Bulletproof composite armor and preparation method thereof

An armor and bulletproof technology, applied in protective equipment, armor, protective equipment, etc., can solve the problems affecting the bulletproof ability of ceramic PE composite decks, reduce tensile strength, etc., to achieve tight fit, reduce the degree of depression, good protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment relates to a preparation method of bulletproof composite armor, comprising the following steps:

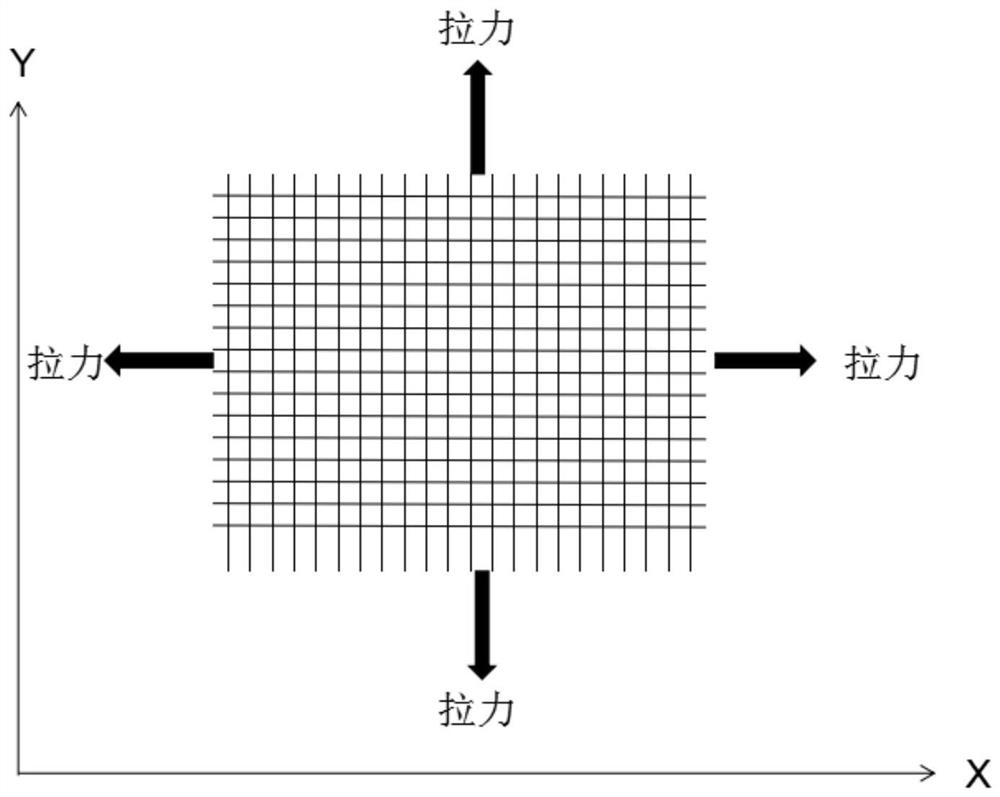

[0030] S1, take several sheets of ultra-high molecular weight polyethylene UD cloth (area density 16kg / m 2 ), according to the axial 0° / 90° cross-lamination and laying, to obtain the laminate 4, the thickness of the laminate 4 is 10mm, and then fix the outer edge of the laminate with a clamp;

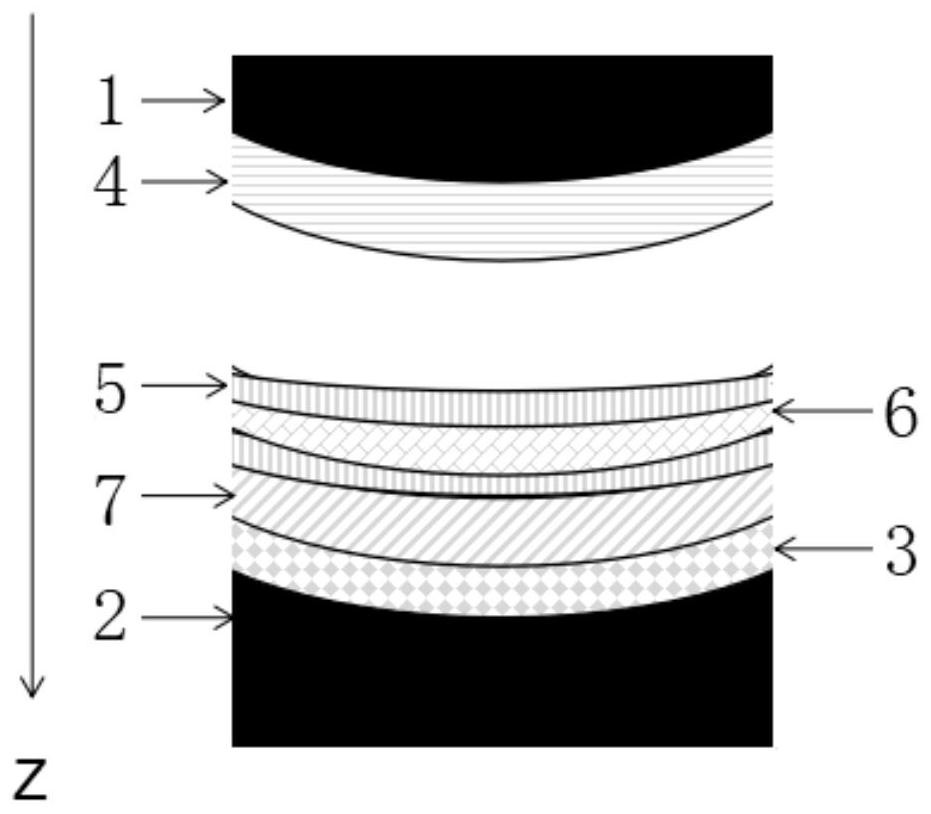

[0031] The pressure-resistant rubber pad 3, the bulletproof ceramic plate (0.08m 2 Single soldier chest plate) 7 and aramid cloth 6 coated with adhesive 5 on both sides are aligned and stacked and then placed on the lower thermal head 2, such as figure 2 As shown; the lower thermal head 2 is heated, and the temperature is maintained at 150 ° C; the upper thermal head 1 is heated to 150 ° C, and then the laminate 4 is pressed down in the direction of the downward thermal head 2, and the pressing pressure is 5 MPa, so that the laminate 4 Deformation occurs, and the l...

Embodiment 2

[0035] This embodiment relates to a preparation method of bulletproof composite armor, comprising the following steps:

[0036] S1, take several sheets of ultra-high molecular weight polyethylene UD cloth (area density 16kg / m 2 ), according to the axial 0° / 90° cross-lamination and laying, to obtain the laminate 4, the thickness of the laminate 4 is 10mm, and then fix the outer edge of the laminate with a clamp;

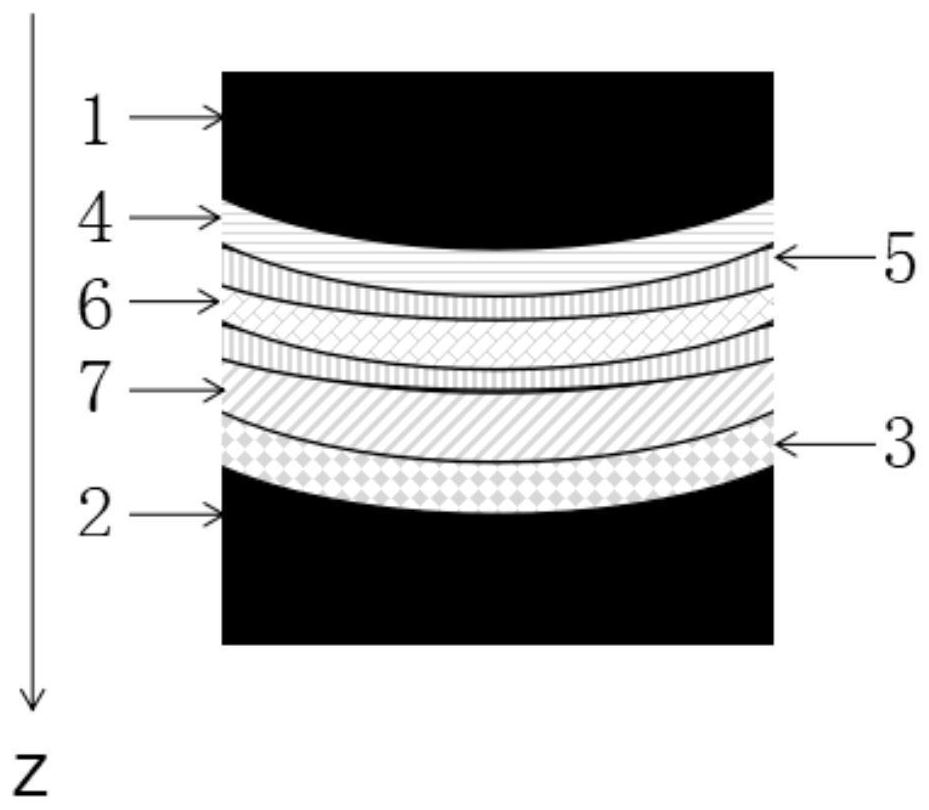

[0037] Such as Figure 4 As shown, the aramid cloth 6 coated with adhesive 5 on both sides and the bulletproof ceramic plate (0.08m 2 Individual chest plate) 7 bonded, then aligned and placed on the composite 4, then stacked on the top of the bulletproof ceramic plate 7 pressure-resistant rubber pad 3, and then aligned and placed on the lower thermal head 2, the upper thermal head 1 Move downward to the direction of the thermal head 2 until the upper thermal head 1 is bonded to the pressure-resistant rubber pad 3; the lower thermal head 2 is heated to 150°C and pres...

Embodiment 3

[0041] This embodiment relates to a preparation method of bulletproof composite armor, comprising the following steps:

[0042] S1, take several sheets of ultra-high molecular weight polyethylene UD cloth (area density 16kg / m 2 ), according to the axial 0° / 90° cross-lamination and laying, to obtain the laminate 4, the thickness of the laminate 4 is 15mm, and then fix the outer edge of the laminate with a clamp;

[0043] The bulletproof ceramic plate (0.5m 2 Equipment bulletproof plate) 7 and aramid cloth 6 coated with adhesive 5 on both sides are aligned and stacked and placed on the lower thermal head 2, the lower thermal head 2 is heated, and the temperature is kept at 150°C; the upper thermal head 1 is heated After reaching 150°C, press down on the laminated product 4 in the direction of the thermal head 2, and the pressing pressure is 5Mpa, so that the laminated product 4 is deformed, and the lengths of the laminated product 4 in the X direction and the Y direction are st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com