Lock catch plate punching die

A locking plate and punching technology, which is applied in the field of punching dies, can solve the problems of easy material jams during stripping, easy damage of lower dies, and reduced production efficiency, so as to save operating time, reduce workpiece burrs, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

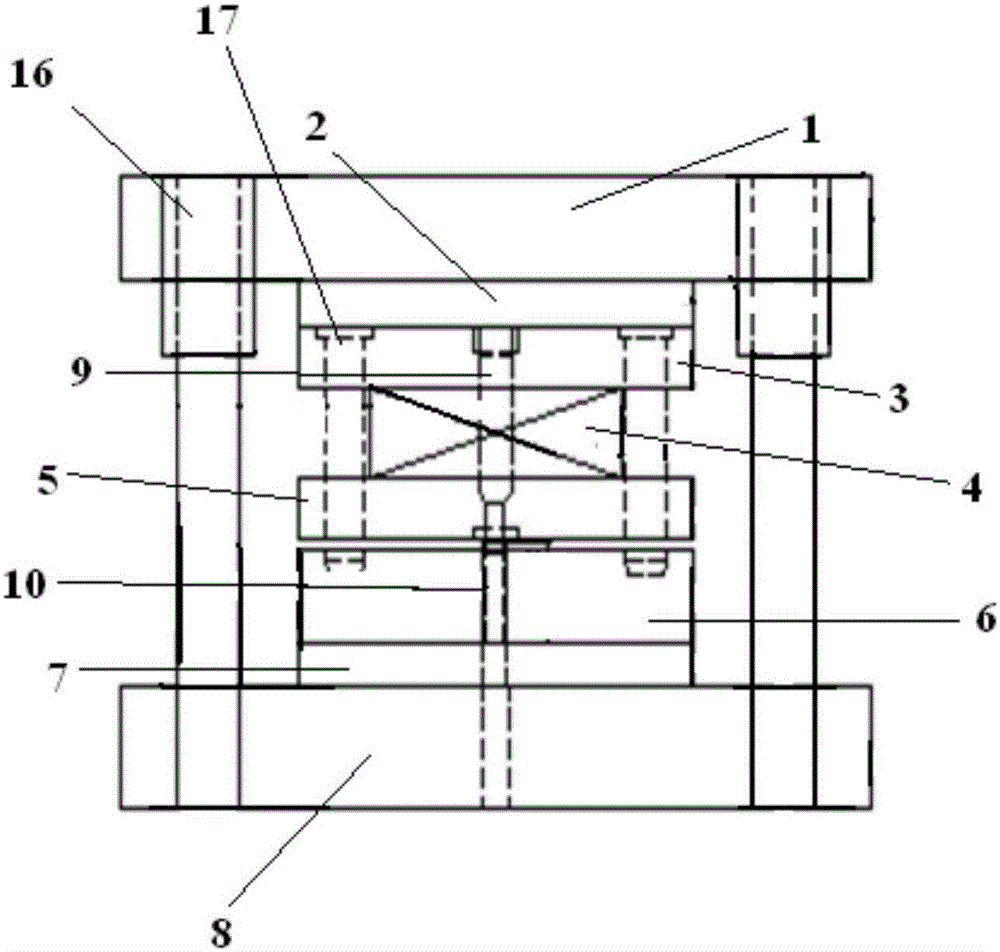

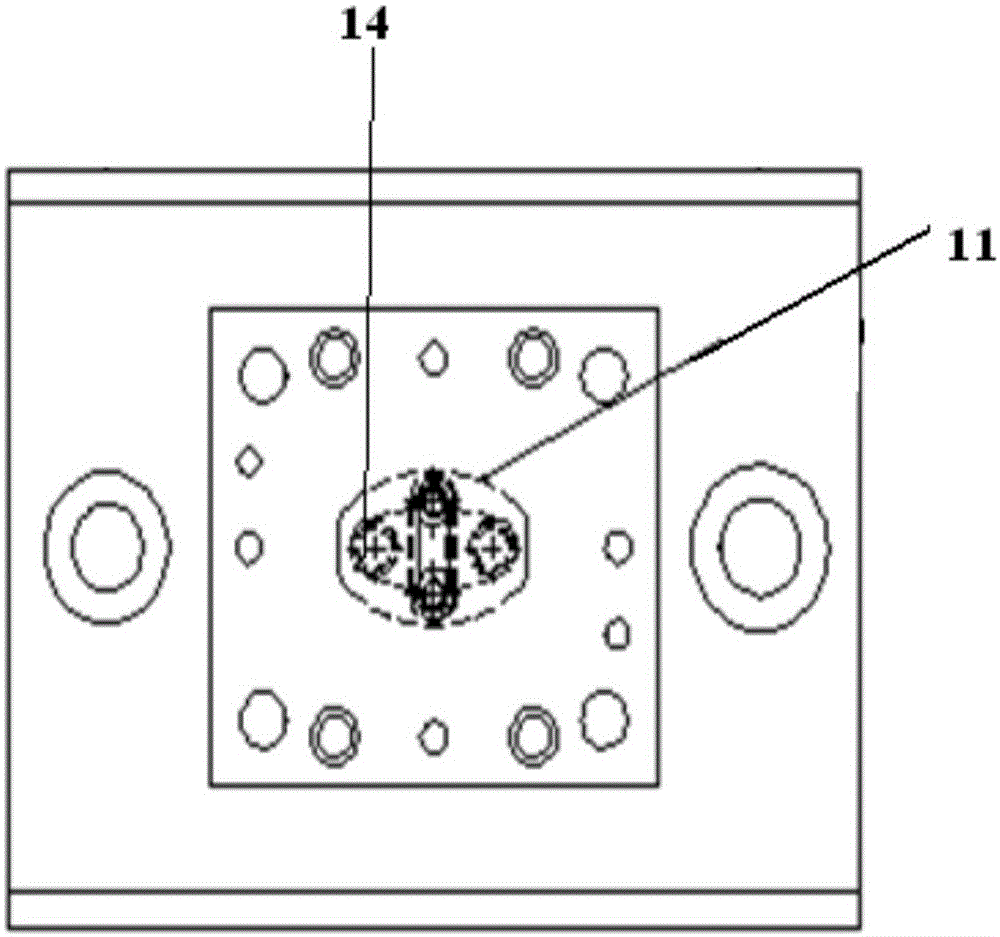

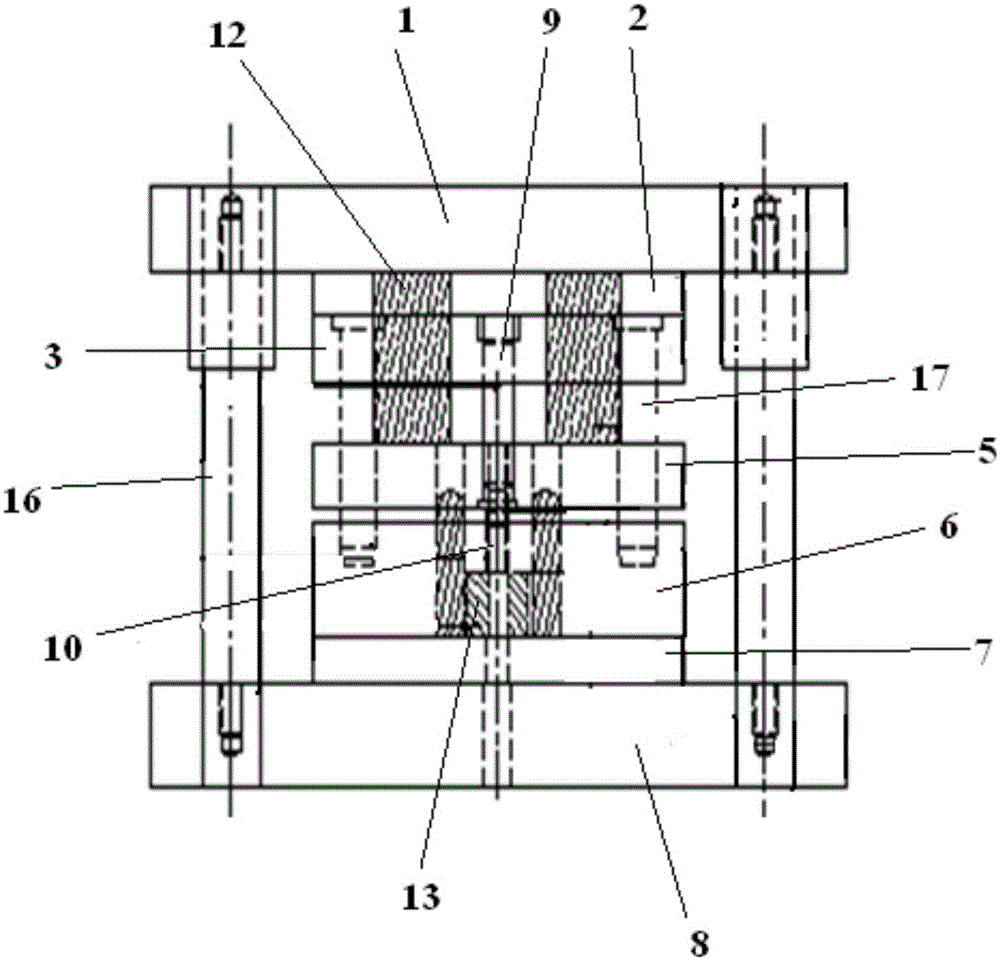

[0025] A punching die for a locking plate, the structure of which is as follows image 3 and Figure 4 As shown, it includes an upper mold assembly and a lower mold assembly. The upper mold assembly includes an upper mold base 1, an upper backing plate 2 and an upper fixing plate 3, and the upper backing plate 2 and the upper fixing plate 3 are sequentially arranged on the Below the upper mold base 1, a punch 9 is arranged on the upper fixing plate 3, and a tungsten-containing high-speed tool steel die edge of the type SKH51 is set on the punch 9, and screw structures 17 are arranged downwards at both ends of the upper fixing plate 3. The screw structure 17 runs through both ends of the stripper plate 5 and connects the lower die assembly. The stripper plate 5 is provided with 9 punch holes for the punch 9 to move up and down, and the stripper plate 5 is connected to the upper die base 1. A nitrogen spring 12 is provided, and the lower mold assembly includes a lower mold base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com