Horizontal sedimentation tank and horizontal sedimentation tank system

An advective sedimentation tank and horizontal technology, applied in the field of sedimentation tanks, can solve the problems of increasing the processing scale, large area, engineering waste, etc., and achieve the effect of reducing the horizontal speed, reducing the area and improving the sedimentation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific implementations described here are only used to illustrate and explain the embodiments of the present invention, and are not used to limit the embodiments of the present invention.

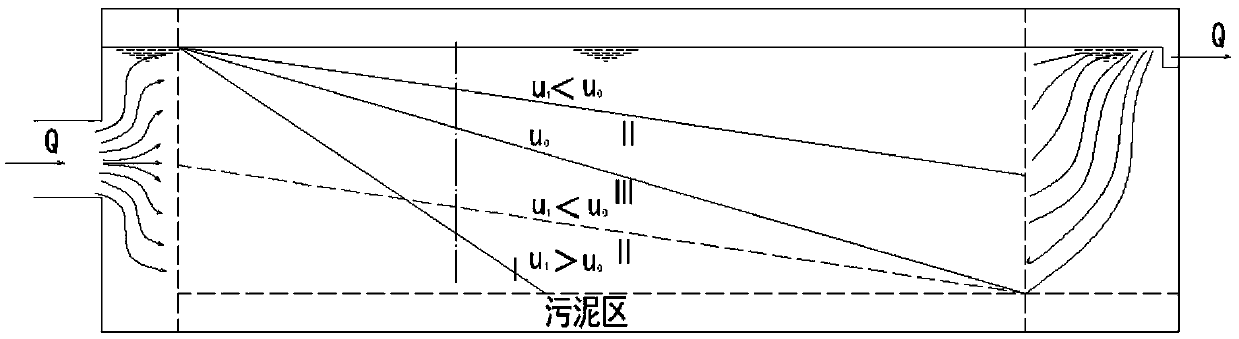

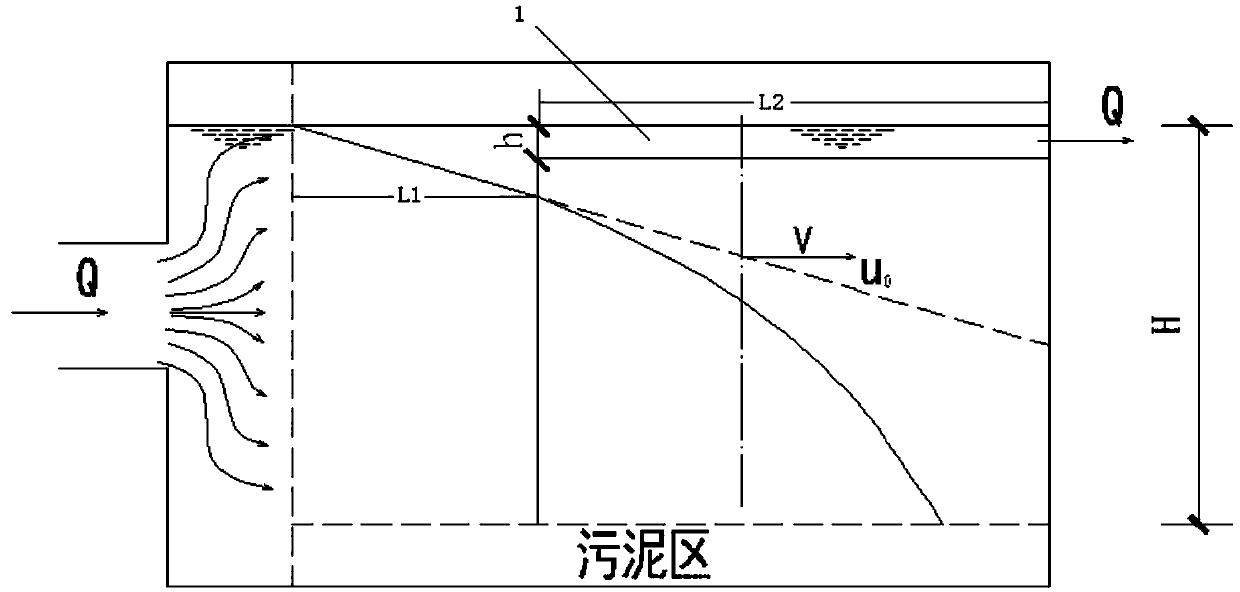

[0027] figure 1 It is a schematic diagram of an ideal advection sedimentation tank. Such as figure 1 As shown, the trajectory of the particles entering from point A is the vector sum of the horizontal flow rate and the sedimentation particle settling velocity. There must be particles of a certain size in these particles, and the settling velocity is u 0 , Just can sink to the bottom of the pool.

[0028] among them,

[0029] Where: u 0 Is the critical particle sedimentation velocity, in m / s;

[0030] Q is the water flow of advection sedimentation tank, unit m 3 / s;

[0031] A is the water surface are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com