Aramid fiber laid fabric as well as preparation method and application thereof

A technology of aramid fiber and weft-free fabric, which is applied in the direction of fiber type, fiber treatment, non-woven fabrics, etc., can solve the problems of increasing the load of general soldiers and increasing the cost of body armor, so as to improve the appearance quality of cloth samples and shorten the drying time. The effect of reducing the time and degree of sagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 700g of ZF-101 type acrylate adhesive with a solid content of 50%, add 300g of water to a beaker, and stir evenly to obtain an aqueous solution of acrylate adhesive with a solid content of 35%. Weigh 5g of aziridine curing agent, fully mix it with 5g of water, and then add it dropwise to the above-mentioned aqueous adhesive solution while stirring and mixing. Then weigh the defoamer composed of 15g of ethylene glycol butyl ether and 5g of diethylene glycol butyl ether, add it into the above-mentioned beaker and mix well to obtain the glue.

[0038] The aramid fiber is wound in parallel on the winding machine, and then the fiber is immersed in the above glue solution, and the yarn is spread by a specific spinning equipment. The adhesive used in this example is the above-mentioned modified acrylic adhesive. After dipping, spread the glue evenly with a squeegee, and dry it under a 50°C electric resistance wire. After it is completely dry, rotate the cloth sample 90°, ...

Embodiment 2

[0042] The difference from Example 1 is that the acrylate adhesive in Example 1 is changed to 500g, 500g of water is added, and the rest of the conditions are the same as in Example 1.

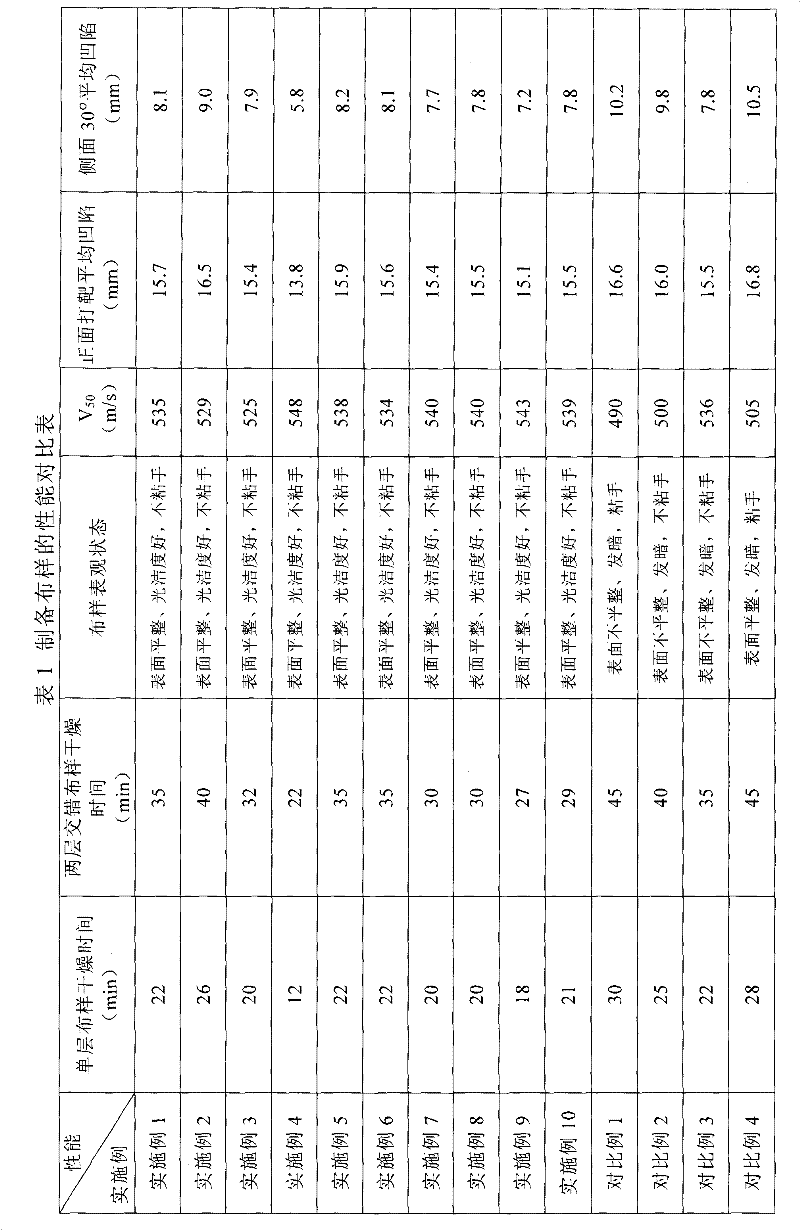

[0043] The drying time of the above-mentioned cloth samples, the drying time of the two-layer interlaced cloth samples, and the apparent quality of the cloth samples were tested and recorded, and various anti-ballistic properties were tested. The results are shown in Table 1.

Embodiment 3

[0045] The difference from Example 1 is that the adhesive in Example 1 is changed to UR303GNP polyurethane adhesive, and the rest of the conditions are the same as in Example 1.

[0046] The drying time of the above-mentioned cloth samples, the drying time of the two-layer interlaced cloth samples, and the apparent quality of the cloth samples were tested and recorded, and various anti-ballistic properties were tested. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com