Pile-penetration filling body reinforcing load-bearing structure and construction method thereof

A load-bearing structure and penetration technology, applied in the direction of infrastructure engineering, underwater structures, artificial islands, etc., to achieve the effect of improving stability, improving grid efficiency, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

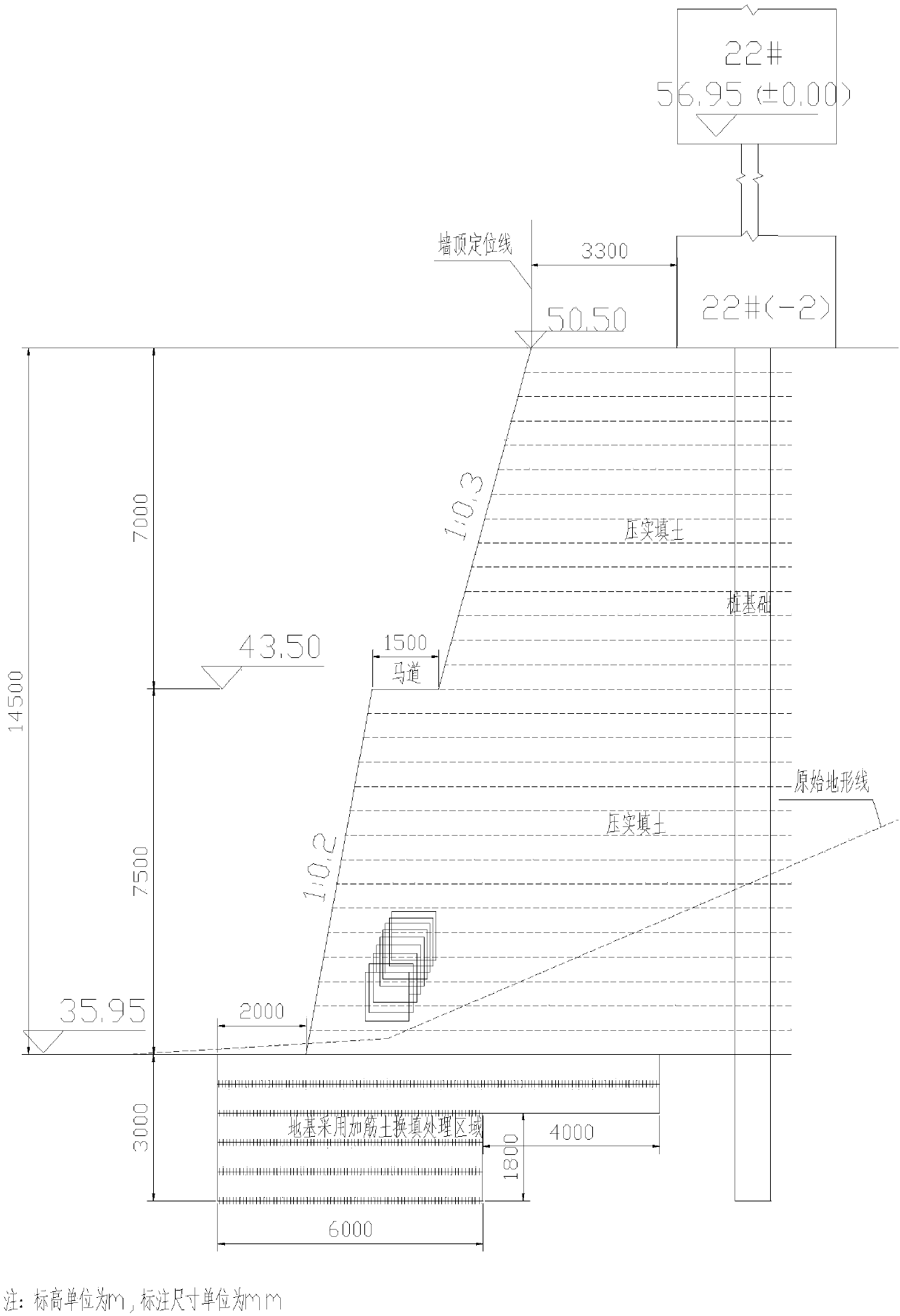

[0040] A certain slope is located in Xianning Mountain, Hubei Province. The site is a fill and excavation area, and the geological environment of the site is a relatively stable area. Large-area filling and small-area excavation shall be carried out on the site at the existing location. The filling height shall be about 15-18m, and a high-voltage electric tower shall be built on the soil layer where the filling reaches the design height. Due to the importance of the slope, according to the above-mentioned project overview, combined with regional experience, and in accordance with the design principles of safety and economy, this project adopts the pile-supported reinforced soil combined retaining structure design scheme. Geogrid reinforced soil structure with two-stage filling, such as figure 2 As shown, the total height of the filling is 14.5m, of which, from bottom to top, the height of the first-level reinforced soil fill slope is 7.5m, and the height of the second-level r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com