Preparation method of high-performance composite bulletproof plate

A high-performance bulletproof board technology, applied in protective equipment, offensive equipment, armor, etc., can solve the problem of low overall performance and achieve the effect of improving bulletproof resistance and good bulletproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

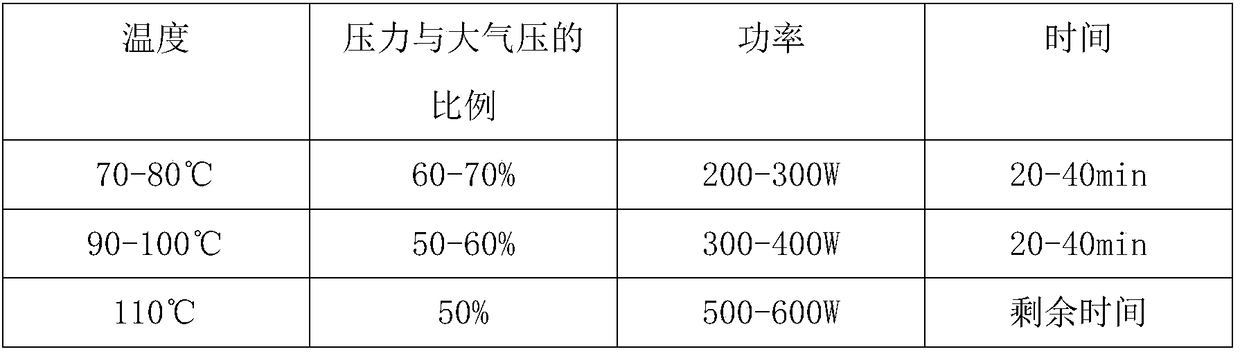

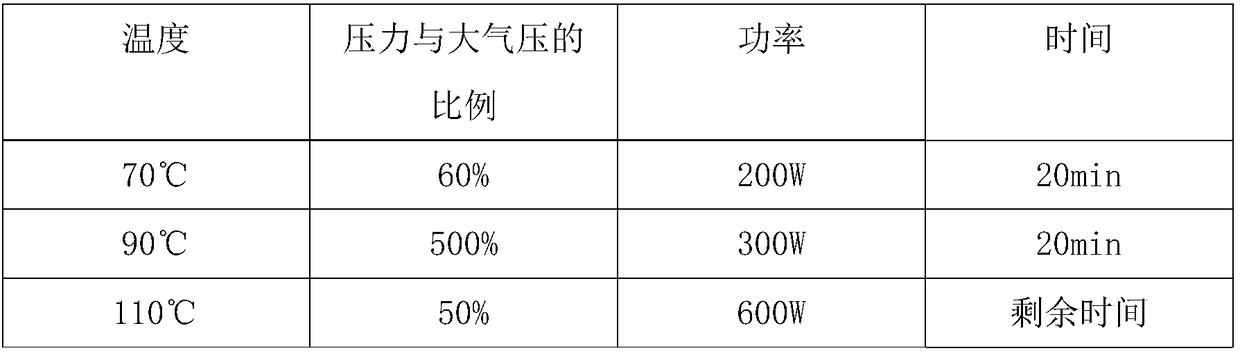

Embodiment 1

[0039] A preparation method of a high-performance composite bulletproof board, the preparation method according to the following steps:

[0040] Step 1. Add soluble aluminum salt to deionized water, then slowly add ammonia water until precipitation no longer occurs, and let stand for 1 hour to obtain aluminum hydroxide suspension;

[0041] Step 2, adding the dispersant to the aluminum hydroxide suspension, and reacting ultrasonically for 10 minutes to obtain a suspension dispersion;

[0042] Step 3: Add graphene particles to absolute ethanol, mechanically stir until a dispersion effect is formed, and then seal and ultrasonically react for 20 minutes to obtain an activated graphene suspension;

[0043] Step 4. Slowly add the activated graphene suspension to the suspension dispersion, and stir to obtain a mixed solution;

[0044] Step 5. Add the mixed liquid to the reaction kettle to form a gradient vacuum distillation reaction for 5 hours to obtain a viscous liquid;

[0045] Step 6, Put t...

Embodiment 2

[0059] A preparation method of a high-performance composite bulletproof board, the preparation method according to the following steps:

[0060] Step 1. Add soluble aluminum salt to deionized water, then slowly add ammonia water until precipitation no longer occurs, and let stand for 3 hours to obtain aluminum hydroxide suspension;

[0061] Step 2, adding the dispersant to the aluminum hydroxide suspension, and ultrasonically react for 30 minutes to obtain a suspension dispersion;

[0062] Step 3: Add graphene particles to absolute ethanol, mechanically stir until a dispersion effect is formed, and then seal and ultrasonically react for 30 minutes to obtain an activated graphene suspension;

[0063] Step 4. Slowly add the activated graphene suspension to the suspension dispersion, and stir to obtain a mixed solution;

[0064] Step 5. Add the mixed liquid to the reaction kettle to form a gradient vacuum distillation reaction for 8 hours to obtain a viscous liquid;

[0065] Step 6. Put the...

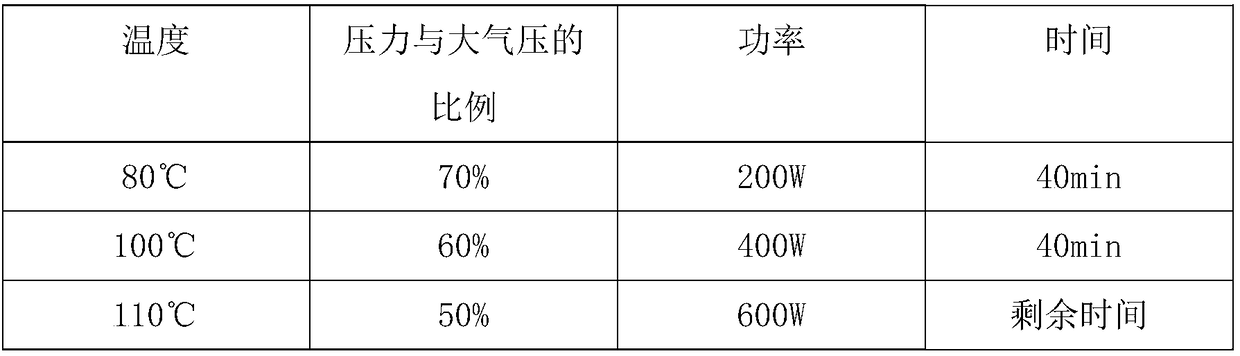

Embodiment 3

[0079] A preparation method of a high-performance composite bulletproof board, the preparation method according to the following steps:

[0080] Step 1. Add soluble aluminum salt to deionized water, and then slowly add ammonia water until precipitation no longer occurs, and let stand for 2 hours to obtain aluminum hydroxide suspension;

[0081] Step 2, adding the dispersant to the aluminum hydroxide suspension, and ultrasonically react for 20 minutes to obtain a suspension dispersion;

[0082] Step 3: Add graphene particles to absolute ethanol, mechanically stir until a dispersion effect is formed, and then seal and ultrasonically react for 25 minutes to obtain an activated graphene suspension;

[0083] Step 4. Slowly add the activated graphene suspension to the suspension dispersion, and stir to obtain a mixed solution;

[0084] Step 5. Add the mixed liquid to the reaction kettle to form a gradient vacuum distillation reaction for 7 hours to obtain a viscous liquid;

[0085] Step 6. Put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com