Patents

Literature

51results about How to "Reduce sag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

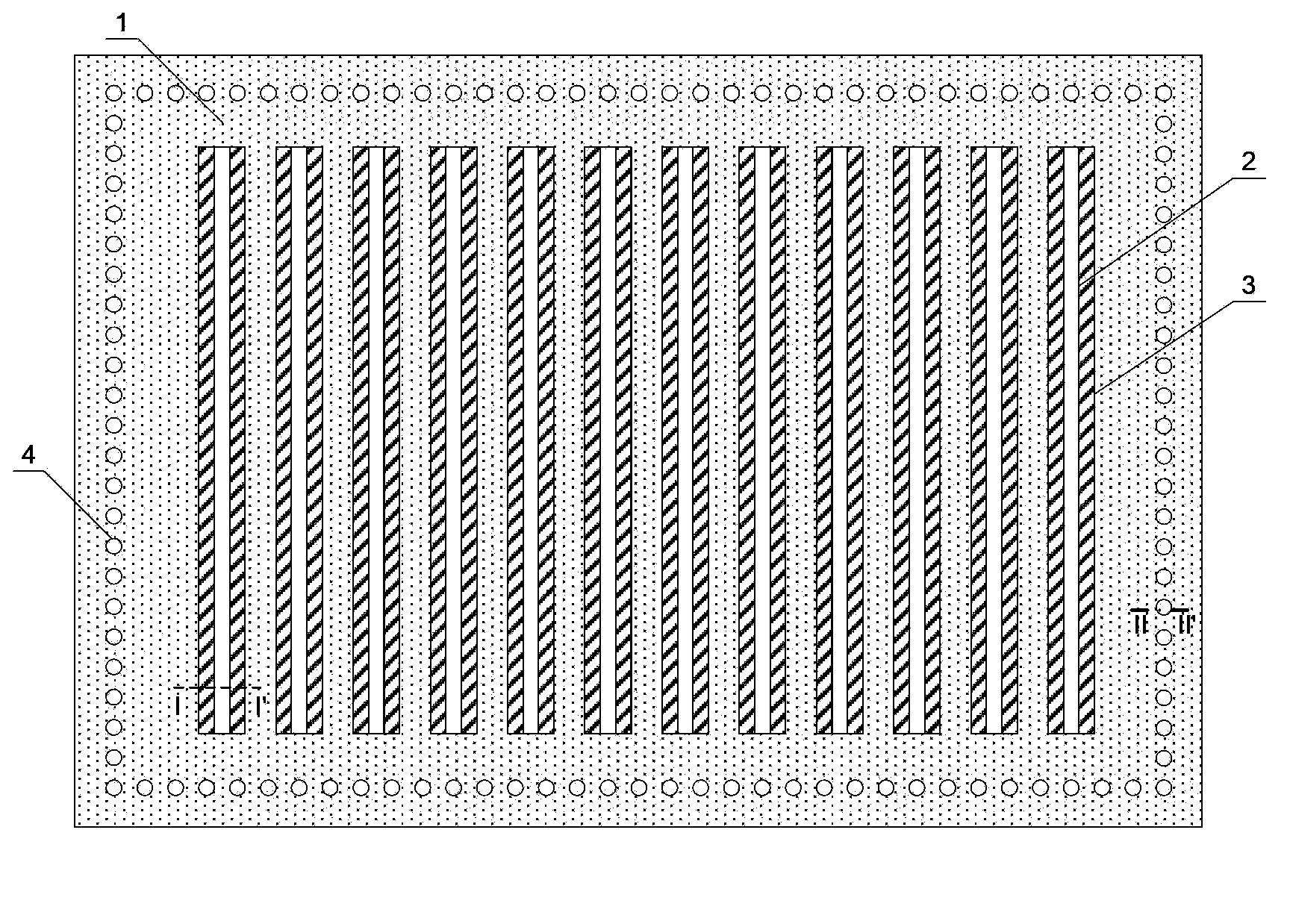

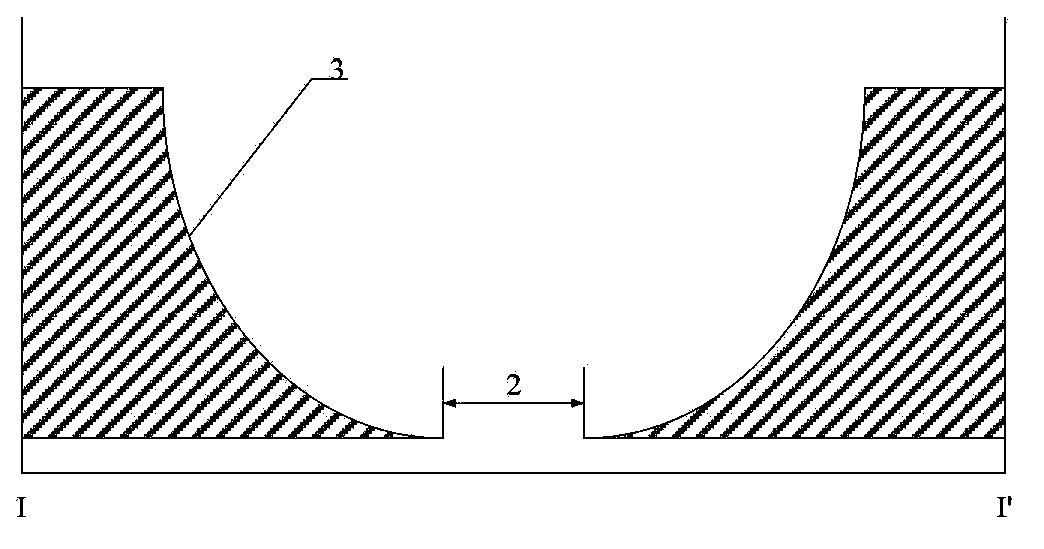

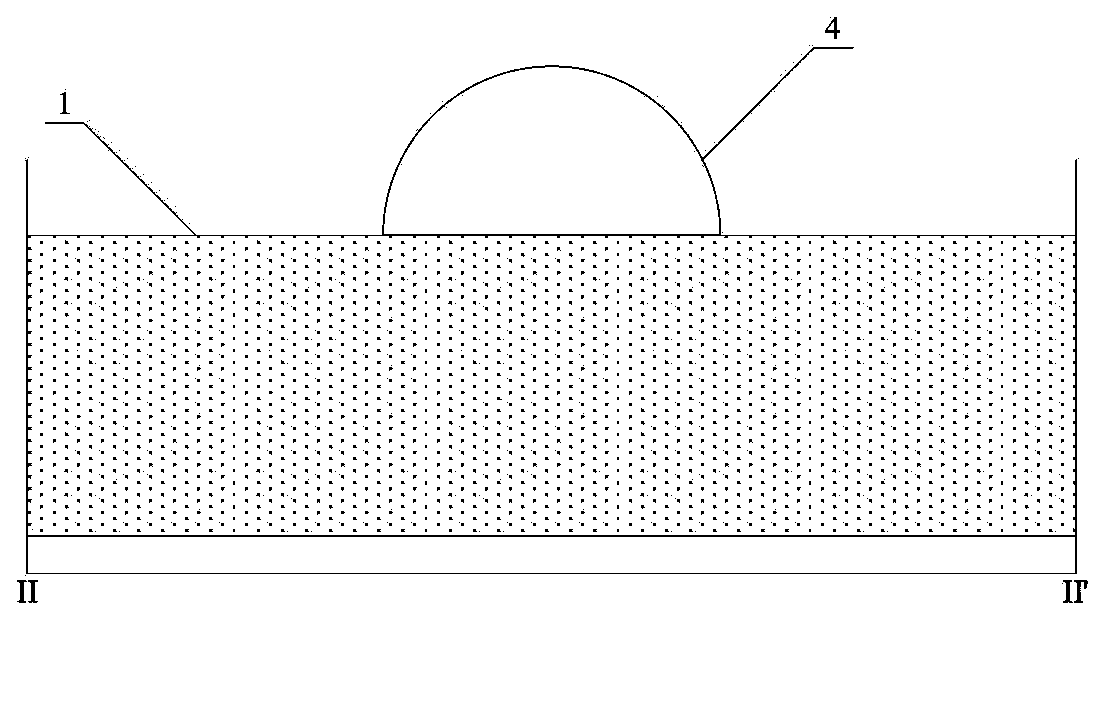

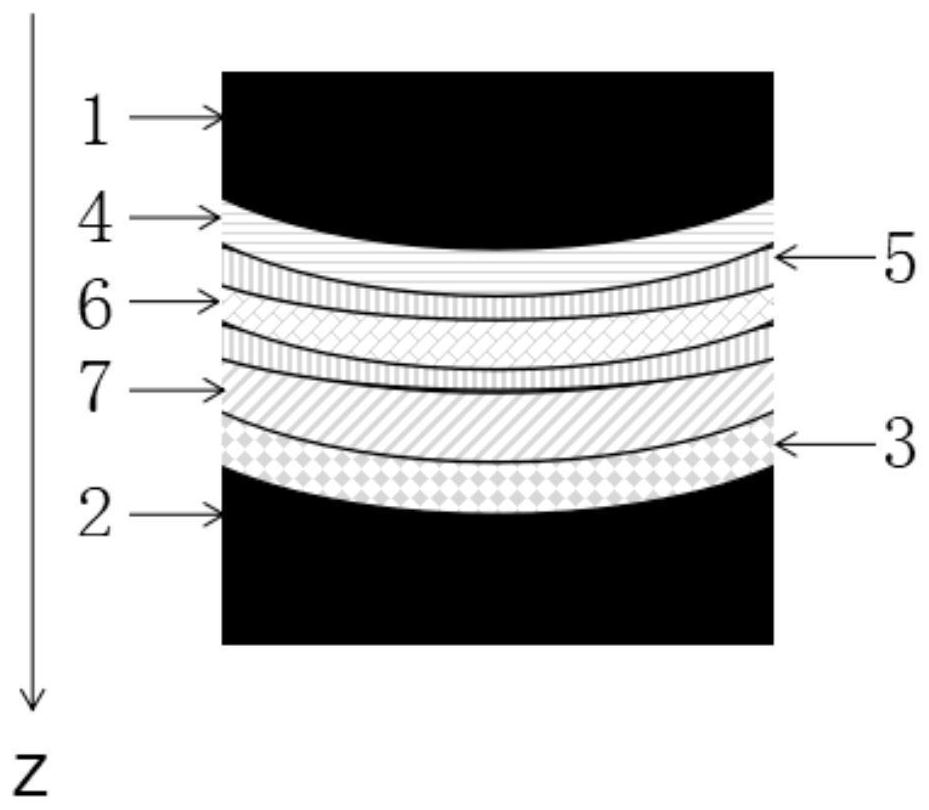

Mask plate

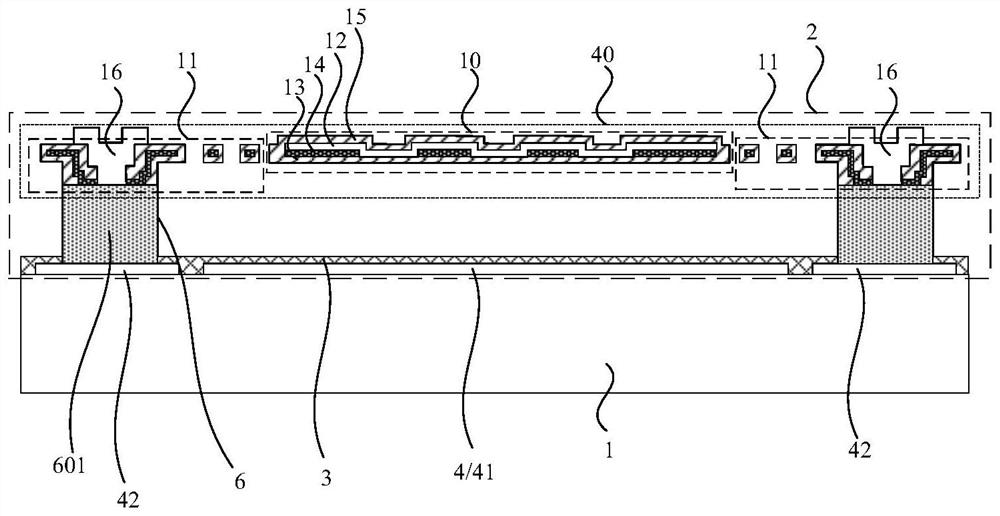

ActiveCN103911584AReduce weightReduce sagVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

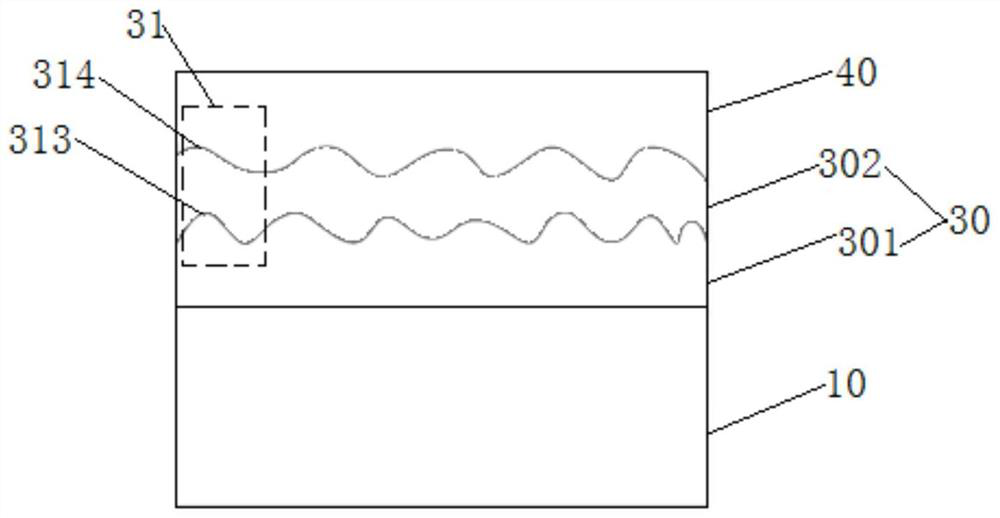

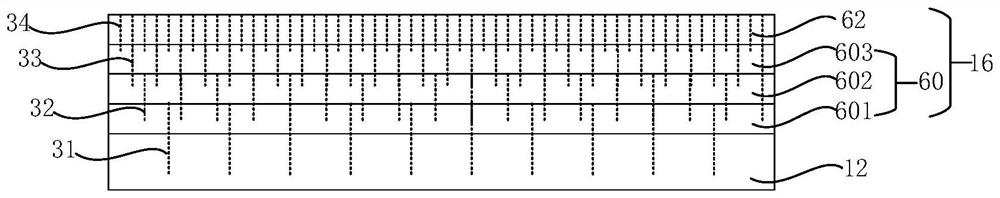

The invention discloses a mask plate and a manufacturing method. The mask plate comprises a first zone and a second zone; the first zone is used for positioning, a welding positioning part between the mask plate edge and a mask plate frame (or support) is provided with a second groove, and the welding positioning part faces back to a substrate and is in the first zone, and the second groove is capable of accommodating one or multiple welding positioning devices; the second zone comprises shielding parts and opening parts which are uniformly arranged at intervals in a parallel manner, the side, facing to the substrate, of each shielding part is provided with first grooves, and each groove is parallel to the opening parts in the longitudinal direction or in the transverse direction. The invention also discloses a preparation method of the mask plate on which the first grooves and the second grove are arranged, and a wet-process etching method is employed. The mask plate has the advantages of light mass, good strength, reduced substrate damages and the like.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Low-temperature fabrication of glass optical components

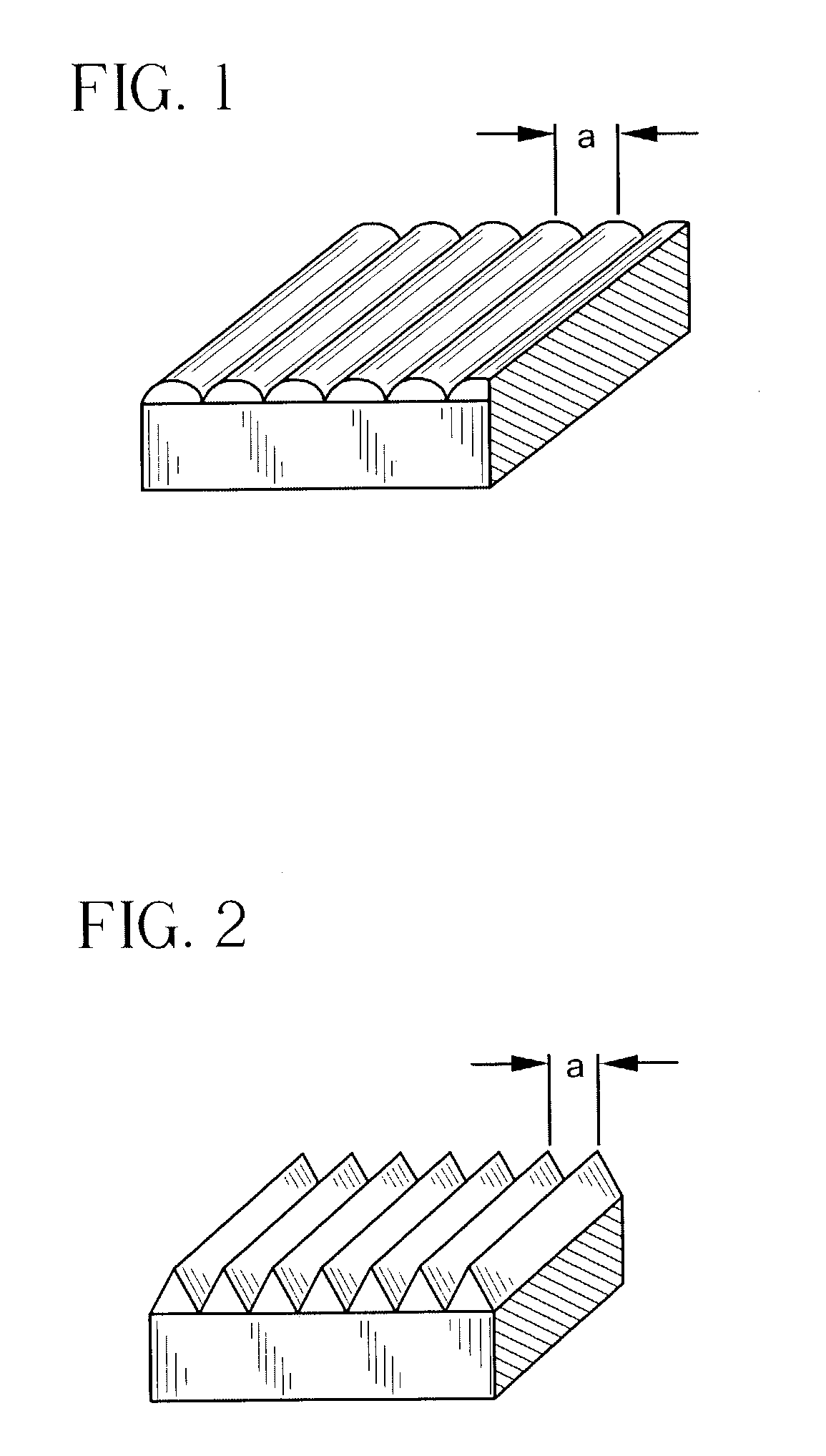

InactiveUS7143609B2High refractive indexLow molding temperatureGlass transportation apparatusGlass pressing apparatusGratingMetallic Nickel

A method is provided for molding from glass certain complex optical components, such as lenses, microlens, arrays of microlenses, and gratings or surface-relief diffusers having fine or hyperfine microstructures suitable for optical or electro-optical applications. Thereby, mold masters or patterns, which define the profile of the optical components, made on metal alloys, particularly titanium or nickel alloys, or refractory compositions, with or without a non-reactive coating are used. Given that molding optical components from oxide glasses has numerous drawbacks, it has been discovered in accordance with the invention that non-oxide glasses substantially eliminates these drawbacks. The non-oxide glasses, such as chalcogenide, chalcohalide, and halide glasses, may be used in the mold either in bulk, planar, or power forms. In the mold, the glass is heated to about 10–110° C., preferably about 50° C., above its transition temperature (Tg), at which temperature the glass has a viscosity that permits it to flow and conform exactly to the pattern of the mold.

Owner:CORNING INC

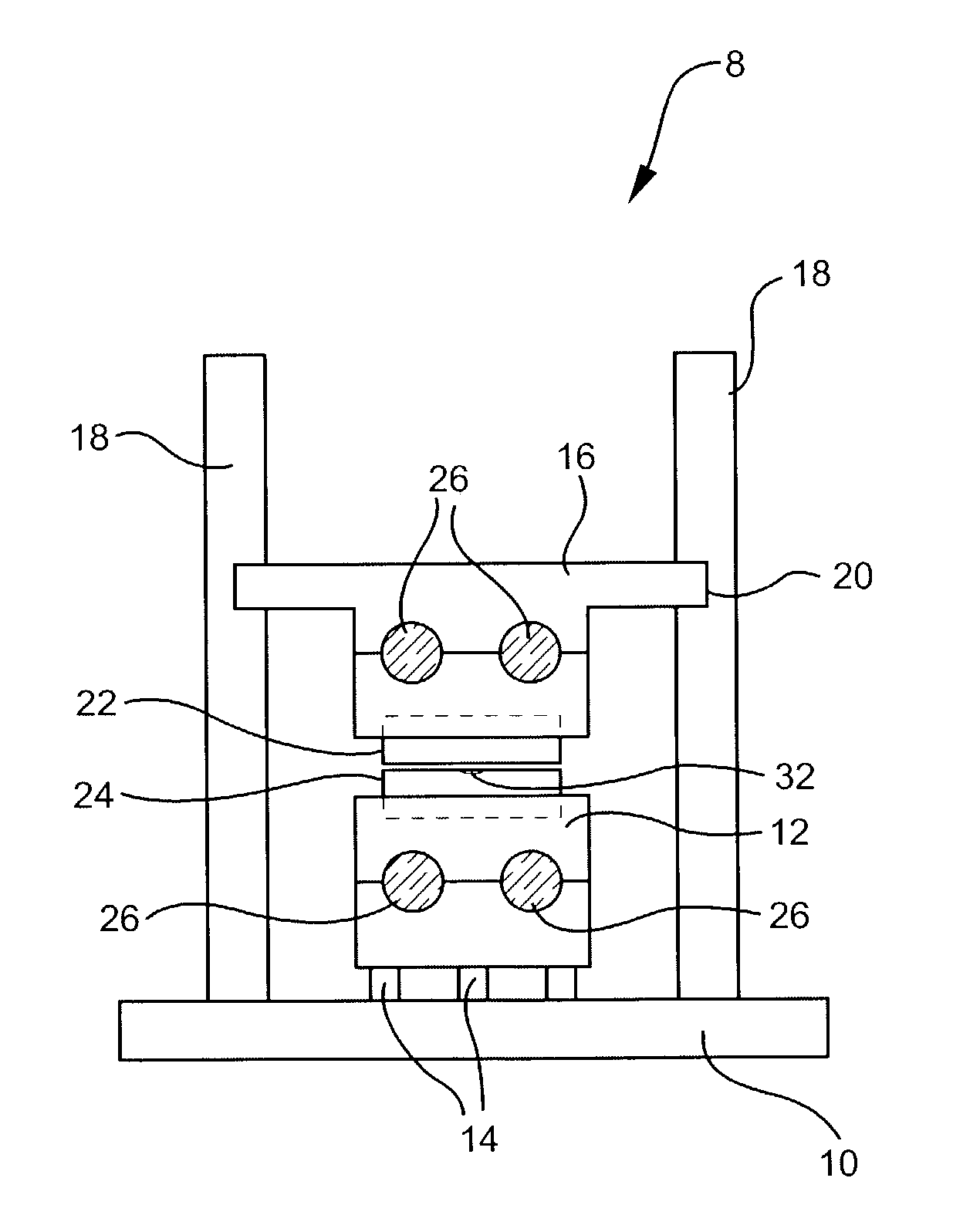

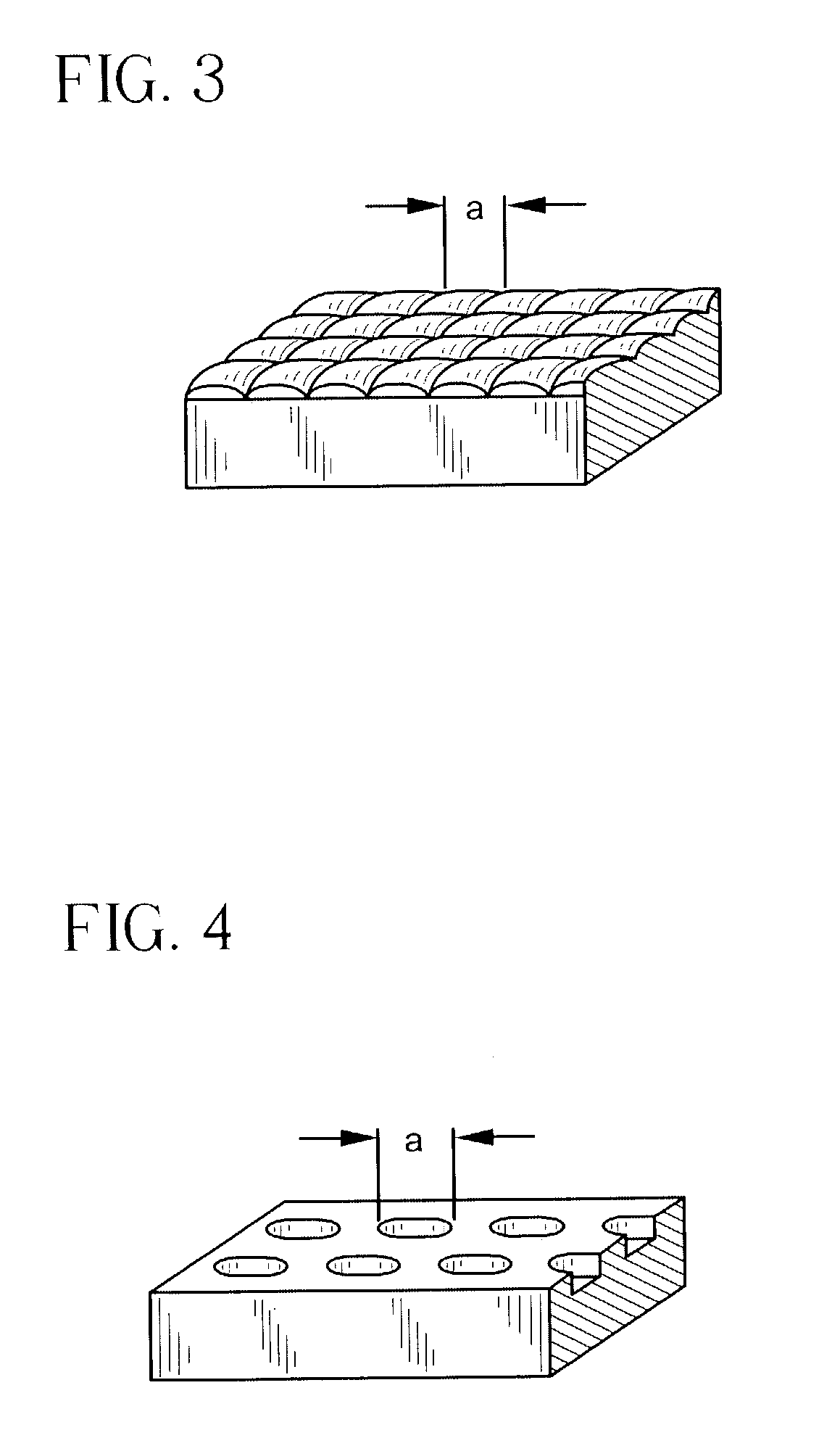

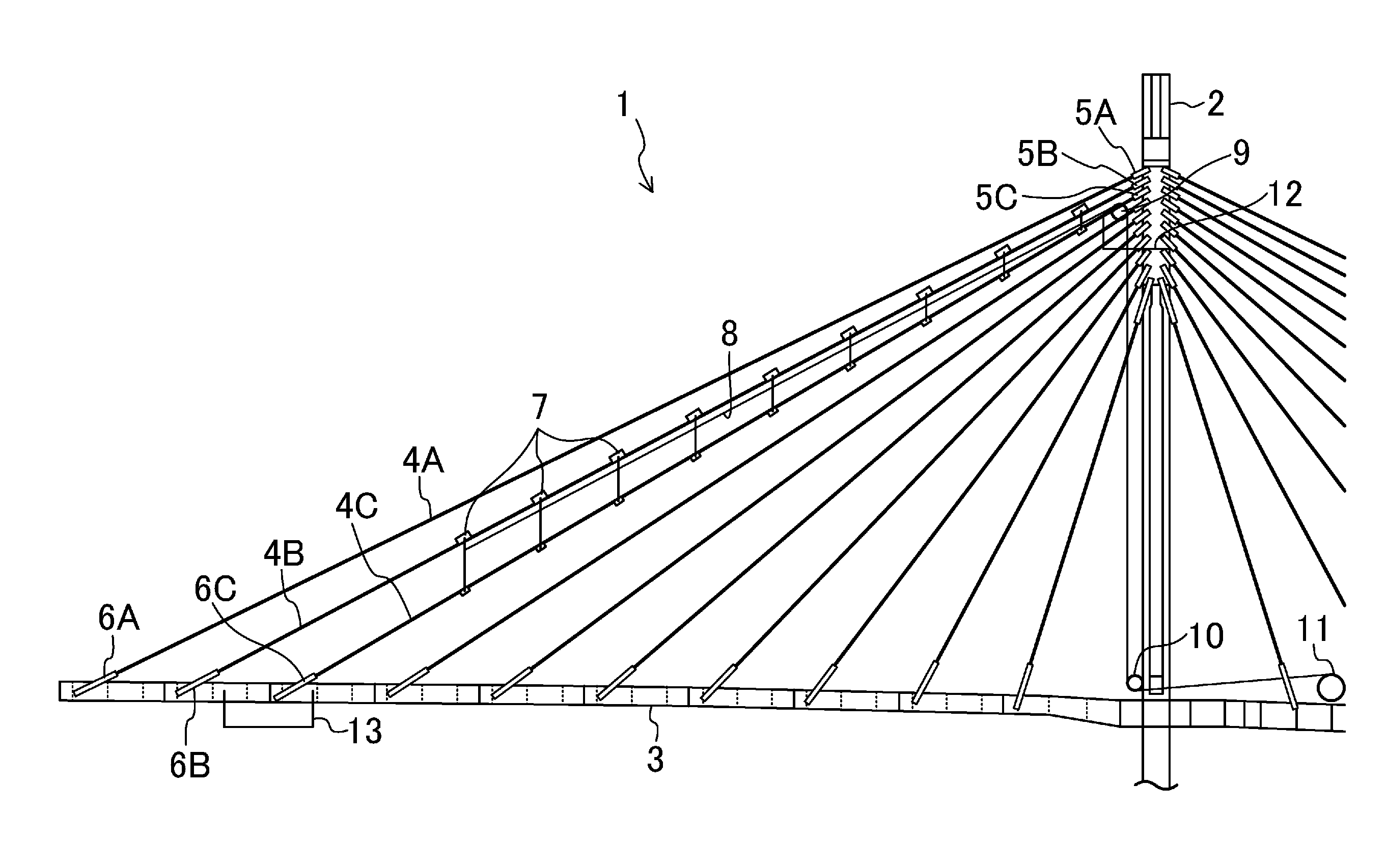

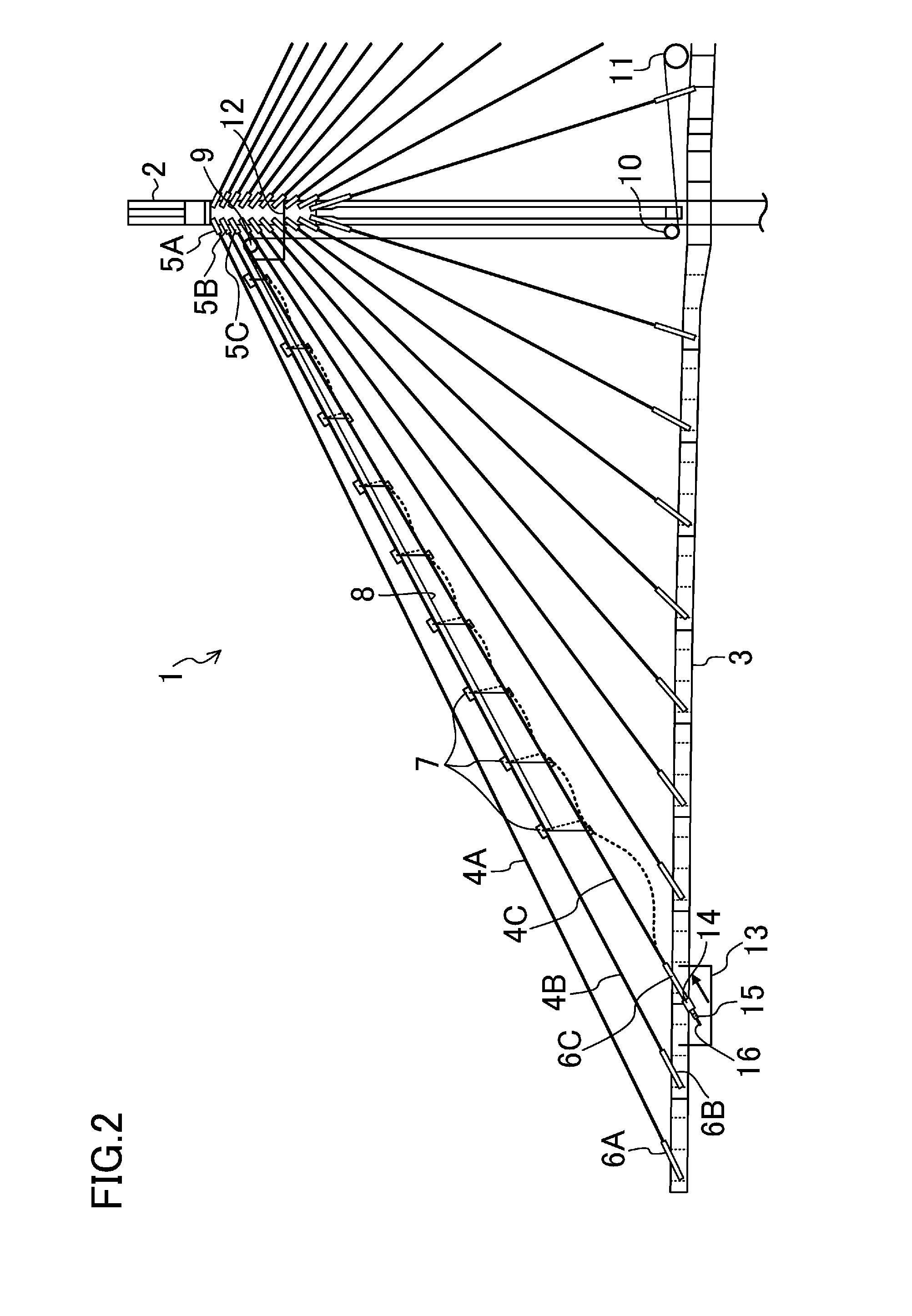

Method for replacing sloped cables, and temporary hanger for replacing sloped cables

ActiveUS20150052694A1Reduce sagHung efficientlyCable-stayed bridgePipe supportsEngineeringMechanical engineering

A plurality of movable temporary hangers 7 are placed on a stay cable 4B hung in tension above a target stay cable 4C, and then the target stay cable 4C is held on a lower portion of the temporary hangers 7. Then, the target stay cable 4C held with the temporary hanger 7 is detached from a bridge deck 3 and a main tower 2. Then, the target stay cable 4C and the temporary hangers 7 holding the target stay cable 4C are moved toward the bridge deck 3 and removed.

Owner:IHI INFRASTRUCTURE SYST CO LTD

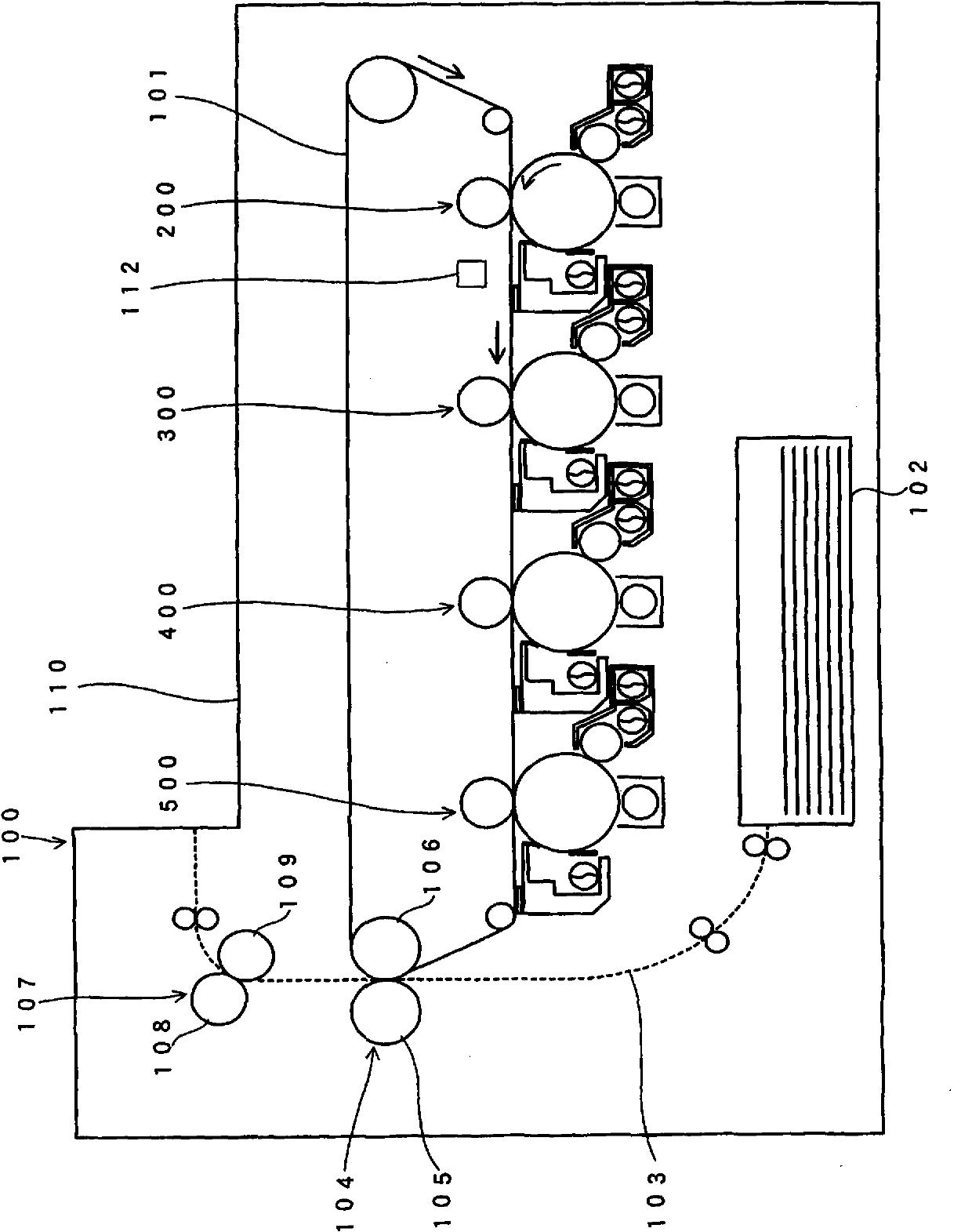

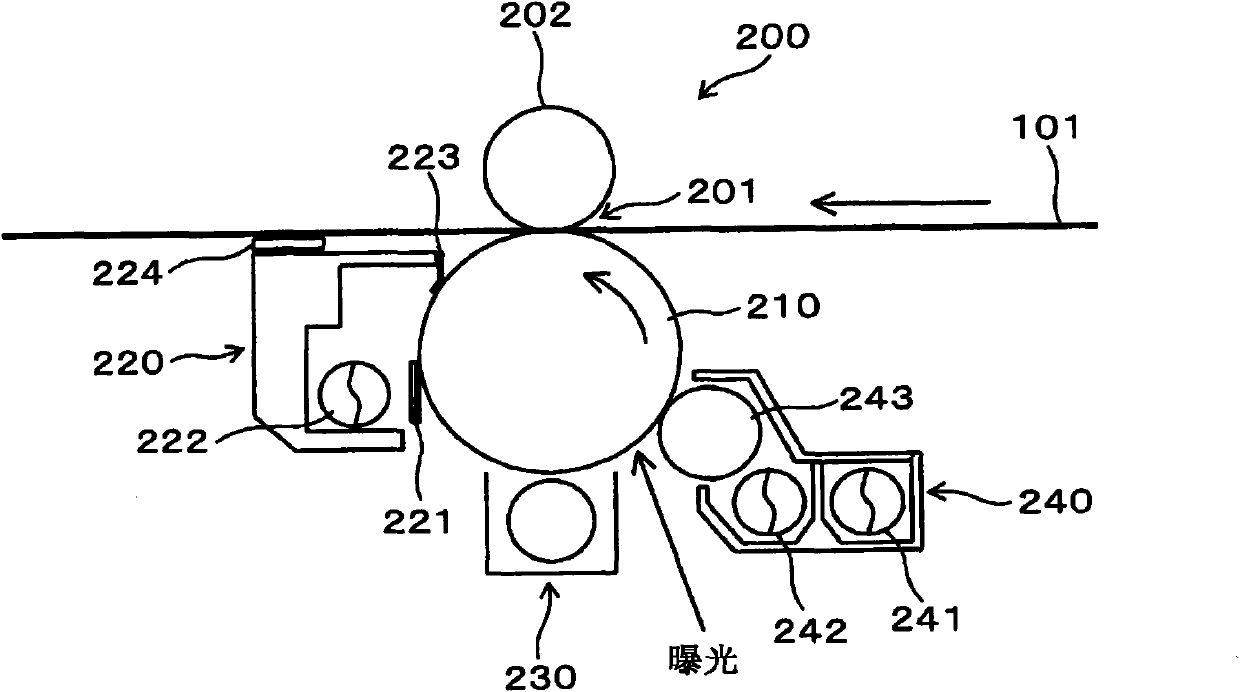

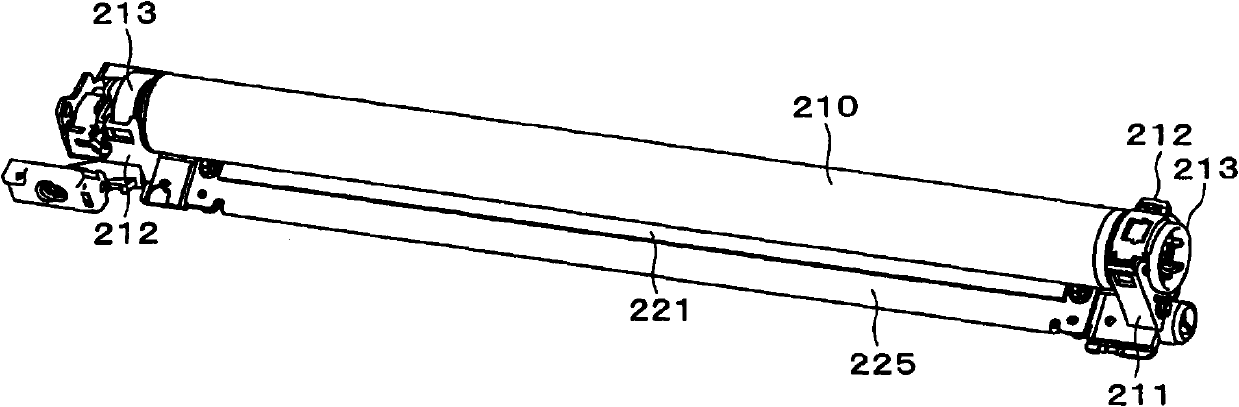

Cleaning blade and image forming apparatus

InactiveCN102200746AReduce friction and wear changesSuppression of streaksElectrographic process apparatusSurface roughnessEngineering

A cleaning blade includes a cleaning layer facing an image holding body, and a back layer wich is disposed at a side opposite to the image holding body and removes discharge products and developer residues that are stuck to a surface of the image holding body in such a manner that an edge of the cleaning layer comes into contact with the surface of the image holding body, and the back layer and the cleaning layer are molded integrally and a surface roughness Ra of the cleaning layer is lower than or equal to 0.12 mum.

Owner:FUJIFILM BUSINESS INNOVATION CORP

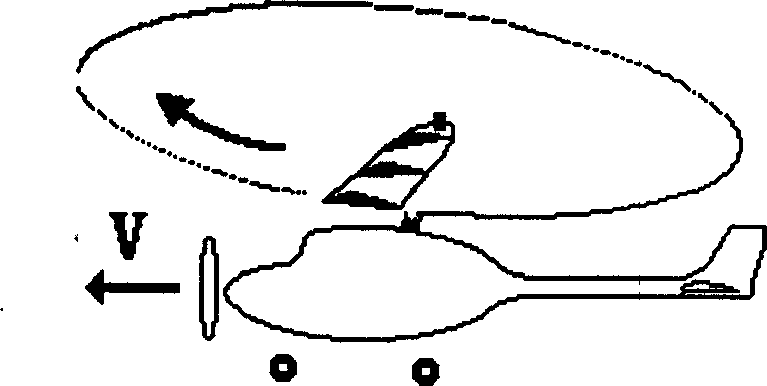

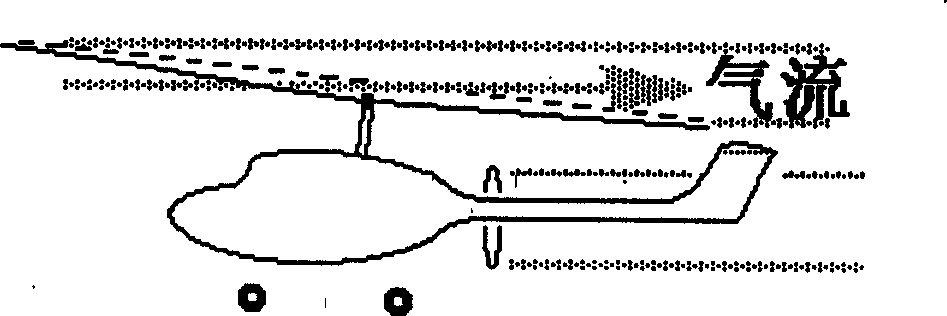

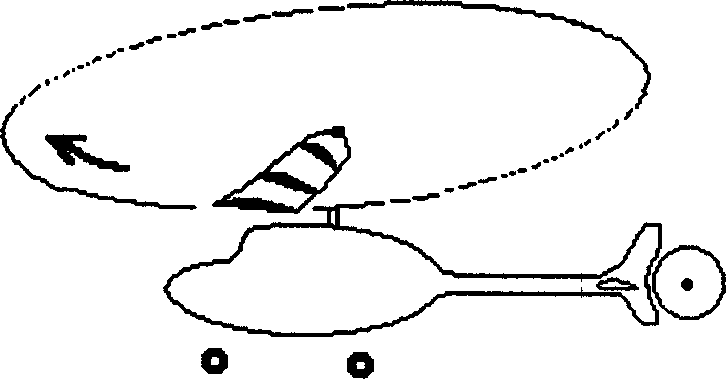

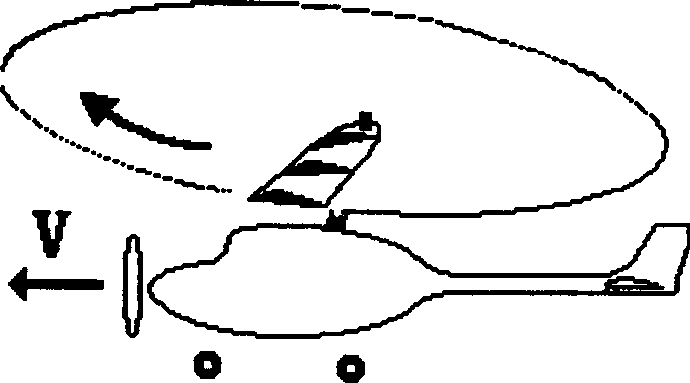

Helirota plane

InactiveCN1651309AGive full play to the advantages of workAvoid aerodynamic efficiencyPropellersRotocraftLow noiseRotary wing

A rotor craft able to vertically take off and land is composed of main body, mainshaft, rotor fixed to mainshaft and with the adjustable torsional blades, horizontally driving clutch, power system, rear fin and propeller for horizontally driving. Its advantages are flexibly taking-off and landing, high safety and low noise.

Owner:章洪

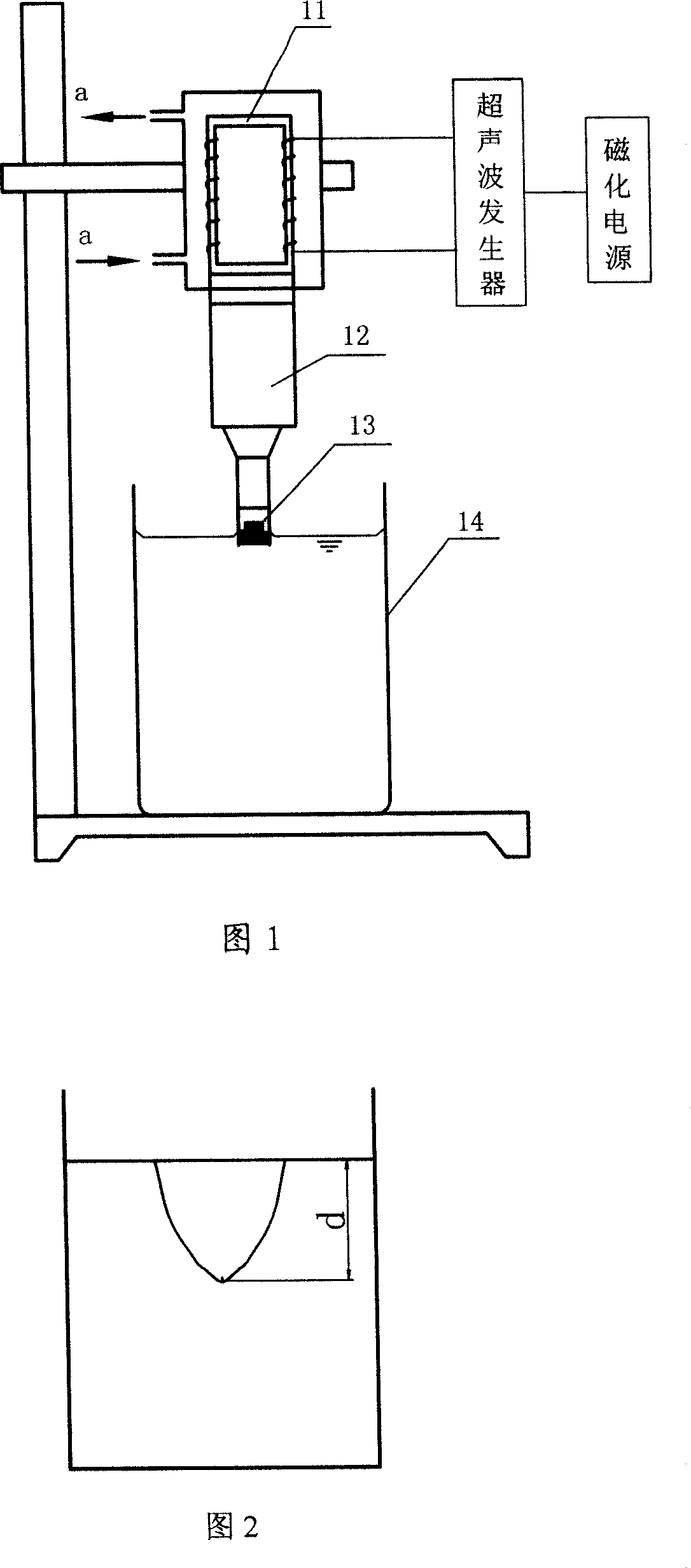

Abrasion generator

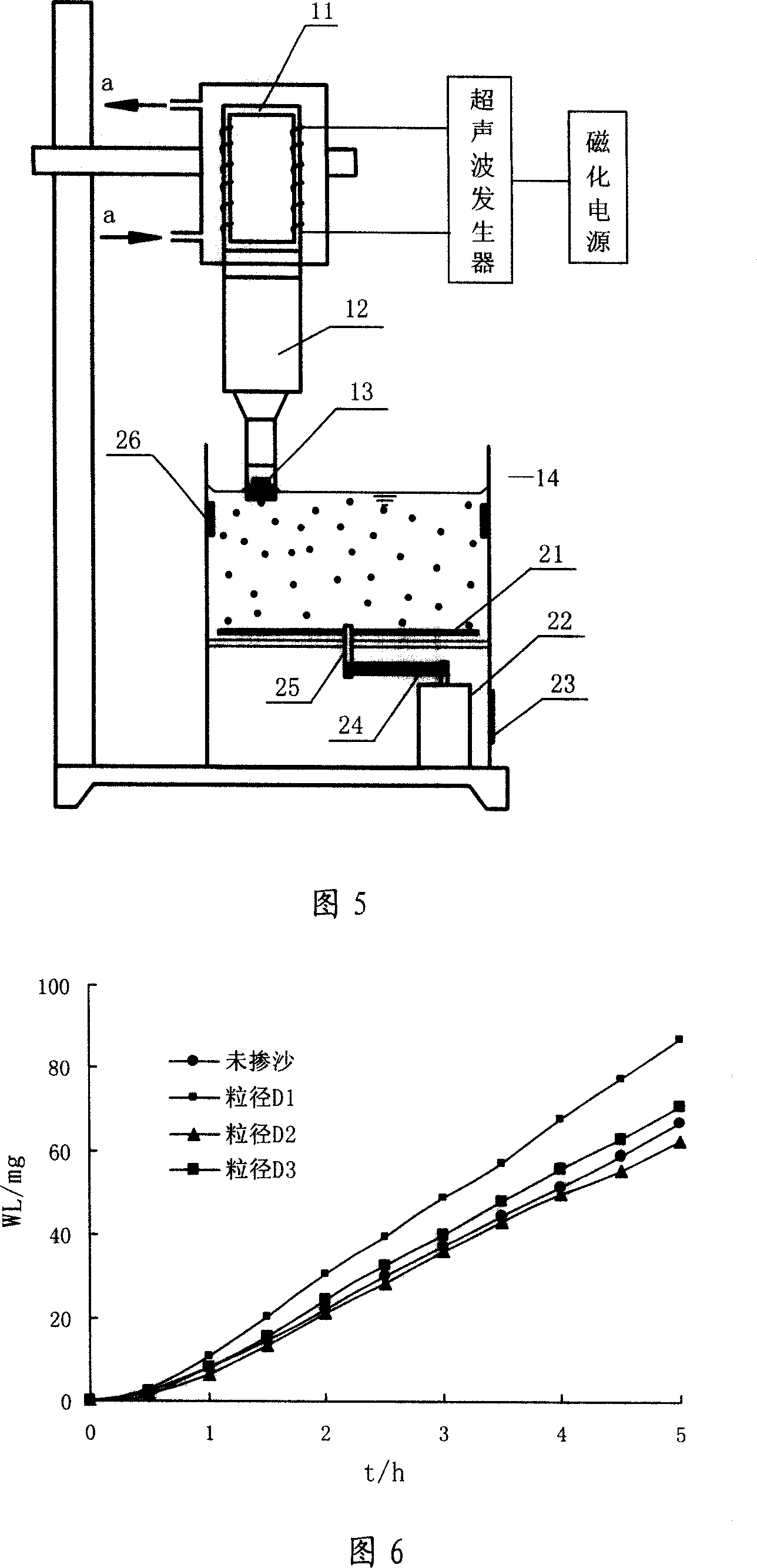

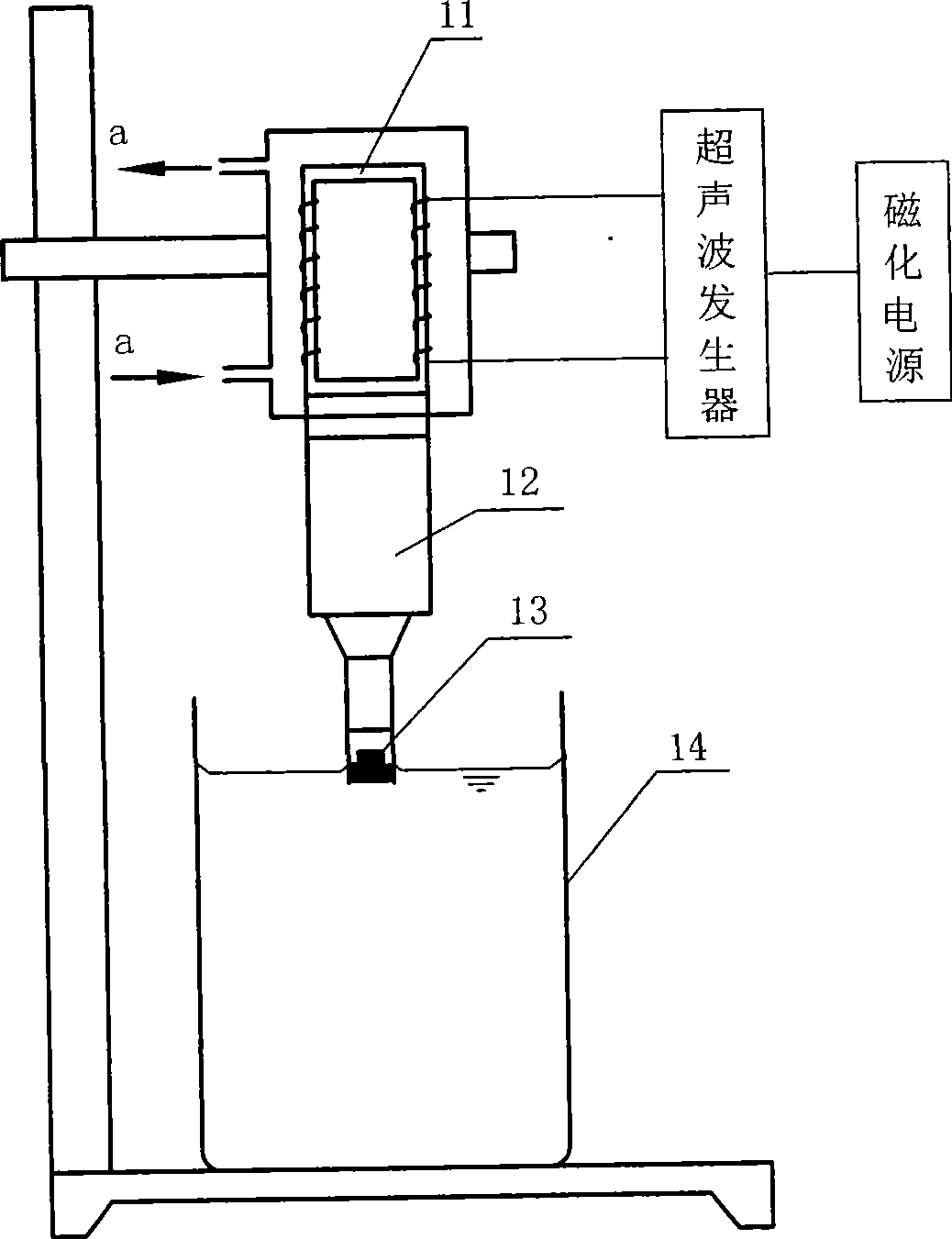

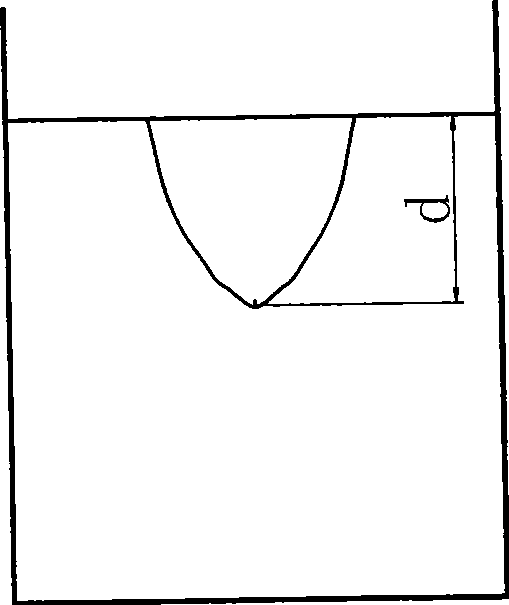

InactiveCN101004371AChange speedReduce sagWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceElectric machineryMagnetostriction

An abrasion generator for measuring abrasion function of slit consists of magnetostriction oscillator and container containing with test liquid. It is featured as erecting test-piece on variable-amplitude rod of megnetostriction oscillator, using water containing sand as test liquid contained in said container, arranging agitator formed by blade and motor in said container.

Owner:HOHAI UNIV

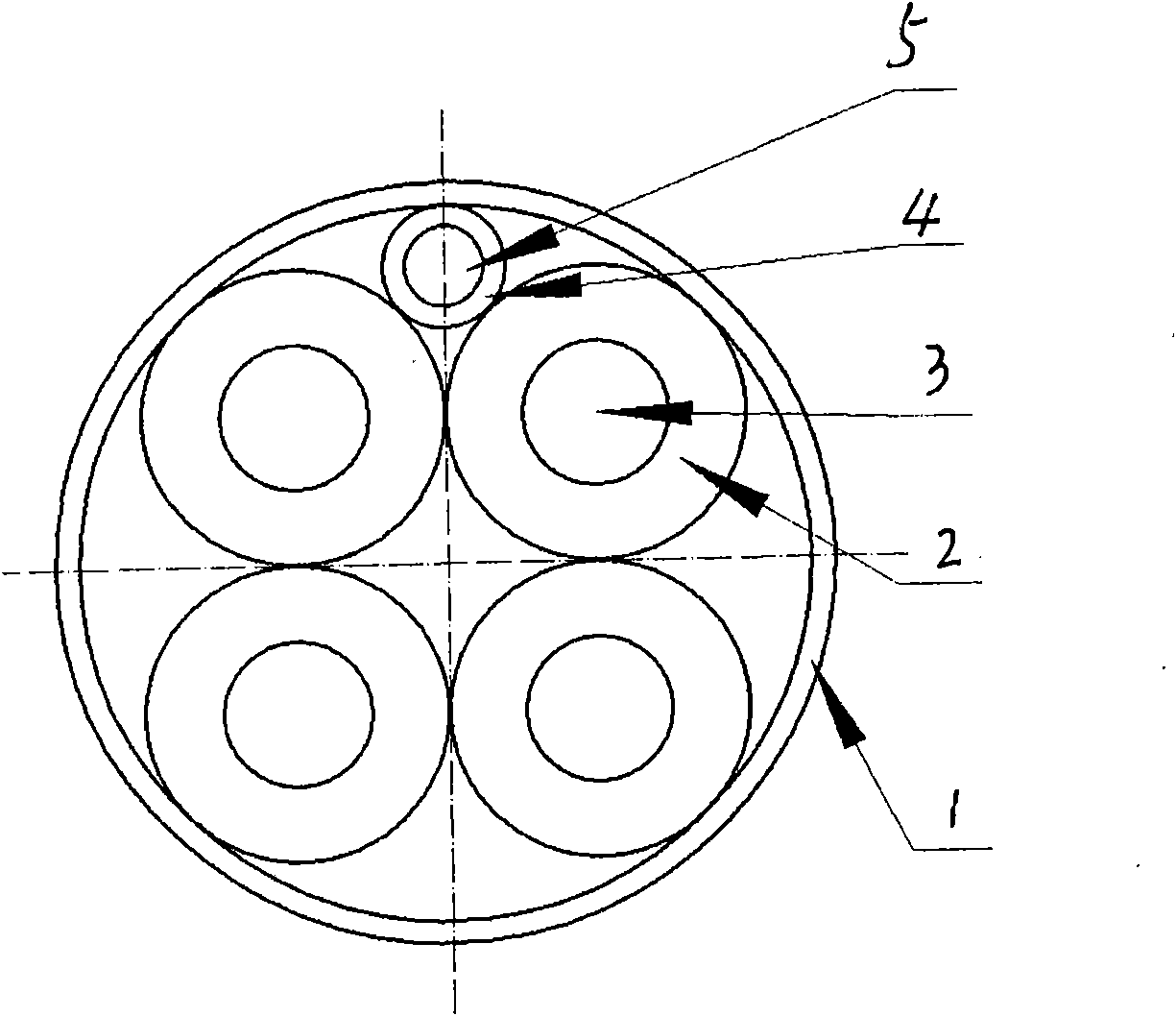

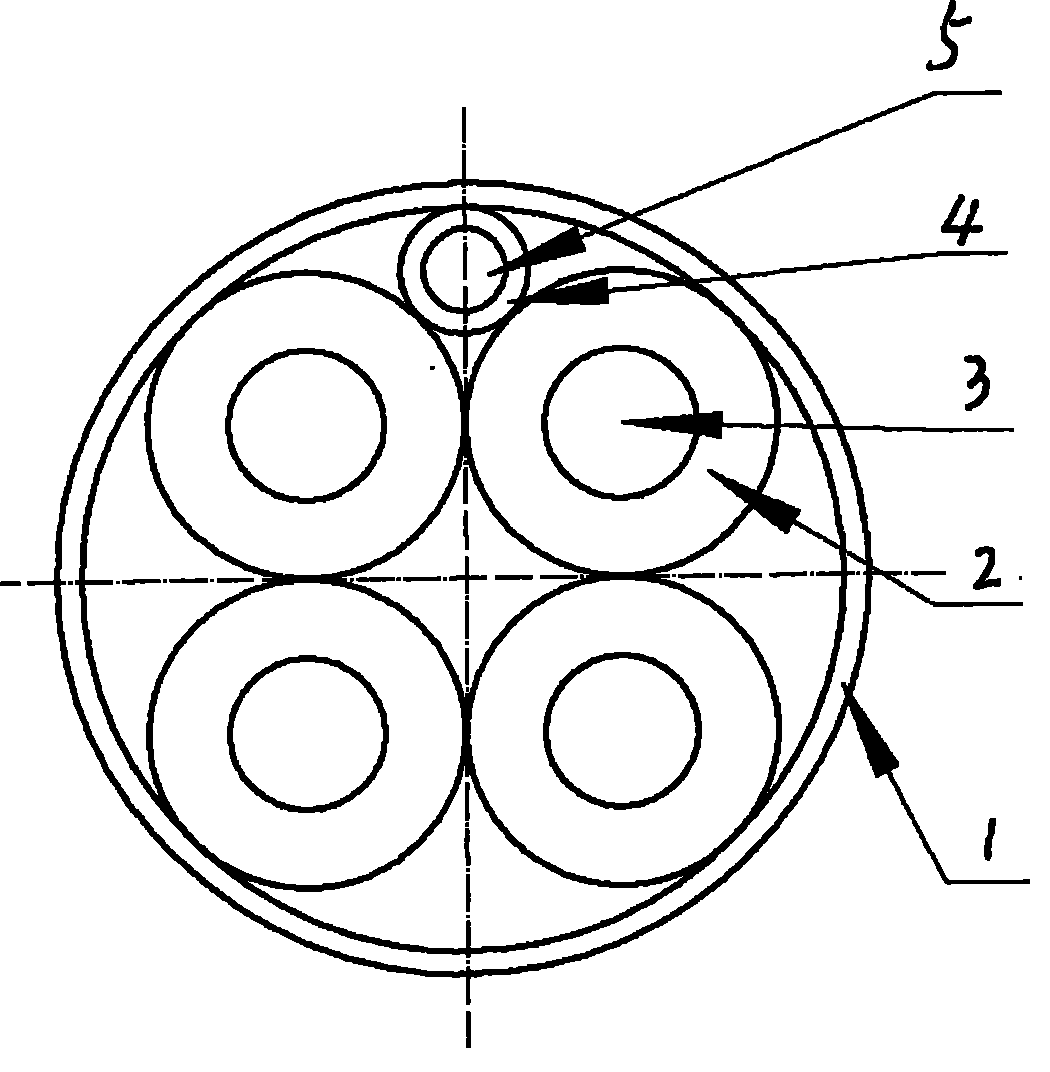

Far infrared anti-ice and snow bunched aerial insulated cable

InactiveCN101916611AHeating up fastHigh electrothermal conversion efficiencyInsulated cablesInsulated conductorsElectrical conductorEngineering

The invention discloses a far infrared anti-ice and snow bunched aerial insulated cable. The cable is characterized by comprising an aerial insulated wire core and a far infrared heating body wire core, wherein the aerial insulated wire core is wrapped in an outer sheath layer and formed by a plurality of metal conductors wrapped by insulating material layers respectively; and the far infrared heating body wire core is formed by at least one far infrared heating conductor wrapped by a heating and insulating material layer. Compared with the prior art, the cable has the advantages of good anti-ice and snow effect, high heating speed, low power consumption, light weight and capability of relieving sag of the aerial insulated cable and effectively reducing the manufacturing cost and the laying cost.

Owner:ZHENGZHOU CABLE

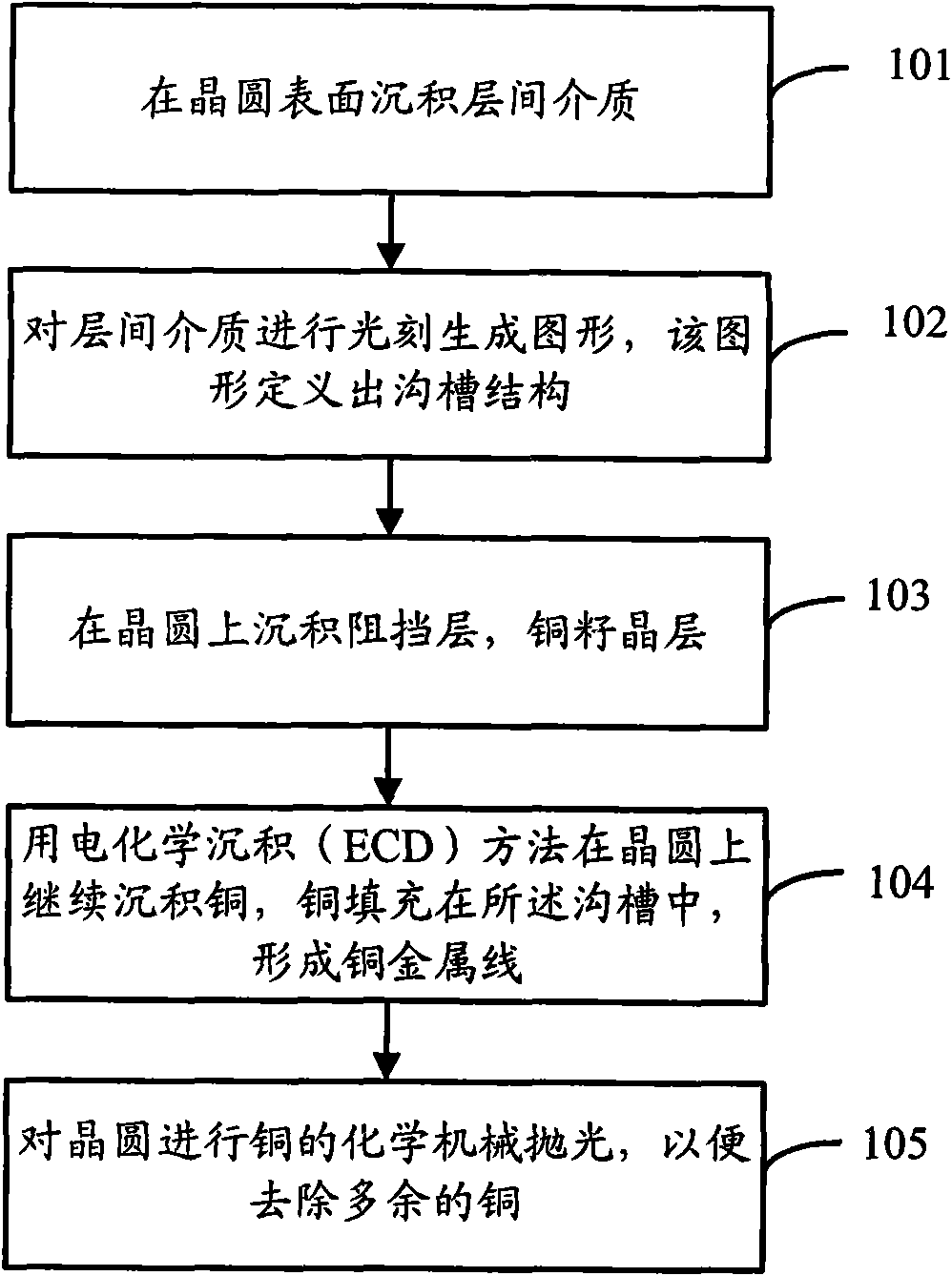

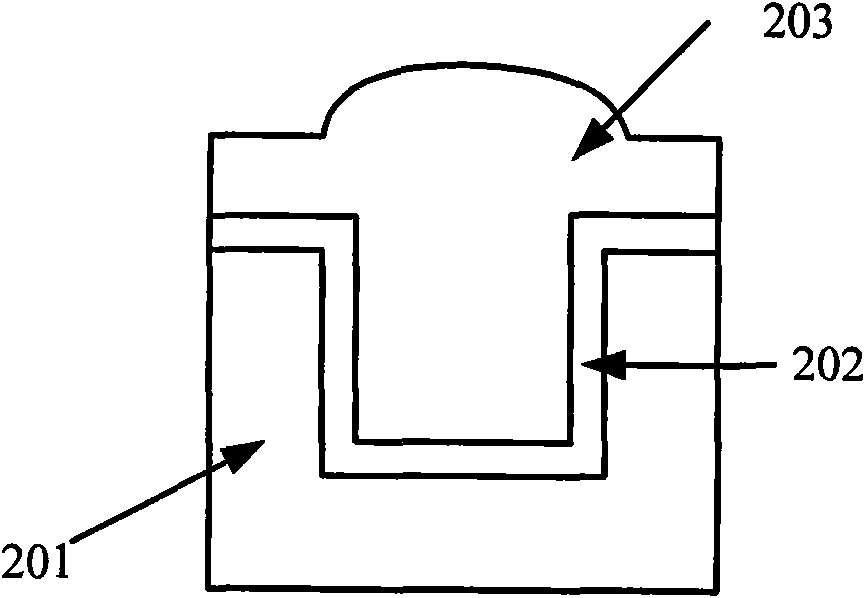

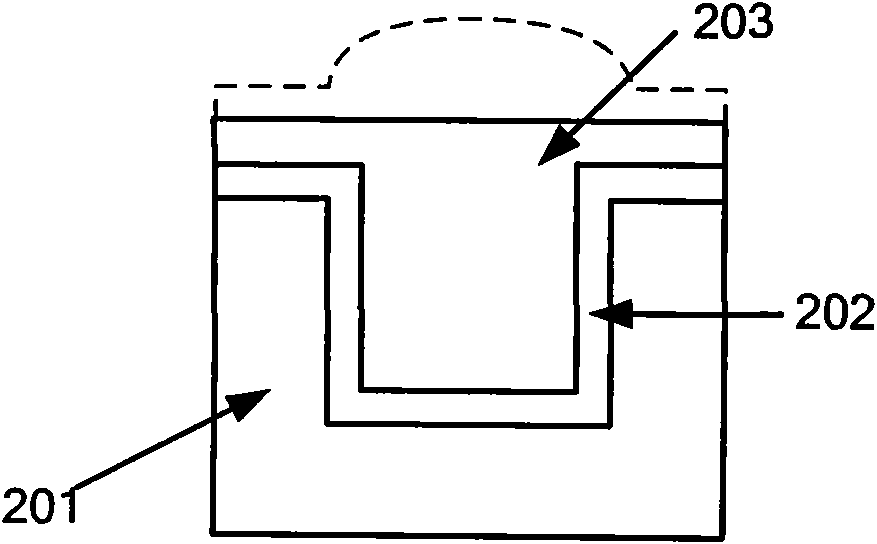

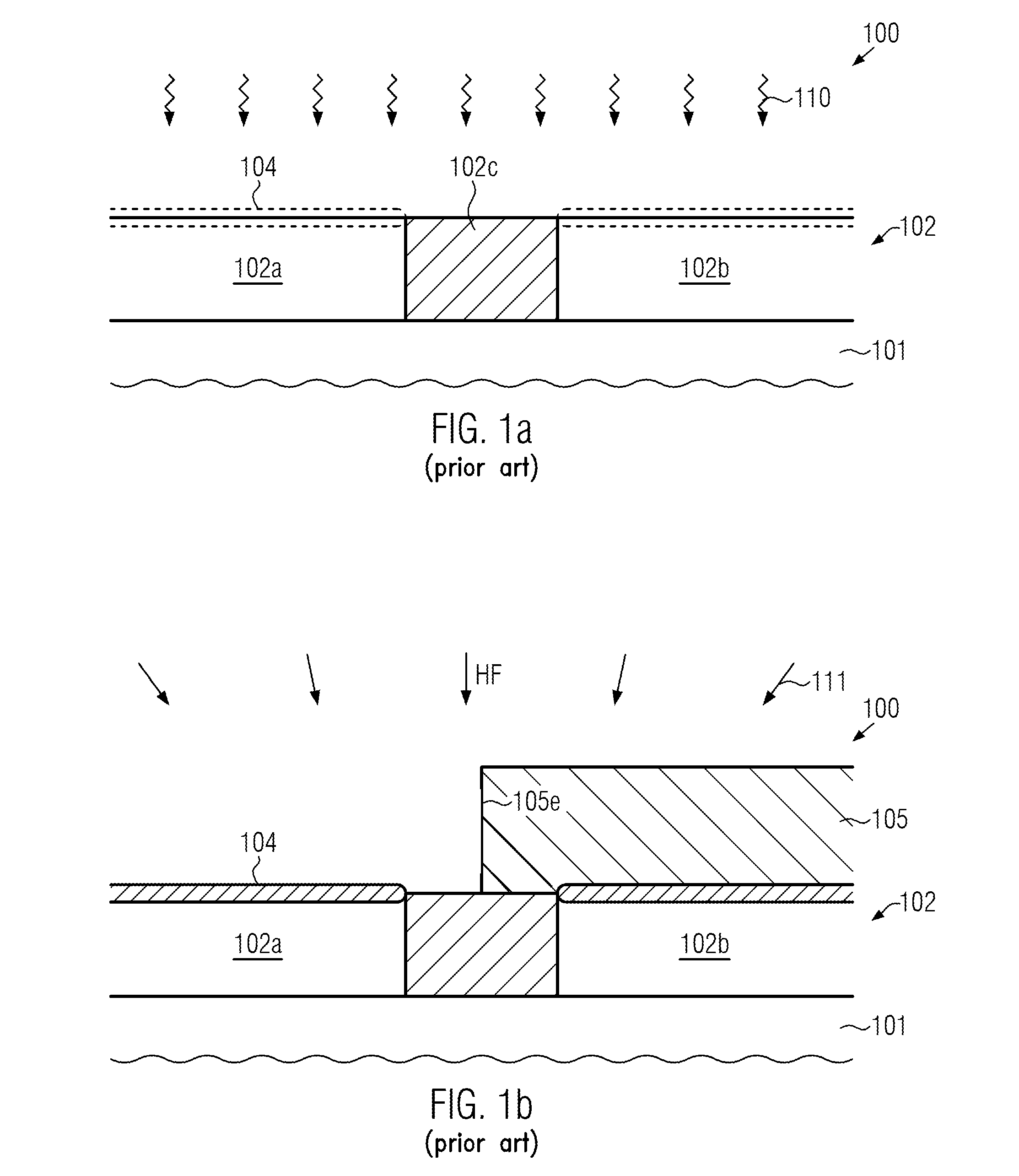

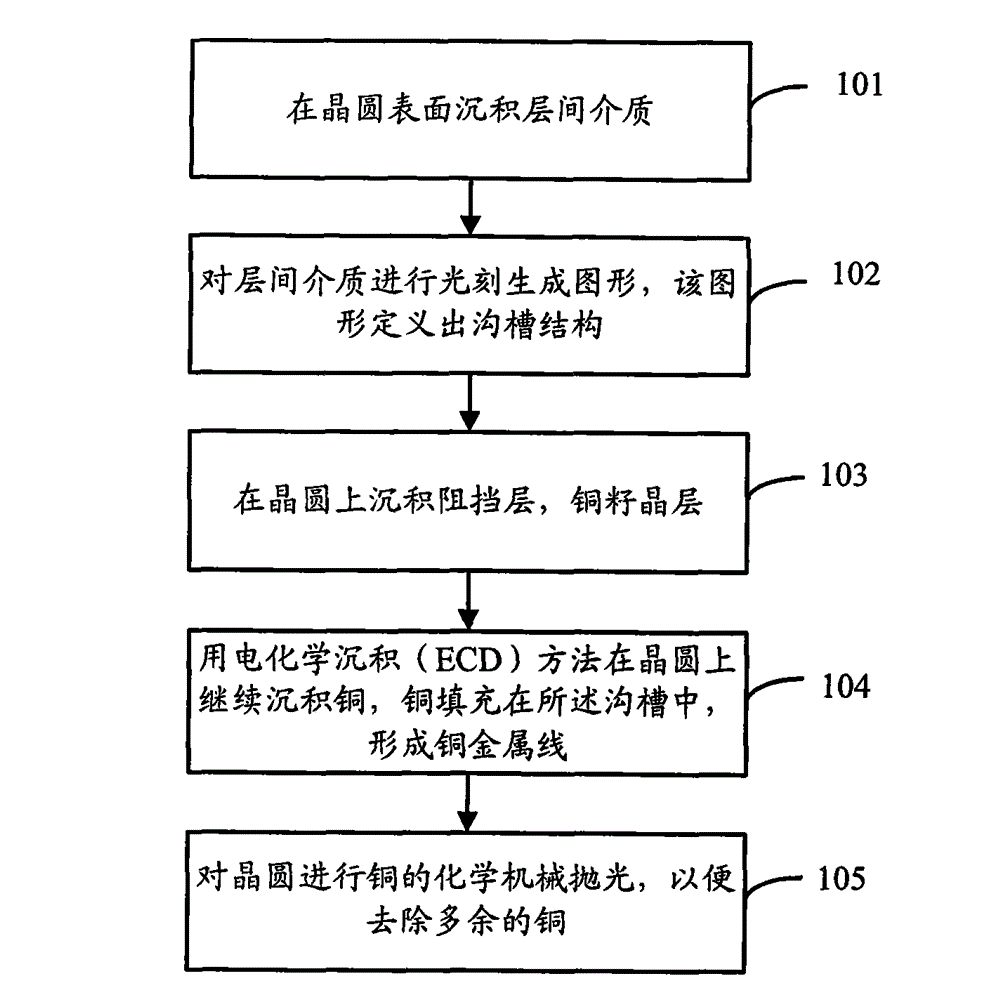

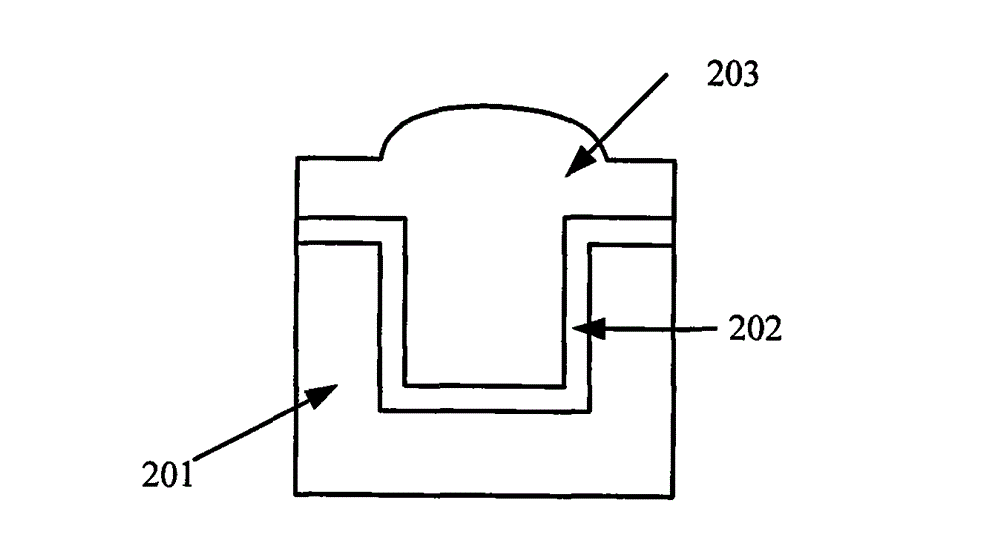

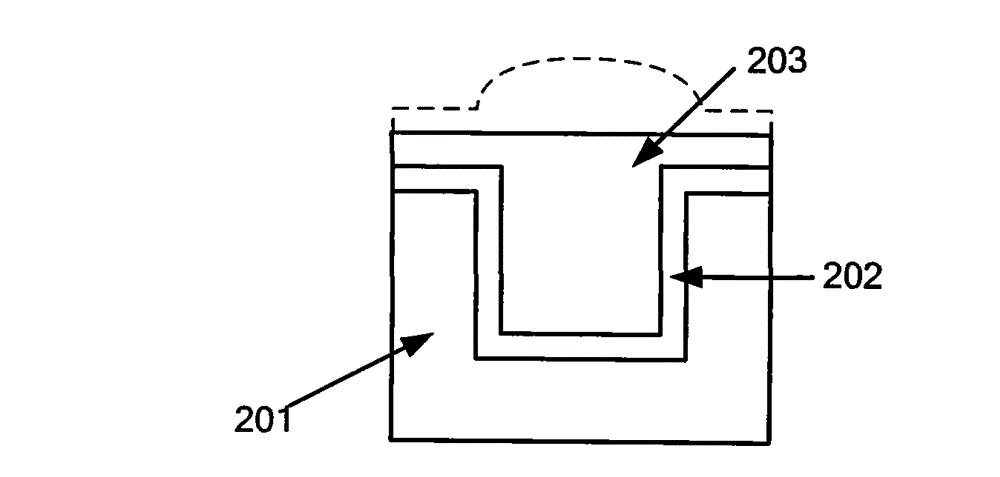

Method for constructing copper wire on wafer and chemical mechanical polishing (CMP) method for copper

ActiveCN101958273AHardness effectReduce sagSemiconductor/solid-state device manufacturingDielectricState of art

The invention discloses a method for constructing a copper wire on a wafer, which comprises the following steps of: depositing a first interlayer dielectric on the upper surface of the wafer; constructing a second interlayer dielectric on the upper surface of the first interlayer dielectric of the wafer, wherein the hardness of the second interlayer dielectric is lower than that of the first interlayer dielectric; photoetching the second interlayer dielectric and the first interlayer dielectric to define a groove structure, wherein the bottom of the groove structure is positioned in the first interlayer dielectric; sequentially depositing a barrier layer and a copper seed crystal layer on the upper surface of the wafer and the inner wall of a groove; depositing copper on the upper surface of the wafer, wherein the copper is filled in the groove to form the copper wire; and performing chemical mechanical polishing (CMP) on the wafer to reach the first interlayer dielectric so as to make the upper surface of the wafer subjected to planarization. The invention also discloses a CMP method for the copper. The sinking degree of the surface of the copper wire constructed by the scheme of the invention is reduced to a certain extent compared with that of the prior art.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

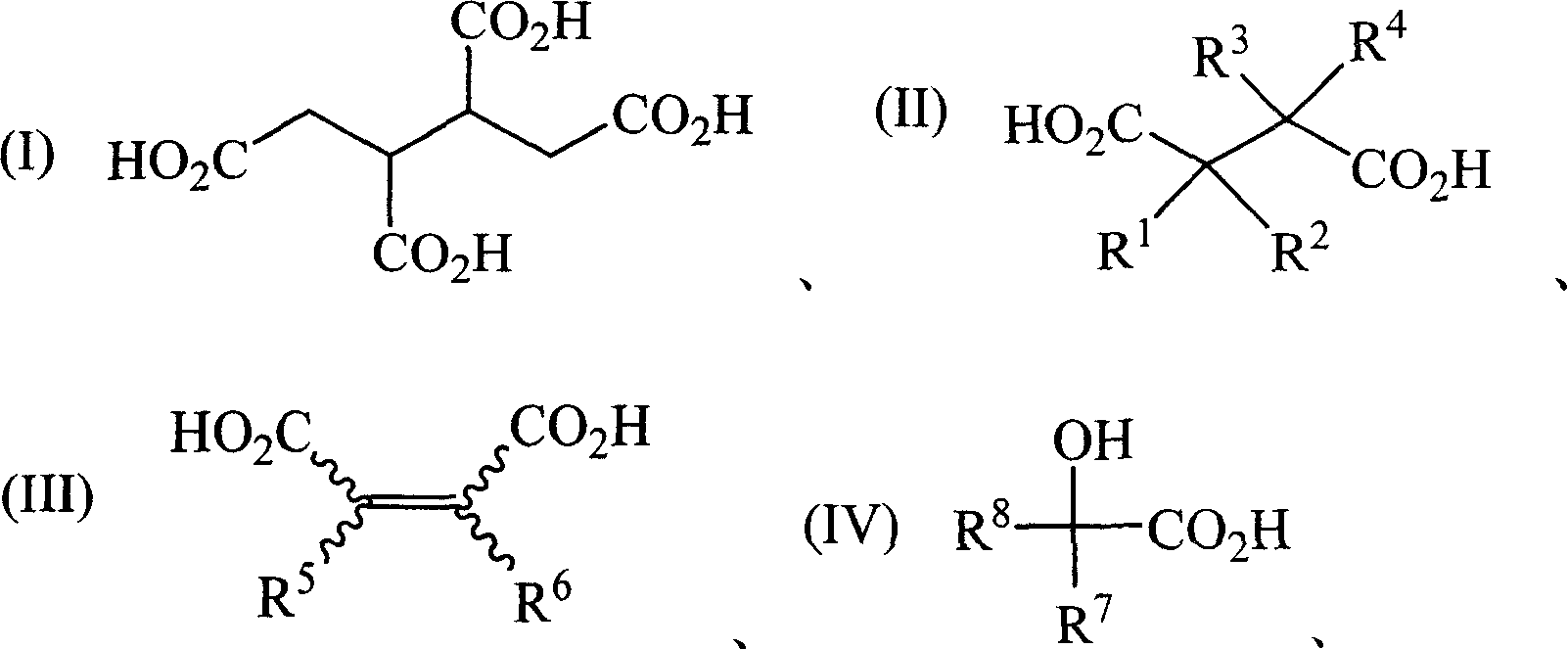

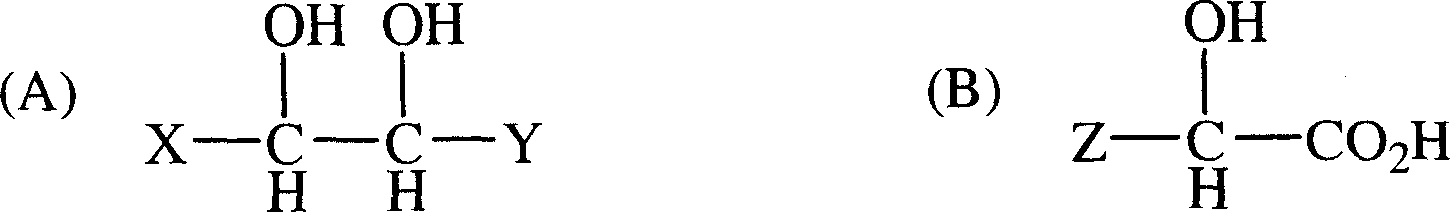

Chemical machinery grinding composition

InactiveCN101058710ALess metal residueReduce sagOther chemical processesSemiconductor/solid-state device manufacturingDielectricCompound (substance)

The invention discloses a chemical mechanical grinding composition, which comprises the following parts with pH value between 2 and 5: aqueous dielectric, grinding material, etching inhibitor, surface activator, diacid compound and residual metal inhibitor, wherein the residual metal inhibitor is composed of the compound as formula (I), compound as formula (II), compound as formula (III), compound as formula (IV), compound as formula (V) and these compound composition; the structure of formula (II)-(V) and the definition of each substituted group are limited by instruction and power requstment; the chemical mechanical grinding composition can be used on the grinding semiconductor crystal circle surface, which can obtain not bad metal grinding velocity and reduce metal pit and residual metal effectively.

Owner:EPOCH MATERIAL CO LTD

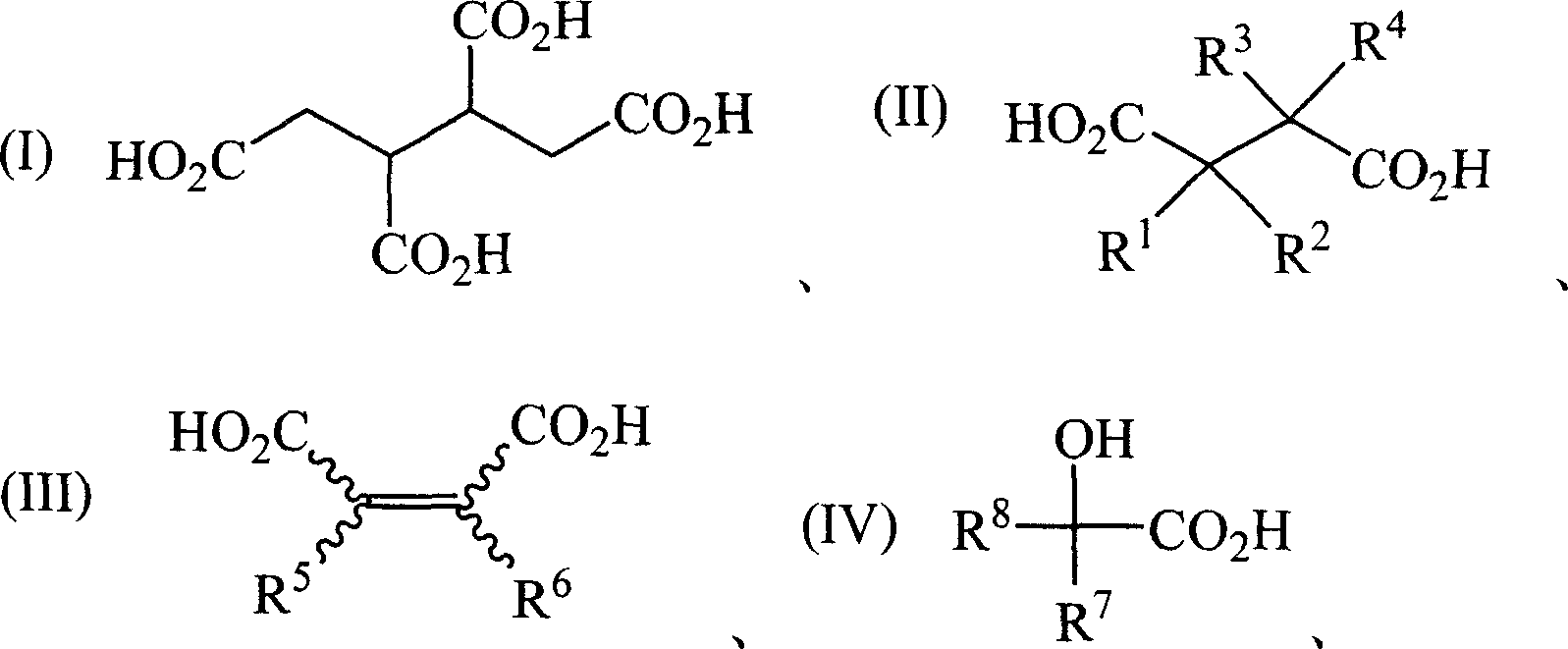

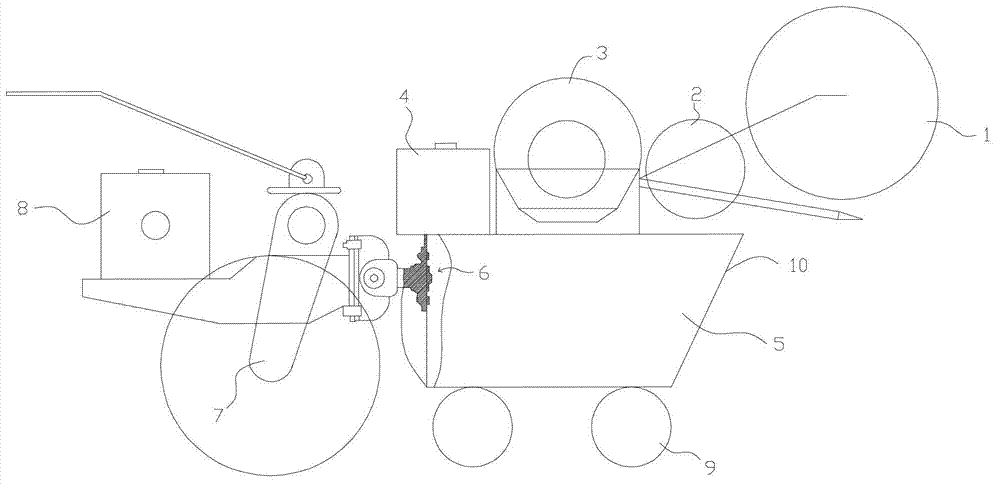

Harvester

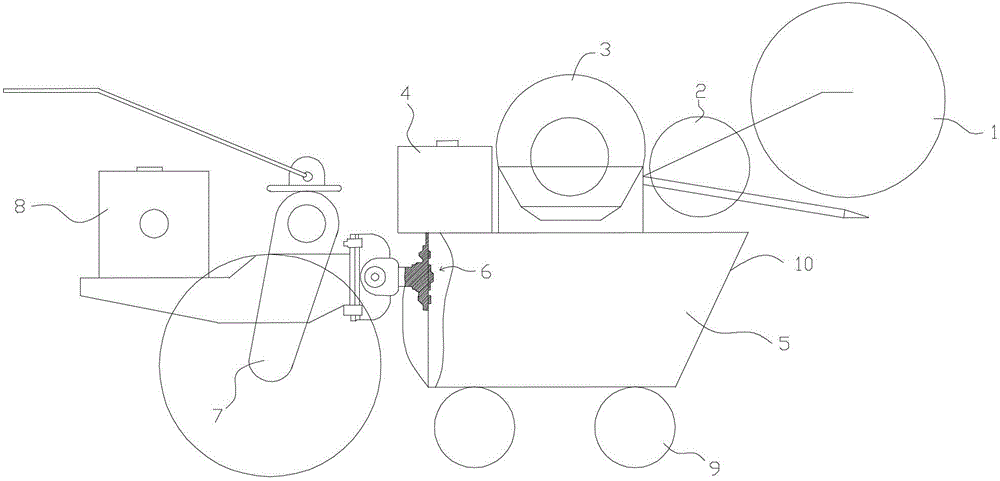

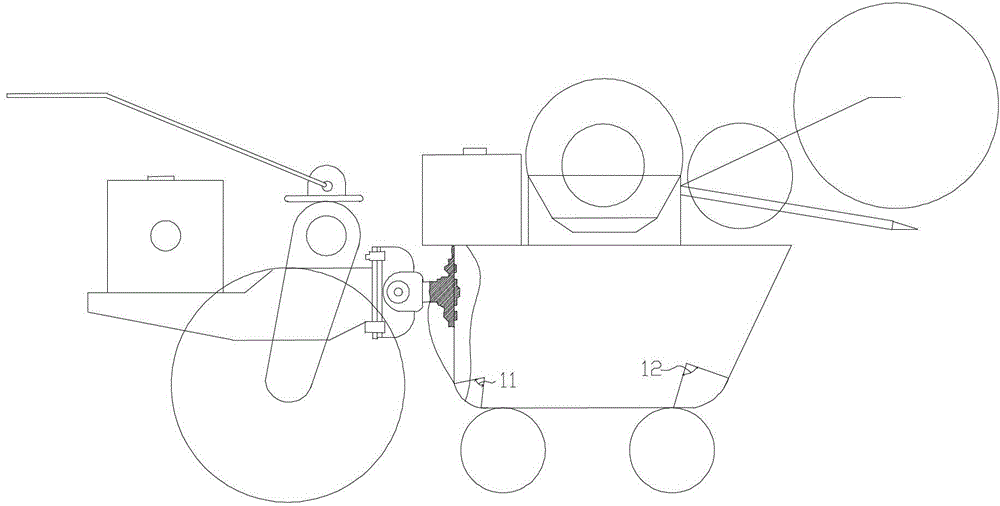

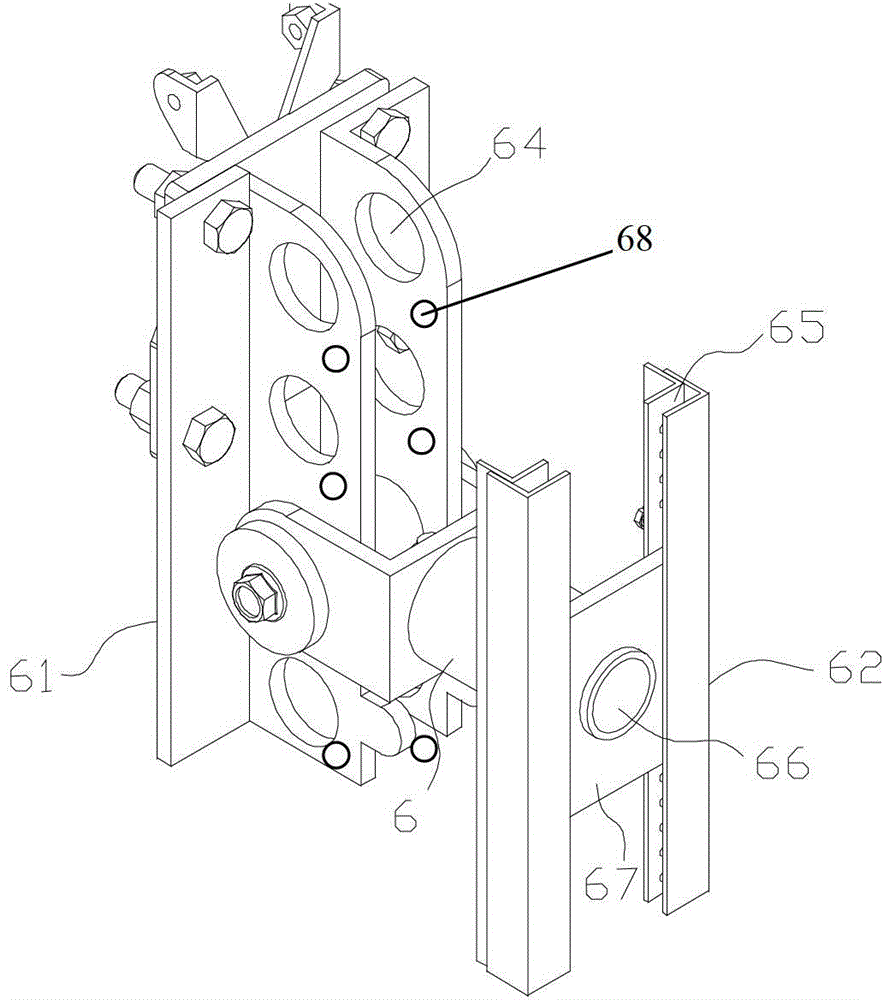

The invention discloses a harvester, comprising a walking mechanism, a power device which is used for providing power to the walking mechanism, a threshing component, a harvesting component, a seedling pulling component and a suspension device which is connected with the walking mechanism through a connector, wherein the connector is capable of realizing the height adjustment and transverse rotation of the suspension device; and the threshing component, the harvesting component and the seedling pulling component are located on the suspension device. According to the invention, through adaptation, the center of gravity of the harvester is borne by the suspension device without inclining, so that the extent of sinking is decreased, the other weight does not press on the walking mechanism and then the inclination of the walking mechanism is decreased.

Owner:SICHUAN WANMA MACHINERY MFG

Compositions for chemical-mechanical planarization of noble-metal-featured substrates, associated methods, and substrates produced by such methods

InactiveUS20090255903A1Erosion of and avoided and minimizedMaterial avoided and minimizedDecorative surface effectsSemiconductor/solid-state device manufacturingAlloySlurry

A composition for chemical-mechanical planarization comprises periodic acid and an abrasive present in a combined amount sufficient to planarize a substrate surface having a feature thereon comprising a noble metal, noble metal alloy, noble metal oxide, or any combination thereof. In one embodiment, the periodic acid is present in an amount in a range of from about 0.05 to about 0.3 moles / kilogram, and the abrasive is present in an amount in a range of from about 0.2 to about 6 weight percent. In another embodiment, the composition further comprises a pH-adjusting agent present in an amount sufficient to cause the pH of the composition to be in a range of from about pH 5 to about pH 10, or of from about pH 1 to about pH 4.A method for planarizing a substrate surface having a feature thereon comprising at least one noble metal, noble metal alloy, or noble metal oxide, or a combination thereof, comprises providing a composition or slurry comprising periodic acid and an abrasive in a combined amount sufficient to planarize the substrate surface, and polishing the surface with the slurry. A substrate produced by such a method is also provided.

Owner:VERSUM MATERIALS US LLC

Compositions of chemical mechanical planarization slurries contacting noble-metal-featured substrates

InactiveUS7524346B2Erosion of and avoided and minimizedMaterial avoided and minimizedPigmenting treatmentOther chemical processesSlurryAlloy

A composition for chemical-mechanical planarization comprises periodic acid and an abrasive present in a combined amount sufficient to planarize a substrate surface having a feature thereon comprising a noble metal, noble metal alloy, noble metal oxide, or any combination thereof. In one embodiment, the periodic acid is present in an amount in a range of from about 0.05 to about 0.3 moles / kilogram, and the abrasive is present in an amount in a range of from about 0.2 to about 6 weight percent. In another embodiment, the composition further comprises a pH-adjusting agent present in an amount sufficient to cause the pH of the composition to be in a range of from about pH 5 to about pH 10, or of from about pH 1 to about pH 4. A method for planarizing a substrate surface having a feature thereon comprising at least one noble metal, noble metal alloy, or noble metal oxide, or a combination thereof, comprises providing a composition or slurry comprising periodic acid and an abrasive in a combined amount sufficient to planarize the substrate surface, and polishing the surface with the slurry. A substrate produced by such a method is also provided.

Owner:VERSUM MATERIALS US LLC

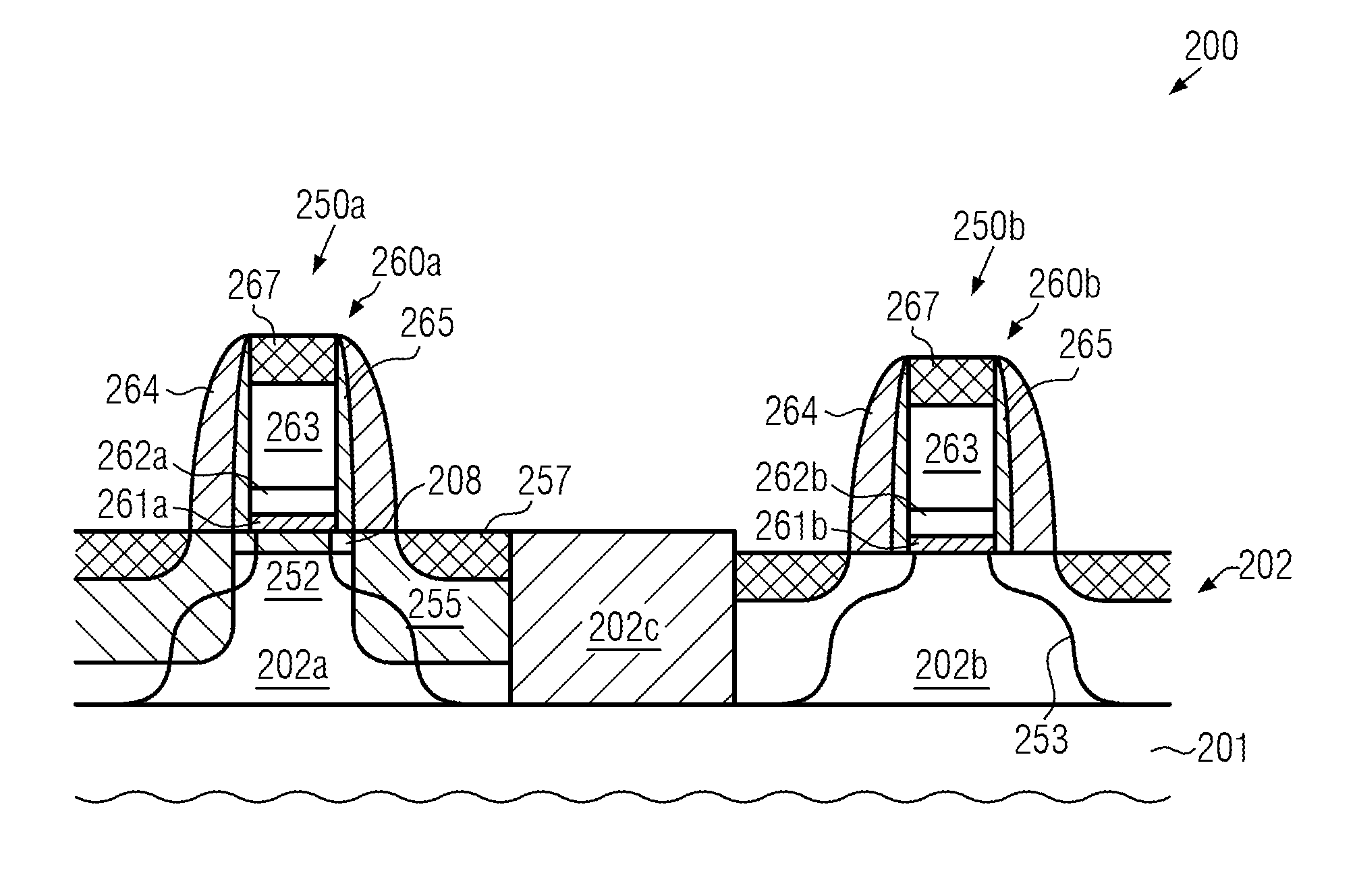

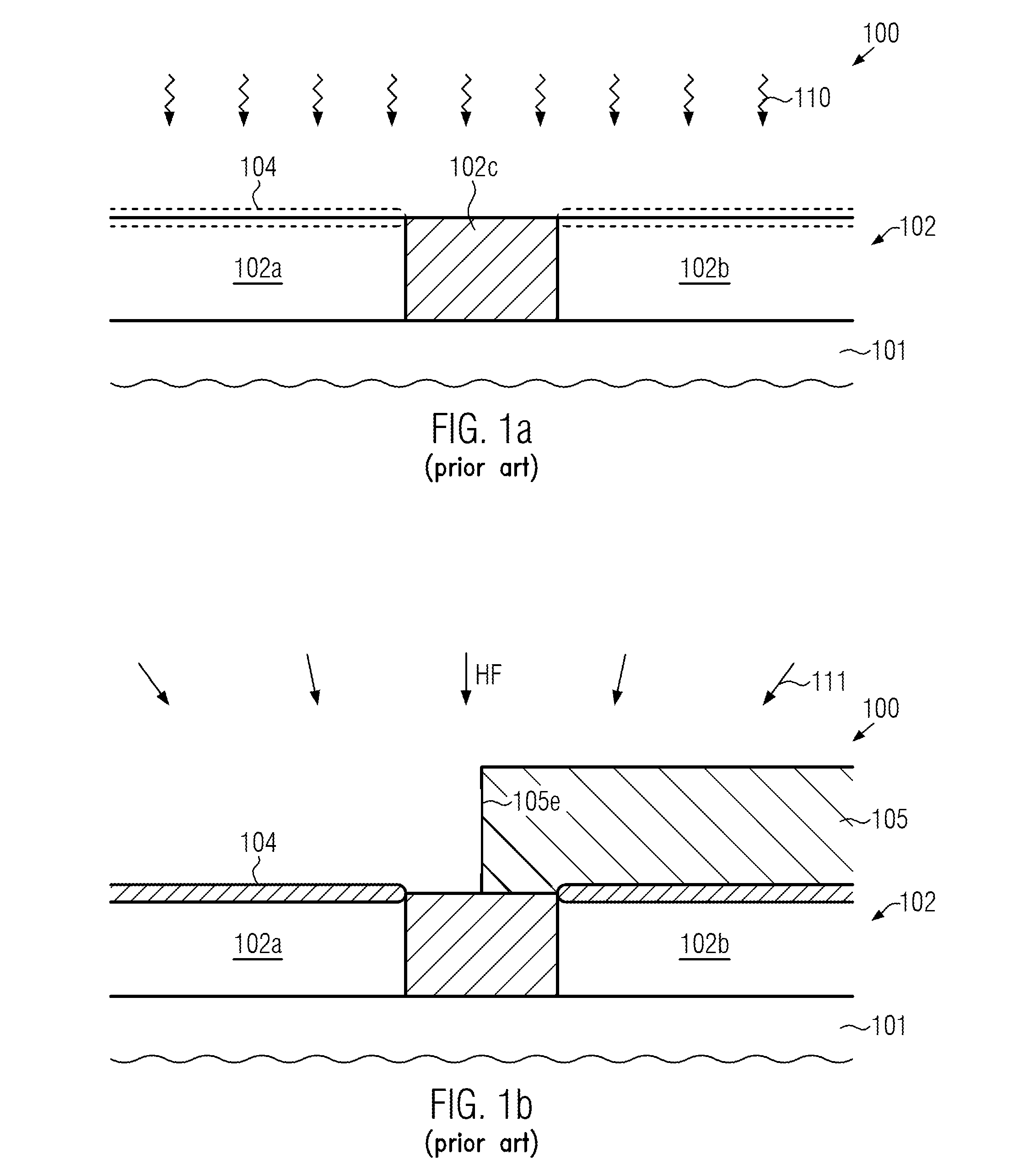

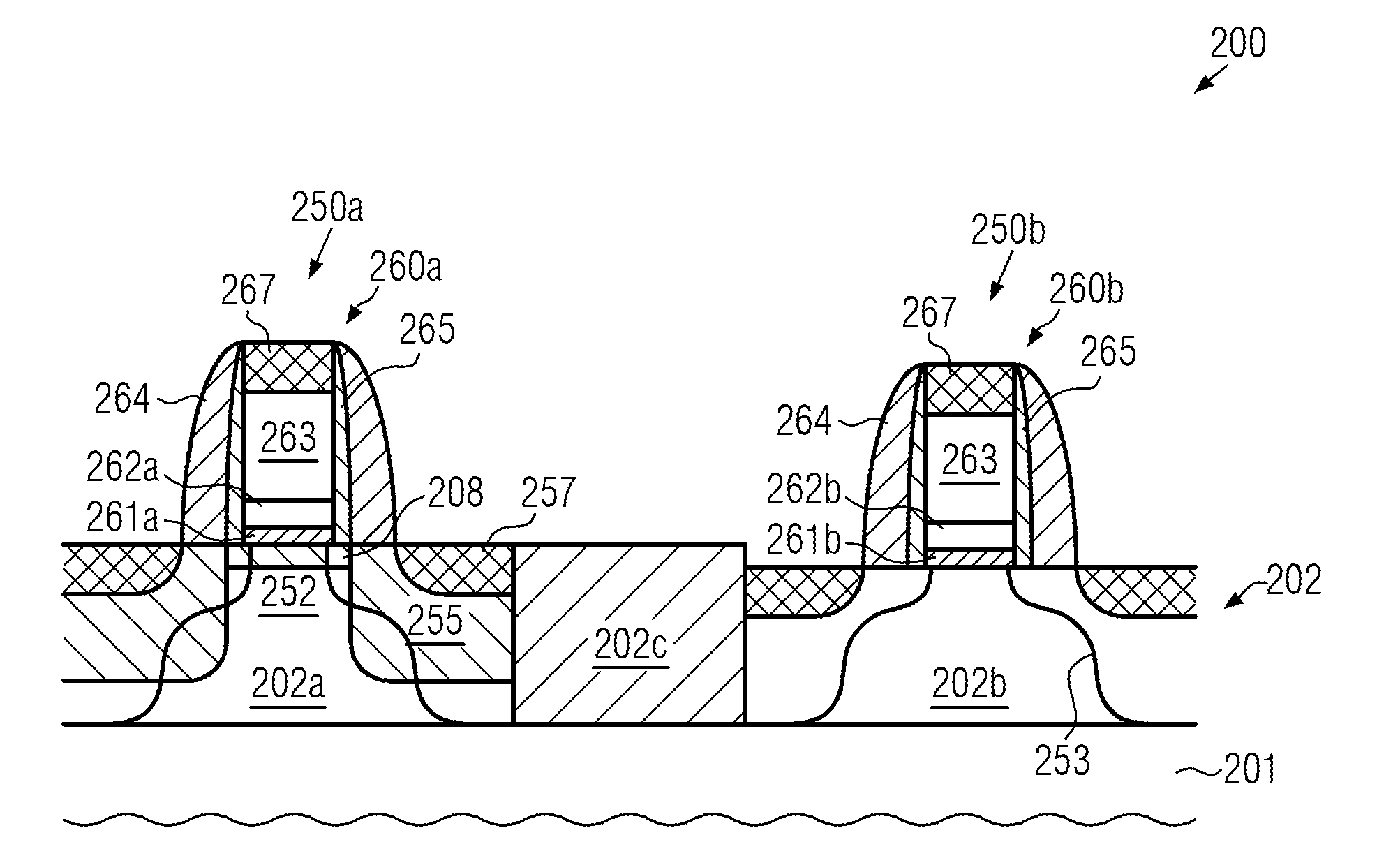

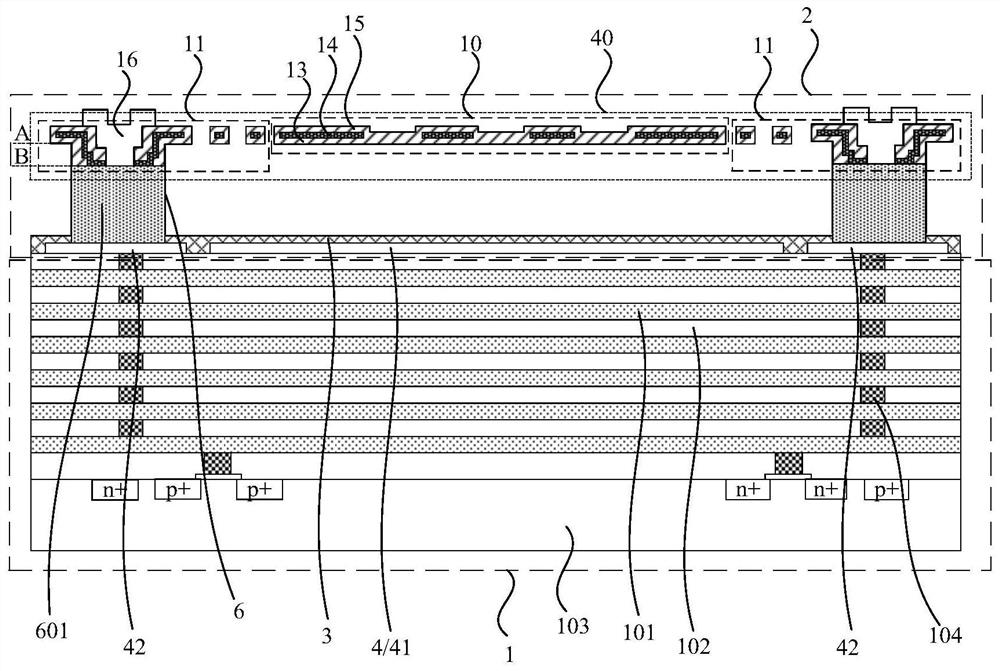

Formation of a channel semiconductor alloy by forming a nitride based hard mask layer

ActiveUS8664066B2Reduce sagImprove uniformityTransistorSolid-state devicesManufacturing technologyAlloy

The present disclosure provides manufacturing techniques in which sophisticated high-k metal gate electrode structures may be formed in an early manufacturing stage on the basis of a selectively applied threshold voltage adjusting semiconductor alloy. In order to reduce the surface topography upon patterning the deposition mask while still allowing the usage of well-established epitaxial growth recipes developed for silicon dioxide-based hard mask materials, a silicon nitride base material may be used in combination with a surface treatment. In this manner, the surface of the silicon nitride material may exhibit a silicon dioxide-like behavior, while the patterning of the hard mask may be accomplished on the basis of highly selective etch techniques.

Owner:GLOBALFOUNDRIES US INC

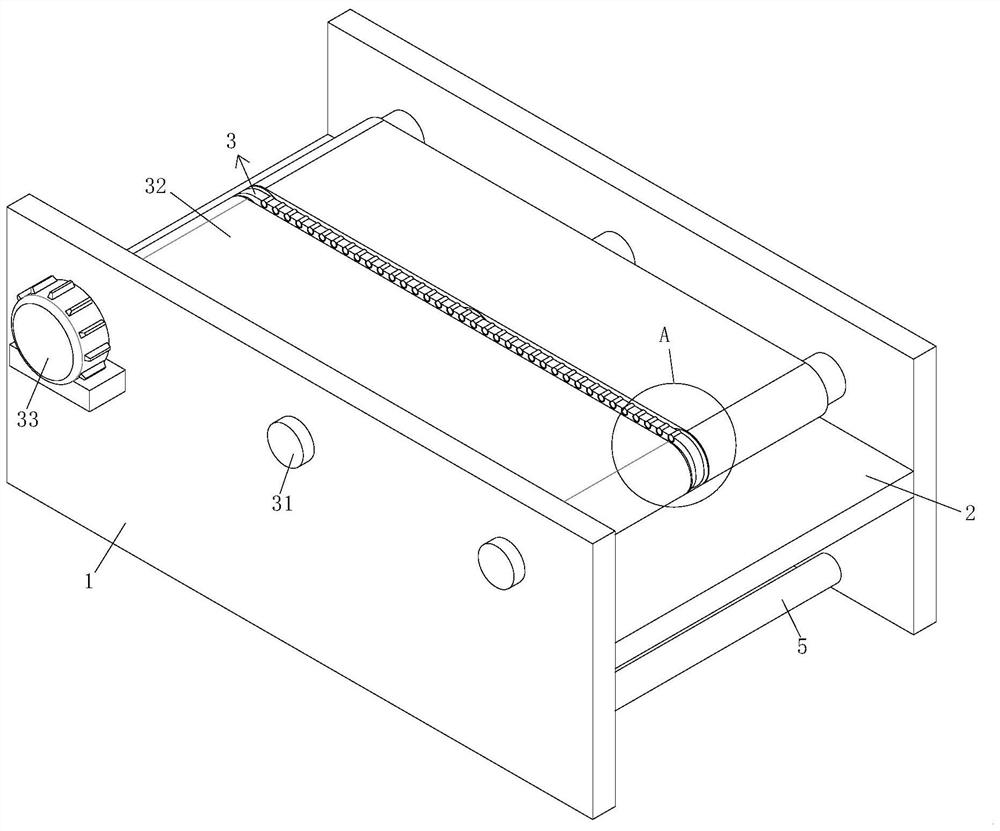

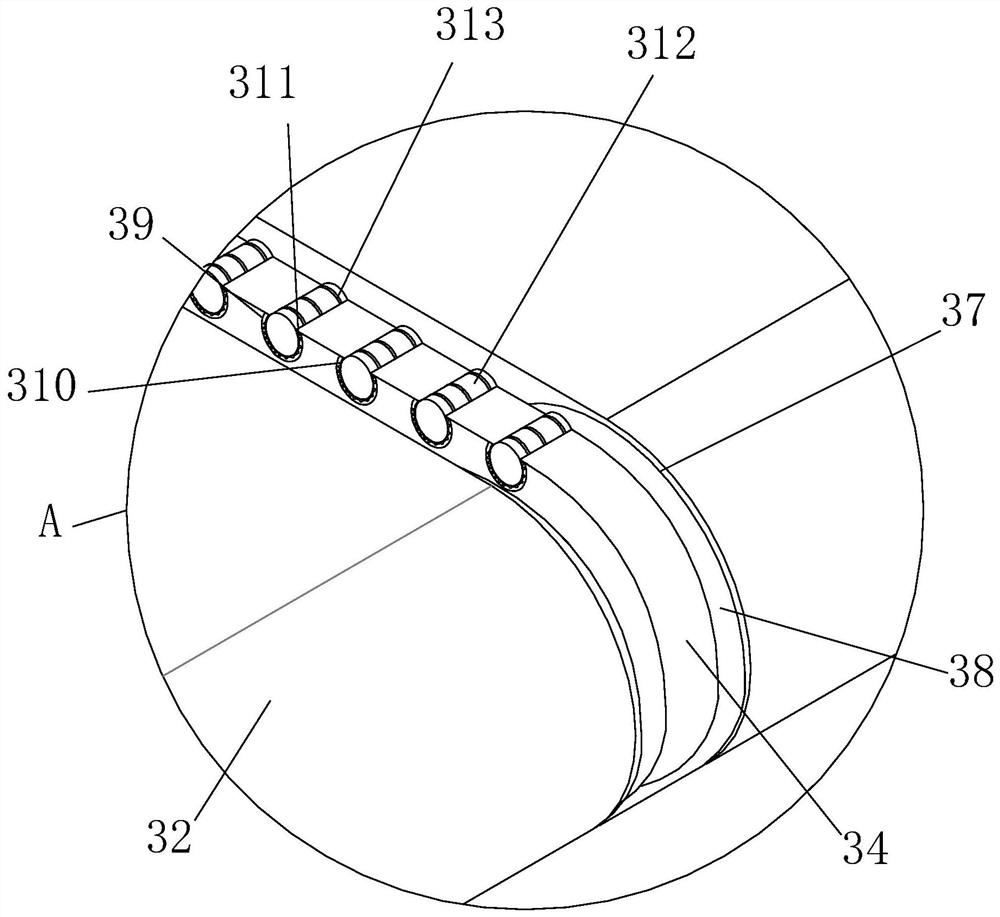

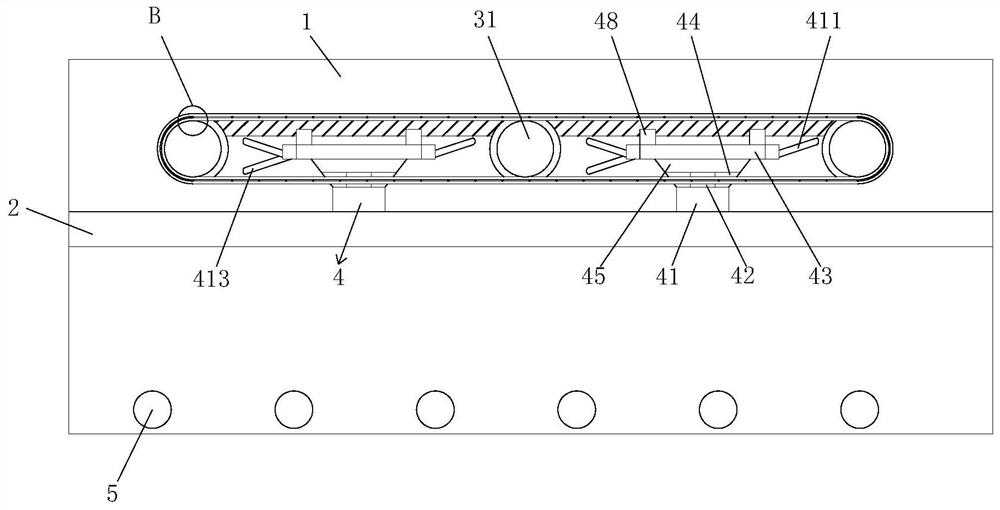

Energy-saving conveying device based on reduction of friction force

InactiveCN112224745AShorten the horizontal lengthReduce sagMechanical conveyorsRoller-waysBalancing machineFriction force

The invention provides an energy-saving conveying device based on reduction of friction force. The energy-saving conveying device comprises two supporting side plates for supporting equipment, a supporting plate for connecting the two supporting side plates, a double-row conveying mechanism for conveying objects and an air-pressure progressive balance mechanism for reducing surface indentation friction force. The two supporting side plates are distributed in parallel, and a supporting plate is fixedly connected between the two supporting side plates. The invention relates to the field of conveying devices. According to the energy-saving conveying device based on reduction of the friction force, a special conveying mechanism and a special supporting structure are designed for solving the problem that an existing conveying crawler belt is too heavy and sunken in use. The sunken surface is reduced by strengthening the supporting force, and therefore the problems are effectively solved that when a common conveying device conveys large objects, surface indentation occurs, the friction resistance is large when the conveying belt makes contact with the shaft face of a conveying shaft, thedriving energy consumption is increased, the conveying belt is prone to being damaged, and limitations exist in most existing processing modes.

Owner:杨磊

Formation of a channel semiconductor alloy by forming a nitride based hard mask layer

ActiveUS20130040430A1Reduce sagImprove uniformitySemiconductor/solid-state device manufacturingSemiconductor devicesManufacturing technologyAlloy

The present disclosure provides manufacturing techniques in which sophisticated high-k metal gate electrode structures may be formed in an early manufacturing stage on the basis of a selectively applied threshold voltage adjusting semiconductor alloy. In order to reduce the surface topography upon patterning the deposition mask while still allowing the usage of well-established epitaxial growth recipes developed for silicon dioxide-based hard mask materials, a silicon nitride base material may be used in combination with a surface treatment. In this manner, the surface of the silicon nitride material may exhibit a silicon dioxide-like behavior, while the patterning of the hard mask may be accomplished on the basis of highly selective etch techniques.

Owner:GLOBALFOUNDRIES US INC

Step type infrared detector

ActiveCN113447146AReduce shipping costsReduce transportationFinal product manufacturePyrometry using electric radation detectorsIr detectorEngineering

The present invention relates to a step type infrared detector. A CMOS measurement circuit system and a CMOS infrared sensing structure in the infrared detector are both prepared by using a CMOS process, and in the infrared detector, the position, corresponding to a columnar structure, of the surface, close to the CMOS measurement circuit system, of a suspended micro-bridge structure is in a stepped shape. The surface, not in contact with the columnar structure, of the suspended micro-bridge structure is higher than the surface, in contact with the columnar structure, of the suspended micro-bridge structure, the columnar structure is a solid columnar structure, and the reinforcing structure corresponds to the columnar structure and is located on the side, away from the CMOS measuring circuit system, of the columnar structure. According to the technical scheme, the problems of low performance, low pixel scale, low yield, poor consistency and the like of a traditional MEMS process infrared detector are solved, the sinking degree of the middle area of the sacrificial layer is effectively reduced, the planarization degree of the whole infrared detector is optimized, and the structural stability of the infrared detector is improved.

Owner:BEIJING NORTH GAOYE TECH CO LTD

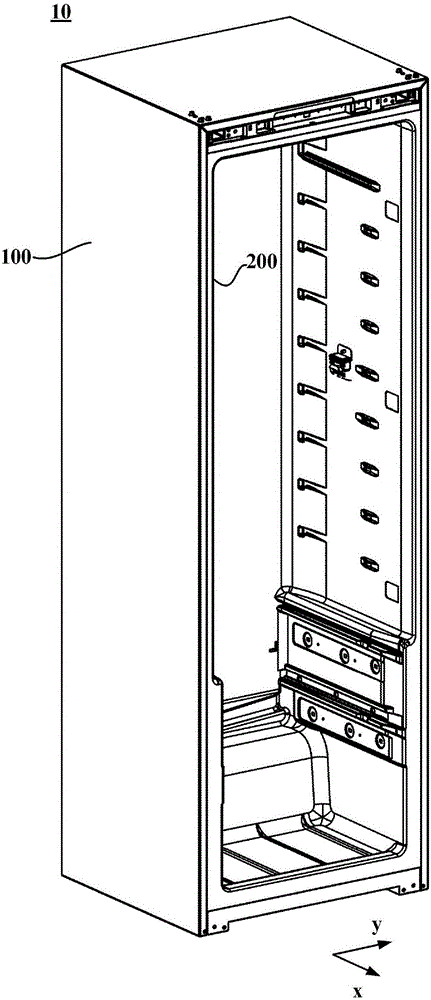

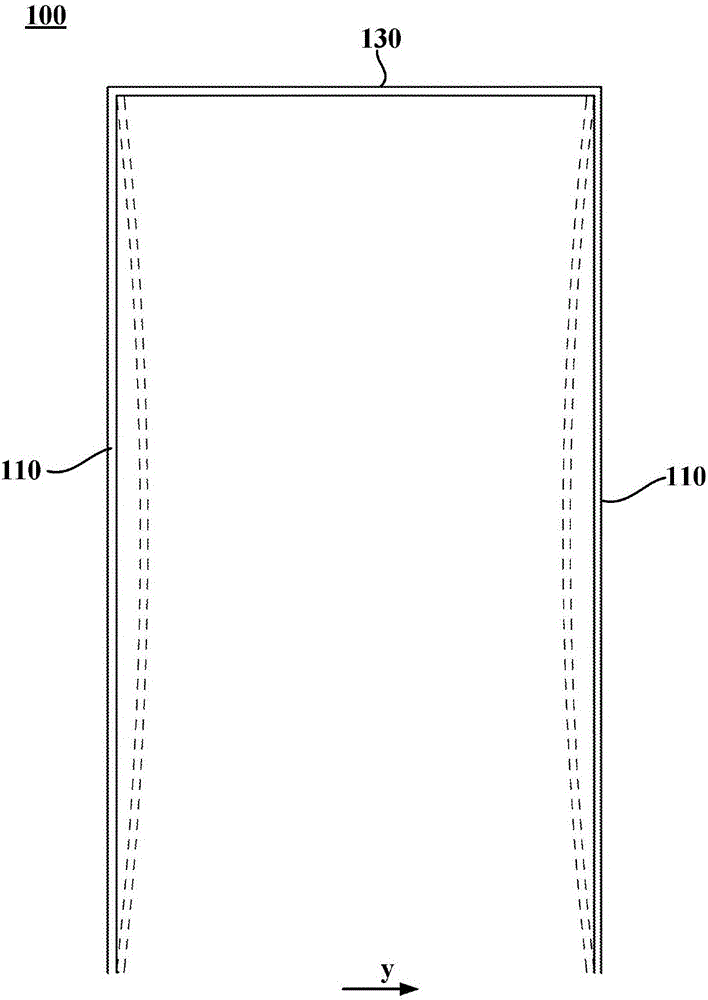

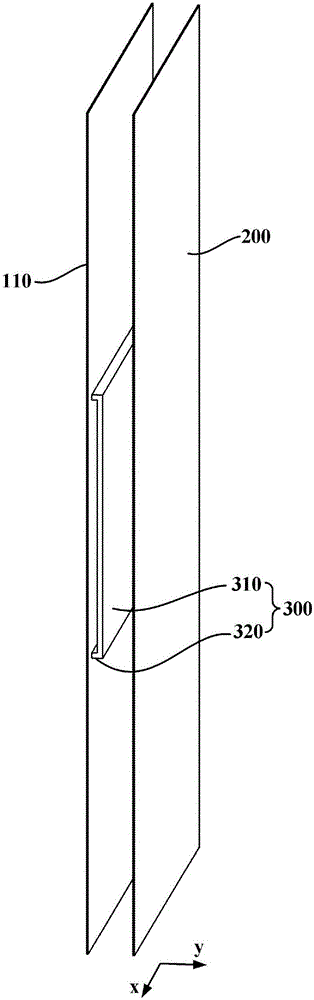

Refrigerator

ActiveCN106568262AAffect flatnessReduce contact areaLighting and heating apparatusDomestic refrigeratorsFoaming agentLiquid state

The invention provides a refrigerator. The refrigerator comprises a refrigerator body. The refrigerator body comprises an outer shell made from a metallic material, a liner made from a non-metallic material and at least one heat insulation partition plate, wherein the liner is arranged on the inner side of the outer shell so that a foaming cavity can be defined by the liner and the outer shell; the foaming cavity is used for containing a liquid foaming agent and solidifying the liquid foaming agent into a foaming layer; the heat insulation partition plates are fixedly arranged on the inner wall of the outer shell; and a space allowing the liquid foaming agent to flow in is defined by the heat insulation partition plates and the inner wall of the outer shell. According to the refrigerator, the contraction amount difference of the outer shell and the liner during cooling can be reduced in the cooling process after foaming of the refrigerator body, and thus the situation that the middle of the refrigerator body is sunken inwards is relieved.

Owner:HAIER SMART HOME CO LTD

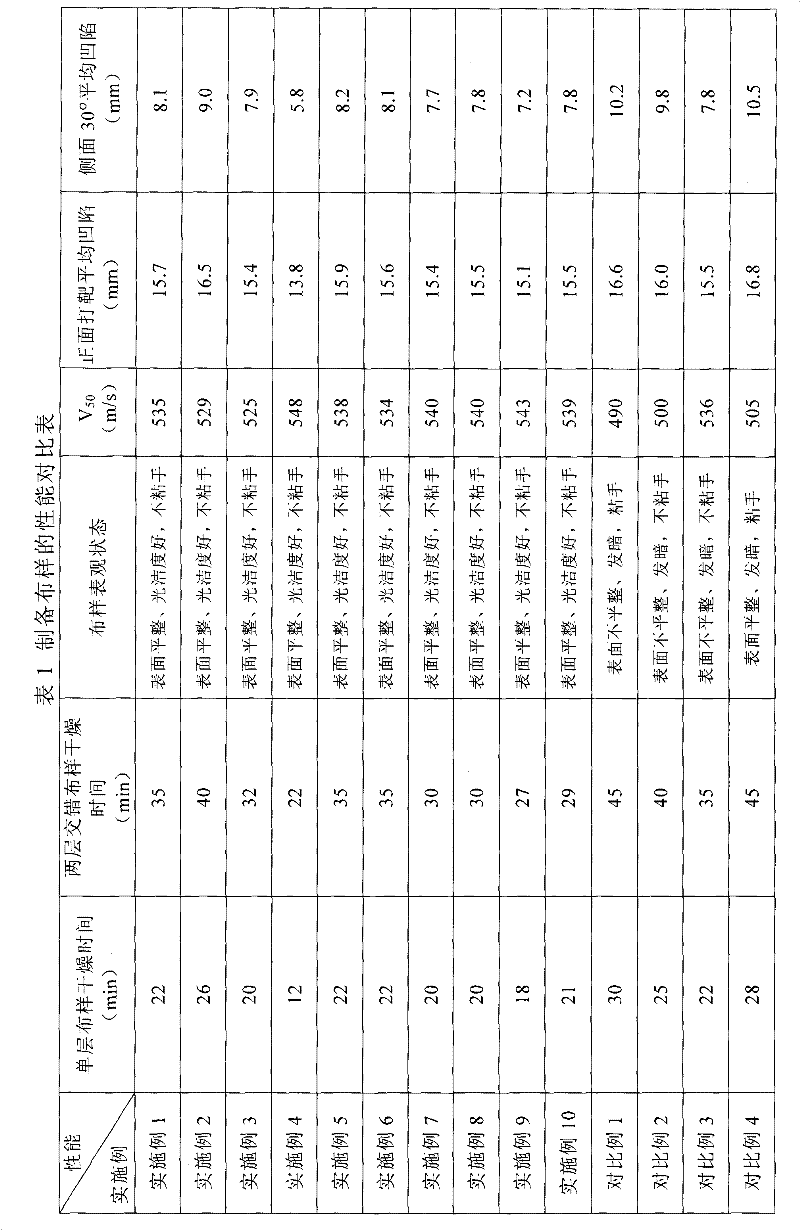

Aramid fiber laid fabric as well as preparation method and application thereof

ActiveCN101892558BImprove ballistic resistanceImprove the appearance quality of cloth samplesFibre typesNon-woven fabricsAdhesiveAqueous solution

The invention provides an aramid fiber laid fabric which is prepared from aramid fibers through processes of filament expanding, gluing and drying. In the gluing process, the used composite glue solution contains an adhesive and a curing agent, and the adhesion and the creep resistance between the adhesive and the aramid fibers can be improved due to the addition of the curing agent to effectively passivate impact force of bullets, so that the aramid fiber laid fabric has higher impact-resistant performance. The mass ratio of the adhesive water solution and the curing agent in the composite glue solution is 100:0.2-2, and the mass ratio of the curing agent, preferentially aziridine curing agent, to the adhesive water solution is 0.5-1.0:100. In the invention, the composite glue solution further contains a defoaming agent for improving the surface morphology of a fabric swatch. The invention simultaneously improves the preparation method of the aramid fiber laid fabric to increase the production efficiency by over 25 percent. A shooting test shows that the elasticity-resistant performance of the laminated laid fabric can be improved by about 20 percent by adopting the technical scheme of the invention.

Owner:BEIJING AEROSPACE RATE MECHANICAL & ELECTRICAL ENG CO LTD

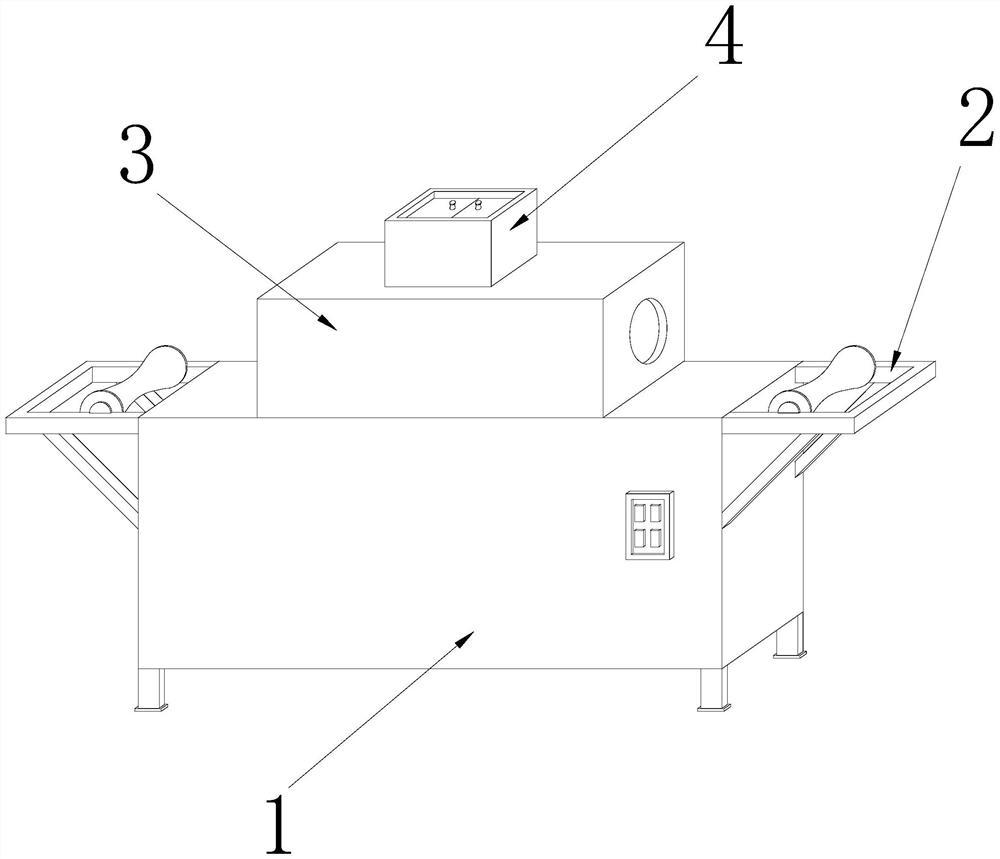

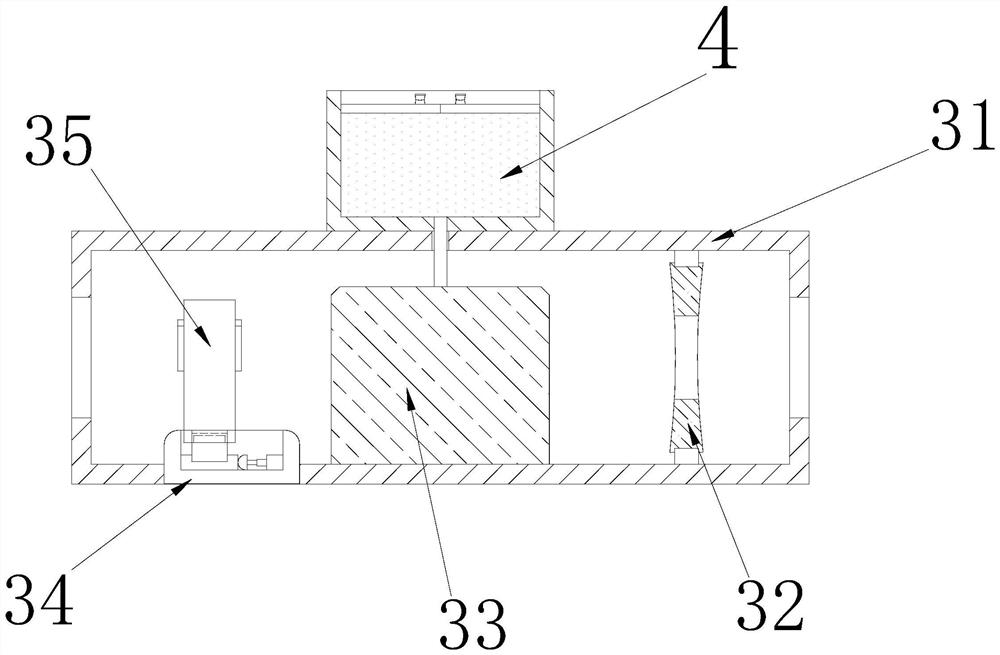

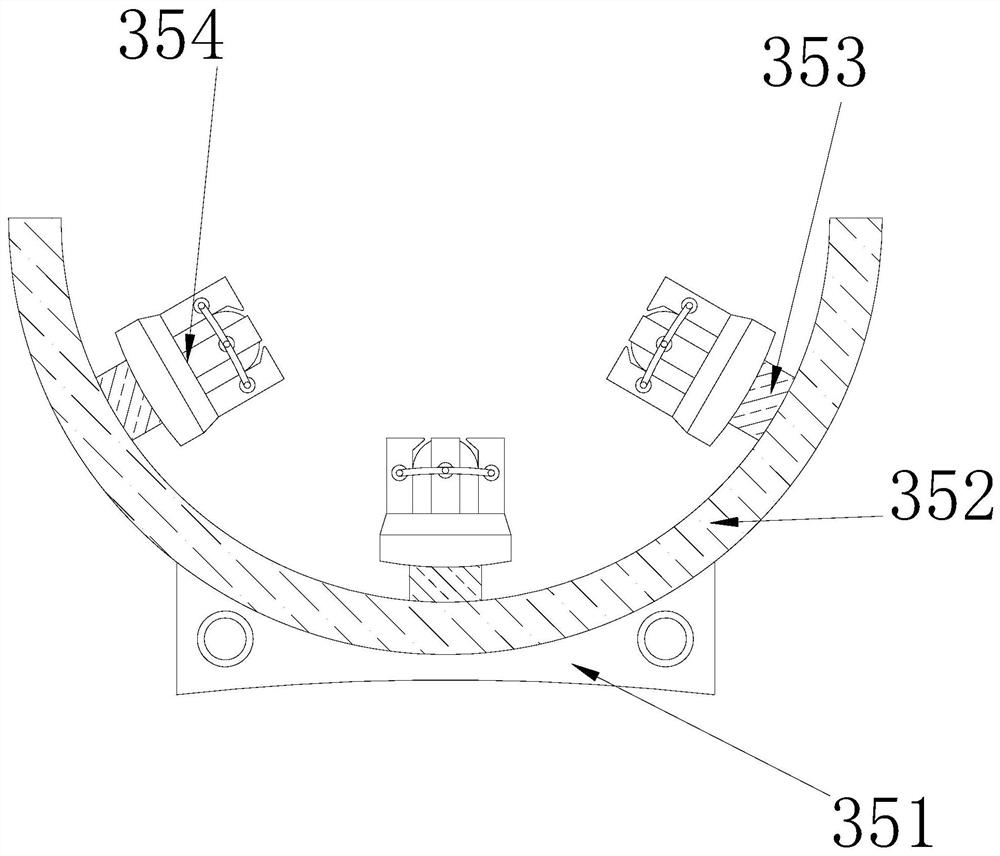

Steel pipe paint spraying processing equipment

The invention discloses steel pipe paint spraying processing equipment. The equipment structurally comprises a machine body, a bearing shaft, a paint spraying device and a paint storage box, the two ends of the bearing shaft are movably clamped to the two sides of the top end of the machine body, the bottom end of the paint spraying device is welded to the center of the top end of the machine body, the bottom end of the paint storage box is connected into the top end of the paint spraying device in an embedded mode, the paint spraying device comprises a shell, a limiting ring, a paint spraying block, a pushing block and a clamping device, the bottom end of the paint spraying block is connected to the center of the bottom end of the interior of the shell in an embedded mode, and the bottom end of the clamping device is movably matched with the top end of the pushing block. After a steel pipe is conveyed and guided into the paint spraying device through the bearing shaft, the steel pipe continues to move to the paint spraying block under limiting of the limiting ring, and is sent out by the clamping device after being subjected to paint spraying treatment, when a clamping block of the clamping device makes contact with the steel pipe, the upper end of a bearing column in the clamping device is pressed and then deforms, the contact area is increased, the contact pressure intensity is reduced, and the situation that the painted steel pipe is sunken after being clamped, and the sunken position is damaged too early during use is avoided.

Owner:磐石铸诚无缝钢管有限公司

Abrasion generator

InactiveCN100498284CChange speedReduce sagWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceElectric machineryEngineering

An abrasion generator for measuring abrasion function of slit consists of magnetostriction oscillator and container containing with test liquid. It is featured as erecting test-piece on variable-amplitude rod of megnetostriction oscillator, using water containing sand as test liquid contained in said container, arranging agitator formed by blade and motor in said container.

Owner:HOHAI UNIV

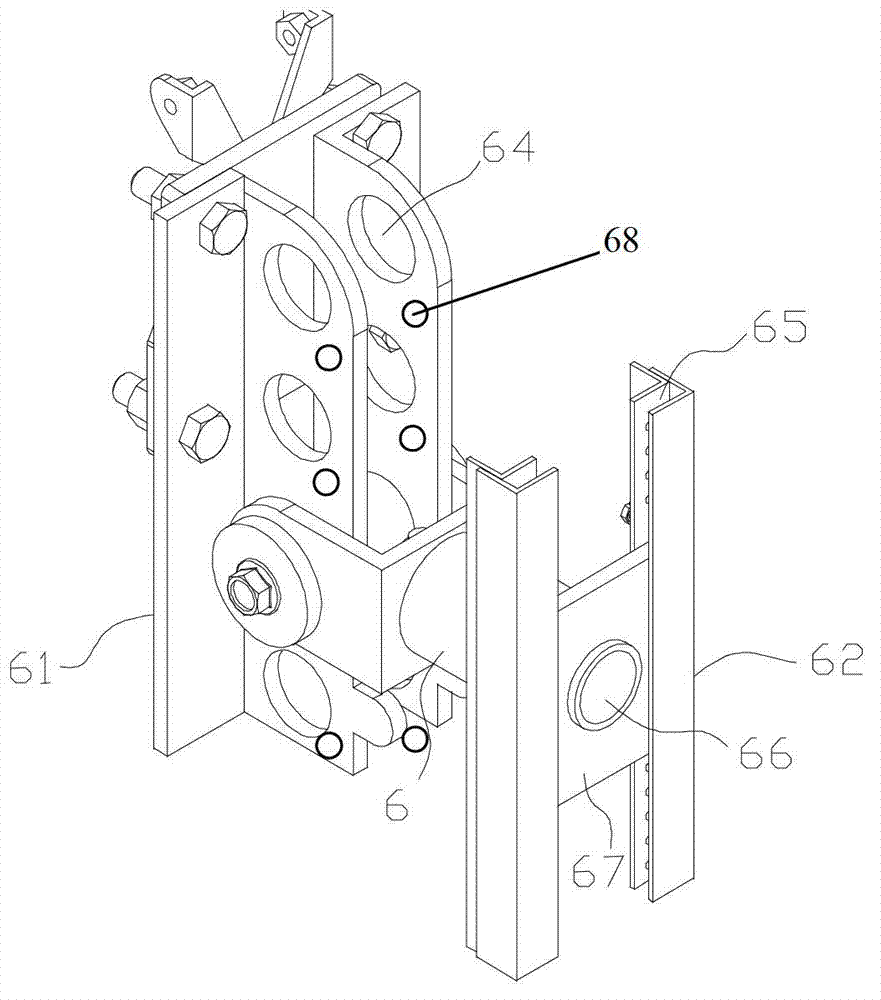

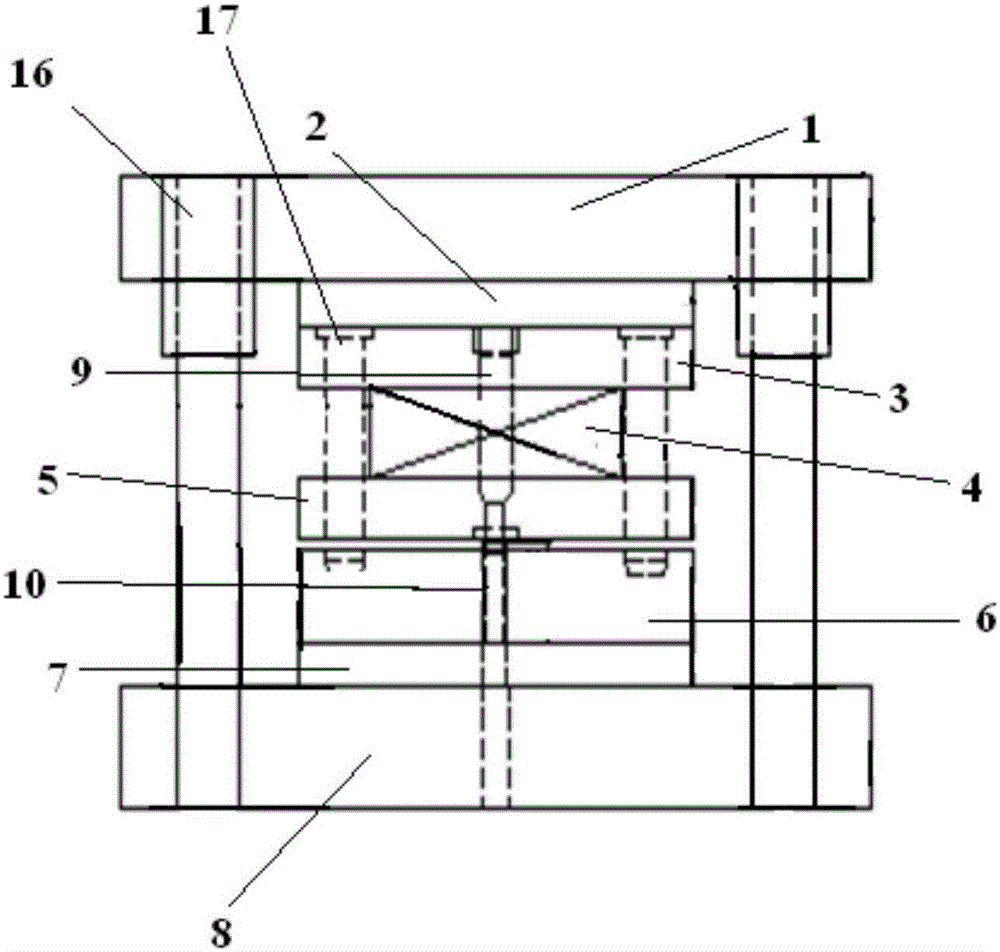

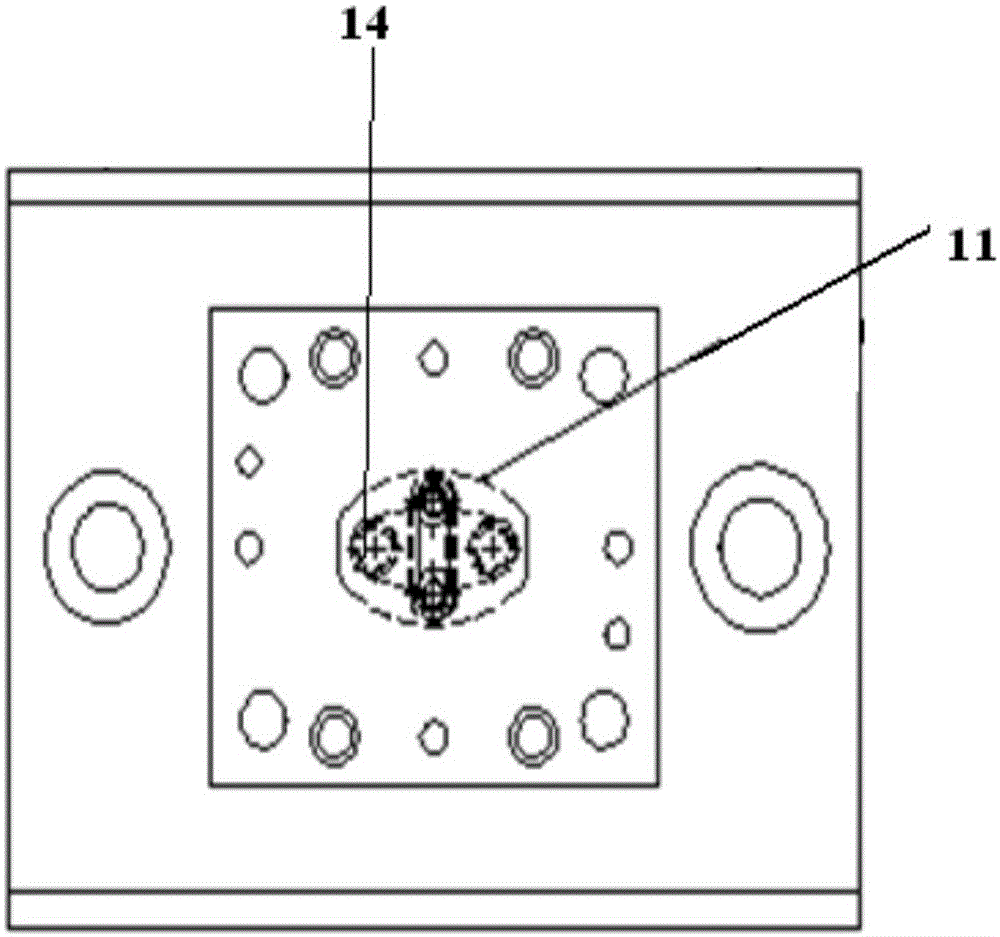

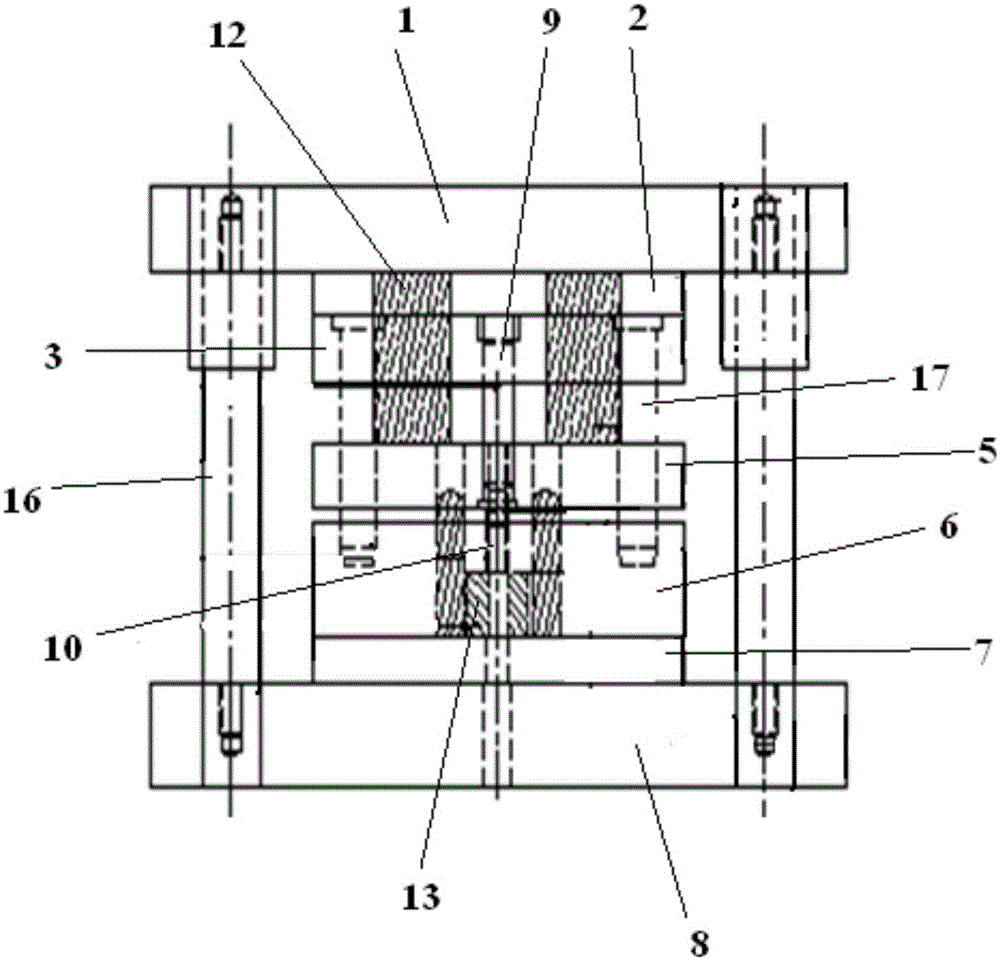

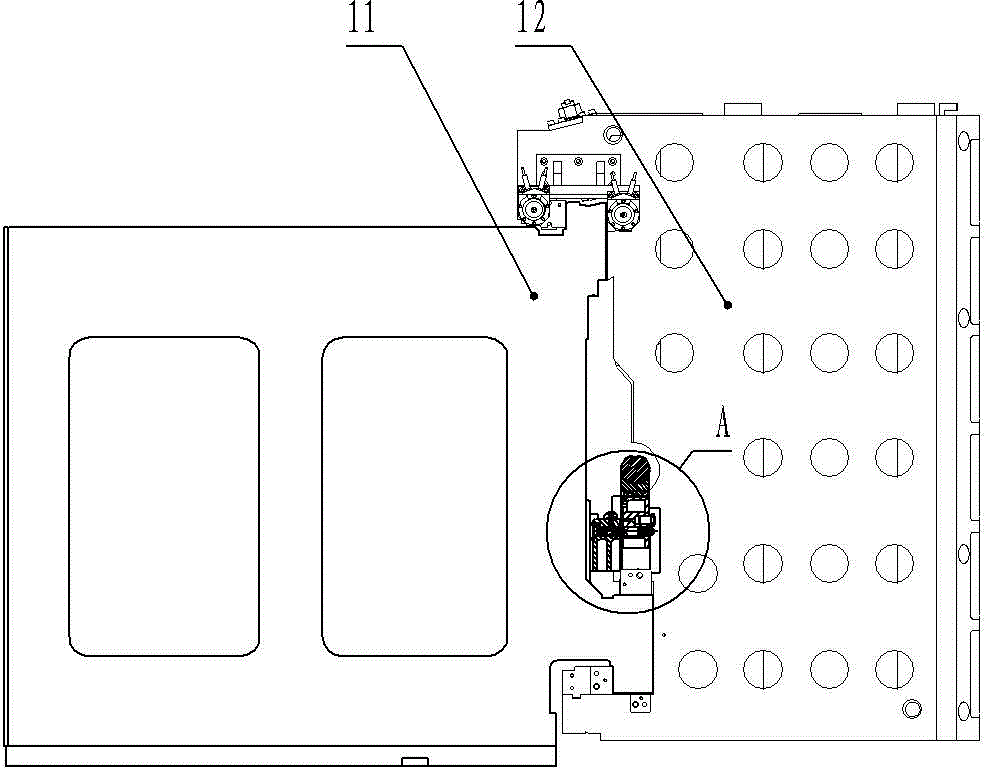

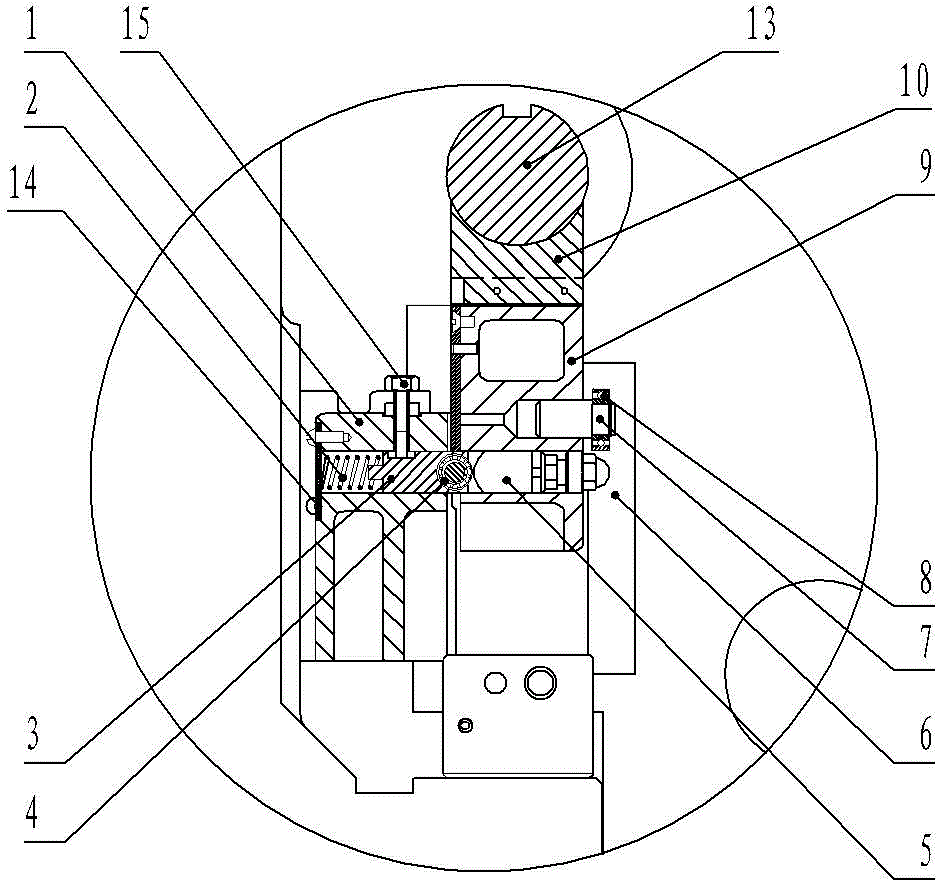

Lock catch plate punching die

ActiveCN105033036AIncrease block strengthSave operating timePerforating toolsMetal-working feeding devicesPunchingNitrogen gas

The invention relates to a lock catch plate punching die. The lock catch plate punching die comprises an upper die assembly and a lower die assembly which are connected to each other. The upper die assembly is provided with a punch (9), and the punch (9) is provided with a die cutter opening. A lower die inlet block (10) for assisting punching is arranged at the position, corresponding to the punch (9), in the lower die assembly. A workpiece (11) to be punched is fixedly arranged on the lower die assembly. A stripping plate (5) is arranged below the upper die assembly. Nitrogen springs (12) for assisting stripping are arranged between the stripping plate (5) and the upper die assembly. A lower die cushion block (13) connected with the lower die inlet block (10) is arranged below the lower die inlet block (10). Compared with the prior art, the lock catch plate punching die has the beneficial effects of being high in production efficiency, good in product quality, low in maintenance cost and the like.

Owner:SHANDONG AOLIN CAR FITTINGS

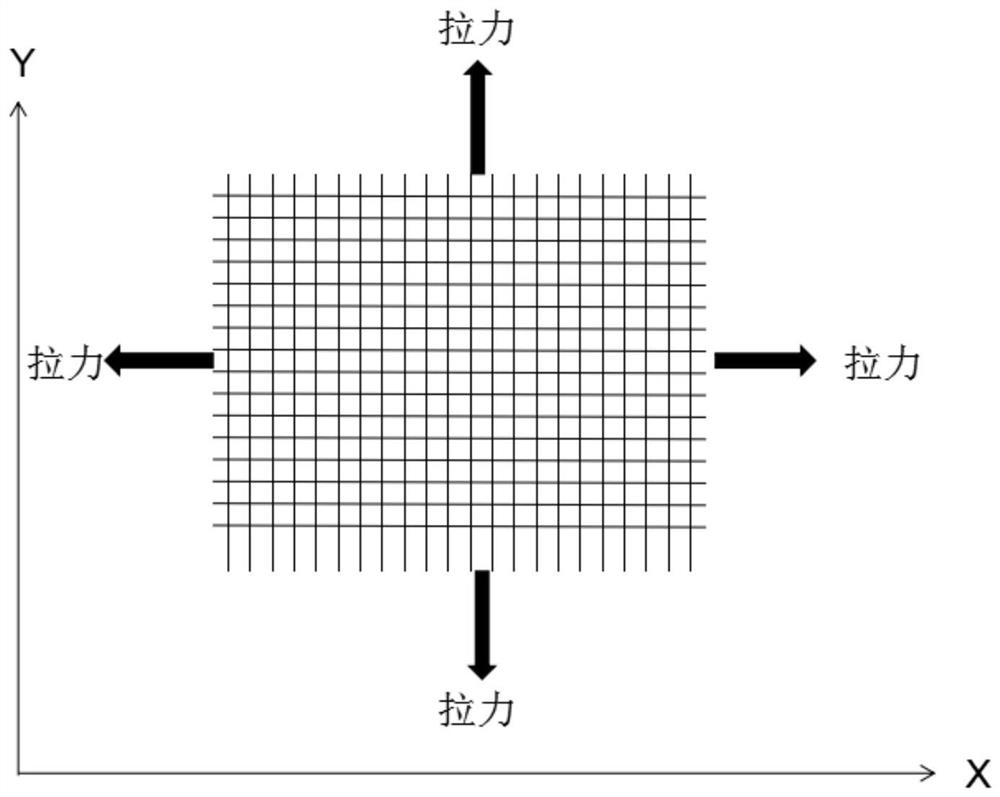

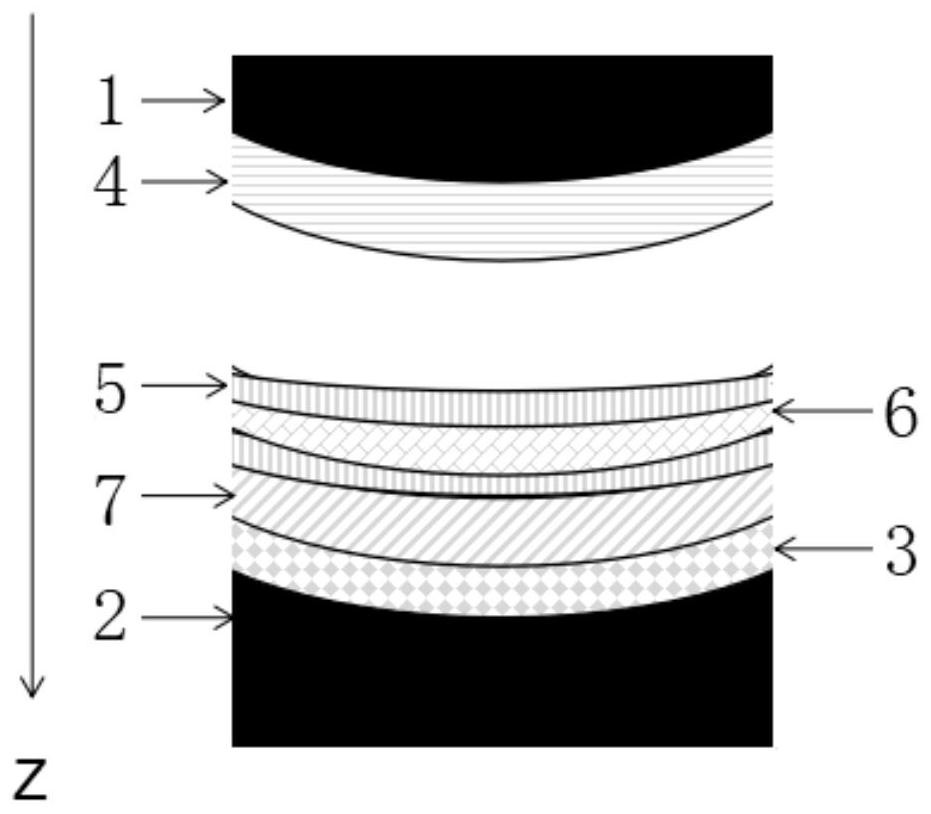

Bulletproof composite armor and preparation method thereof

PendingCN113028901ANot easy to break awayFit tightlyLamination ancillary operationsProtective equipmentPolymer scienceAdhesive

The invention discloses bulletproof composite armor and a preparation method thereof, and belongs to the technical field of composite materials. The preparation method of the bulletproof composite armor comprises the following steps that S1, multiple layers of ultra-high molecular weight polyethylene UD cloth are stacked, the outer edge of a stacked object is fixed through a clamp, and then the stacked object is heated and stretched in the horizontal direction to generate prestress; and S2, under the condition that the heating state and the stacked object stretching state are kept, a bulletproof ceramic plate, an adhesive, a crack arrest layer, an adhesive and the stacked object are vertically pressurized, hot-pressed and compounded in the Z direction, finally cooling is conducted to the room temperature, and the bulletproof composite armor is obtained. The prepared bulletproof composite armor is of a ceramic layer / crack arrest layer / ultra-high molecular weight polyethylene UD cloth stacked layer structure, the ultra-high molecular weight polyethylene UD cloth stacked layer has certain prestress, the sinking degree can be reduced after the bulletproof composite armor is stuck by a bullet, and therefore a better protection effect is achieved.

Owner:SUZHOU FIRST ELEMENT NANO TECH

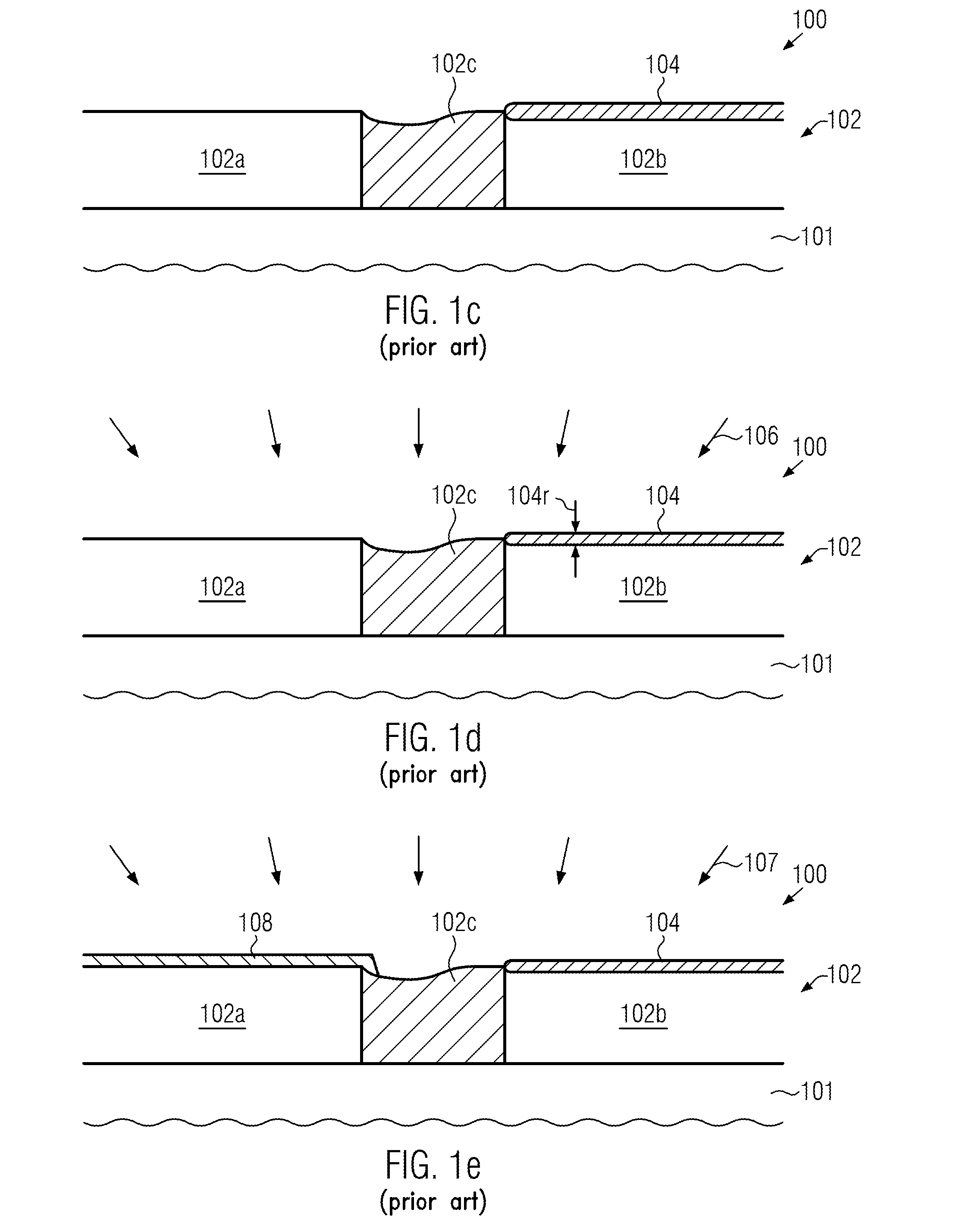

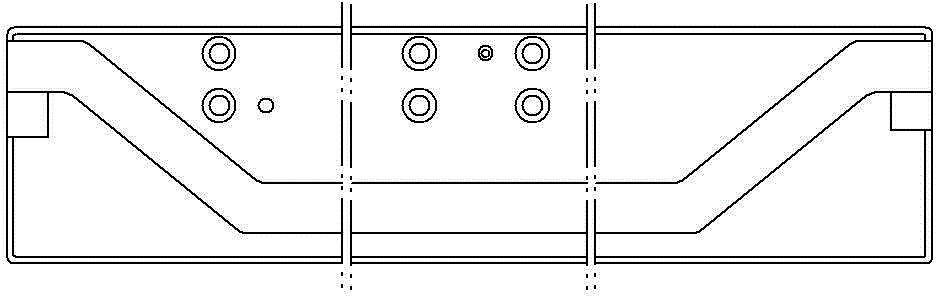

Auxiliary supporting device for machine tool beam screw rod

InactiveCN104647109AAdd auxiliary support pointsReduce sagFeeding apparatusMetal working apparatusEngineeringSlide plate

The invention discloses an auxiliary supporting device for a machine tool beam screw rod and relates to the technical field of machinery manufacturing. The auxiliary supporting device is installed between a machine tool transverse sliding plate and a beam. A fixing support is arranged on the machine tool beam. A movable bracket is connected on the fixing support in a pressing mode and provided with a supporting block which is used for supporting the screw rod. The fixing support is provided with a horizontal first through hole, wherein the first through hole is sequentially provided with a spring, a pin and a bearing. One end, close to the spring, of the first through hole is provided with a sealing plate. The movable bracket is provided with a second through hole. The bearing is arranged in the first through hole of the fixing support and the second through hole of the movable bracket. A lifting pin is arranged in the second through hole. One side of the second through hole is provided with a third through hole. The third through hole is provided with a shaft and a bearing, wherein the bearing abuts against a guiding plate which is provided with a guiding groove, and the bearing extends into the guiding groove of the guiding plate. The auxiliary supporting device for the machine tool beam screw rod can solve the problems that the supporting device for the heavy machine tool beam screw rod is complex in structure and high in production cost and can only support partial drooping screw rods.

Owner:柳州金盛重型数控机床有限责任公司

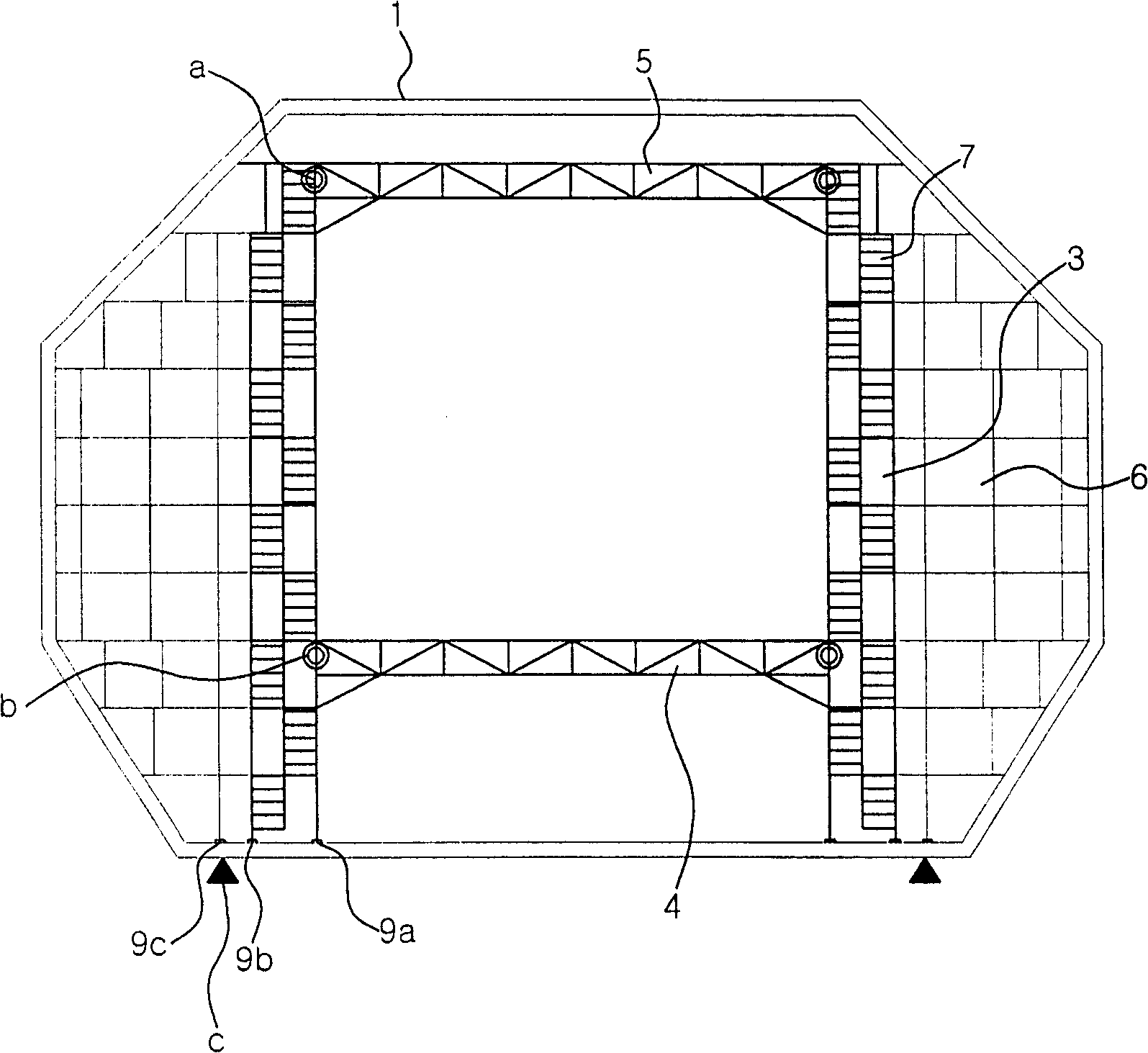

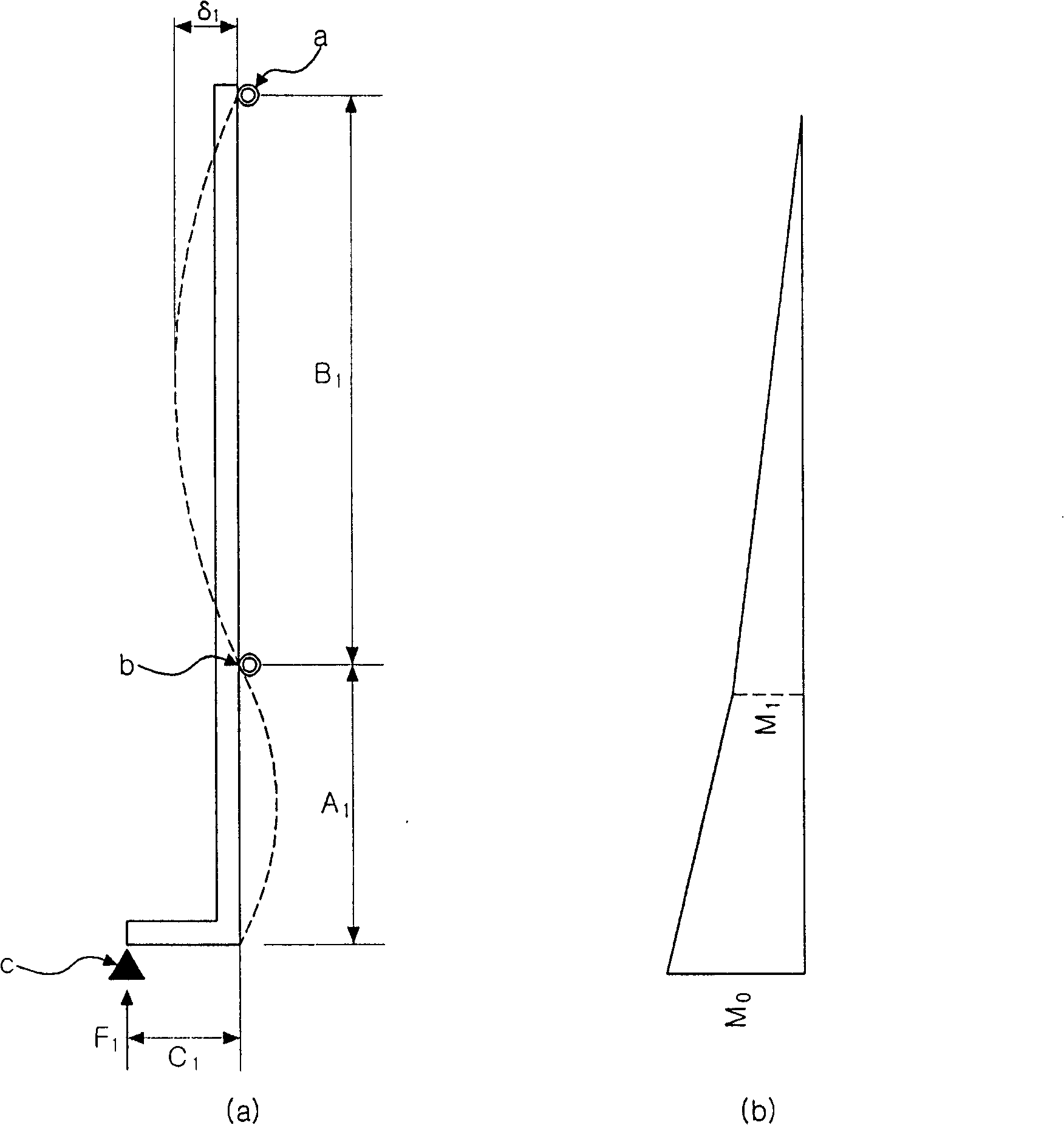

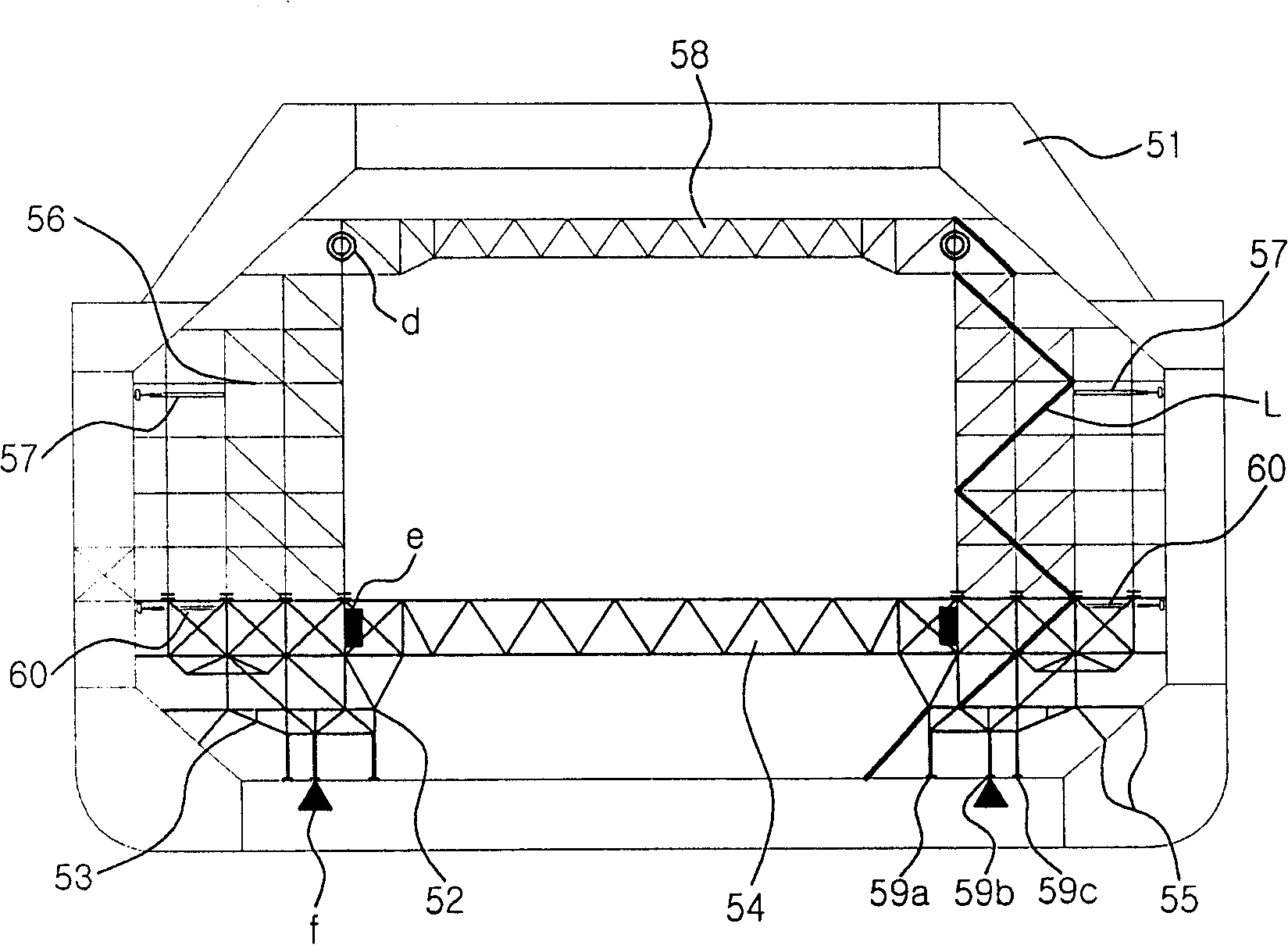

Scaffold

InactiveCN100419192CSimple structureReduce sagVessel designingBuilding support scaffoldsFalseworkMarine engineering

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

Gyroplane

InactiveCN1533947AGive full play to the advantages of workAvoid aerodynamic efficiencyPropellersRotocraftFlight vehicleRotary wing

A novel rotary-wing aircraft is composed of main body, mainshaft, rotary wings, horizontal drive clutch, power system, rear wings and horizontal drive propeller. The rotary wings fixed to top end of mainshaft are adjustable-pitch torsional blades and used for vertical taking off or landing. Said horizontal drive propeller is used for horizontal flying. Its advantages are high safety and efficiency, and low cost and noise.

Owner:章洪

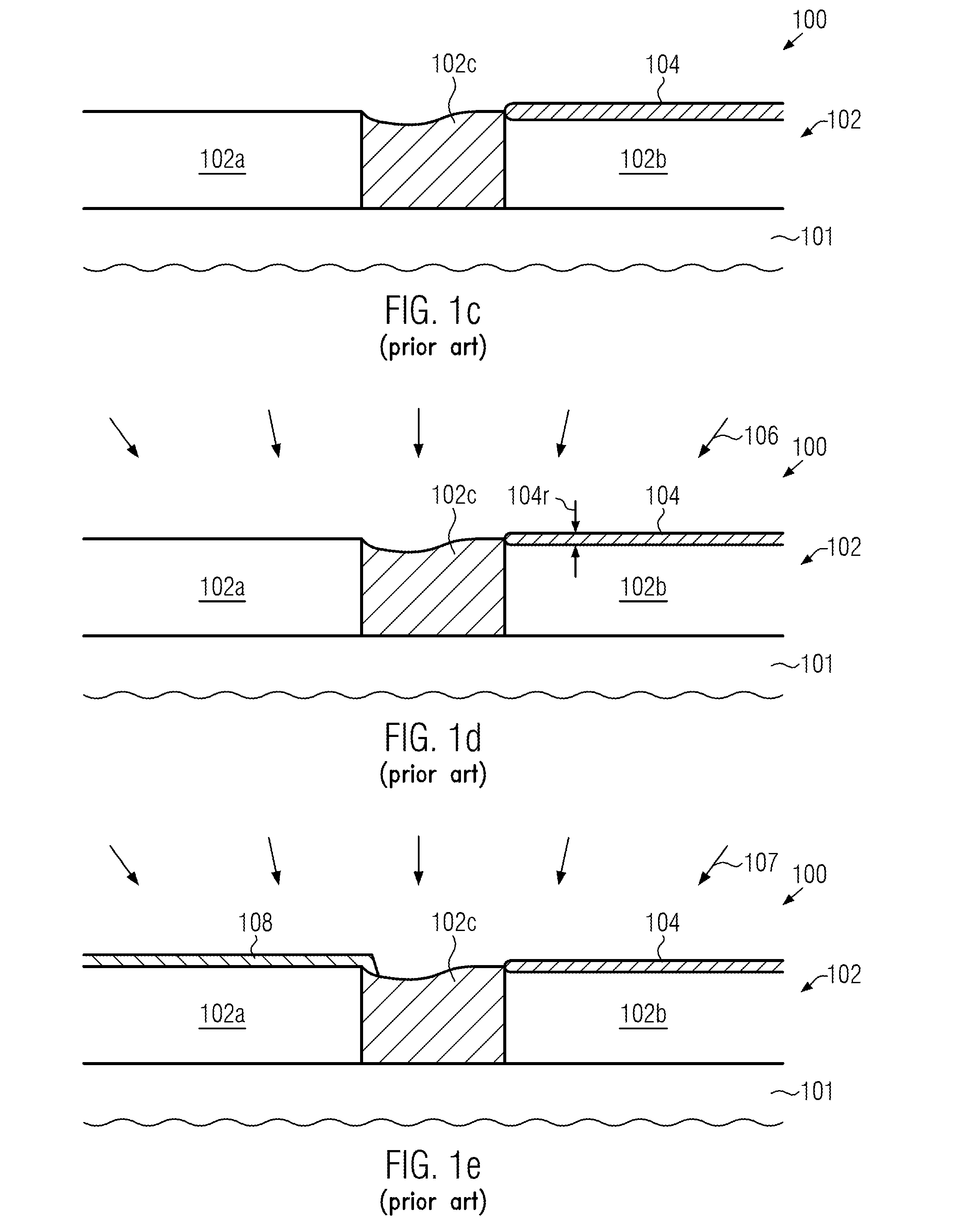

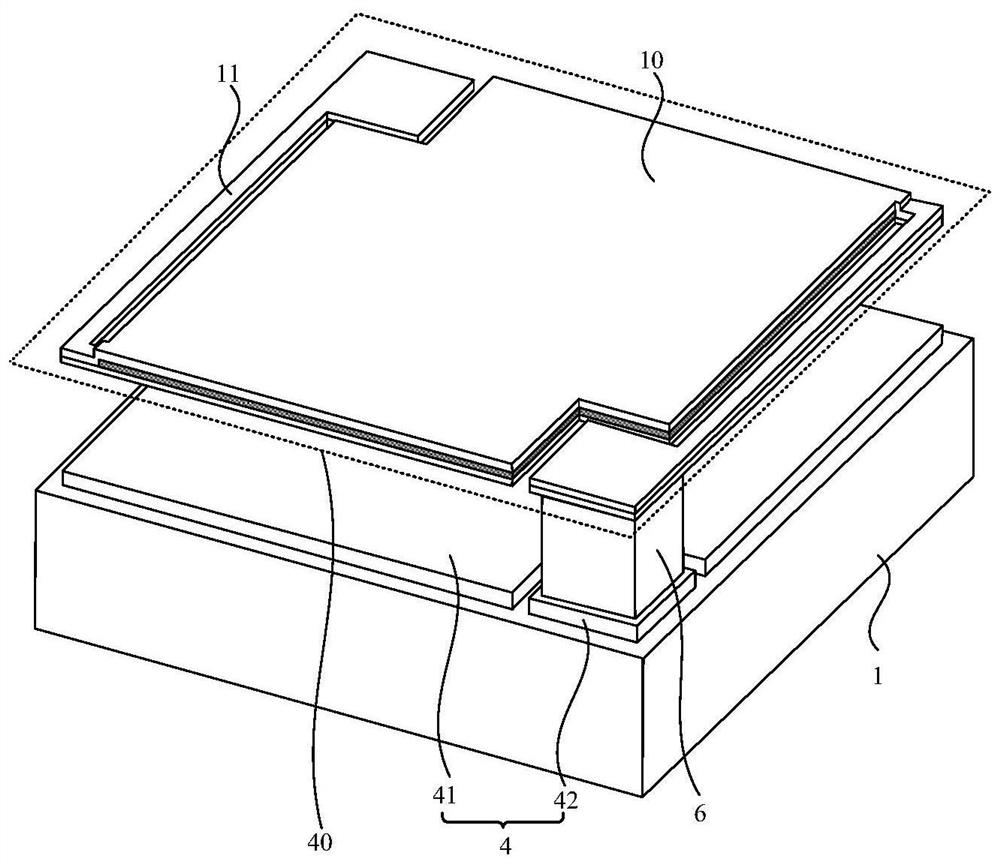

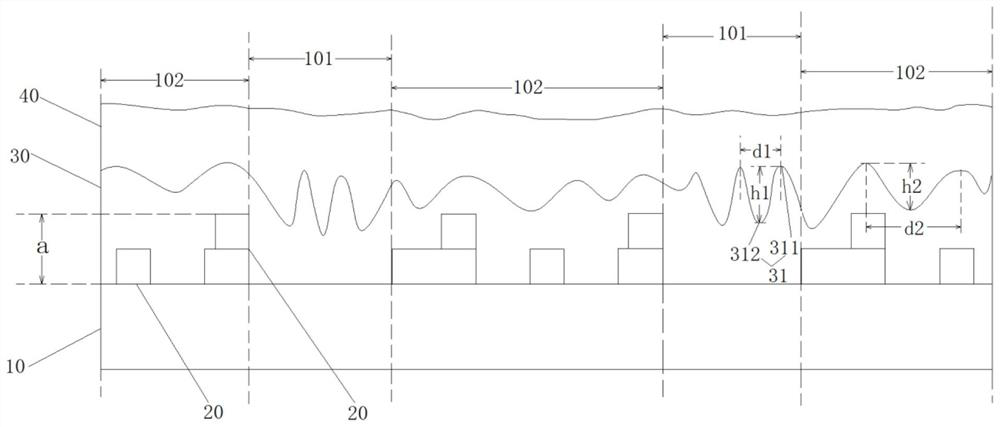

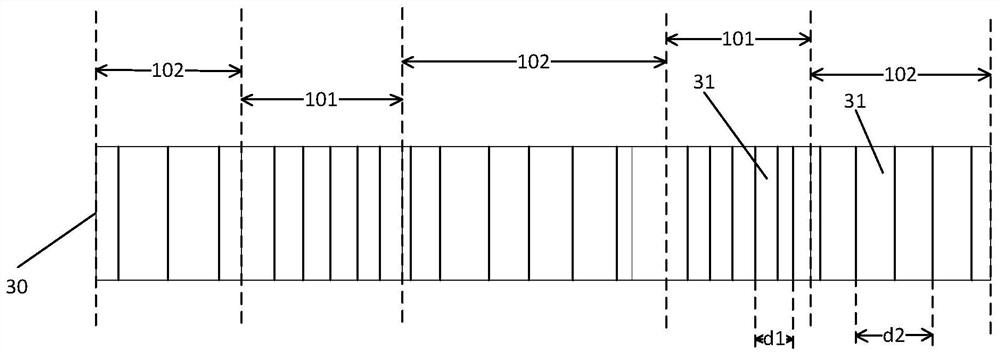

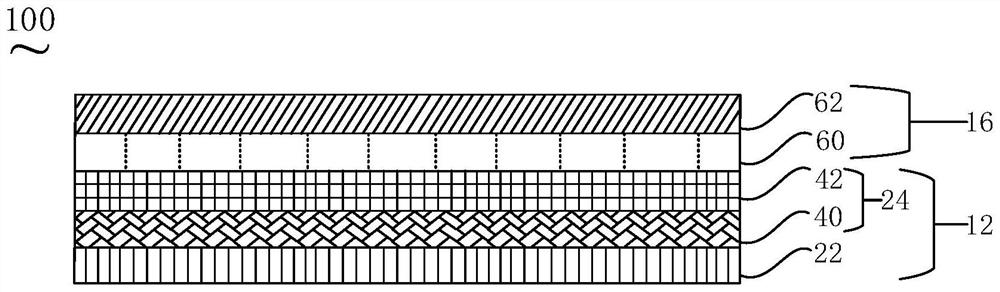

Display panel, preparation method thereof and display equipment

ActiveCN113013212AGuarantee job stabilityReduce sagSolid-state devicesSemiconductor/solid-state device manufacturingGraphicsDisplay device

The embodiment of the invention provides a display panel, a preparation method thereof and a display device. In the display panel provided by the embodiment of the invention, modification layers are arranged on the sides, away from a substrate, of graphic structures and the sides, exposed out of the graphic structures, of the substrate, the modification layers comprise a plurality of fold structures, and the height difference between the protrusion and the adjacent groove in any fold structure in the first area is smaller than the maximum segment difference between the graphic structures on the two sides of the first area and the surface of one side of the substrate, and therefore the segment difference in the first area of the display panel can be effectively reduced through the fold structures, the fold structures can effectively support a flat layer, and the display effect is improved. Therefore, the concave degree of the flat layer in the first area can be reduced, the flat effect of the flat layer is enhanced, and the working stability of the display panel can be guaranteed.

Owner:BOE TECH GRP CO LTD

Process for paving latticed pavement of pedestrian walkway

The invention discloses a process for paving a latticed pavement of a pedestrian walkway. The process mainly comprises the following steps of (1) paving steel bars with groove-shaped sections on a foundation after tamping the foundation, and then, filling lumpy macadam between every two steel bars, wherein the height of each steel bar is not smaller than 15cm, through holes are formed in each steel bar, a layer of geotechnical cloth is paved in the groove of each steel bar, the size of the lumpy macadam is not larger than 10cm, and the paving thickness of the lumpy macadam is not smaller than 20cm; (2) after finishing the operation of paving the lumpy macadam, paving more than one layer of geotechnical cloth between every two adjacent steel bars, and fixing the ends of the geotechnical cloth on the steel bars; and (3) after finishing the operation of paving the geotechnical cloth, paving a layer of fine sand with the thickness of 10-20cm on the geotechnical cloth, and paving face bricks on the fine sand by using concrete after finishing the operation of paving the fine sand. The process has the advantages of rapidly draining water and reducing uneven conditions caused by different subsidence degrees at different positions of the layer below the face bricks.

Owner:CHENGDU RONGDE CONSTR LABOR

Harvester

Owner:SICHUAN WANMA MACHINERY MFG

Method for constructing copper wire on wafer and chemical mechanical polishing (CMP) method for copper

ActiveCN101958273BHardness effectReduce sagSemiconductor/solid-state device manufacturingDielectricCopper wire

The invention discloses a method for constructing a copper wire on a wafer, which comprises the following steps of: depositing a first interlayer dielectric on the upper surface of the wafer; constructing a second interlayer dielectric on the upper surface of the first interlayer dielectric of the wafer, wherein the hardness of the second interlayer dielectric is lower than that of the first interlayer dielectric; photoetching the second interlayer dielectric and the first interlayer dielectric to define a groove structure, wherein the bottom of the groove structure is positioned in the firstinterlayer dielectric; sequentially depositing a barrier layer and a copper seed crystal layer on the upper surface of the wafer and the inner wall of a groove; depositing copper on the upper surfaceof the wafer, wherein the copper is filled in the groove to form the copper wire; and performing chemical mechanical polishing (CMP) on the wafer to reach the first interlayer dielectric so as to make the upper surface of the wafer subjected to planarization. The invention also discloses a CMP method for the copper. The sinking degree of the surface of the copper wire constructed by the scheme ofthe invention is reduced to a certain extent compared with that of the prior art.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

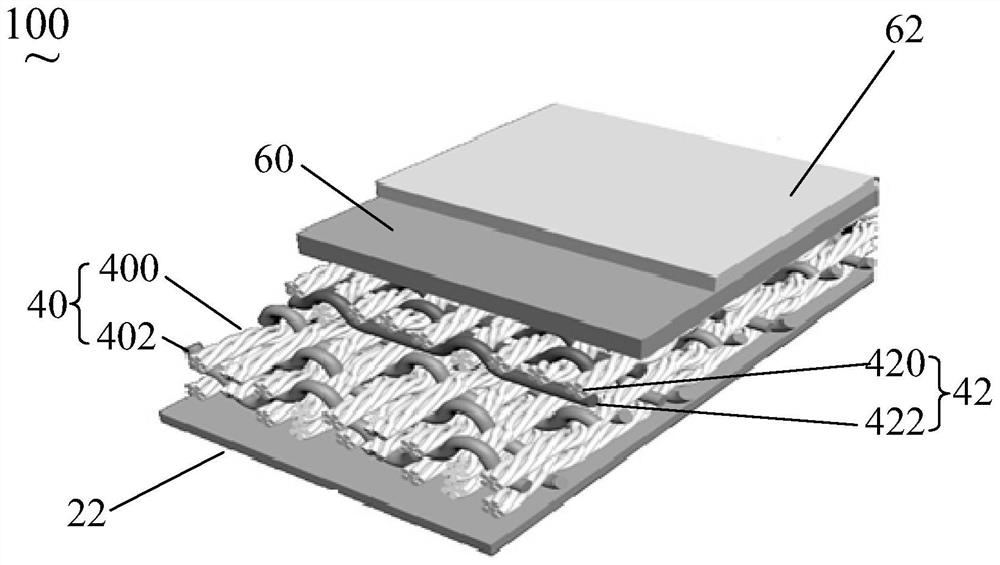

Composite papermaking felt and preparation method thereof

PendingCN114645483AReduce depthReduce sagLamination ancillary operationsSynthetic resin layered productsFiberPolymer science

The invention discloses a composite papermaking felt and a preparation method thereof, the composite papermaking felt comprises a first composite fiber layer and a second composite fiber layer, and the second composite fiber layer is laid on the first composite fiber layer; wherein the second composite fiber layer is provided with a plurality of wool layers, needling traces are formed on the wool layers, and the depths of the needling traces are gradually reduced along with the increase of the number of the wool layers. Through a special flocking needling method, the manufactured composite papermaking felt is not prone to hair falling, the smooth and fine effect of the felt is guaranteed, and the composite papermaking felt is particularly suitable for papermaking of paper products such as decorative paper, cultural paper and tissue paper with the high flatness requirement.

Owner:JIANGSU JINNI ENGINEERED FABRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com