Heavy-load power and free chain conveying system used for conveying big long workpieces

A technology of conveying system and accumulation chain, which is applied in the field of heavy-duty accumulation chain conveying system, can solve the problem of large occupied space, and achieve the effect of reducing occupied space, reducing production input cost, and reducing horizontal length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

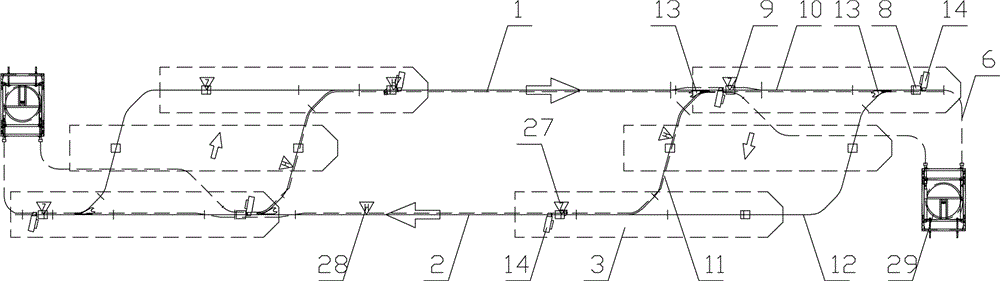

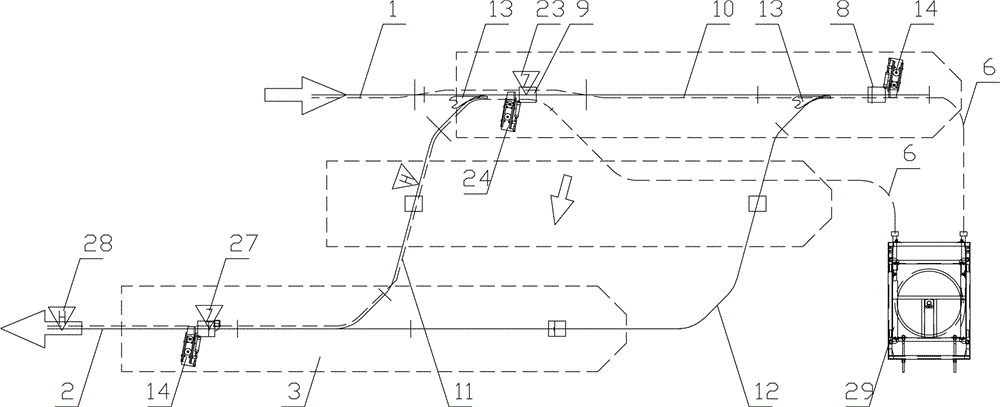

[0026] Embodiment 1, in this embodiment, two adjacent conveying tracks that are parallel to each other and arranged in a straight line are represented by conveying track A1 and conveying track B2 respectively, and this embodiment is represented by conveying track A1, transporting track B2 and two The closed-loop heavy-duty accumulating chain conveyor system composed of lateral translation track groups is taken as an example for specific description, see figure 2 , image 3 .

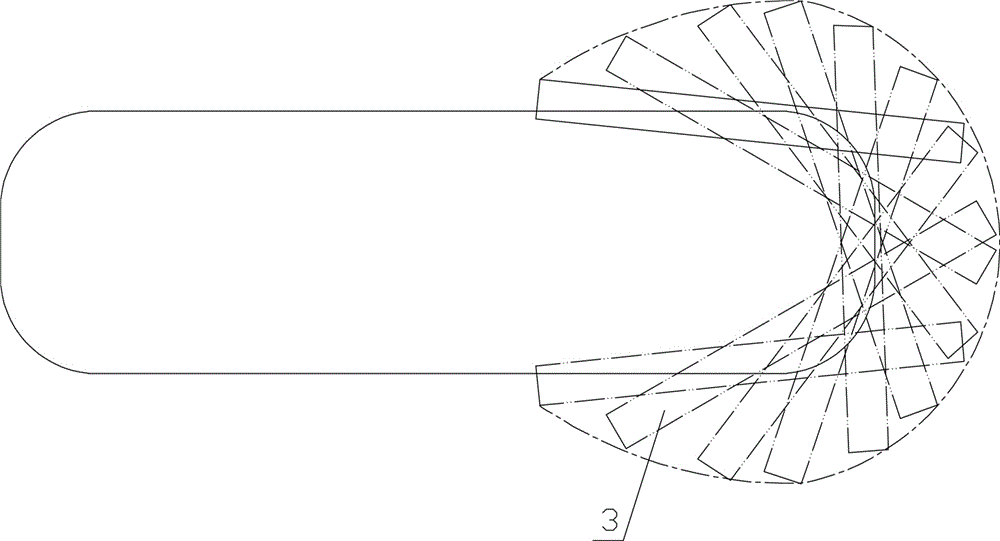

[0027] The heavy-duty accumulation chain conveying system also includes several heavy-duty train groups, which walk along the conveying track A1, conveying track B2 and lateral translation track group, and carry large and long workpieces 3 in the process of walking; the conveying track Both A1 and the conveying track B2 have a traction rail 5, a chain rail 6 and two load rails 7 placed in the frame 4; each heavy-duty car group is composed of two No. It is composed of No. 2 car 9, two load-carrying rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com