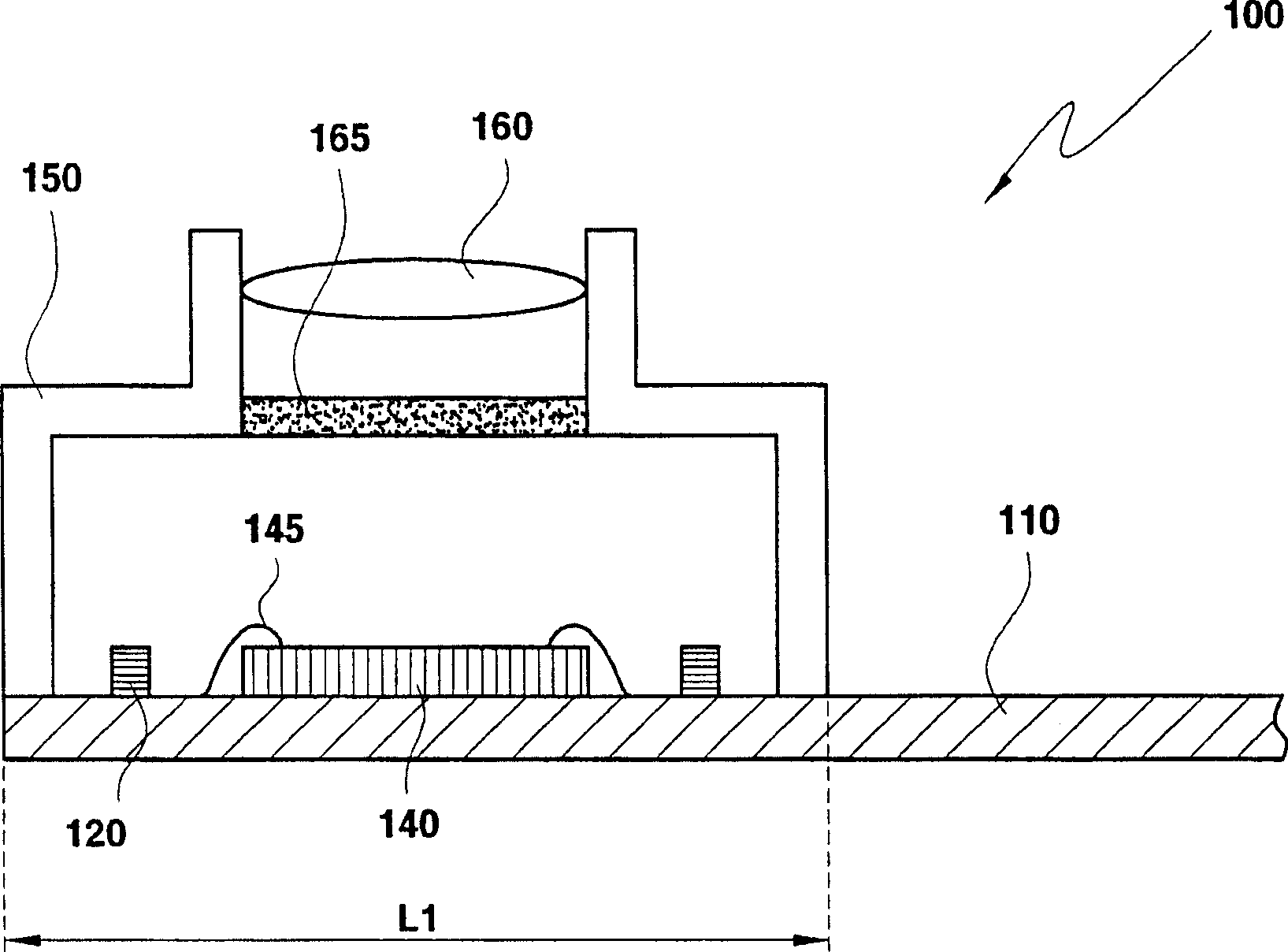

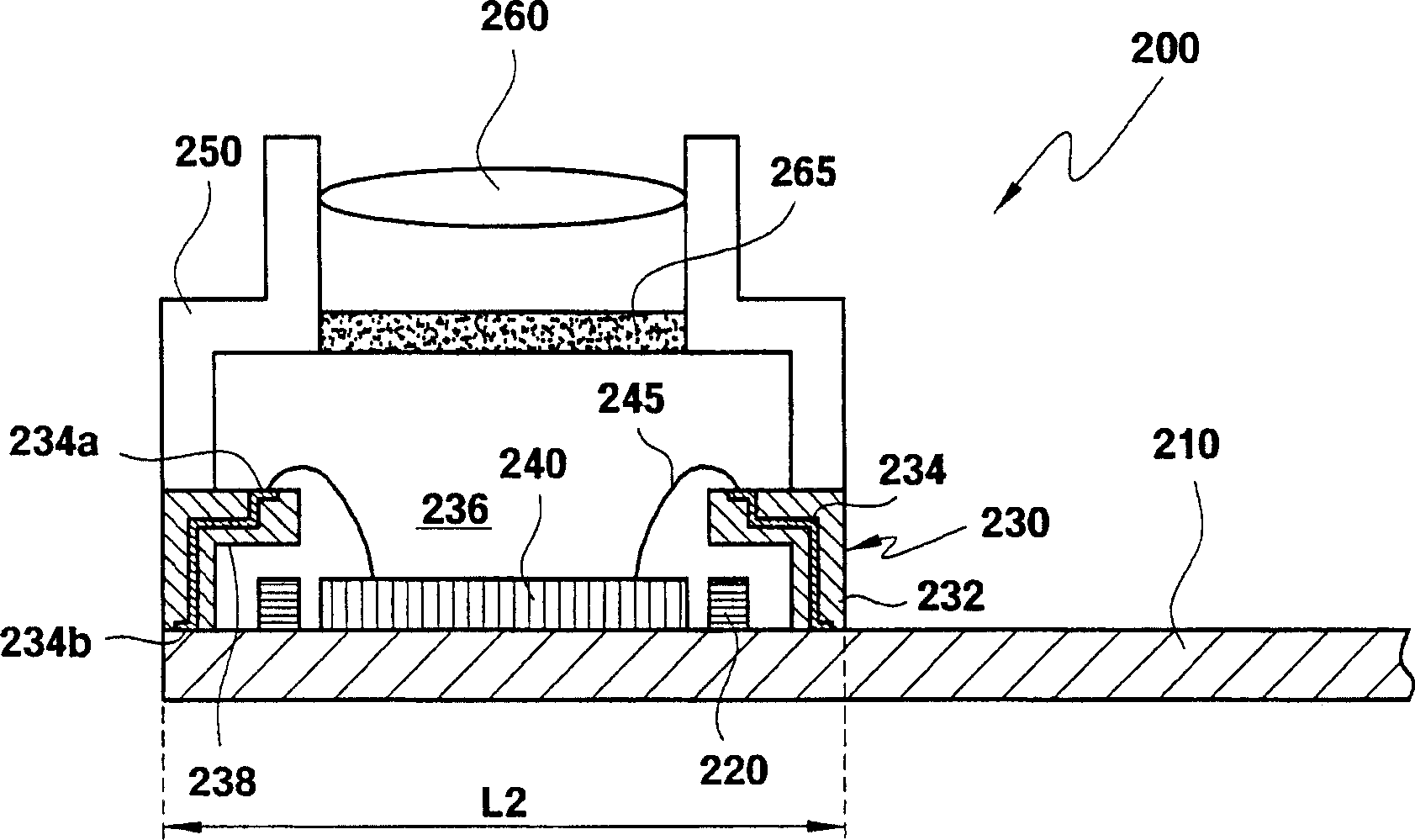

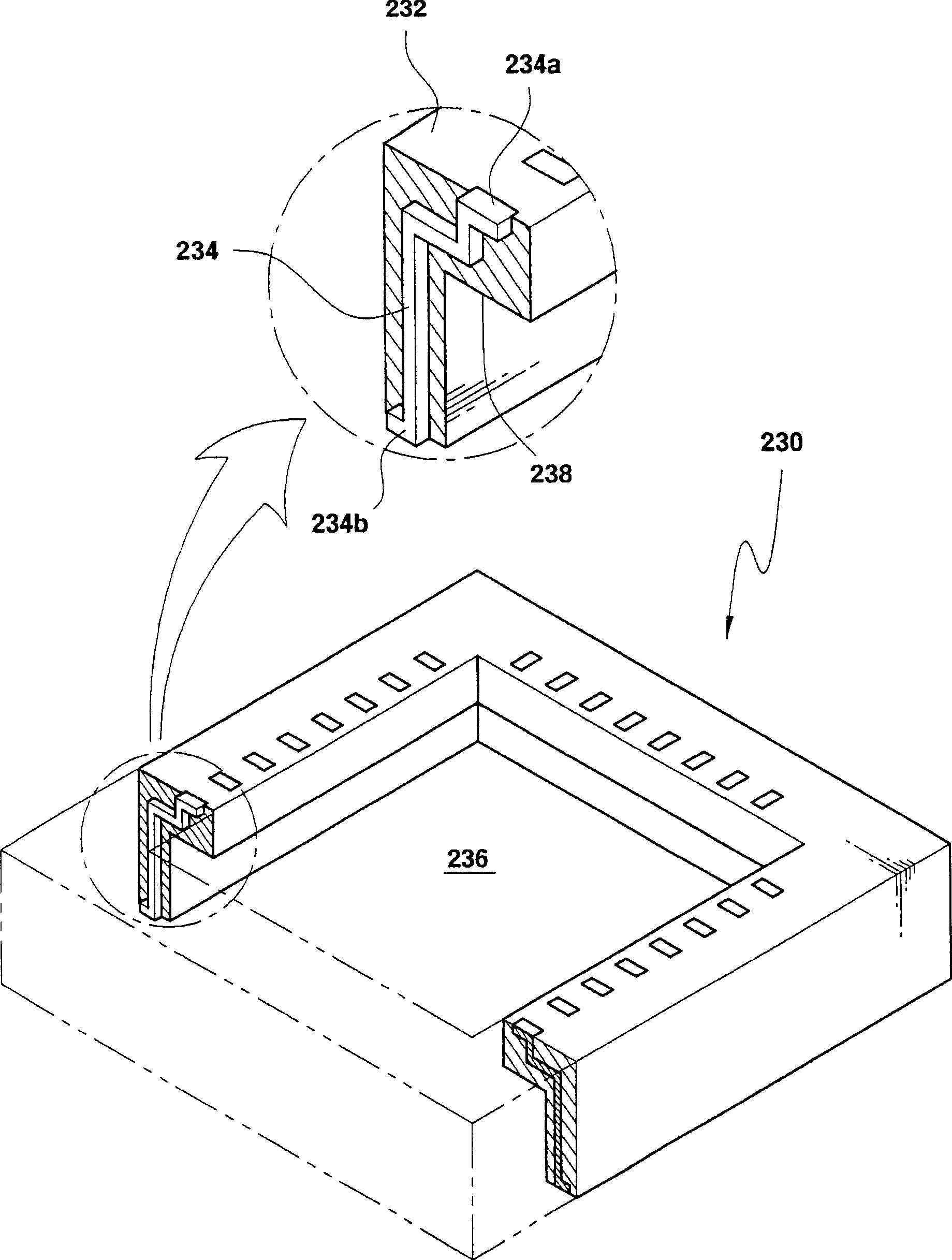

Wiring substrate, solid-state imaging apparatus using the same, and manufacturing method thereof

InactiveCN1674264AShorten the horizontal lengthTelevision system detailsStatic indicating devicesMiniaturizationSemiconductor chip

In one embodiment, a miniaturized solid-state imaging apparatus includes a body having a cavity for mounting a semiconductor chip therein. The body has an overhanging portion extending toward the cavity. Further, a lead is disposed within the body. The lead has one end exposed through a top surface of the body and the other end exposed through a bottom surface of the body for electrical connection thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

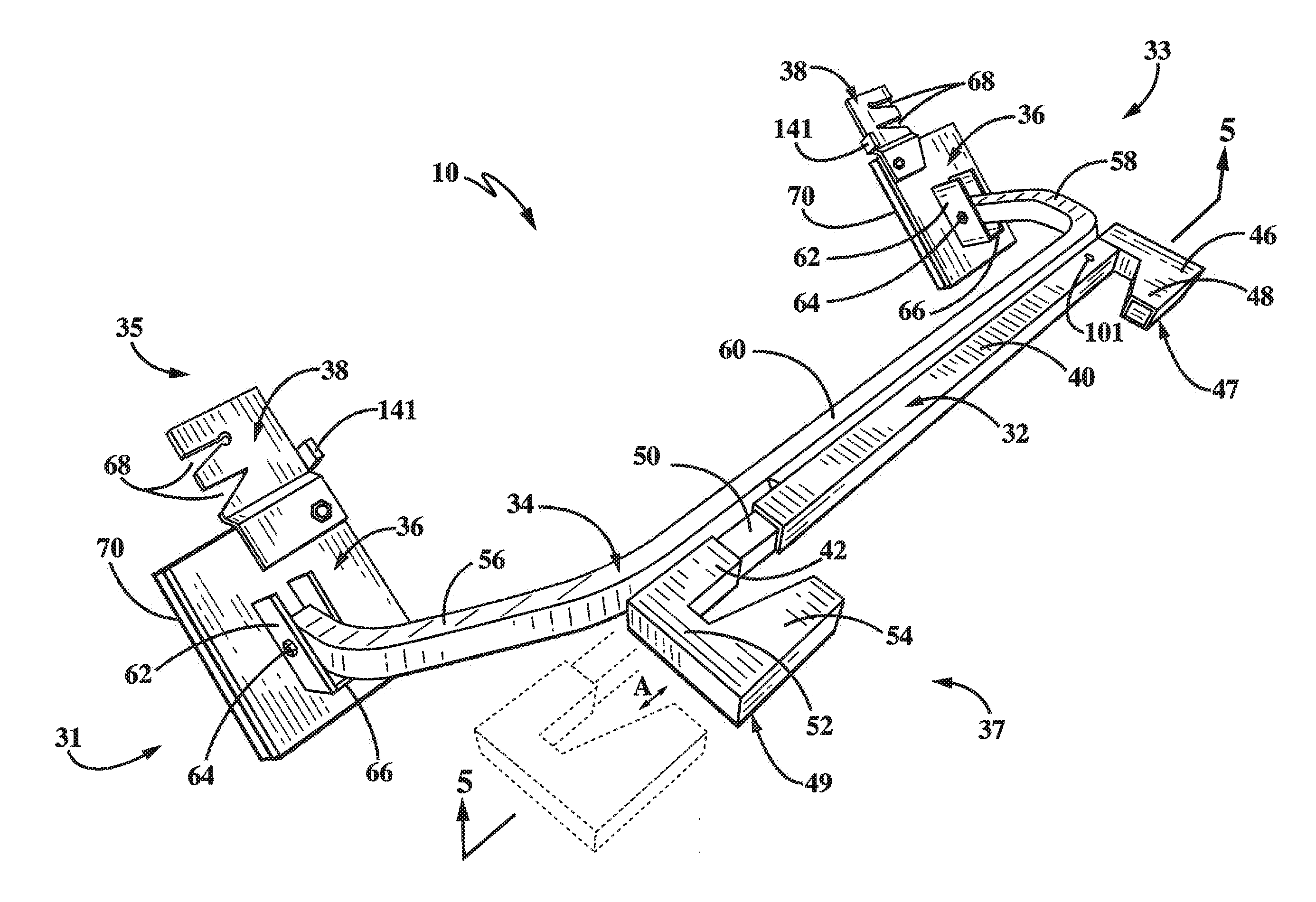

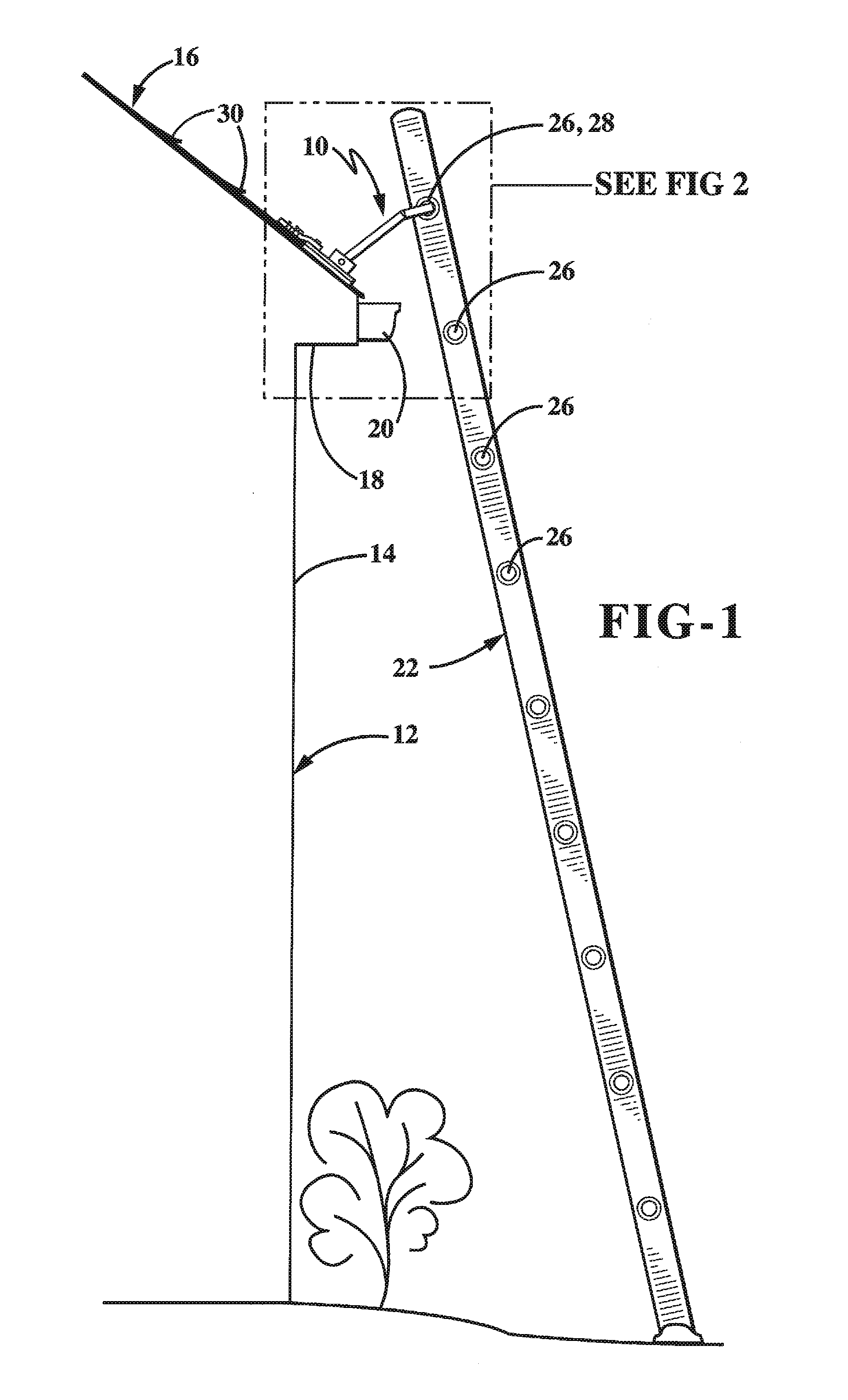

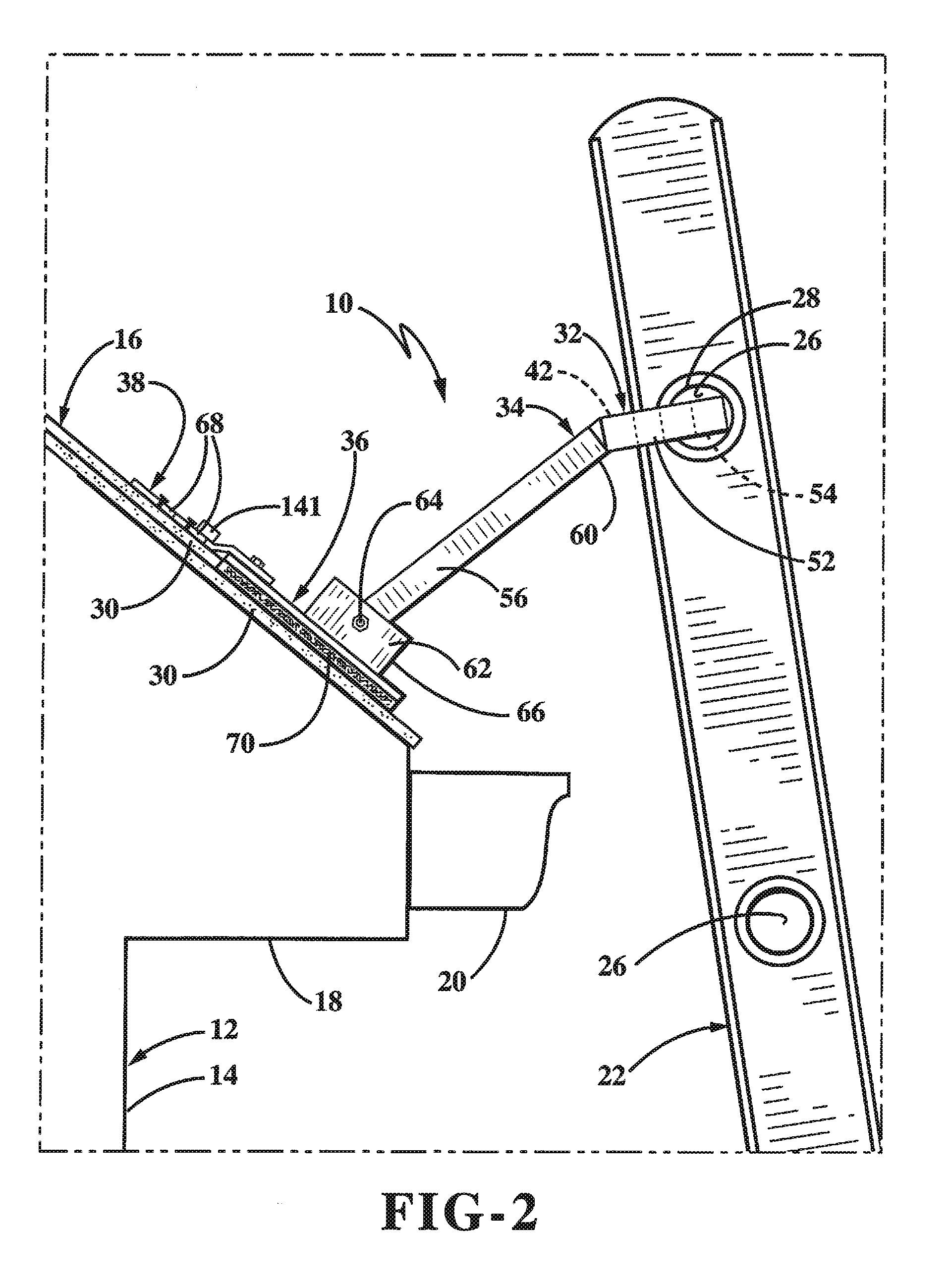

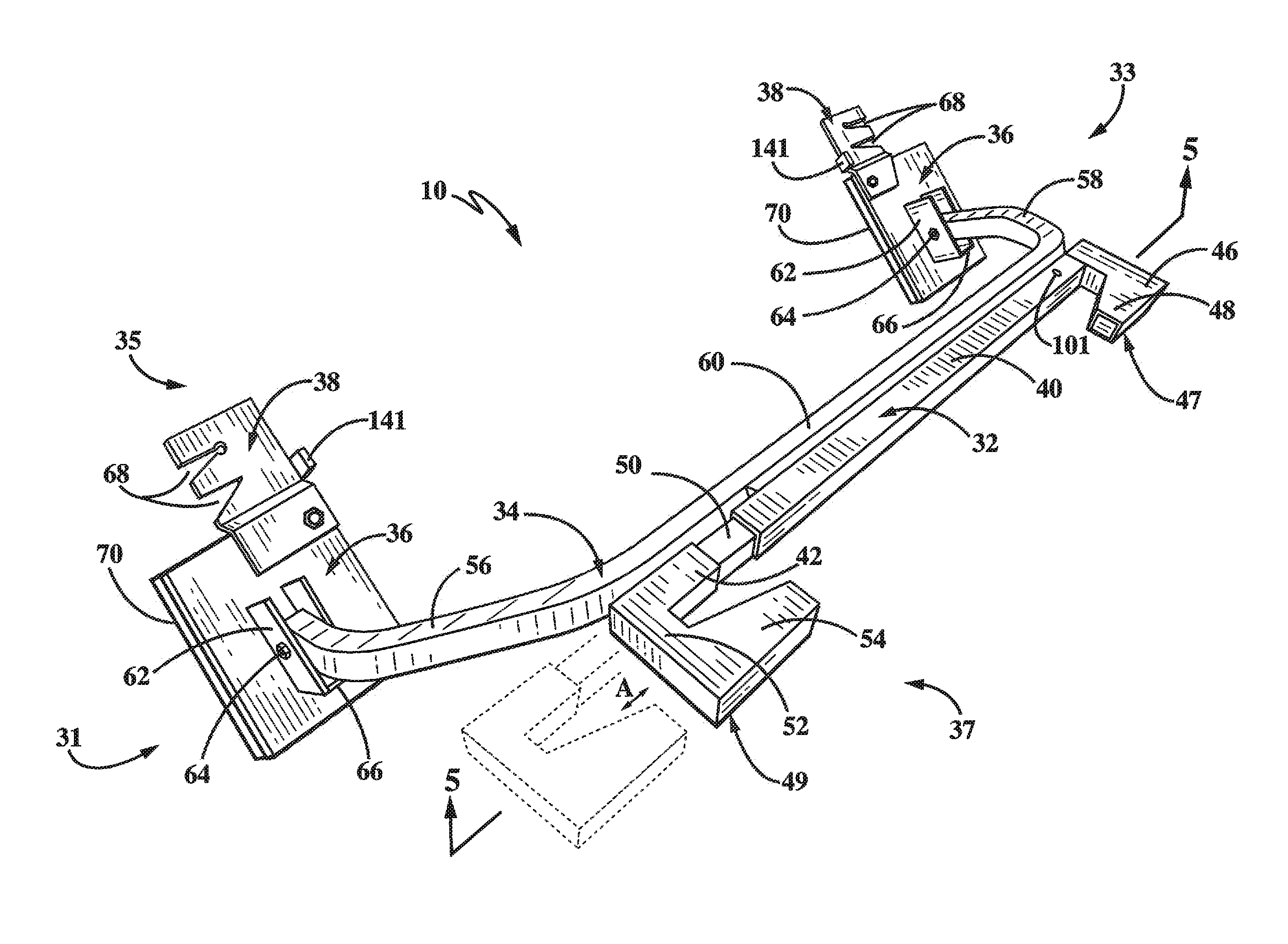

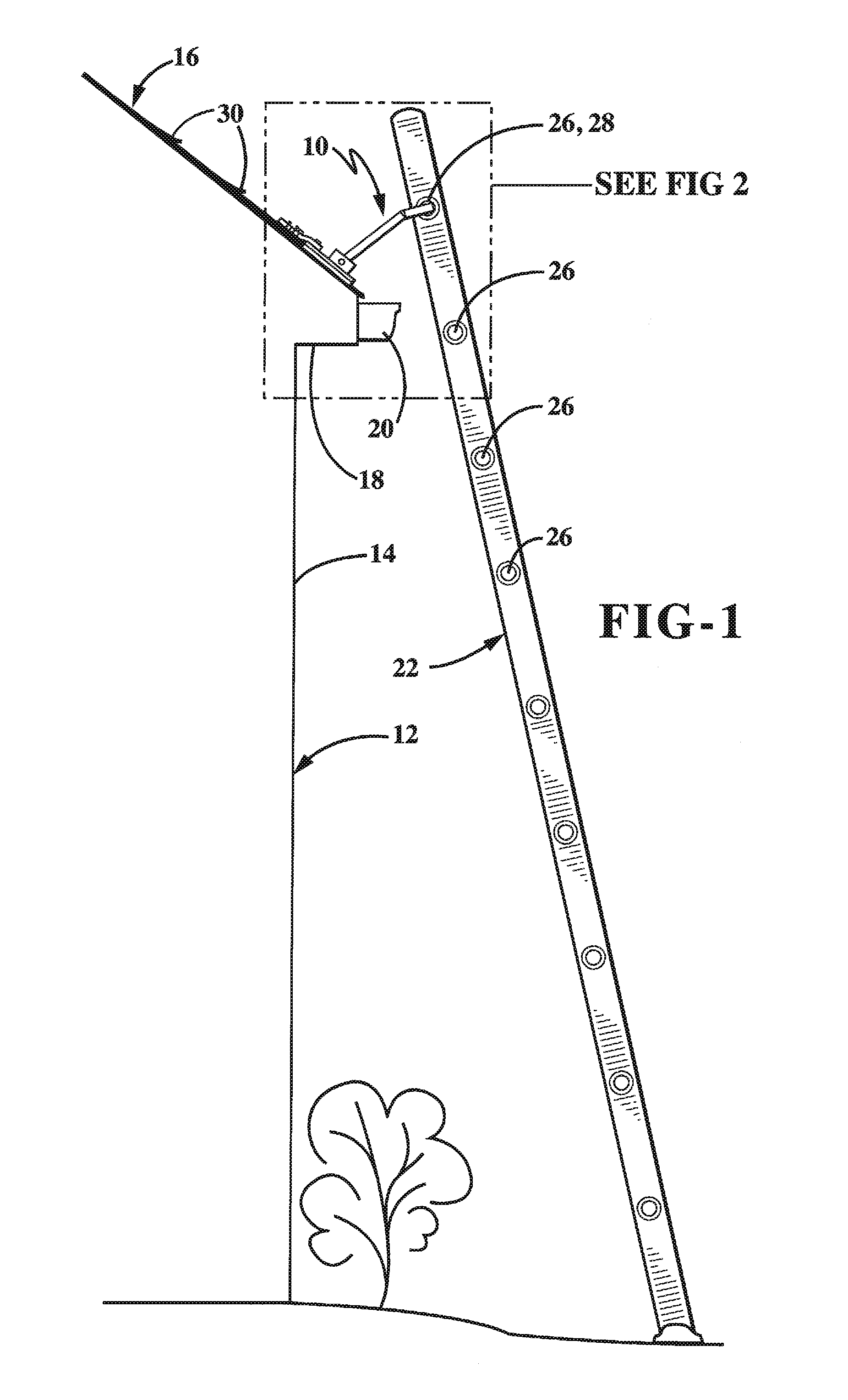

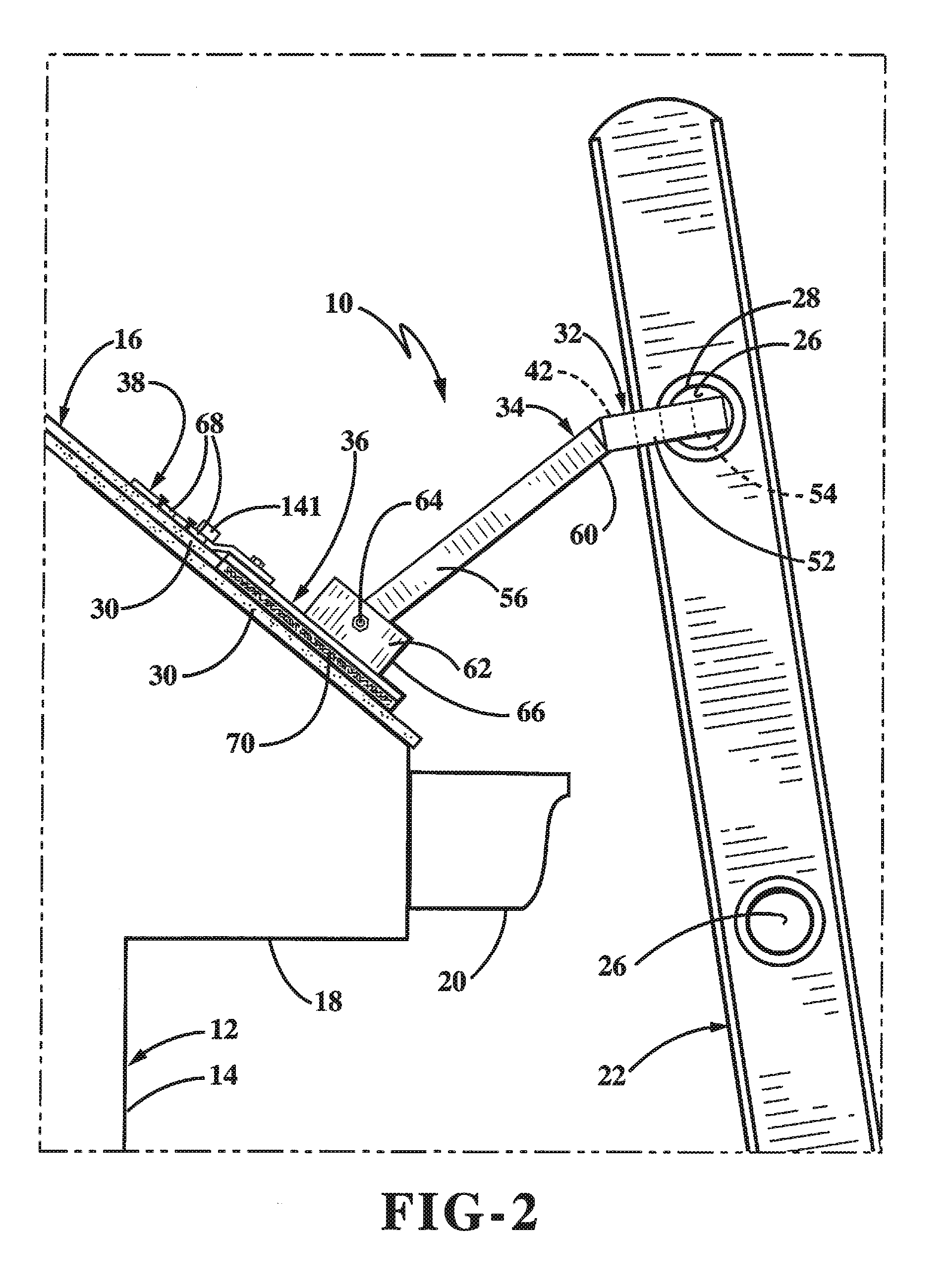

Ladder stabilizing tool

ActiveUS20150337596A1Increase the lengthShorten the horizontal lengthMetal working apparatusScaffold accessoriesEngineeringMechanical engineering

A ladder stabilizing tool for use with an extension ladder may include a U-shaped brace coupled to a ladder grasping member. A pair pivotable of feet may be attached to the ends of U-shaped brace permitting the stabilizing tool to secure an extension ladder to a roof at any slope between zero and ninety degrees. The grasping member has a pair of tapered supports configured to fit within the apertures formed in the rails of an extension ladder. The stabilizing tool ensures stability of the ladder for the safety of an operator, while further providing clearance from any gutter attached to housing fascia.

Owner:CHEREVKO PIOTR

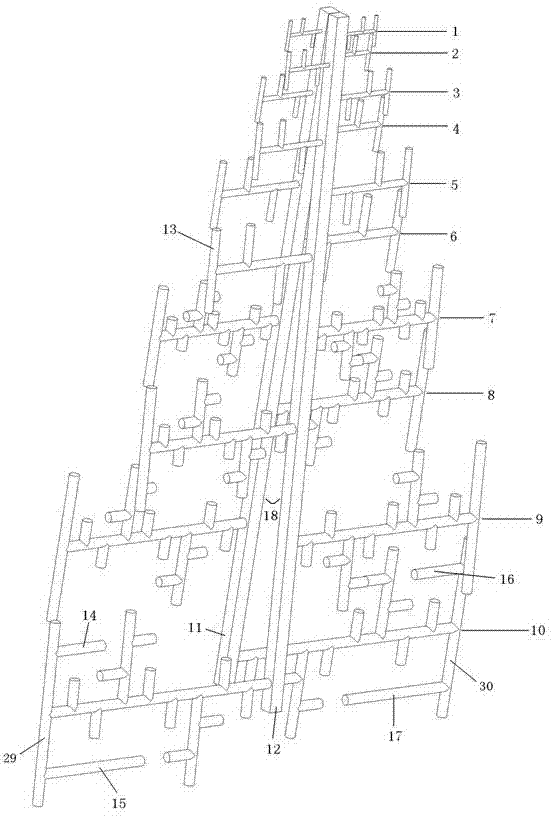

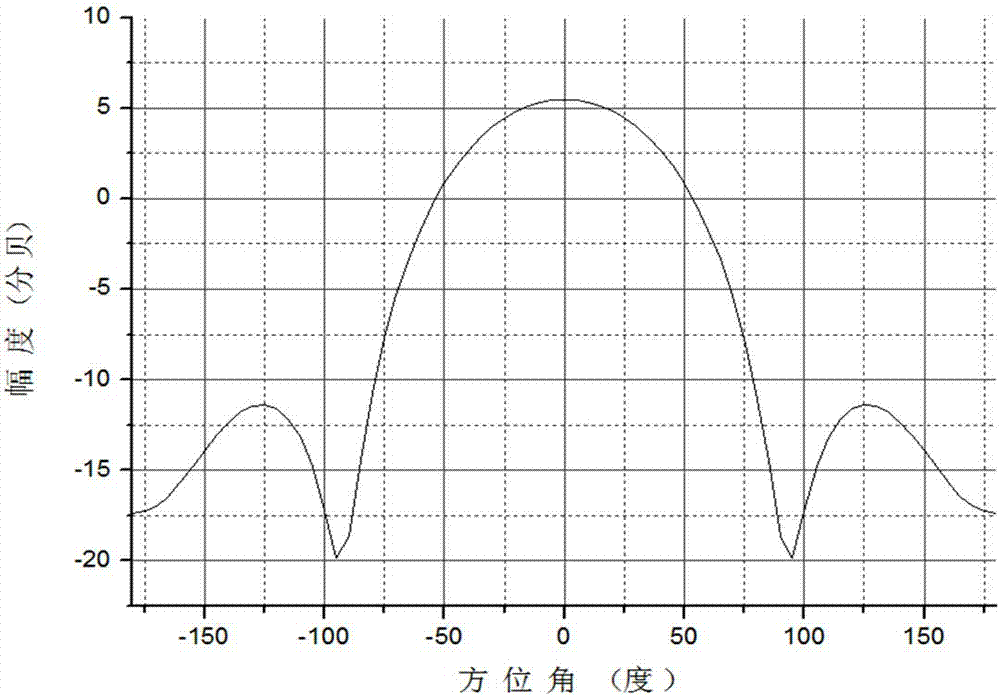

Tree-shaped antenna

ActiveCN103500874ASmall footprintSolve miniaturizationRadiating elements structural formsAntennas earthing switches associationTree shapedControl theory

The invention relates to a tree-shaped antenna, which comprises two feeding poles and more than three pairs of oscillators, wherein each pair of oscillators are in one step; the more than three pairs of oscillators are increased step by step from top to bottom; the upper ends of two feeding poles are connected to form a herringbone; each pair of oscillators are respectively and symmetrically installed on the two feeding poles; each pair of oscillators have the same structure but different sizes; the oscillators are one-stage fractons or two-stage fractons; each fracton comprises three fraction arms which are successively connected and are in the horizontal pole shape; the junction of adjacent fracton arms is provided with a vertically-upward fracton arm or a vertically-downward fracton arm; the lengths of the fracton arms are equal; one end of three successively-connected fracton arms is connected with one feeding pole, and the other end is connected with a one-stage loading metal bar. According to the tree-shaped antenna disclosed by the invention, the volume of the antenna is greatly reduced, the problem that the common metre wave log-periodic antenna can not be suitable to install on an airborne platform is solved, antenna cross coupling is lowered, and the electrical property can satisfy the system use requirement.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

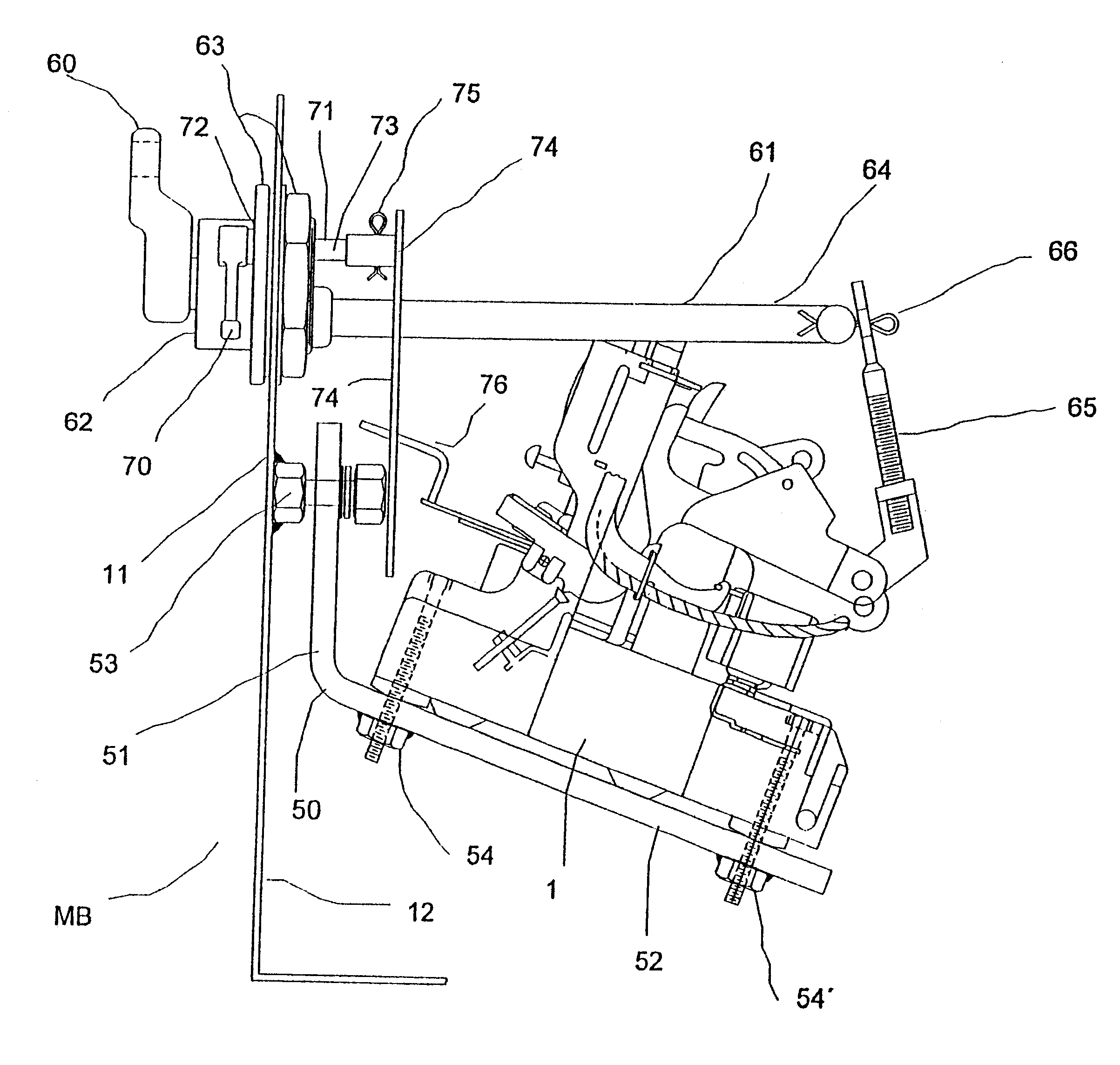

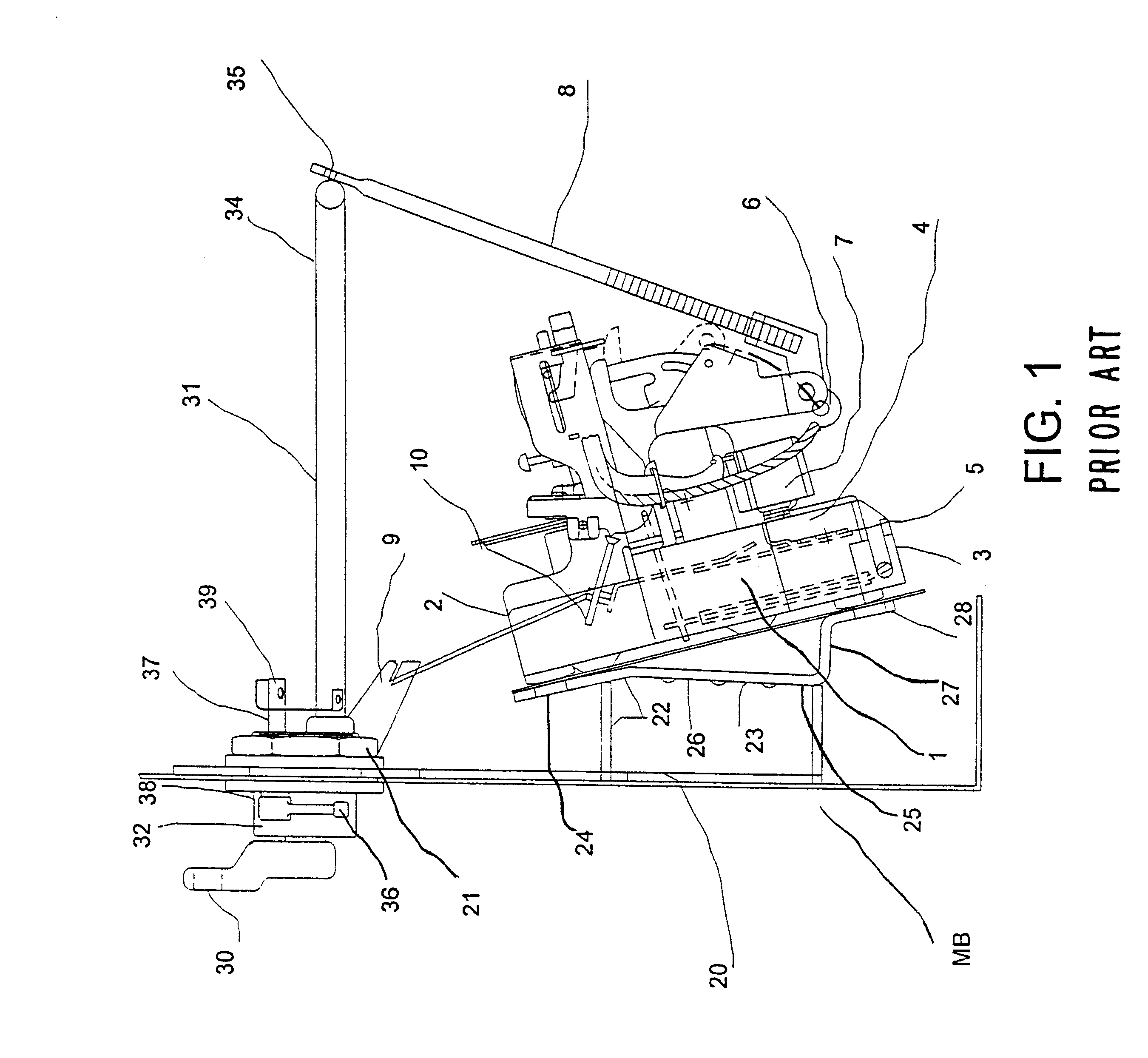

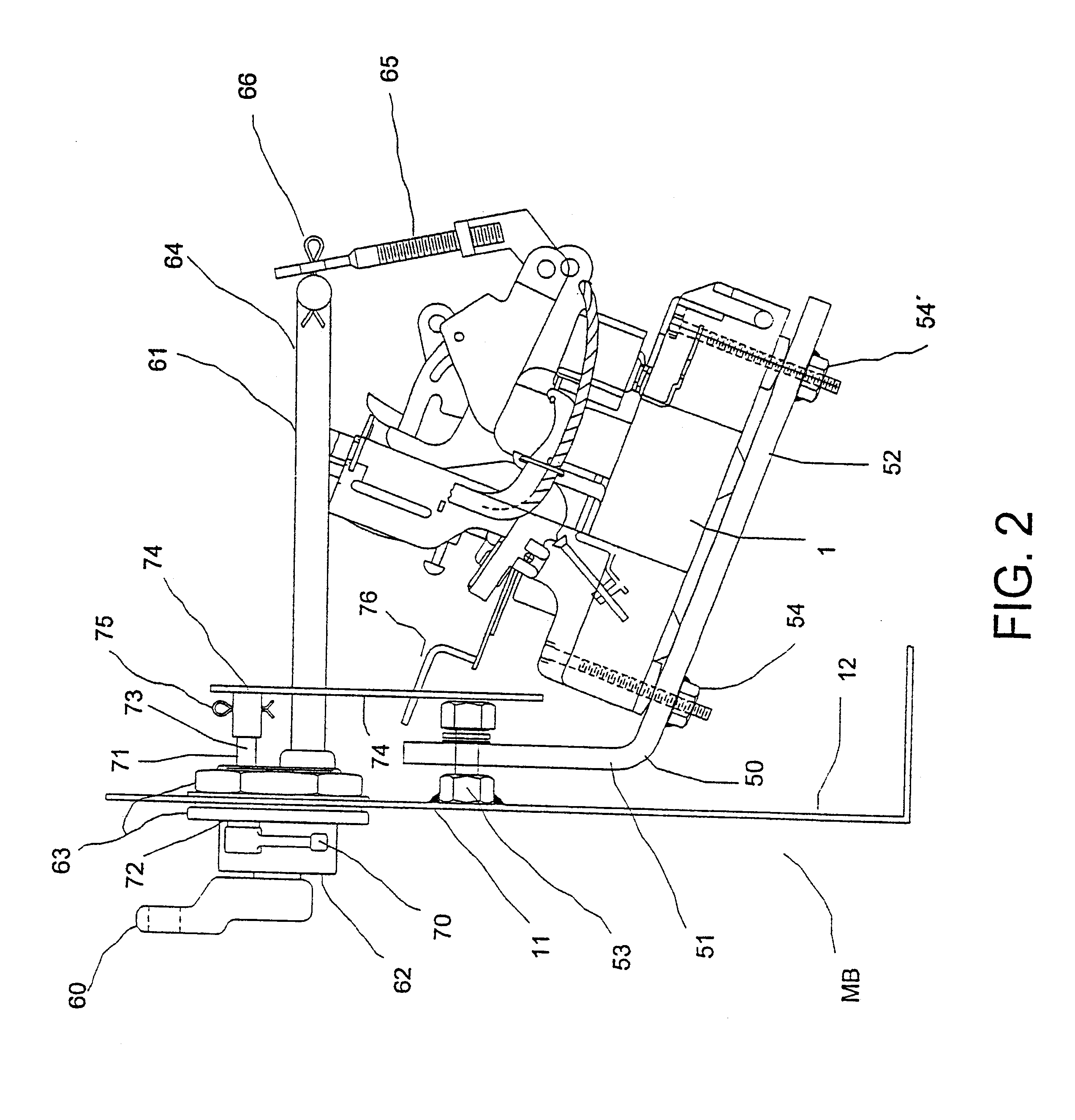

Mounting system for a circuit breaker

InactiveUS6331685B1Reduce the overall heightSave materialSubstation/switching arrangement detailsTumbler/rocker switchesActuatorControl theory

A mounting system for a circuit breaker comprising: a mounting box; an angular mounting plate, including a planar portion retained to a mounting wall of a mounting box, and an angular portion at about 200° in which a circuit breaker body is retained; a mechanical breaker actuator handle, retained to the mounting wall, including an actuator bar coupled to the breaker actuator handle; an actuator rod coupled to the actuator bar of the breaker actuator handle, and to a movable break contact of the circuit breaker, in order to operate it against a fixed breaker contact, on and off, by a rotational operation of the breaker actuator handle; and an overload actuator handle including a short overload actuator arm coupled to the overload actuator handle; and a link arm coupled to the overload actuator arm, in order to operate it, on and off, by a rotational operation of the overload actuator handle.

Owner:PROLEC GE INT S DE R L DE

Adjusting method for positions of saw blades of floor dividing and cutting machine and floor dividing and cutting machine

InactiveCN105856333AAffect cutting accuracyEasy to adjustCircular sawsEngineeringMechanical engineering

The invention discloses an adjusting method for positions of saw blades of a floor dividing and cutting machine. The adjusting method is characterized by comprising specific steps that firstly, each saw blade is mounted on an independent working motor to manufacture an independent cutting head, a stepping motor is arranged on each cutting head, and hollow rotating shafts of all the stepping motors are spirally and fixedly arranged on a lead screw of the dividing and cutting machine in a sleeving manner; and secondly, the fact that a single stepping motor is driven to move on the lead screw is used for achieving adjustment of the positions of the cutting heads. The invention further discloses the floor dividing and cutting machine. The floor dividing and cutting machine is characterized by comprising the fixedly-arranged lead screw and the cutting heads, each cutting head comprises the corresponding saw blade, the corresponding working motor for driving the saw blade to rotate and the corresponding stepping motor, the stepping motors are provided with the hollow rotating shafts, and the hollow rotating shafts are spirally arranged on the lead screw in the sleeving manner. Adjustment of the saw blade positions is convenient to operate, the saw blade positions are accurate in positioning, and the divided and cut materials are high in size precision.

Owner:江苏豪凯机械有限公司

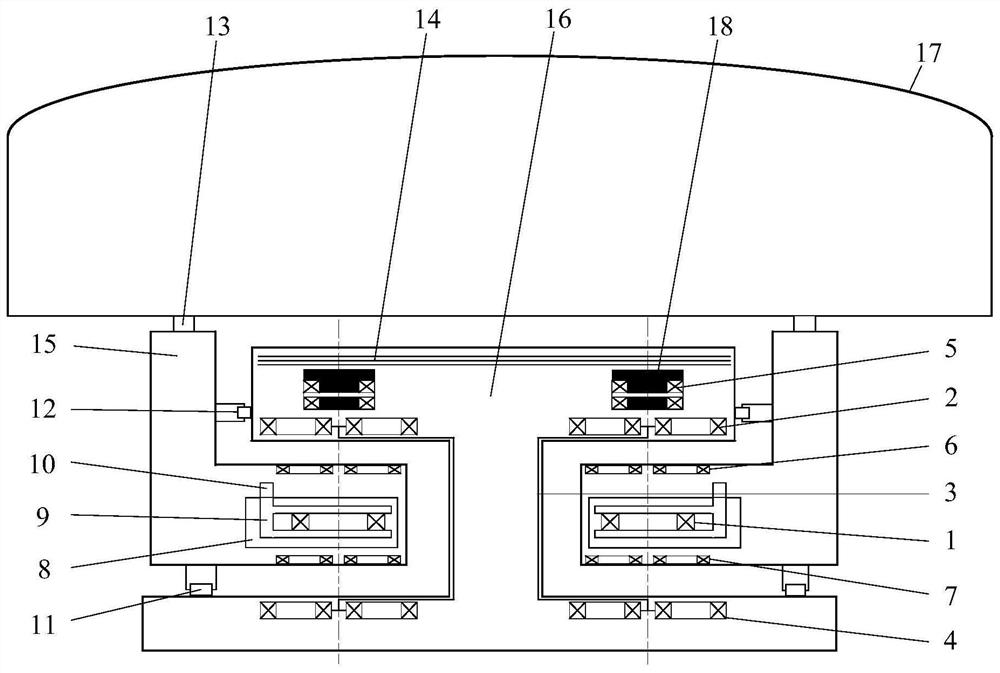

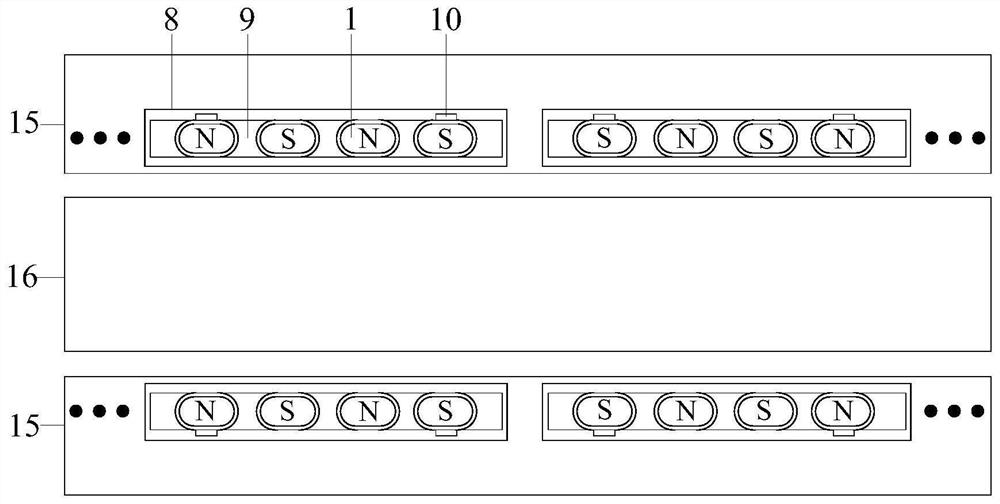

Superconducting electric-electromagnetic hybrid maglev train

PendingCN111873808ALarge operating air gapGood self-stabilityRailway vehiclesElectric propulsionAir springSuperconducting Coils

The invention discloses a superconducting electric electromagnetic hybrid maglev train, which comprises L-shaped suspension frames and an I-shaped ground rail, and is characterized in that the upper end of each suspension frame is connected with a train body through an air spring; the suspension frames are arranged on the two sides of the ground rail, and the suspension frames and the ground railare arranged at intervals. A plurality of superconducting magnets is arranged at the lower end of each suspension frame. An 8-shaped upper-layer suspension coil and an 8-shaped lower-layer suspensioncoil are arranged at the upper end and the lower end of the ground rail respectively, an upper-layer power generation coil and a lower-layer power generation coil are arranged at the lower end of thesuspension frame, and the upper-layer suspension coil is electrically connected with the lower-layer suspension coil; and a propelling coil is arranged above the upper-layer suspension coil. The invention has the advantages of large operation air gap, self-stabilization, good suspension guiding dynamic performance, better curve passing capacity, higher superconducting magnet magnetic field utilization rate and lower track construction cost.

Owner:SOUTHWEST JIAOTONG UNIV

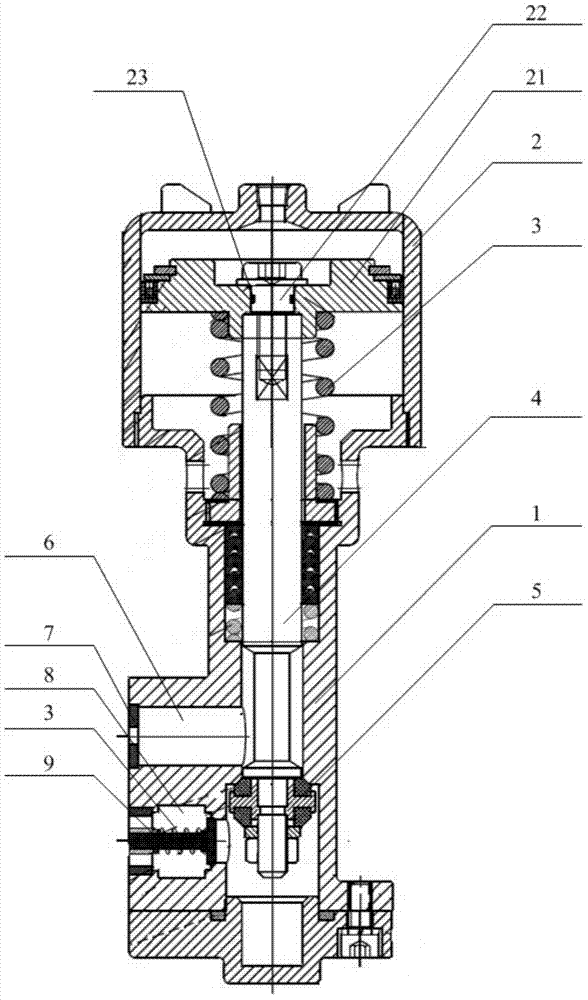

Pneumatic cut-off valve

InactiveCN104847903AShorten the horizontal lengthSave spaceOperating means/releasing devices for valvesLift valvePistonEngineering

The invention discloses a pneumatic cut-off valve. The pneumatic cut-off valve comprises a gas valve shell, a cylinder piston component is arranged at one end of the gas valve shell, a valve rod is connected at one end of a piston in the cylinder piston component and is accommodated in a columnar slideway in the gas valve shell, a valve element for blocking a gas passage is arranged at the other end of the valve rod, the columnar slideway is communicated with a gas inlet passage and a gas outlet passage, a compressed spring for pushing the valve element tightly is arranged in the gas valve shell, the gas inlet passage and the gas outlet passage are arranged along the axial direction of the columnar slideway side by side vertically sequentially and are arranged on the same side of the columnar slideway, a narrow port in seal fit with the valve element is formed between the gas inlet passage and the gas outlet passage, and the compressed spring enables the valve element to butt against the narrow port. The pneumatic cut-off valve has the advantages that by the aid of the design that the gas inlet passage and the gas outlet passage are arranged side by side vertically, the gas inlet passage and the gas outlet passage are arranged on the same side of the cut-off valve which is integrally columnar, so that transverse length of a cut-off valve body is decreased greatly, and occupied space required by cut-off setting is reduced.

Owner:杨舟

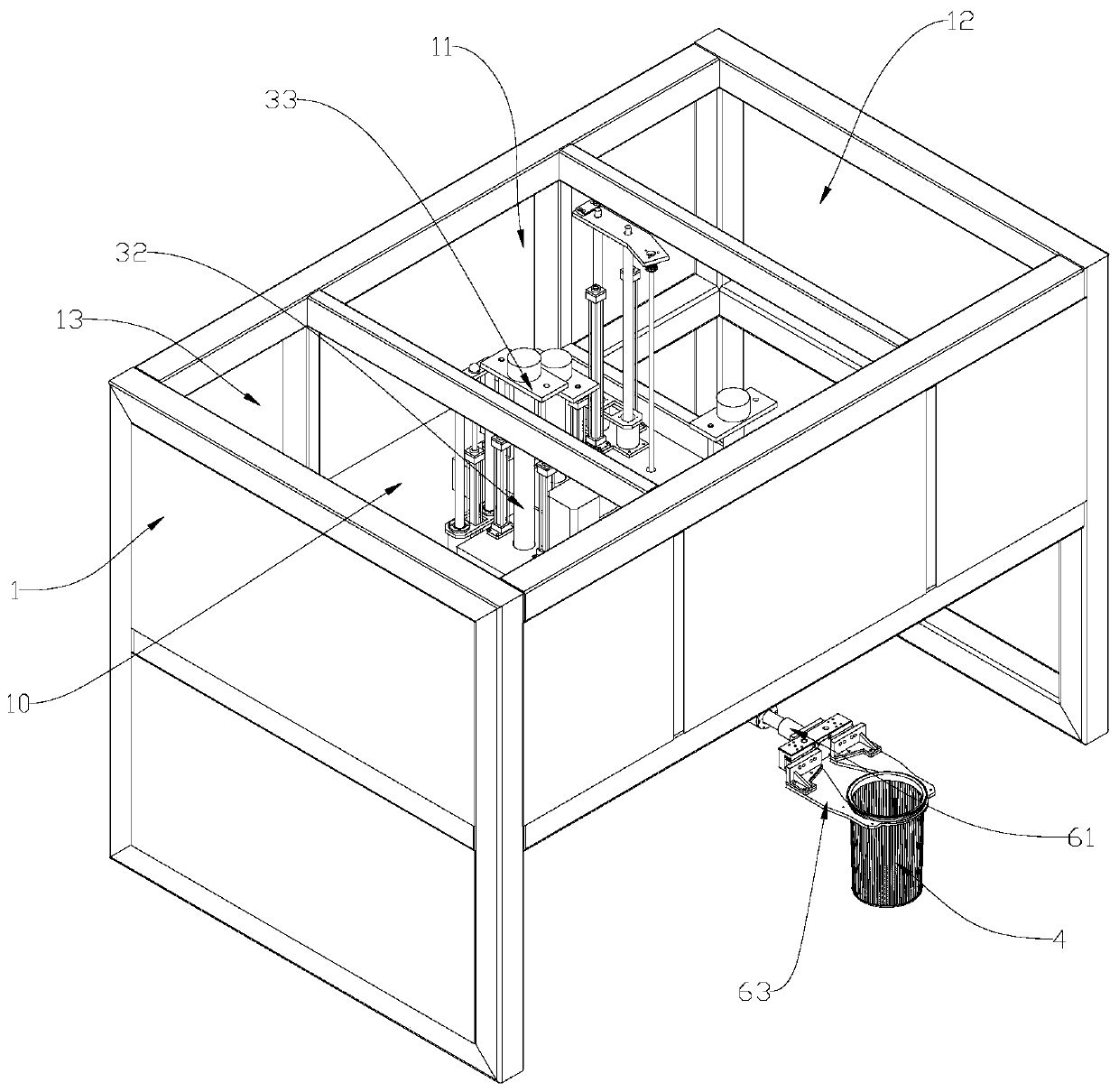

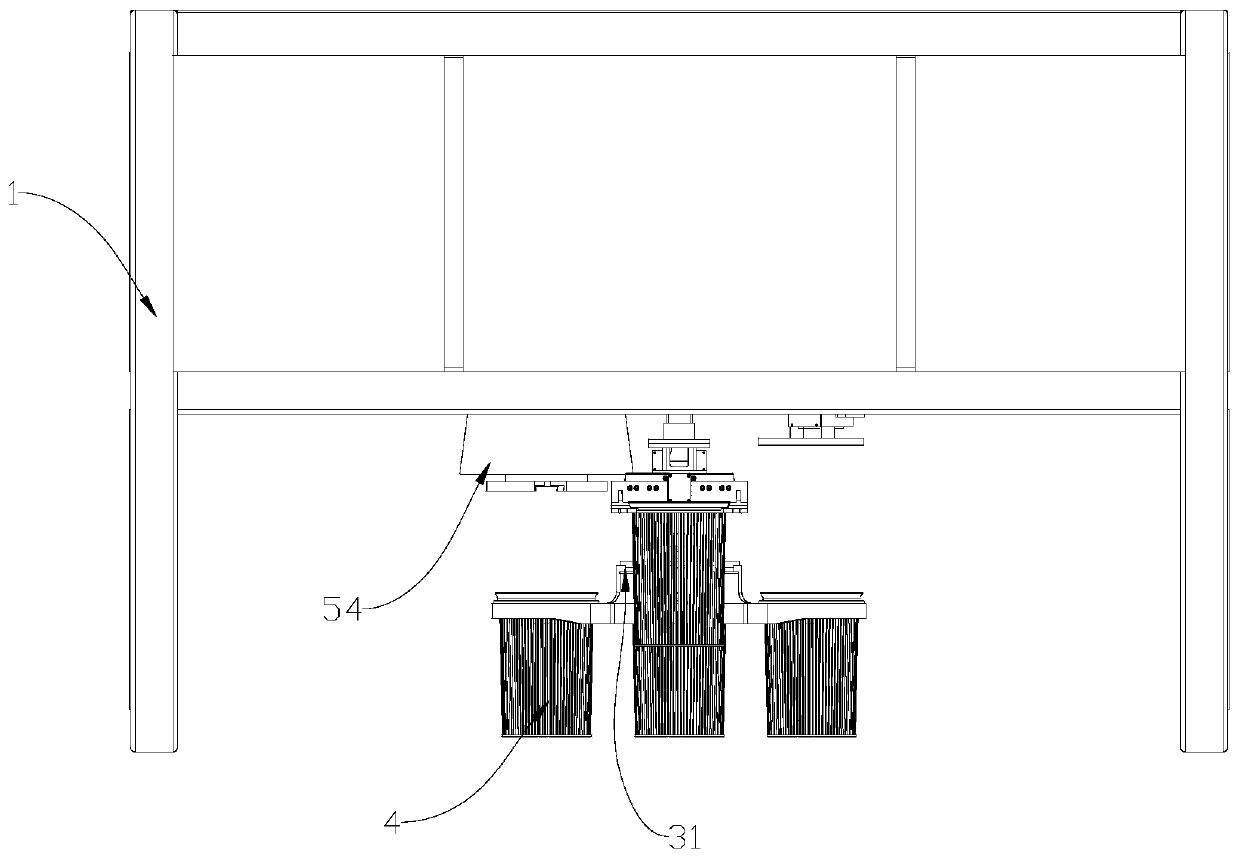

Continuous production system of rotary elevation type hot galvanizing and production process

ActiveCN110735100AShort cycleShorten the horizontal lengthHot-dipping/immersion processesLifting framesCentrifugationProcess engineering

The invention discloses a continuous production system of rotary elevation type hot galvanizing. The continuous production system of rotary elevation type hot galvanizing includes a galvanizing rig, acentrifugal device and a transfer device. The galvanizing rig comprises a first spindle and a plurality of bracket bodies. The centrifugal device comprises a second spindle, a centrifugal clamping mechanism and a second lifting mechanism. The centrifugal clamping mechanism can be driven by the second lifting mechanism to move up and down to clamp galvanizing baskets on the bracket bodies, and iscircumferentially rotated along with the second spindle to achieve centrifugation. The transfer device comprises a third spindle and a turnover mechanism. The transfer device is at least provided witha centrifugal station, a waiting station, a discharging station, a feeding station and a zinc blanking station. The five stations are sequentially arranged clockwise with the third spindle as the center. The invention further discloses a production process of the continuous production system of hot galvanizing. The transfer device is rotated circumferentially with the third spindle as the center,galvanizing, so that centrifugation, discharging and feeding are arranged on a same circumference, not only is the size and the floor area reduced, but also the speed of discharging is fast, the galvanizing cycle is shortened and the production efficiency is high.

Owner:嘉兴宝利机械股份有限公司

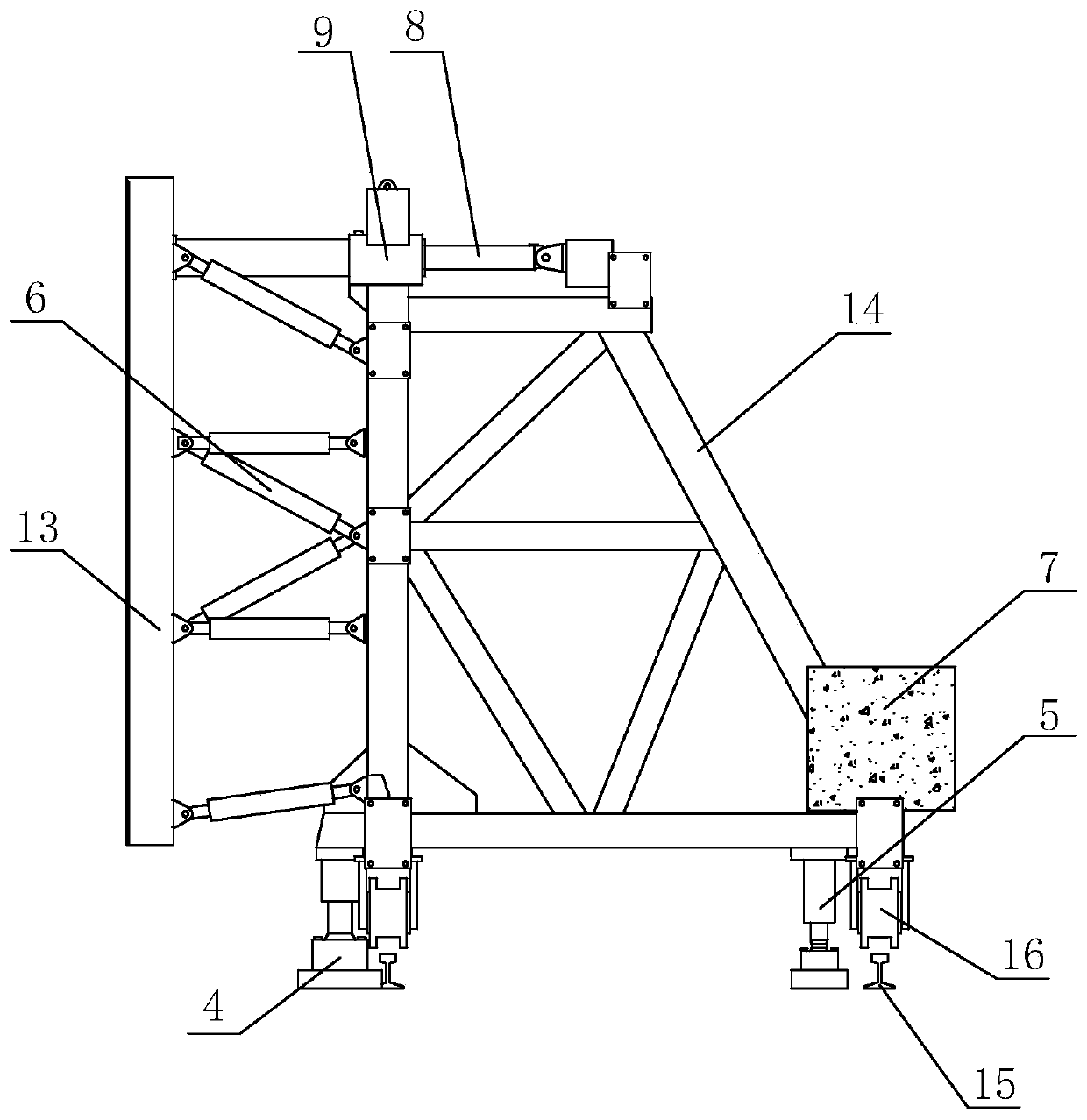

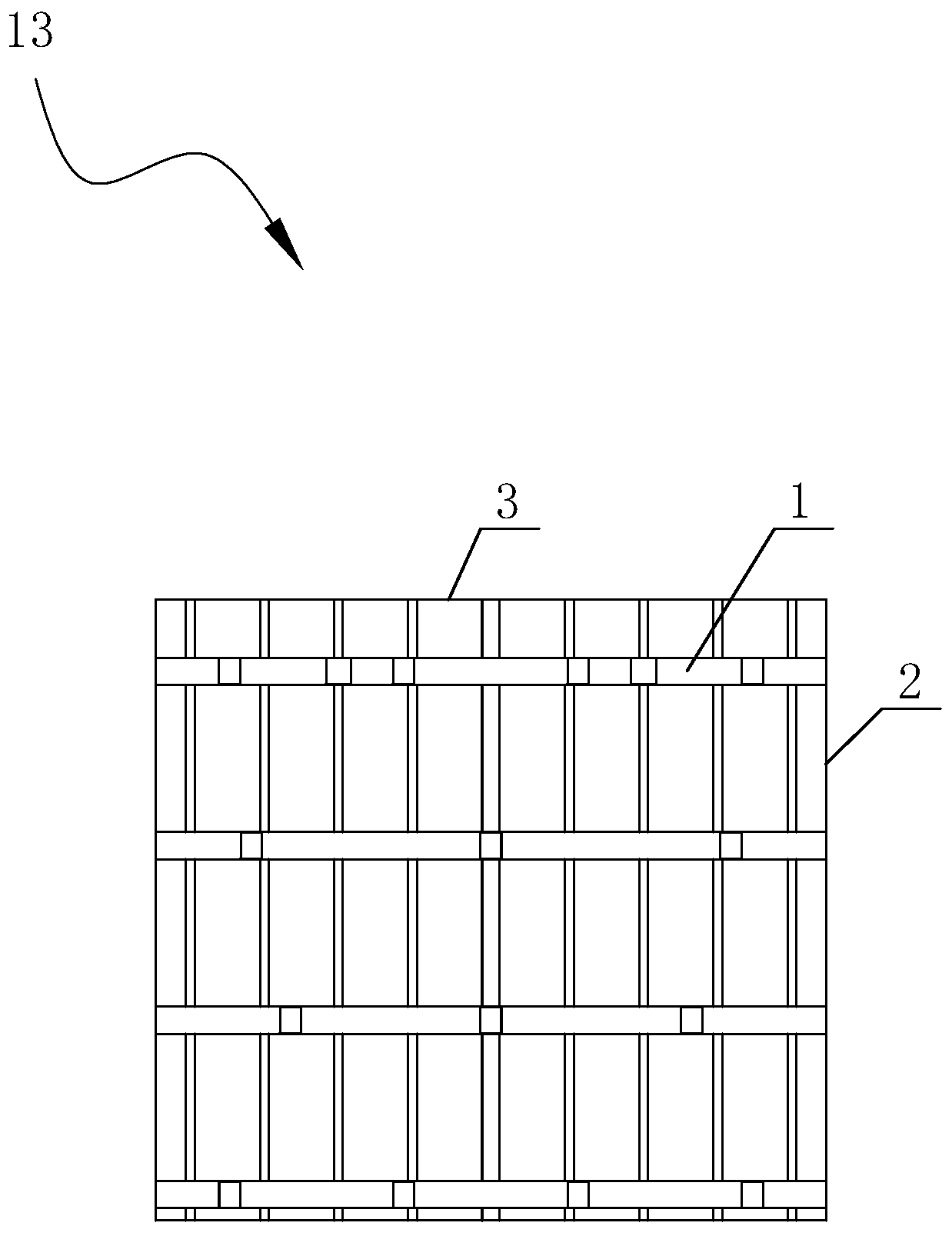

Self-inclined side wall formwork trolley, device and application method of device

PendingCN111075480ASimple demoulding methodReduced need for operating technologyUnderground chambersTunnel liningVehicle frameMechanism (engineering)

The invention discloses a self-inclined side wall formwork trolley, and relates to the technical field of building engineering construction. The self-inclined side wall formwork trolley comprises a vehicle frame, a formwork is arranged on one side of the vehicle frame in an adjustable mode, and an adjusting device for adjusting the position of the formwork is arranged between the formwork and thevehicle frame, a wheel walking device which is convenient for moving the position of the vehicle frame is arranged at the bottom of the vehicle frame, and a self-inclined demoulding device for pushingthe vehicle frame to incline is further arranged at the bottom of the vehicle frame; and the self-inclined demoulding device comprises a rotating mechanism and a pushing gear, and the rotating mechanism and a pushing gear are separately arranged on two sides of the vehicle frame. In order to solve the problem of difficulty in demoulding in the prior art, the vehicle frame is arranged in an inclined mode, and then the self weight of the vehicle frame is used for restoring the horizontal placement position to achieve demoulding, the demolding efficiency is improved, and the operation requirement is low.

Owner:SHANGHAI MECHANIZED CONSTR GRP

Ladder stabilizing tool

ActiveUS9488001B2Increase the lengthShorten the horizontal lengthLaddersEngineeringMechanical engineering

A ladder stabilizing tool for use with an extension ladder may include a U-shaped brace coupled to a ladder grasping member. A pair pivotable of feet may be attached to the ends of U-shaped brace permitting the stabilizing tool to secure an extension ladder to a roof at any slope between zero and ninety degrees. The grasping member has a pair of tapered supports configured to fit within the apertures formed in the rails of an extension ladder. The stabilizing tool ensures stability of the ladder for the safety of an operator, while further providing clearance from any gutter attached to housing fascia.

Owner:CHEREVKO PIOTR

Tire-moved-type construction waste treatment device

ActiveCN102847702AEliminate or reduce pollutionEasy to moveConstruction waste recoverySolid waste disposalVehicle frameSingle vehicle

The invention relates to a tire-moved-type construction waste treatment device comprising a vehicle frame with a tire-type walking device. A feeding device, a construction waste special-purposed separation and crushing device, and a vibration screen are sequentially arranged on the vehicle frame from one end to the other end. A first discharging belt conveyor tilted upward on a direction towards the feeding device, and a second discharging belt conveyor tilted upward on a direction opposite to that of the first discharging belt conveyor are sequentially arranged between the construction waste special-purposed separation and crushing device and the vibration screen. The upward-tilting end of the first discharging belt conveyor is arranged above the feeding end of the second discharging belt conveyor. A sundries discharging port is provided on the vibration screen. An upward-tilted material returning belt conveyor is arranged between a coarse material discharging port of the vibration screen and a raw material chamber. According to the invention, an entire construction waste treatment process is accomplished by using a single vehicle. The structure is compact, device integral length is reduced, and the device can be moved rapidly according to actual situations. Therefore, manufacturing and operating costs are reduced.

Owner:ZHENGZHOU ZHONGYI MINING MACHINERY

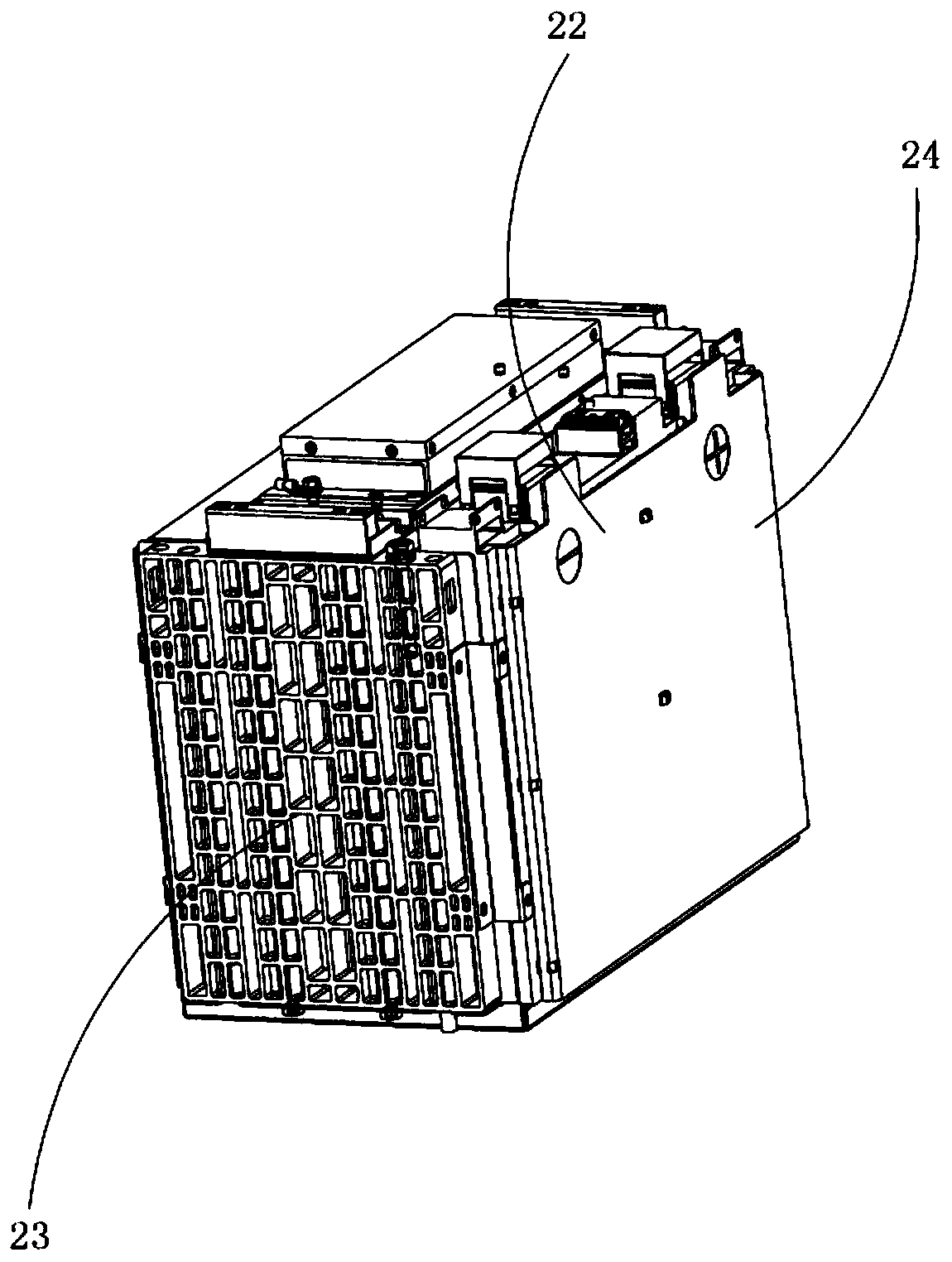

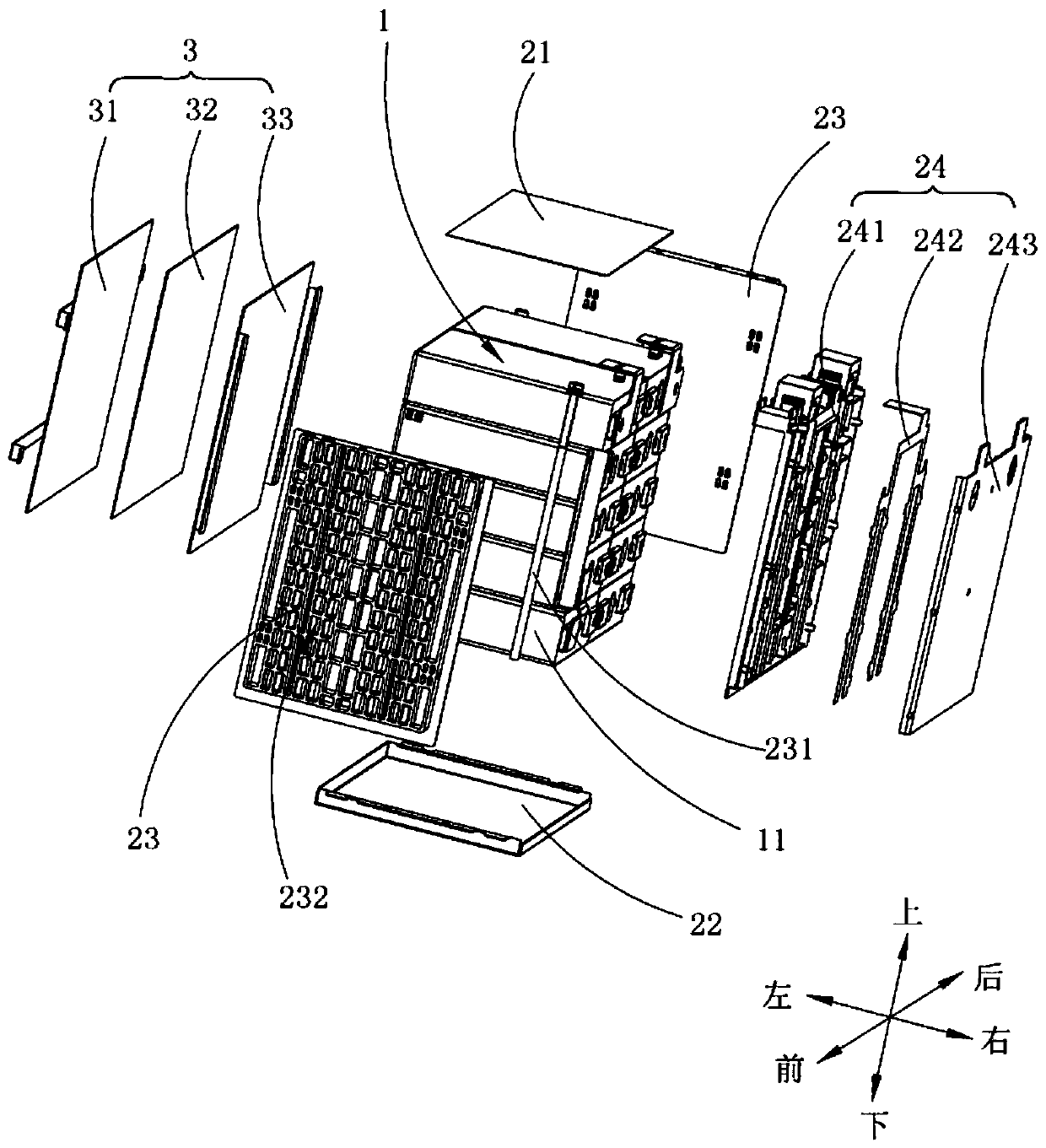

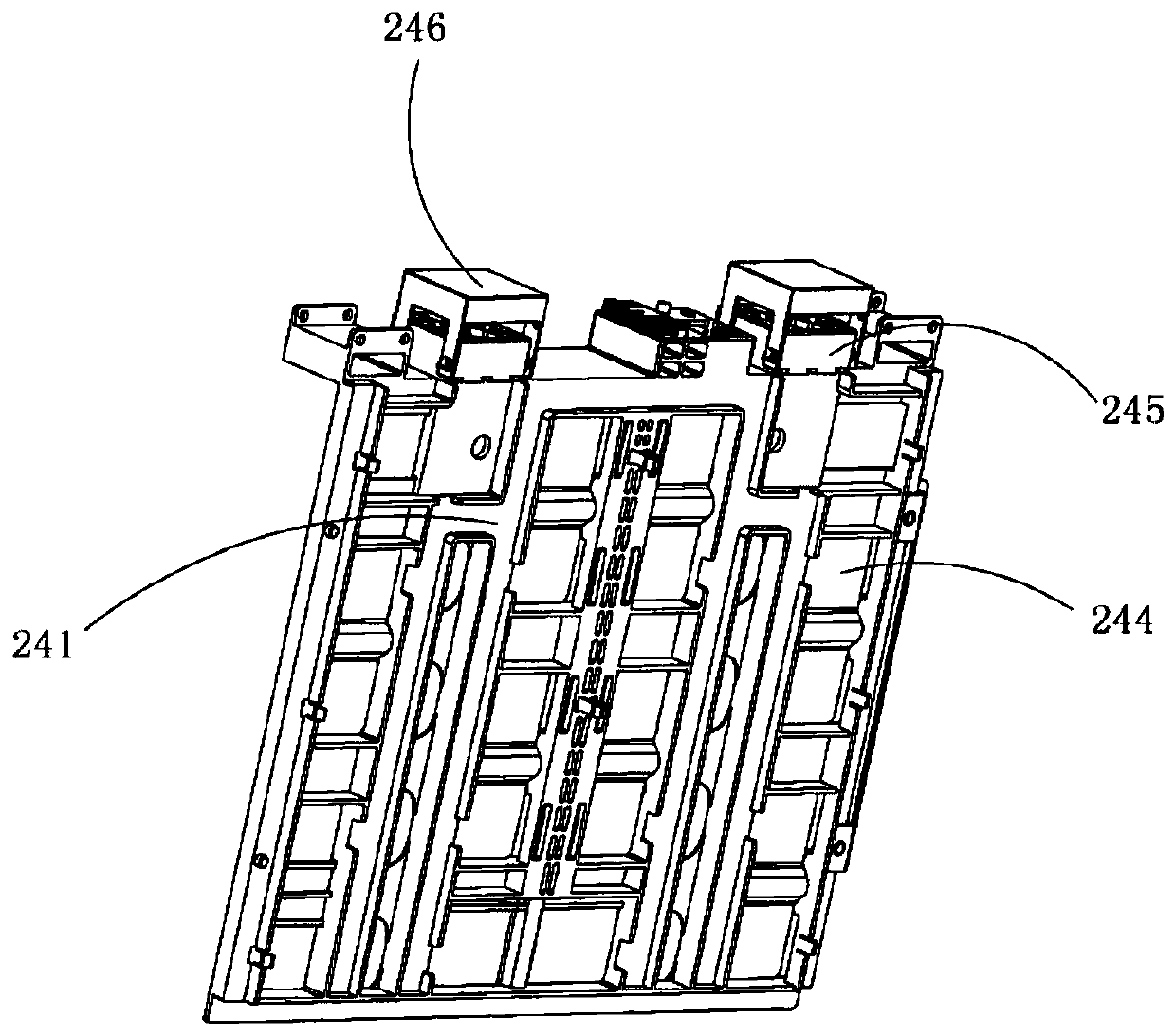

Battery module and light logistics vehicle

ActiveCN111599959AHeating mildImprove securitySecondary cellsCell component detailsBattery cellElectrical and Electronics engineering

The invention discloses a battery module and a light logistics vehicle. The battery module comprises a battery cell assembly, a shell and a heating assembly, wherein the battery cell assembly comprises a plurality of battery cells stacked up and down; an opening is formed in one side of the shell; the heating assembly is arranged at the opening of the shell, an accommodating space is defined by the heating assembly and the shell, the battery cell assembly is accommodated in the accommodating space, the heating assembly comprises a heating film, an insulating sheet and a heat conducting plate arranged between the heating film and the insulating sheet, and the insulating sheet covers the side, which deviates from the opening, of the battery cell assembly; and the heating film is used for heating the heat conducting plate, and the battery cell assembly is heated through the insulating sheet. According to the invention, the battery cell assembly of the battery module is formed by stackingbattery cells, the capacity of the battery module is improved, the battery cell assembly adopts a mode of heating by the heating film, and the transverse width of the battery module is reduced, so that the battery module meets the arrangement requirement of the light logistics vehicle in the width direction, and the battery module which is low in cost, safe, high in capacity and large in size canbe applied to the light logistics vehicle.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

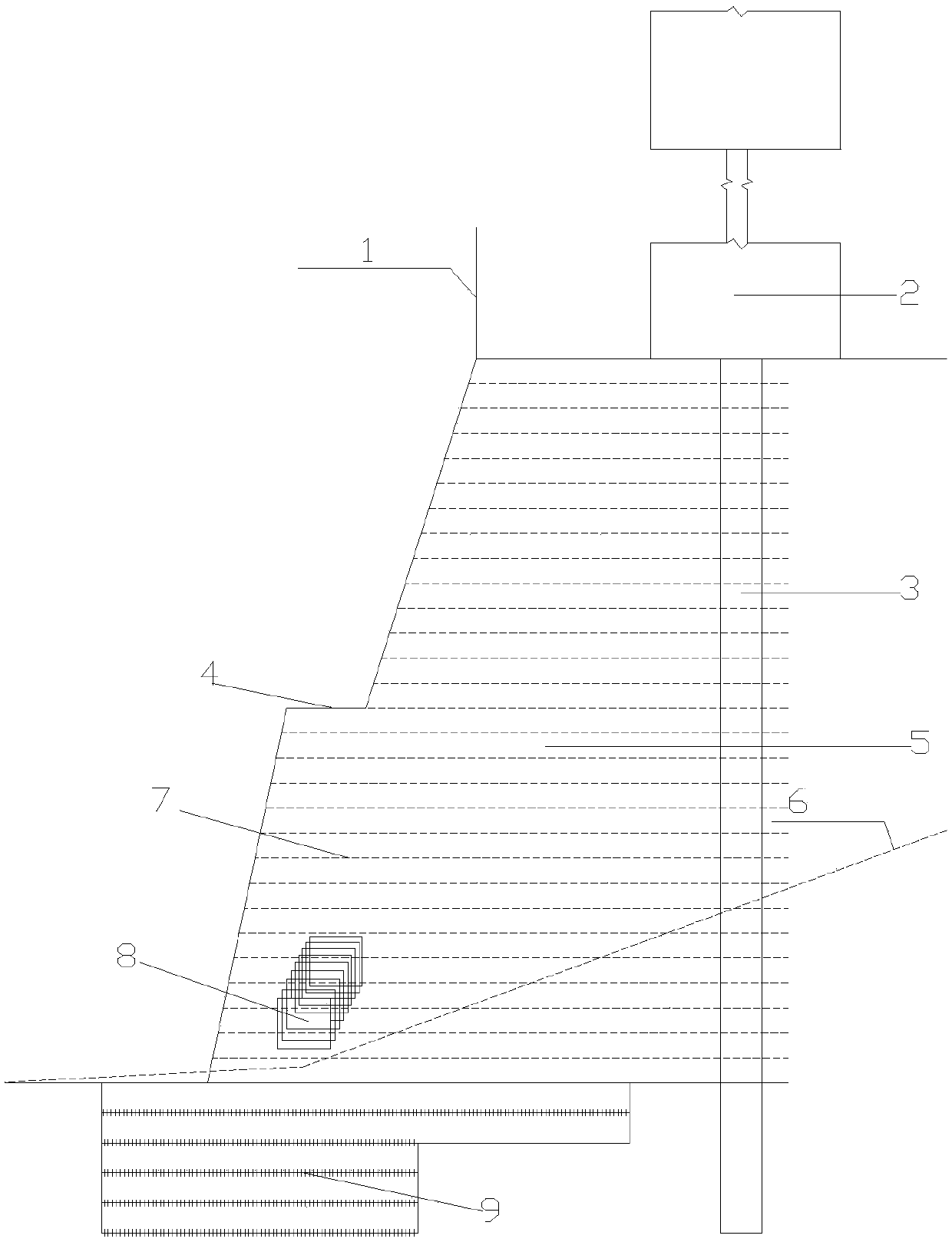

Pile-penetration filling body reinforcing load-bearing structure and construction method thereof

PendingCN107700528AImprove horizontal constraintsShorten the horizontal lengthArtificial islandsUnderwater structuresSoil scienceLandslide

Owner:HUBEI UNIV OF TECH

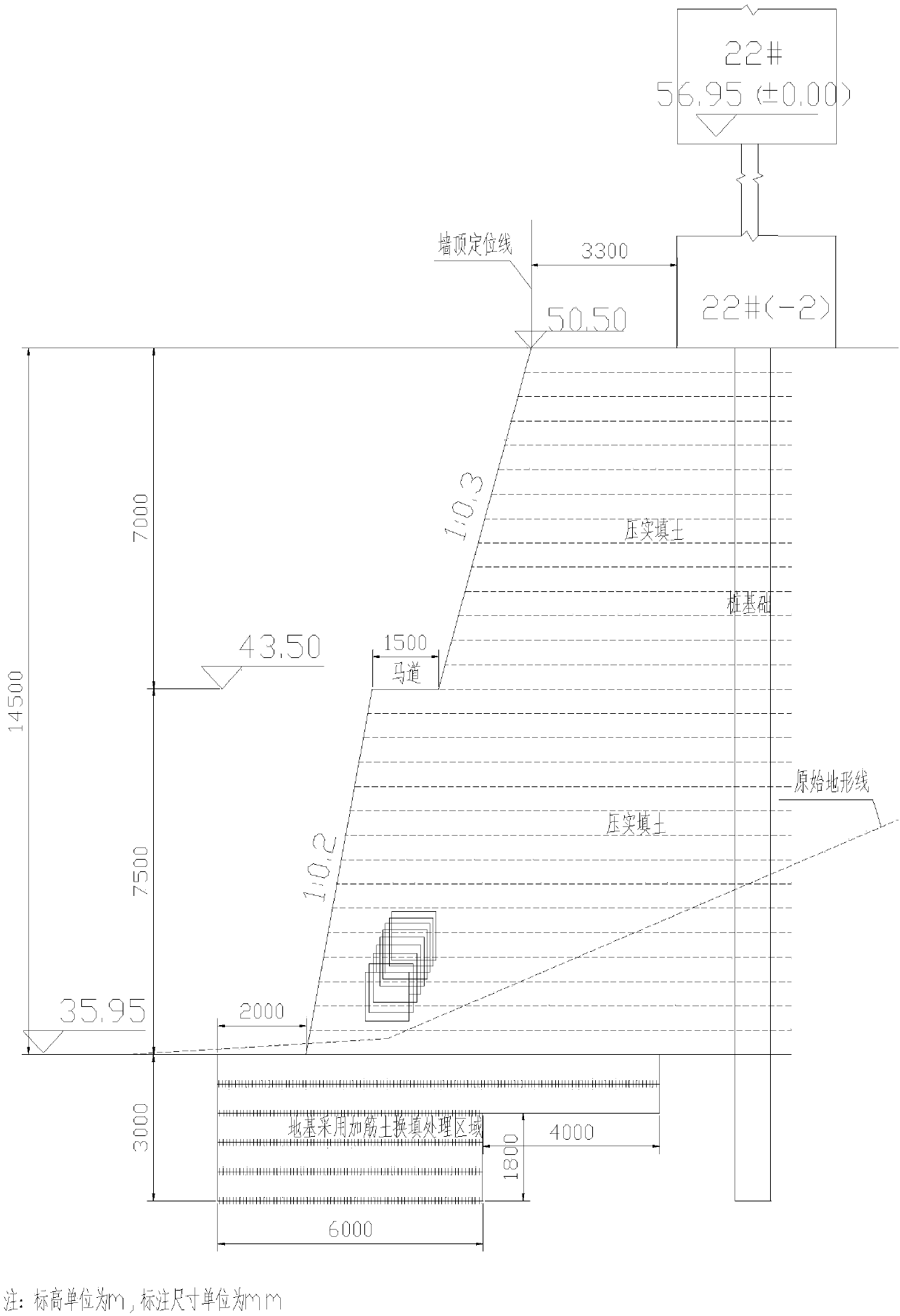

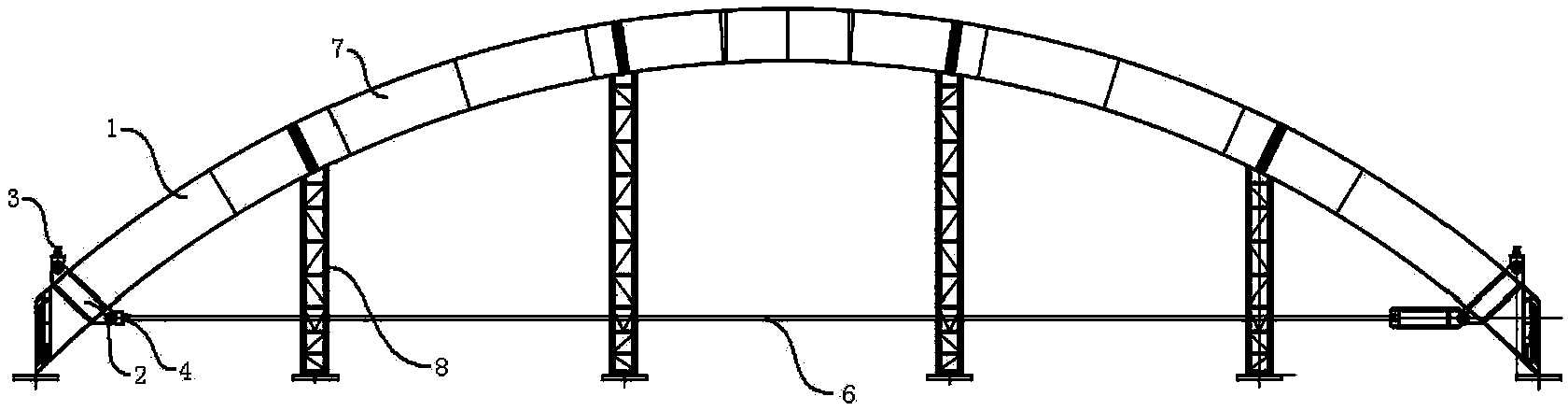

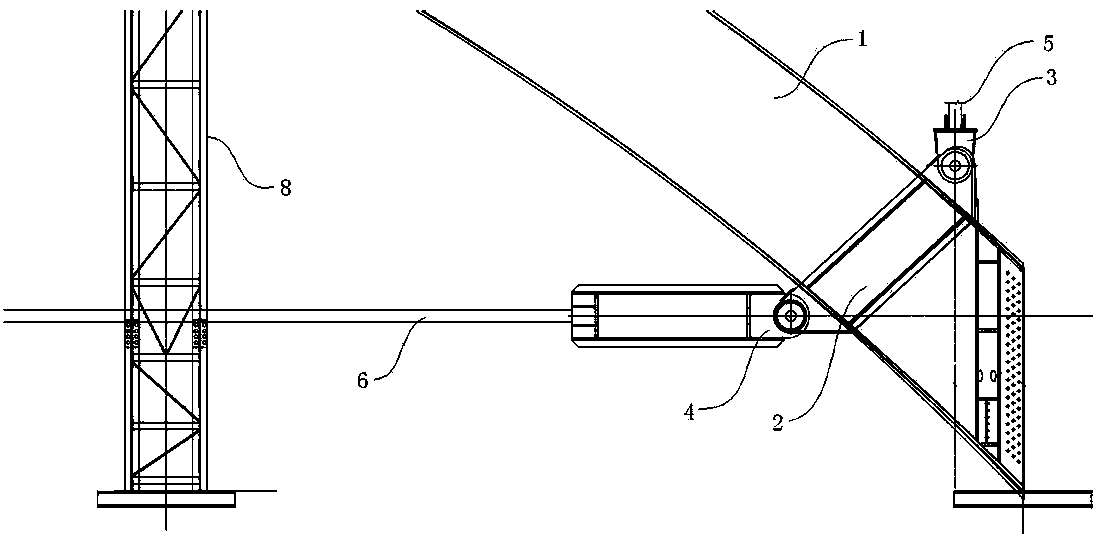

Double-cable lifting device and lifting method for large-span solid-web arc beam

ActiveCN104018684AFacilitates perforation alignmentEasy to operateBuilding material handlingInstabilityEngineering

The invention discloses a double-cable lifting device for a large-span solid-web arc beam. The double-cable lifting device comprises L-shaped lug plates arranged at the two ends of the arc beam, and each L-shaped lug plate is provided with a vertical lifting tool and a horizontal lifting tool. The two vertical lifting tools are hinged to the upper portions of the L-shaped lug plates through hinge pins and connected with vertical inhaul cables extending upwards respectively. The two horizontal lifting tools are hinged to the opposite sides of the two L-shaped lug plates through hinge pins, and a horizontal inhaul cable is arranged between the two horizontal lifting tools and connected with a horizontal hydraulic tensioning device. The horizontal length of the whole arc beam is adjusted through tensioning, length adjustment in the horizontal direction is carried out according to needs, and therefore the problem that a high-strength bolt can not penetrate into a bolt hole of a main structure under the conditions of reverse arc deformation generated in the lifting process of the arc beam, expansion deformation caused by temperature, out-of-plane instability caused in the installation process of an arc structure and the like is solved, and hole penetration and alignment after the arc beam is lifted in position can be easy.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

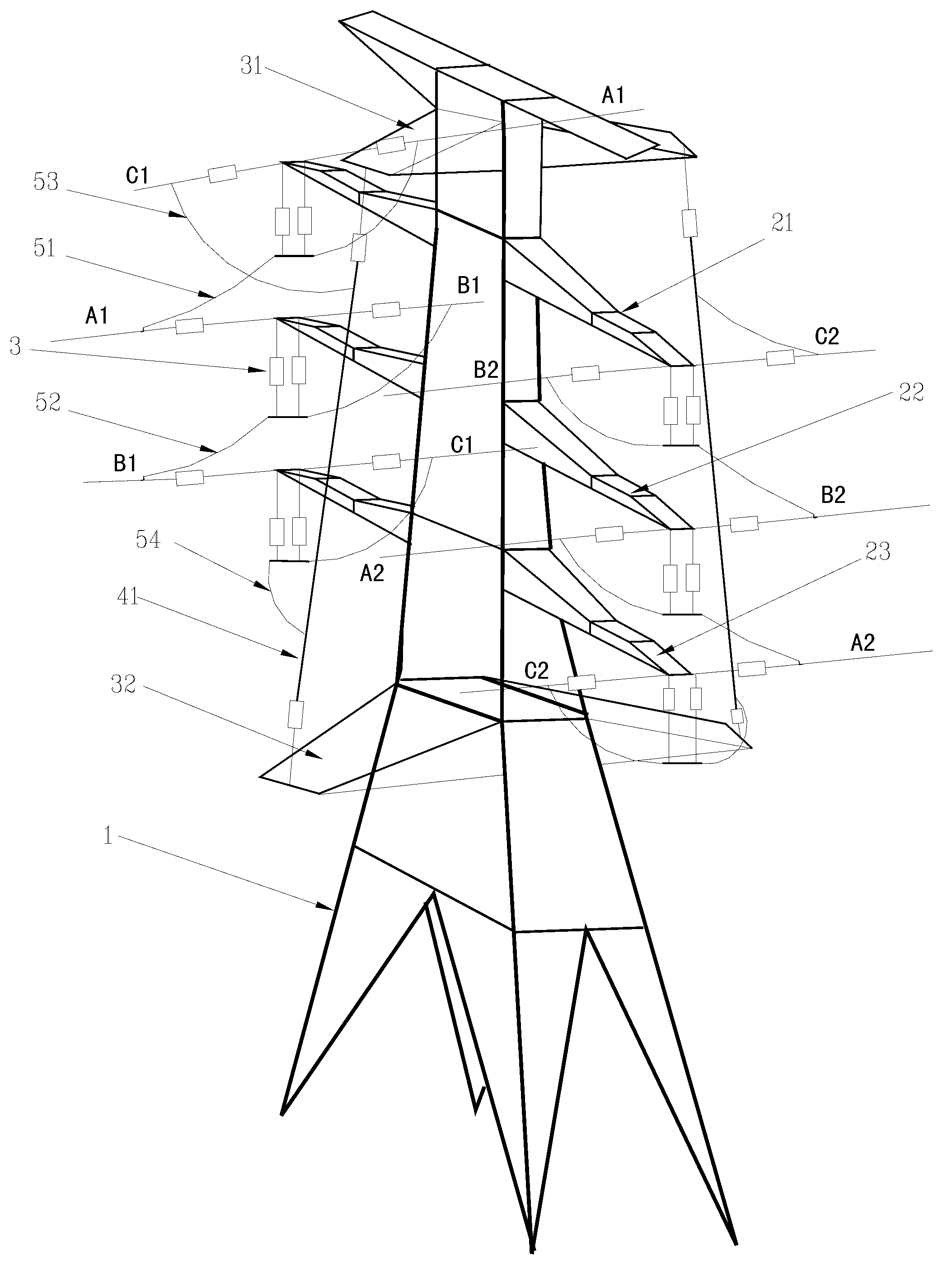

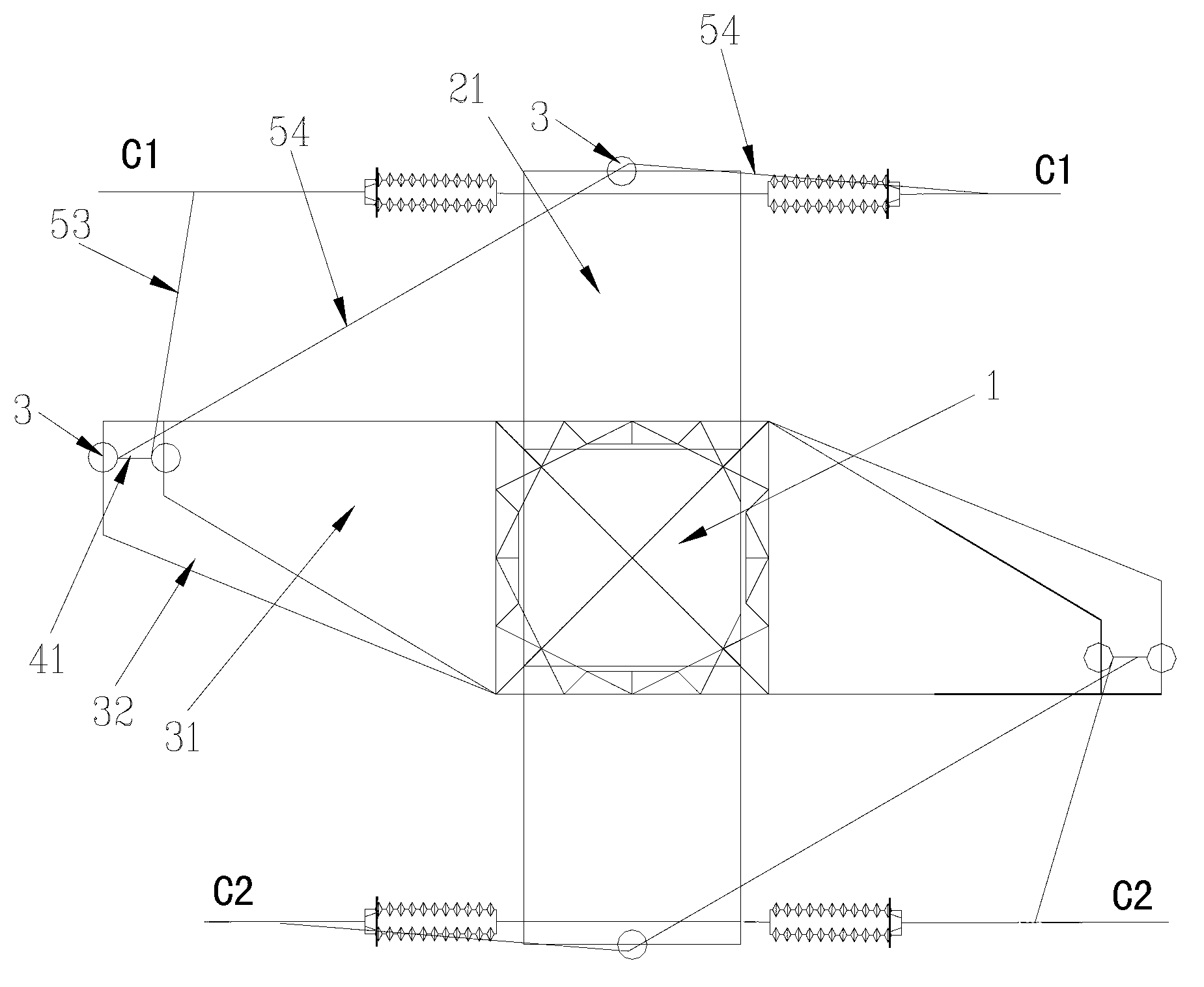

Jumping around transposition tower in common-tower double-circuit transmission line

ActiveCN103022951AShorten the horizontal lengthReduce weightTowersSpatial arrangements/dispositions of cablesElectric power systemTransposition tower

The invention discloses a jumping around transposition tower, for power system transmission lines, in a common-tower double-circuit transmission line. The jumping around transposition tower is especially suitable for transposition of high-altitude high-voltage transmission lines. The jumping around transposition tower aims to provide the jumping around transposition tower which is capable of realizing transposition without increasing jumper cross arm length. The transposition tower comprises a tower body. An upper wire cross arm and a lower wire cross arm are mounted on the front side and the rear side along the direction of the transmission line. An upper jumper and a lower jumper are connected between the upper wire cross arm and the lower wire cross arm. The front section of a third transmission line is connected to the upper cross arm and connected with one of the upper jumper and the lower jumper through a third upper transposition jumper. The rear section of the third transmission line is connected to the lower cross arm and connected with the same one of the upper jumper and the lower jumper through a third lower transposition jumper. Consumable materials and manufacturing cost are saved, tower weight is reduced, transport and mounting in area with inconvenient traffic are facilitated, jumper leading is simple, construction and operation maintenance are facilitated, and the jumping around transposition tower is worthy of popularization.

Owner:四川电力设计咨询有限责任公司

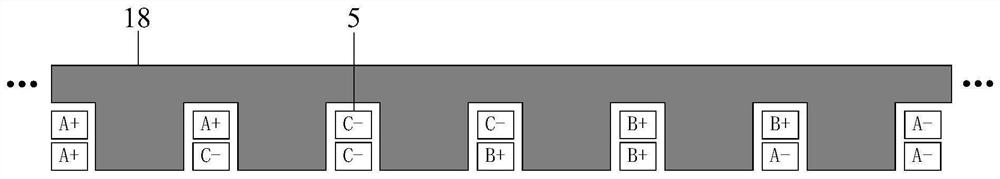

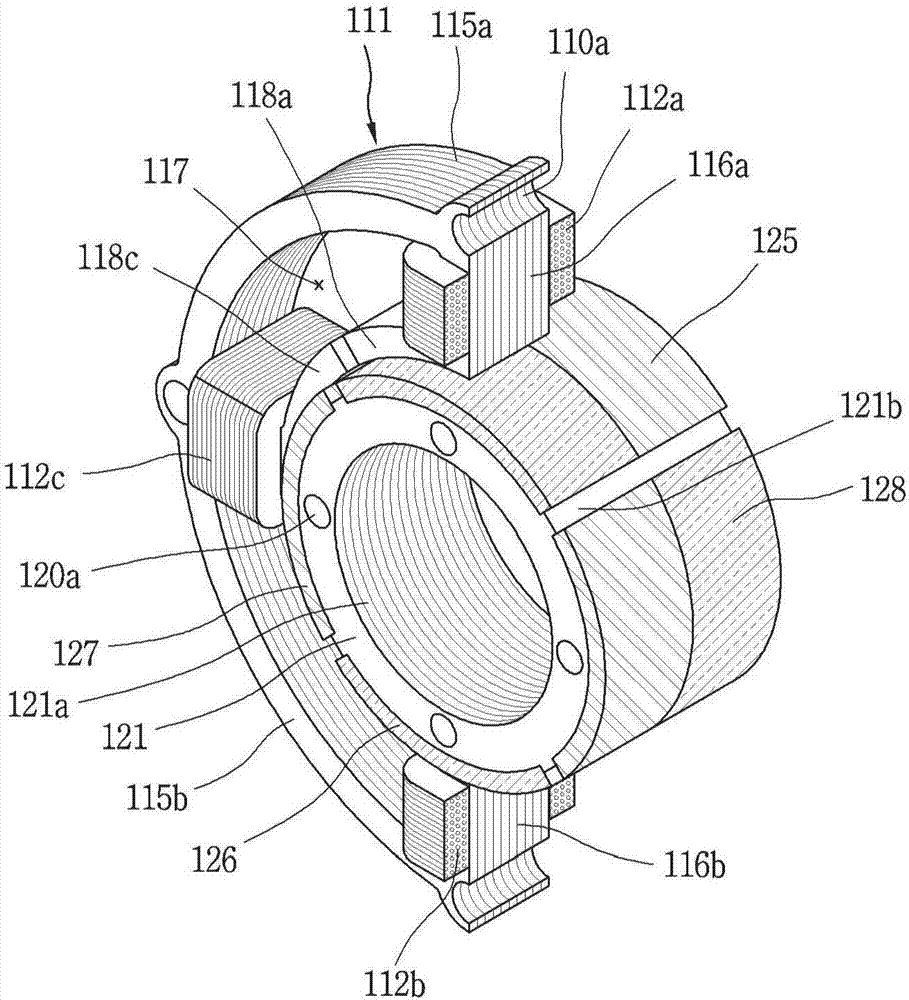

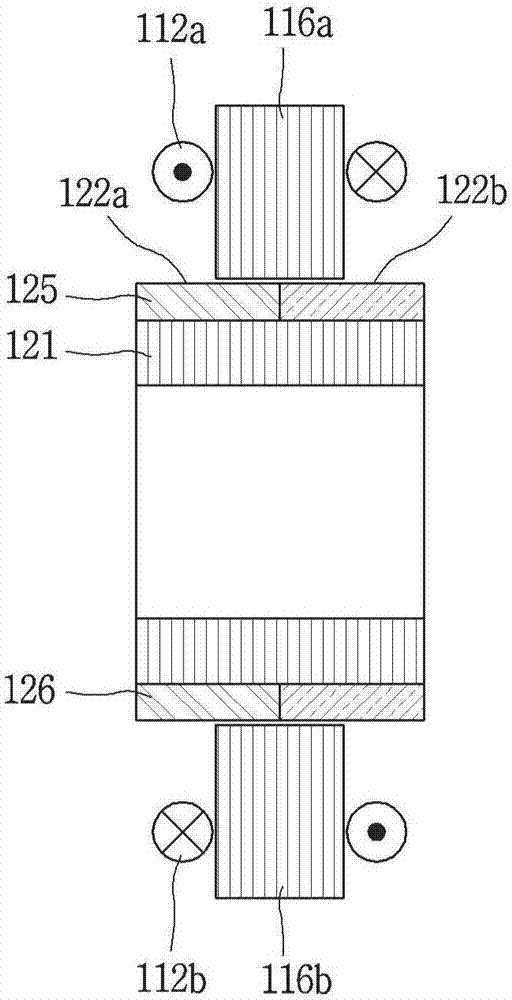

Transverse flux reciprocating motor and reciprocating compressor having a transverse flux reciprocating motor

ActiveCN107546948AReduce in quantityReduce manufacturing costsReciprocating/oscillating/vibrating magnetic circuit partsPositive displacement pump componentsTransverse fluxResonance

A transverse flux reciprocating motor and a reciprocating compressor having a transverse flux reciprocating motor are provided. The transverse flux reciprocating motor may include a stator wound witha magnet coil, a mover inserted into the stator and coupled with a magnet having opposite magnetic poles in an orthogonal direction with respect to a magnetic flux generated by the magnet coil, and aresonance spring that allows the mover to perform a resonance motion with respect to the stator using a force trying to move toward a side with low magnetic resistance between the stator and the mover, whereby the transverse flux reciprocating motor and the reciprocating compressor having a transverse flux reciprocating motor may be reduced in size and weight and obtain high efficiency.

Owner:LG ELECTRONICS INC

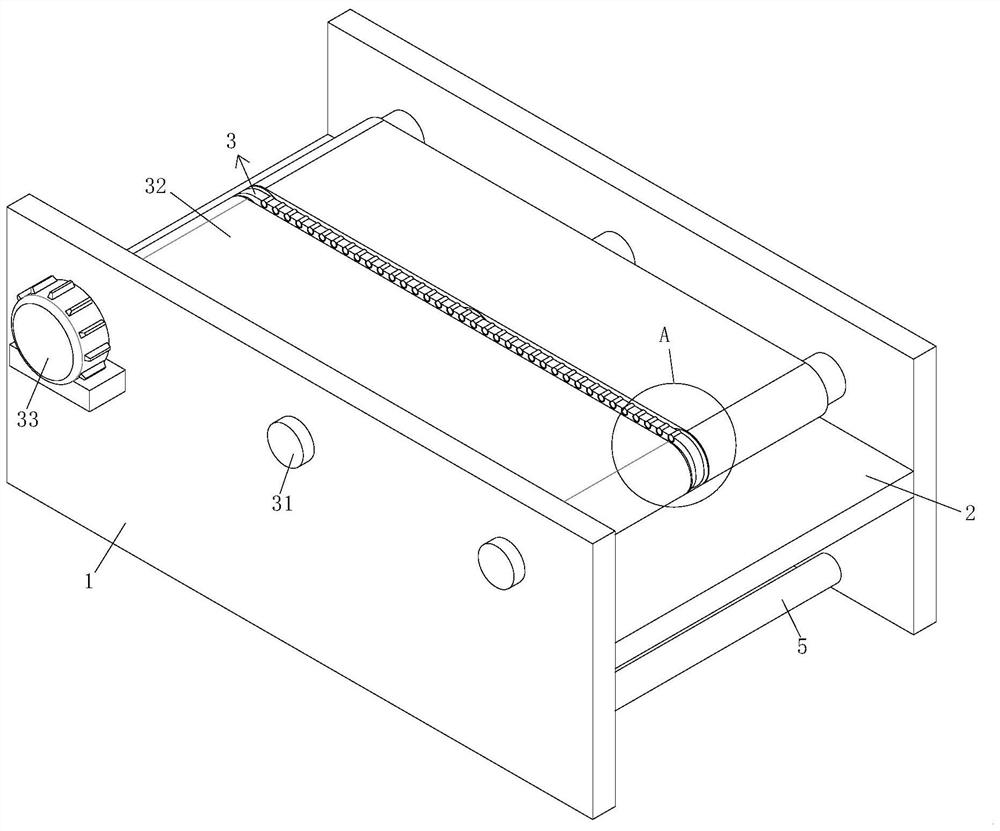

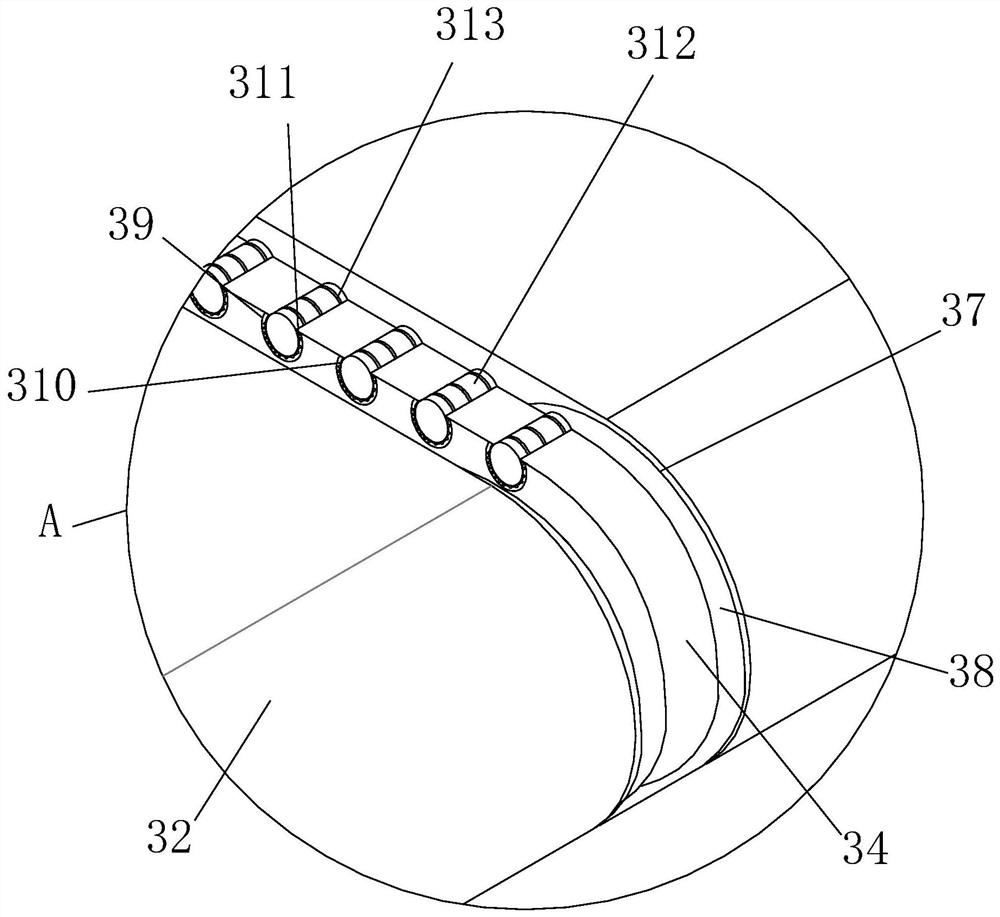

Energy-saving conveying device based on reduction of friction force

InactiveCN112224745AShorten the horizontal lengthReduce sagMechanical conveyorsRoller-waysBalancing machineFriction force

The invention provides an energy-saving conveying device based on reduction of friction force. The energy-saving conveying device comprises two supporting side plates for supporting equipment, a supporting plate for connecting the two supporting side plates, a double-row conveying mechanism for conveying objects and an air-pressure progressive balance mechanism for reducing surface indentation friction force. The two supporting side plates are distributed in parallel, and a supporting plate is fixedly connected between the two supporting side plates. The invention relates to the field of conveying devices. According to the energy-saving conveying device based on reduction of the friction force, a special conveying mechanism and a special supporting structure are designed for solving the problem that an existing conveying crawler belt is too heavy and sunken in use. The sunken surface is reduced by strengthening the supporting force, and therefore the problems are effectively solved that when a common conveying device conveys large objects, surface indentation occurs, the friction resistance is large when the conveying belt makes contact with the shaft face of a conveying shaft, thedriving energy consumption is increased, the conveying belt is prone to being damaged, and limitations exist in most existing processing modes.

Owner:杨磊

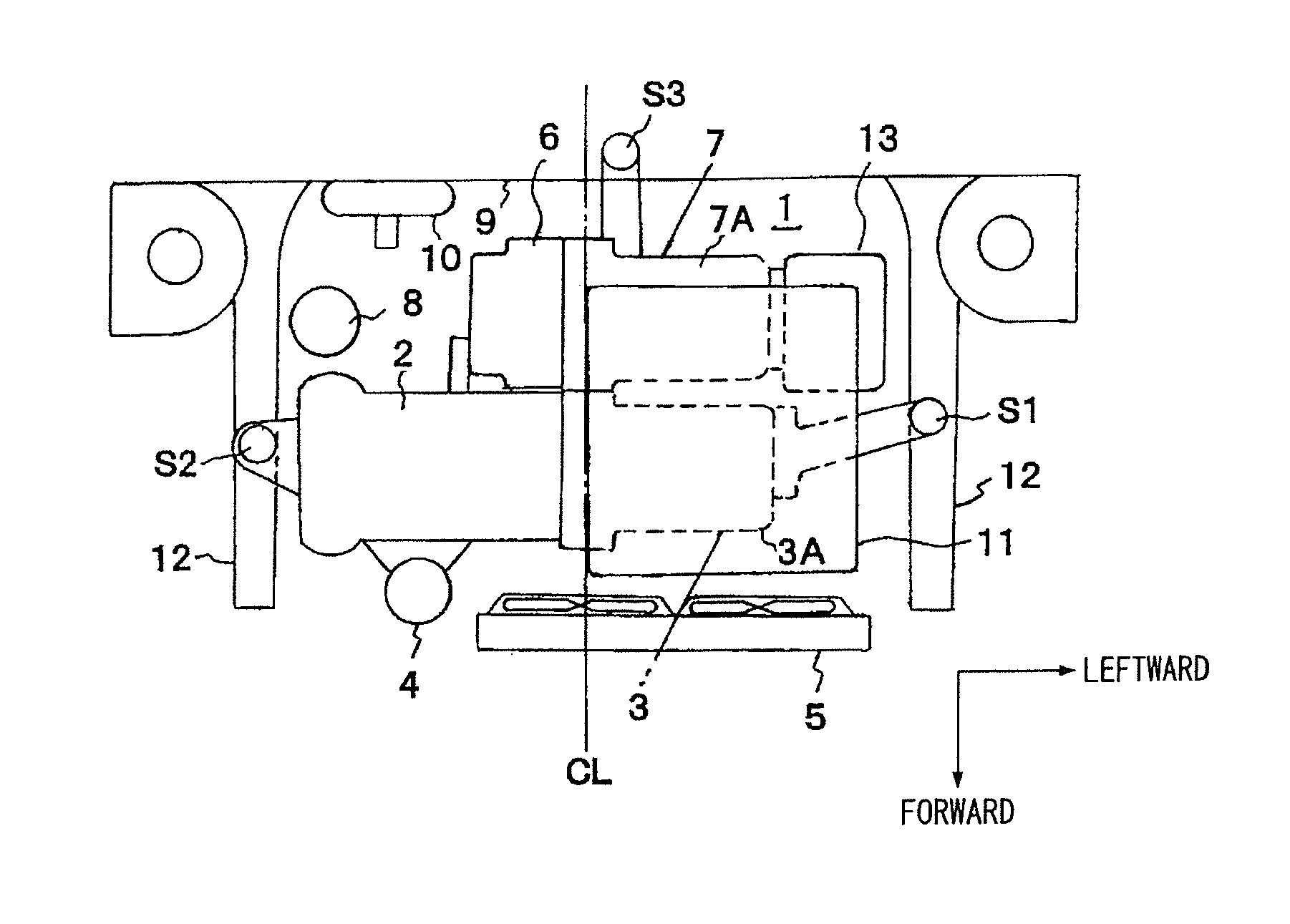

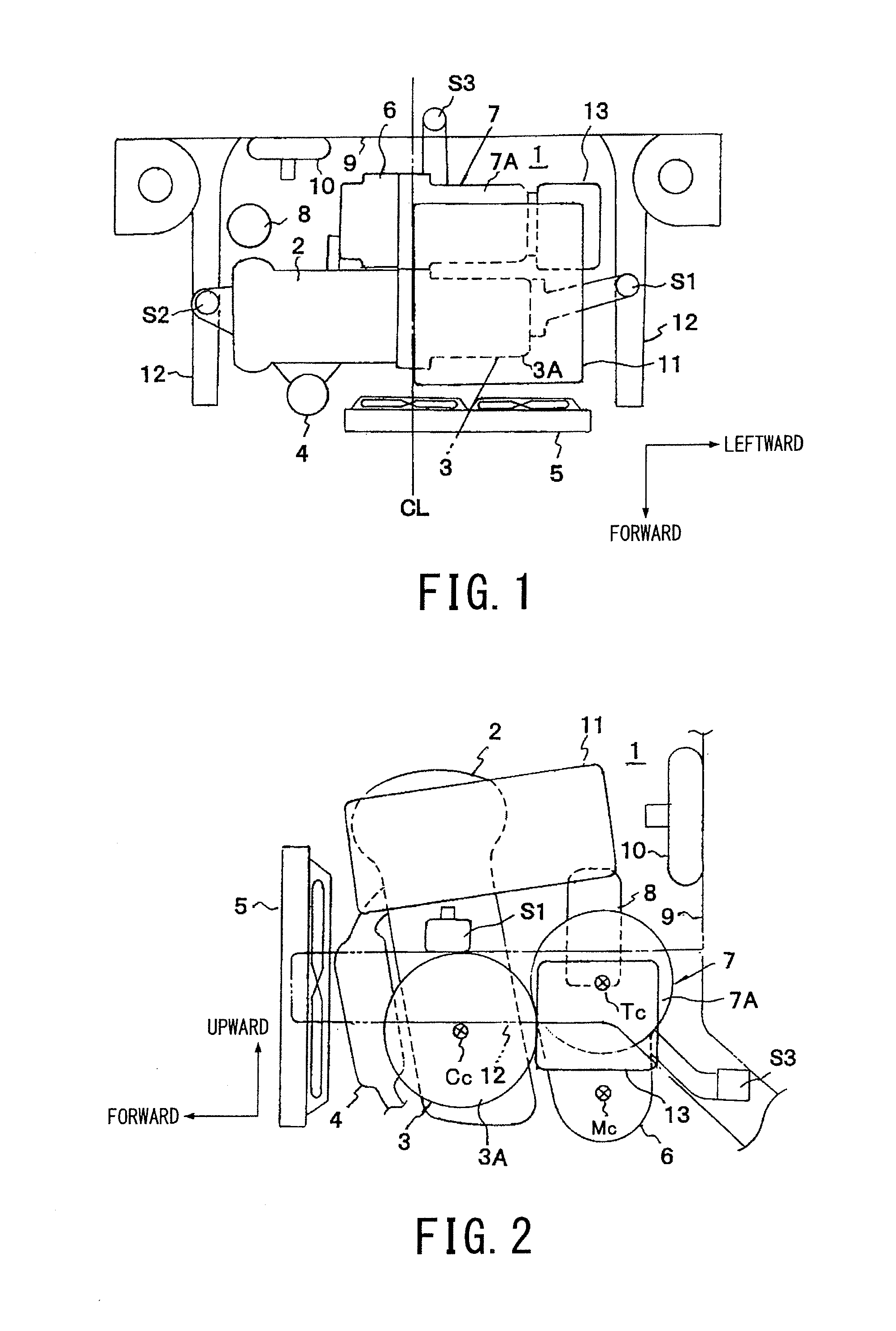

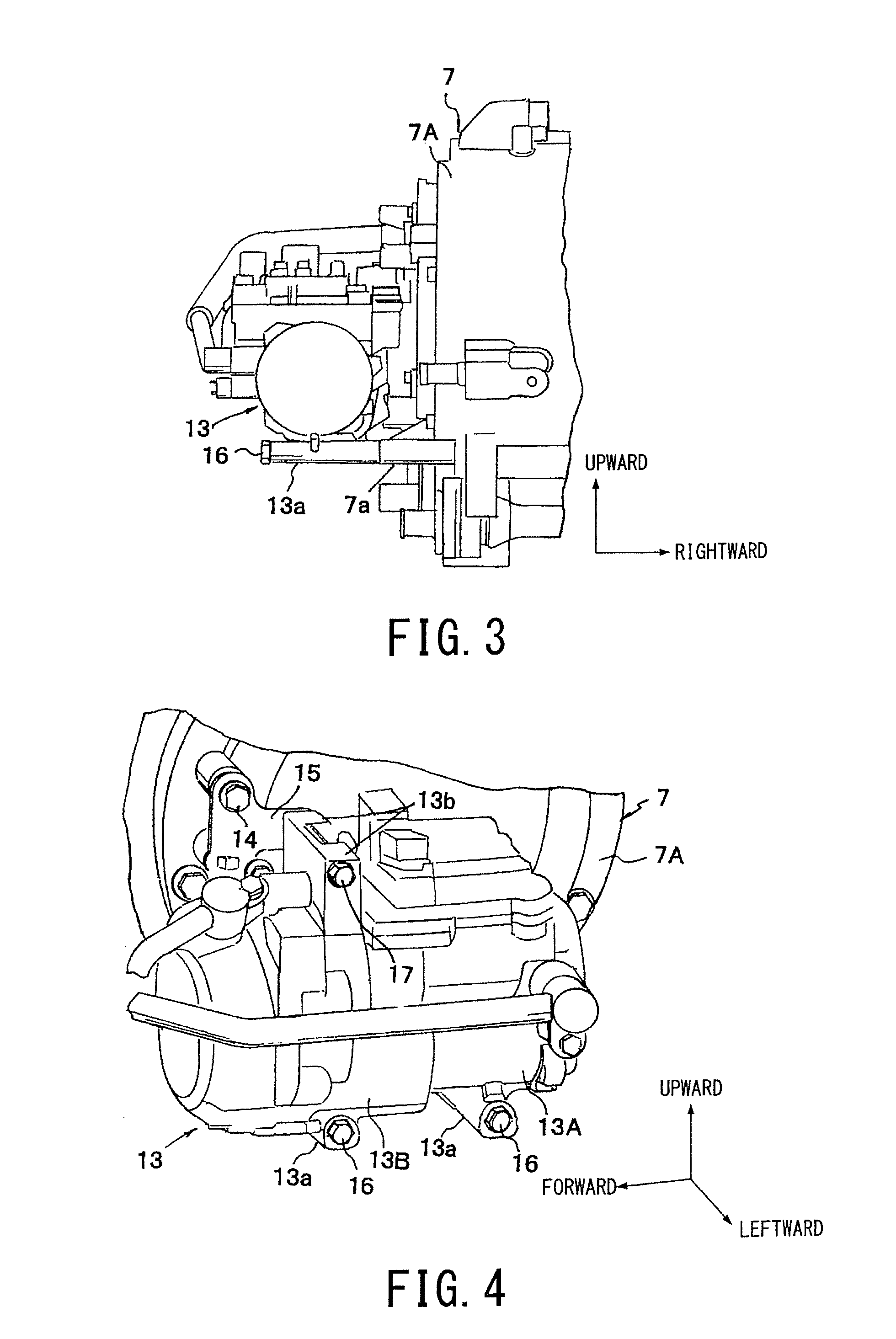

Arrangement structure for air-conditioning compressor in hybrid electric vehicle

ActiveUS20130305761A1Reduce component countAvoid vibrationAir-treating devicesVehicle heating/cooling devicesDrive motorAir conditioning

In an arrangement structure for an air-conditioning compressor in a hybrid electric vehicle, an engine, a power generating motor, a driving motor, and an air-conditioning compressor are disposed in an engine room, the engine and the power generating motor being arranged in series, in which the air-conditioning compressor is arranged on a side portion of the power generating motor. The power generating motor and the driving motor are provided in parallel with each other in a vehicle longitudinal direction and are accommodated respectively in separate motor cases, and one of the motor cases on which the air-conditioning compressor is fixed is arranged at a position behind and higher than another one of the motor cases.

Owner:SUZUKI MOTOR CORP

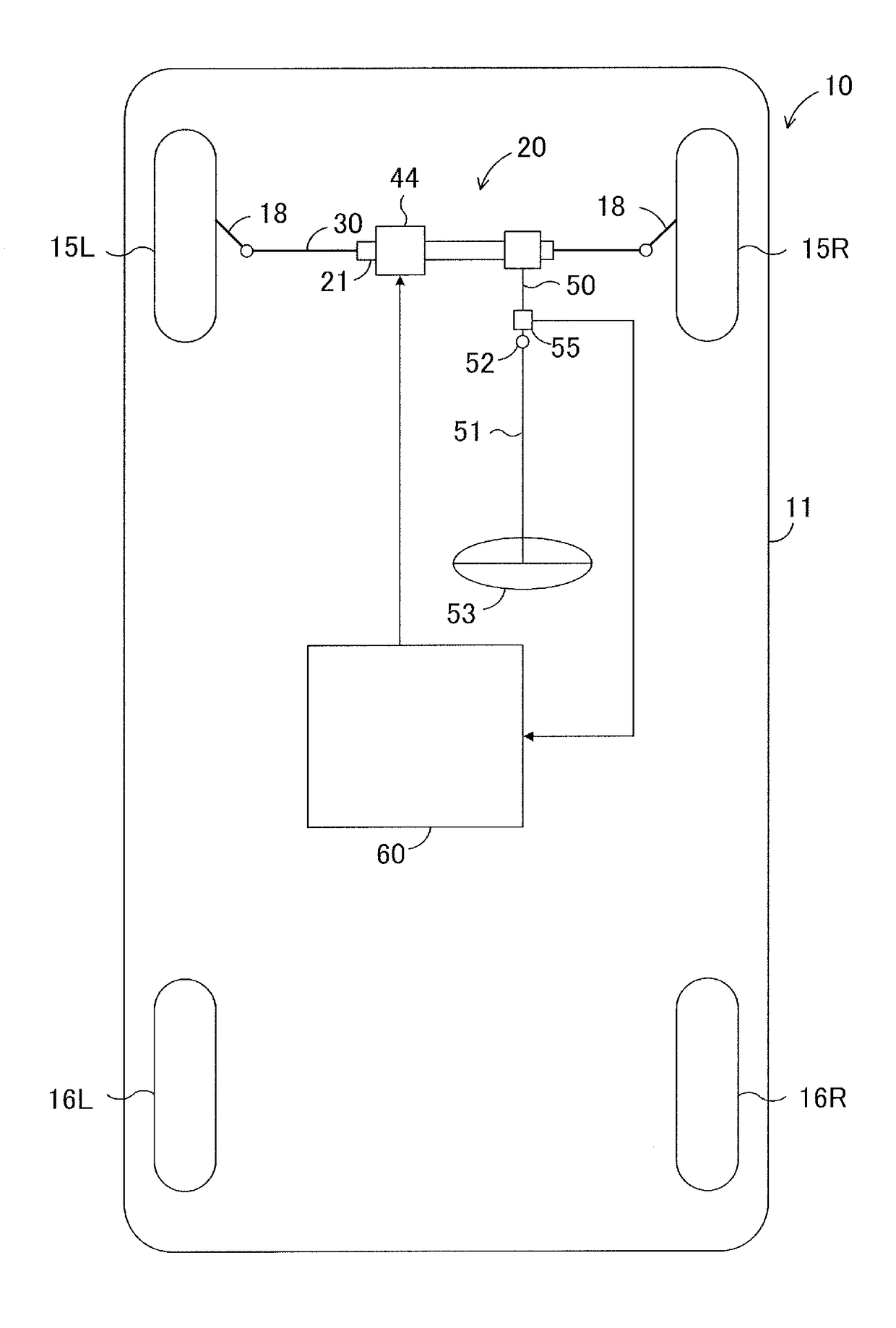

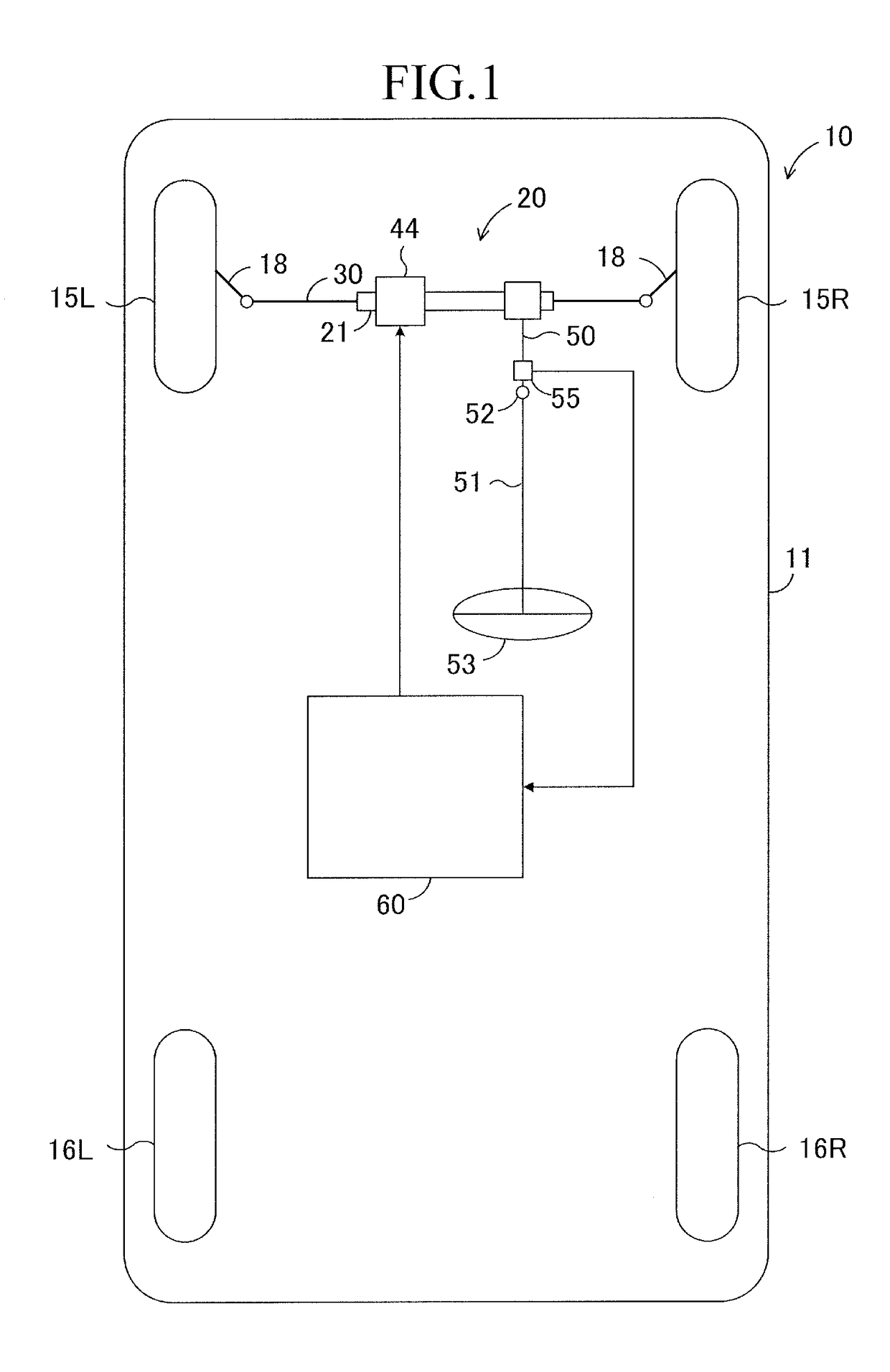

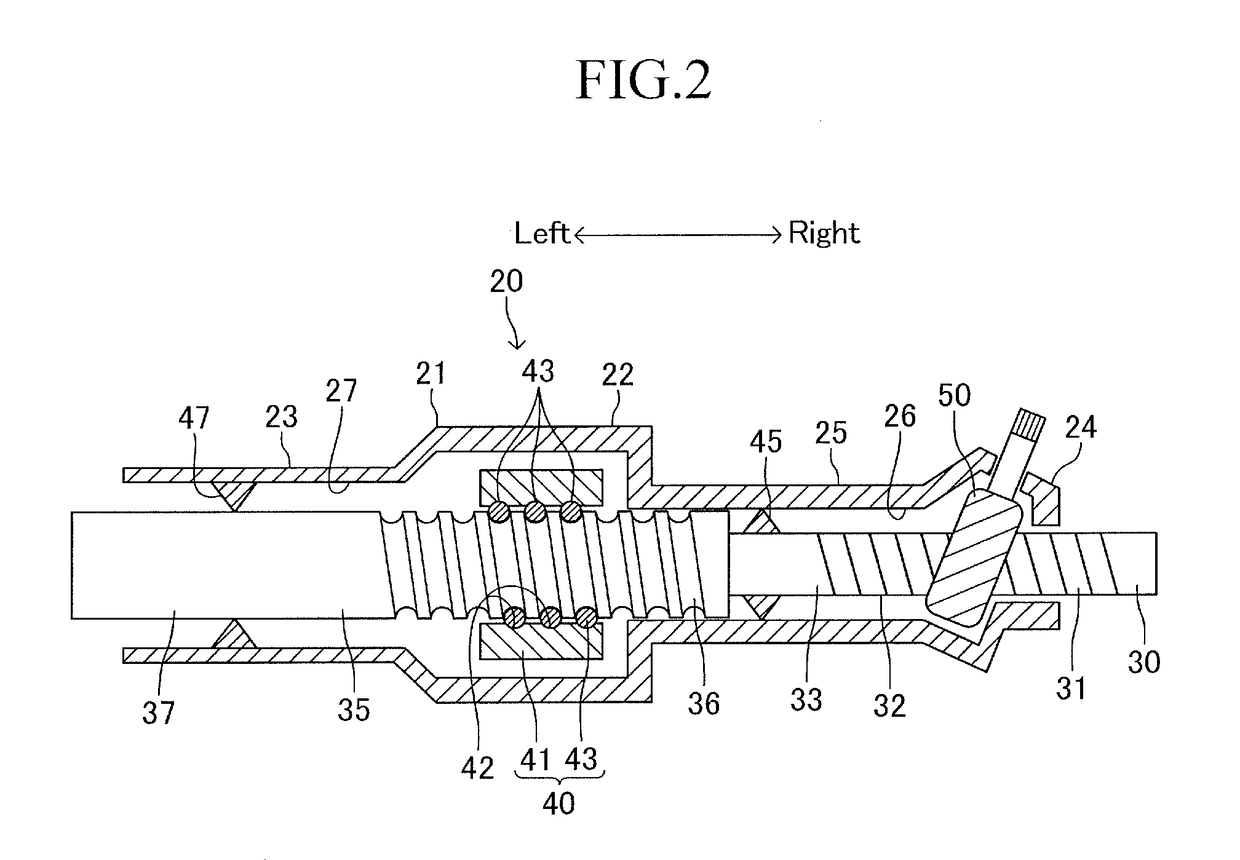

Steering apparatus

ActiveUS20170203783A1Reduce air pressureChange in ratioSteering linkagesMechanical steering gearsEngineeringMechanical engineering

The steering apparatus includes a first seal member and a second seal member. The first seal member is fixed to one of an outer peripheral surface of a rack shaft and an inner peripheral surface of a housing. The first seal member slidably contacts with a cylindrical surface which is centered on the axis and is provided on the other of the outer peripheral surface of the rack shaft and the inner peripheral surface of the housing. The second seal member is fixed to the other of the outer peripheral surface and the inner peripheral surface. The second seal member slidably contacts with a cylindrical surface which is centered on the axis and is provided on the one of the outer peripheral surface of the rack shaft and the inner peripheral surface of the housing.

Owner:TOYOTA JIDOSHA KK +1

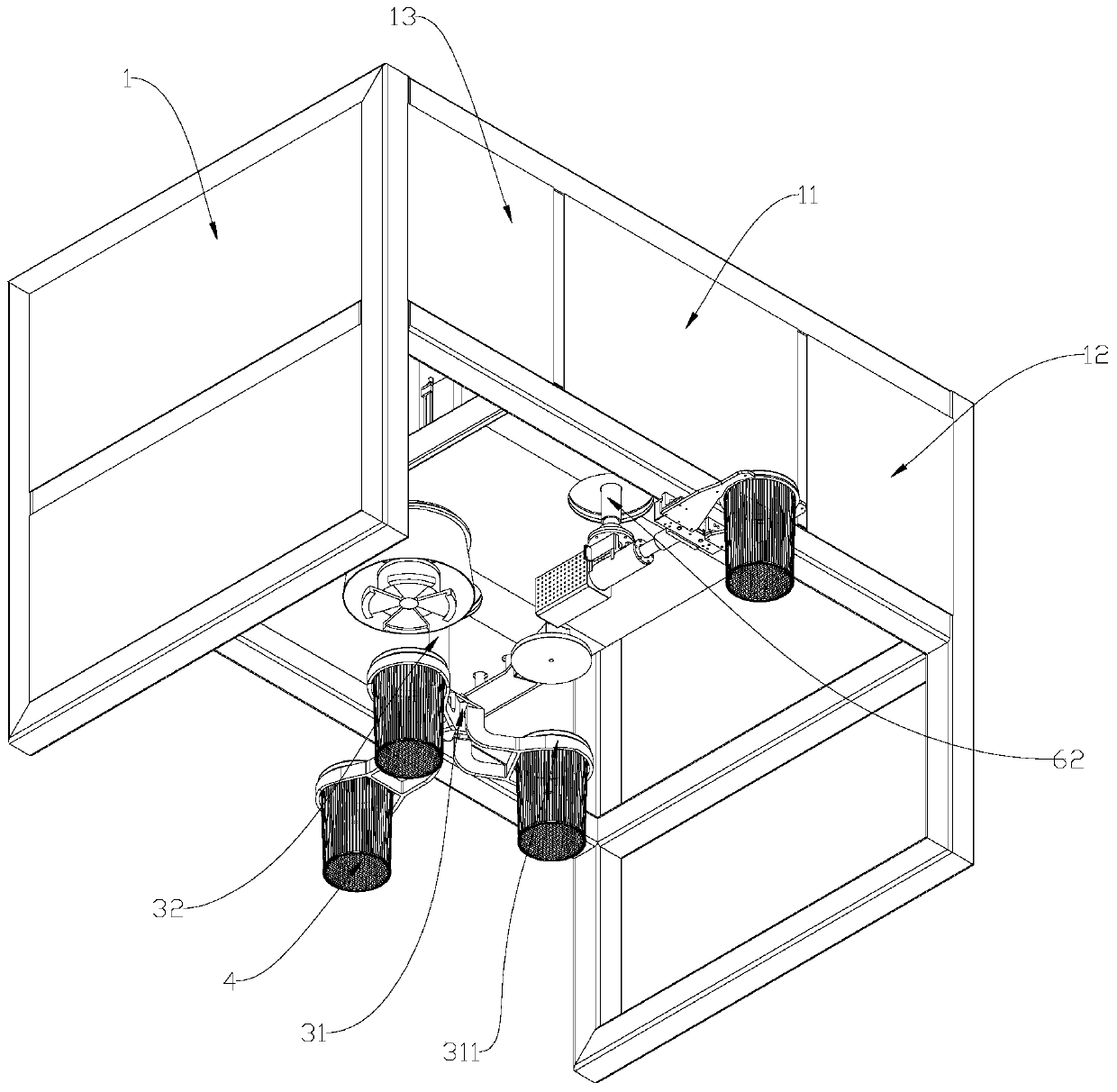

Microbial fertilizer producing strain screening device and fermentation process thereof

ActiveCN112251325ASmall footprintEasy to cultivate and observeBioreactor/fermenter combinationsBio-organic fraction processingFertilizerCulture mediums

The invention relates to the technical field of strain culture, and discloses a microbial fertilizer producing strain screening device and a fermentation process thereof. The microbial fertilizer producing strain screening device comprises a bearing box, wherein holes are formed in the left side surface and the right side surface of the bearing box at equal intervals; side frames are fixedly connected in the holes; the side frames are C-shaped bodies; the concave surfaces of the side frames on the left side and the right side correspond to each other; a transverse guide rail is fixedly arranged in the center of the front surface of the bearing box; a vertical guide rail is fixedly connected to a transmission shaft of the transverse guide rail; the vertical guide rail corresponds to the center of the bearing box; a plurality of side frames are provided with culture mechanisms and movement mechanisms; and a material taking mechanism is arranged on the inner wall of the bearing box. According to the microbial fertilizer producing strain screening device and the fermentation process thereof, the culture mechanisms and the material taking mechanism are arranged, so that culture equipment is stacked up and down in order to achieve the purposes of high flux and reduction of occupied space; and culture boxes loaded with culture media can be stored and taken through simple operation, the problem of rummaging caused by stacking of the culture equipment is avoided, workers can conveniently culture and observe strains, and therefore the screening efficiency is improved.

Owner:沈阳丰恒泰农业科技有限公司

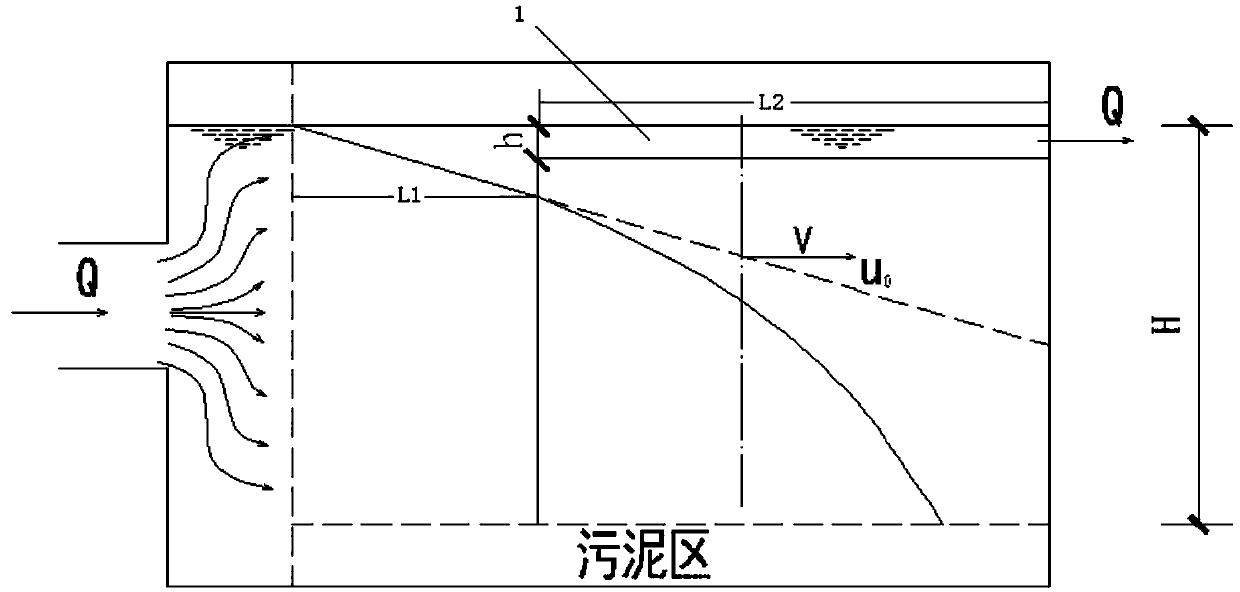

Horizontal sedimentation tank and horizontal sedimentation tank system

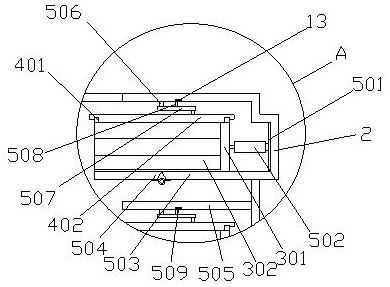

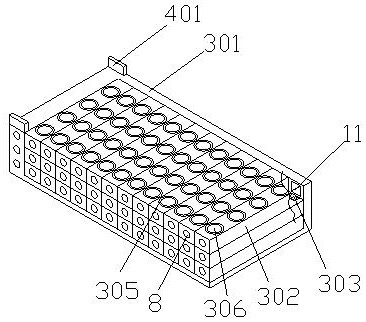

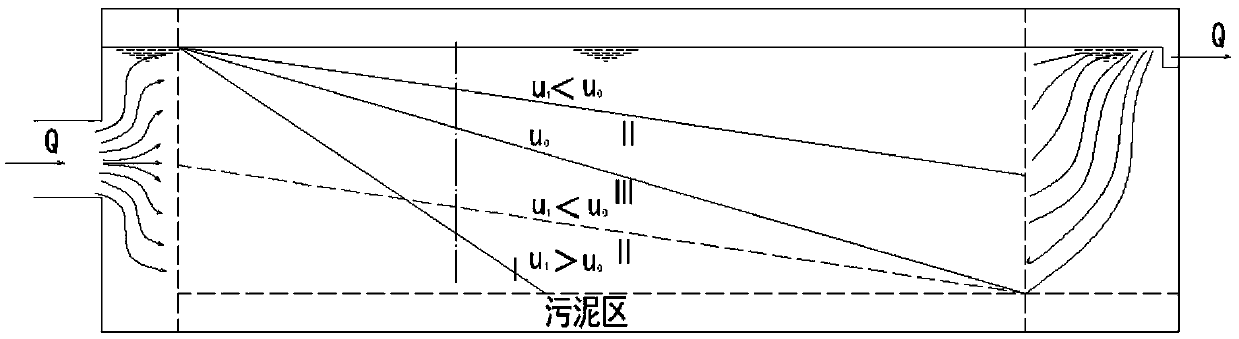

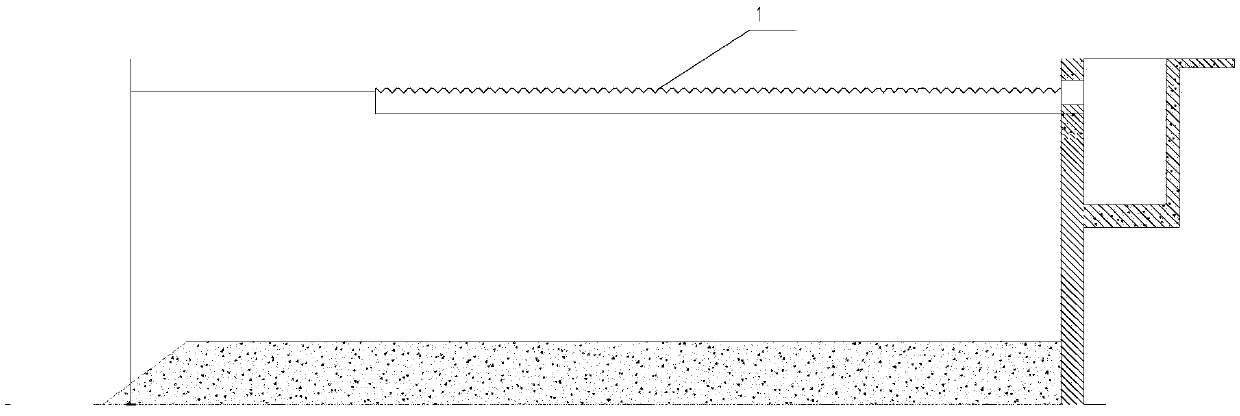

PendingCN109529411AReduce horizontal speedShorten horizontal lengthSettling tanks feed/dischargeSedimentation settling tanksWater collectionSedimentation coefficient

The invention provides a horizontal sedimentation tank and a horizontal sedimentation tank system, which belong to the field of the sedimentation tank. The horizontal sedimentation tank contains waterand has a water outlet, the horizontal sedimentation tank includes: a water collecting groove connected with a water outlet, and partially disposed under the water surface of the horizontal sedimentation tank for water collection during flowing of water in the horizontal sedimentation tank and water discharge through the water outlet, so that the horizontal length of a sedimentation path of the precipitated particles can be shortened. The horizontal sedimentation tank and the horizontal sedimentation tank system can improve the sedimentation efficiency and reduce the land occupation area required for sedimentation of the sedimentation tank.

Owner:BEIJING INST OF WATER

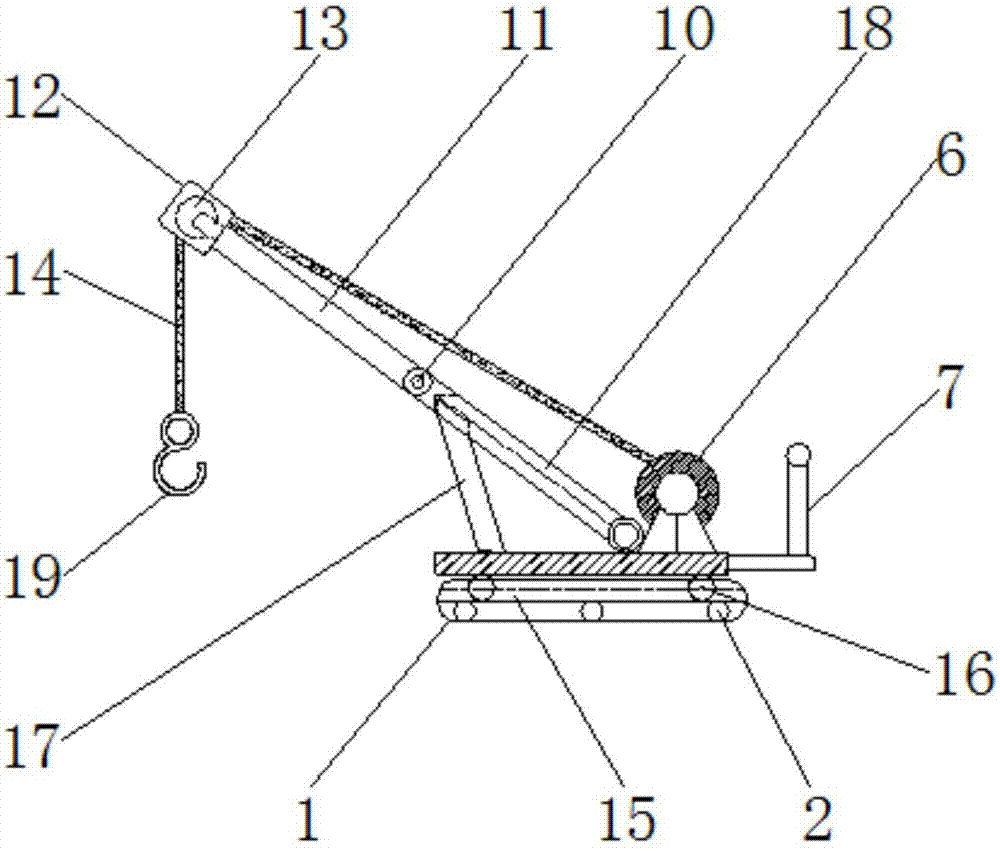

Hoisting and swinging machine for construction site

The invention relates to a hoisting machine for a construction site, which includes a support base and a second rotating shaft. The upper surface of the support base is provided with a first chute, and the inner side of the first chute is connected with a steel pipe casing. The support The bases are connected through the fourth rotating shaft, the first chute is connected with the connecting base through rollers, and the upper end of the connecting base is connected with the support rod through the first rotating shaft, and the outer end of the second rotating shaft is connected with the second rotating shaft. A connecting rod, and the upper end of the first connecting rod is connected with the second connecting rod through the third rotating shaft, the lower surface of the first connecting rod is provided with a second chute, and the upper end of the second connecting rod is provided with a connecting rod head, and pulleys are installed inside the connecting head. The construction site hoist adopts the design of the steel pipe casing, the first rotating shaft, the second rotating shaft, the third rotating shaft, the fourth rotating shaft, the lock hole and the locking block, which can increase the supporting area, improve the stability and reduce the Small size, easy to carry, and can reduce the labor intensity of workers.

Owner:安徽新兴翼凌机电发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com