Jumping around transposition tower in common-tower double-circuit transmission line

A technology of double circuits on the same tower and transposition towers, which is applied in the spatial arrangement/configuration of towers and cables, building types, etc., can solve the problem of increasing tower loads and tower material consumption, increasing transportation costs and construction costs, and unsuitability, etc. problems, to achieve the effect of facilitating construction and operation and maintenance, enhancing promotional value, saving consumables and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

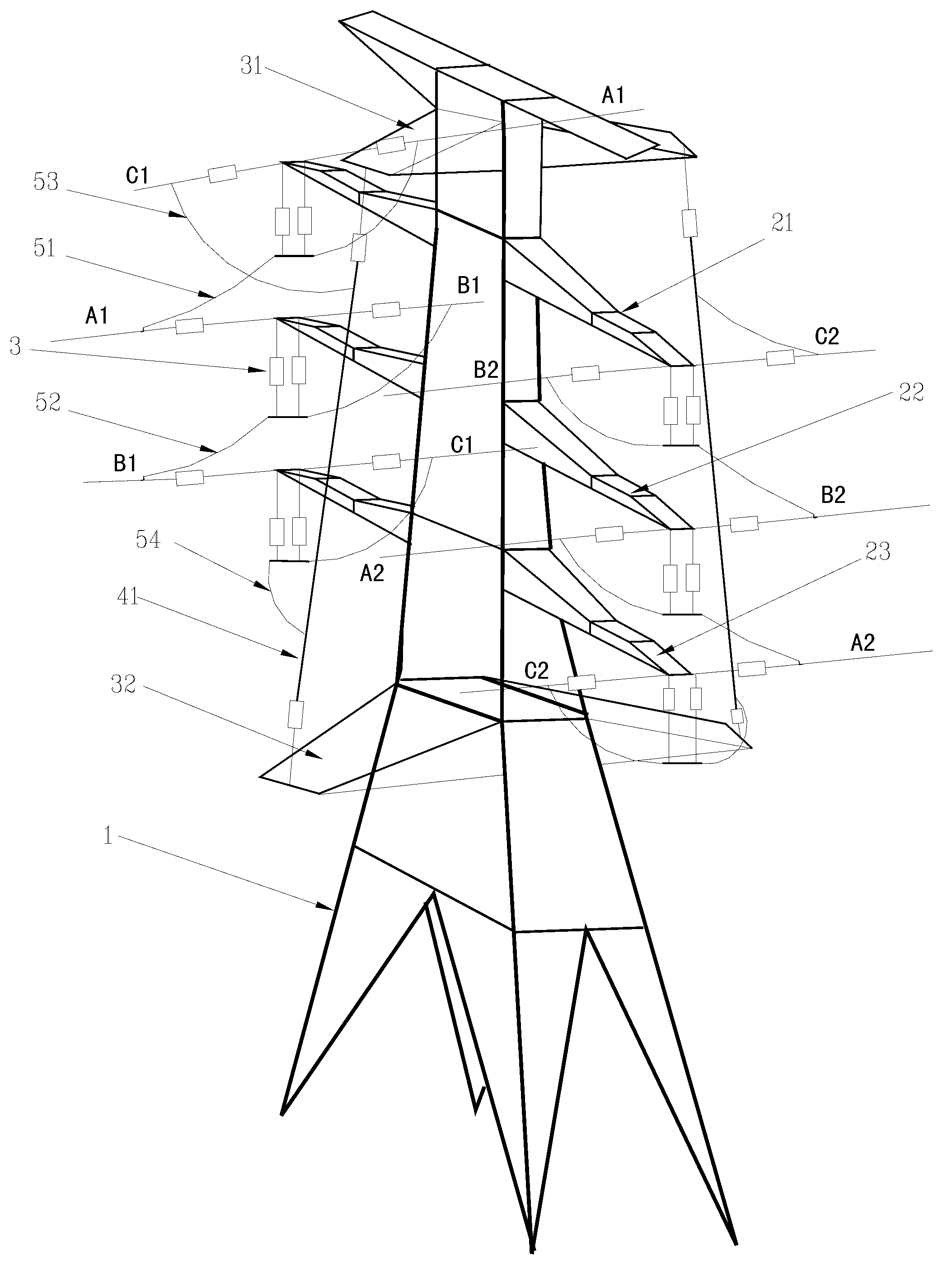

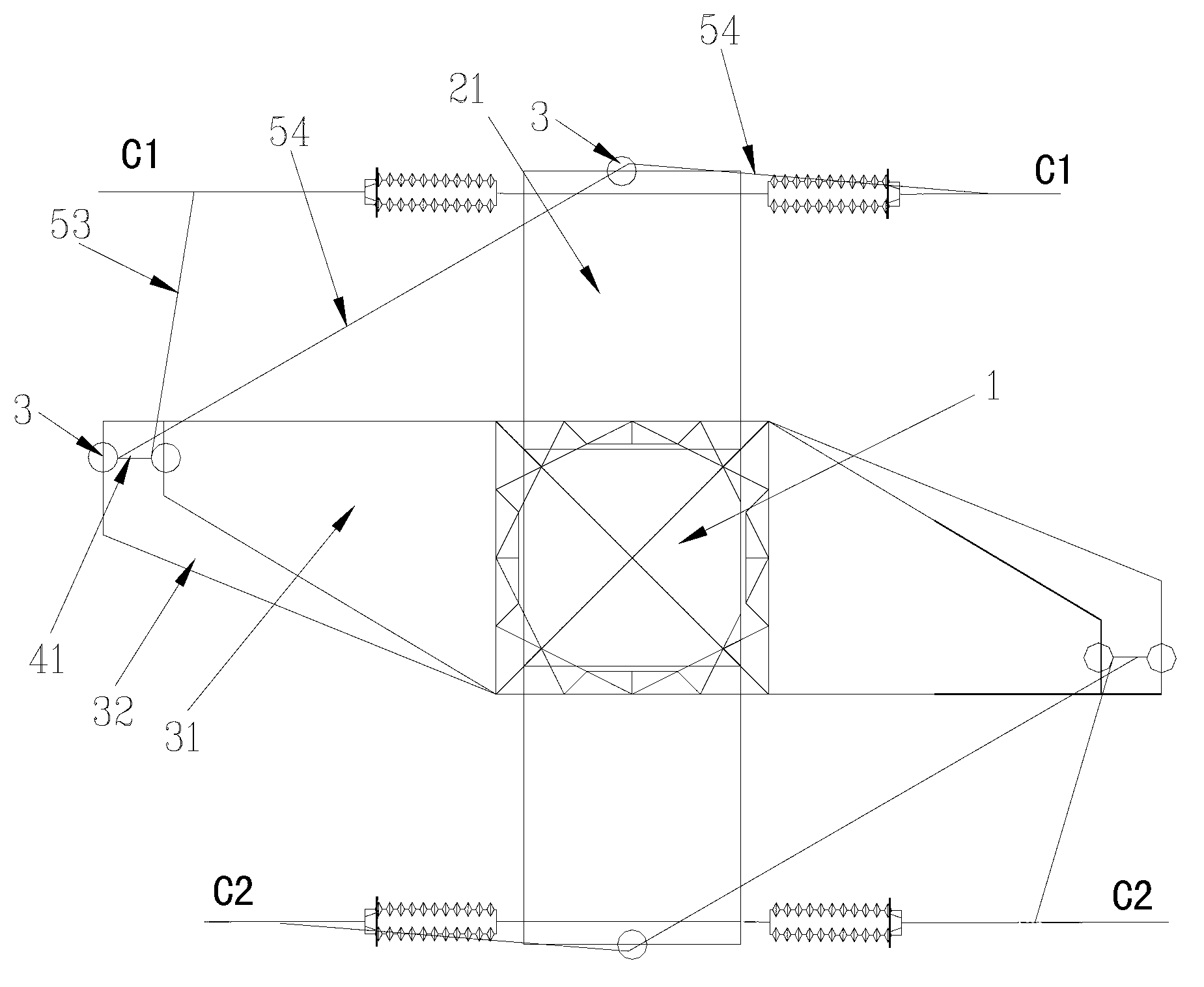

[0013] The present invention's double-circuit inner winding transposition tower on the same tower, such as figure 1 As shown, the tower body 1 is included, and the left and right side upper cross arms 21, the middle cross arm 22 and the lower cross arm 23 perpendicular to the direction of the transmission line are installed on the tower body 1, and the upper cross arm 21, the middle cross arm 22 and the lower cross arm 23 are installed on the tower body 1. The same side of the cross arm 23 is respectively connected with the same loop transmission line. The transmission line of the same circuit is composed of the first transmission line A, the second transmission line B and the third transmission line C. figure 1 The two same-loop transmission lines in include a first loop formed by transmission lines A1, B1, and C1, and a second loop formed by transmission lines A2, B2, and C2.

[0014] On the top of the tower body 1, an upper conductor cross arm 31 is respectively installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com