Magnetic functional material

A technology of magnetic function and raw materials, applied in the field of magnetic functional materials, can solve the problems of low performance, and achieve the effects of reducing porosity, reducing hysteresis loss, and reducing magnetic domain rotation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

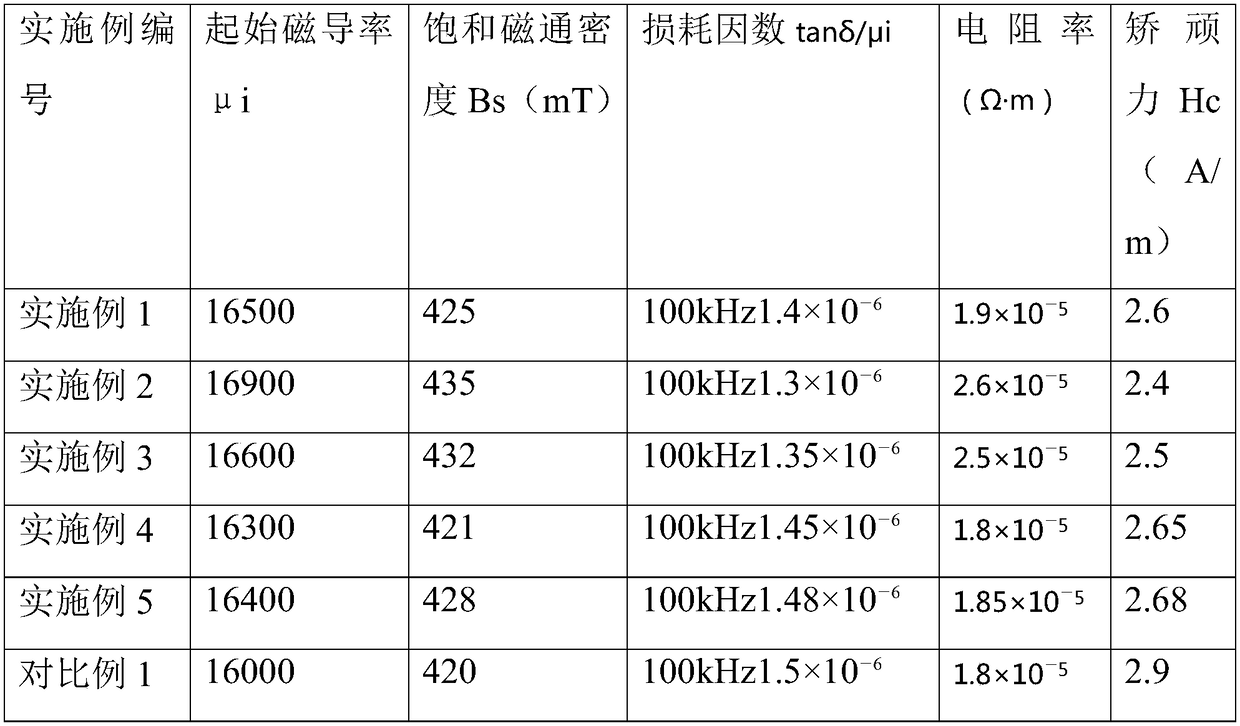

Examples

preparation example Construction

[0027] Preparation of material A: C, Nd, Cd, Mn, S and Fe are compounded according to weight percentage, and C, Cd, Mn, Nd and Fe are pure substances (element content greater than 99.9%). S is added in the form of sulfur-iron master alloy. The S content of the sulfur-iron master alloy is 50%, and the rest is iron; first put the raw materials into the induction furnace, heat up and melt, and when the melting temperature reaches 1575°C, keep it for 20 minutes Then inject the alloy liquid into the tundish located above the atomizing nozzle, the alloy liquid flows out from the leak hole at the bottom of the tundish, and is atomized into fine droplets when it meets the high-speed airflow through the nozzle, and the atomized droplets are in the closed fog The alloy powder is rapidly solidified in the cylinder, the average particle size of the alloy powder is 9μm, the atomization gas pressure is 6.5MPa, the liquid metal fluid flow rate is 3kg / min, the alloy liquid injection temperatur...

Embodiment 1

[0033] Carry out the preparation of magnetic function material according to above-mentioned method, wherein, material A comprises following raw material composition by weight: C0.28%, Nd 3%, Cd 0.01%, Mn 21%, S 2.3% and balance Fe; Material B comprises following Raw material components in parts by weight: Fe 1%, Cd 0.01%, Nd 3%, Si 0.02%, Sb 11% and balance Sn; material C includes the following raw material components in parts by weight: PbO 2 0.1%, Al 2 o 3 0.1%, CaO 0.1%, CdO 0.1%, K 2 O 8% and balance SiO 2 ; Material D includes the following raw material components in parts by weight: PbO 2 0.1%, Mn 2 o 3 16%, CdO 0.1%, Nd 2 o 3 0.1% and balance Fe 2 o 3 ; The weight ratio of material A, material B, material C and material D is 0.1:0.005:0.005:10; the weight ratio of material B and material C is 1:1.

Embodiment 2

[0035] Carry out the preparation of magnetic function material according to the above-mentioned method, wherein, material A comprises following raw material composition by weight: C0.32%, Nd 4%, Cd 0.04%, Mn 23%, S 2.5% and balance Fe; Material B comprises following Raw material components in parts by weight: Fe 3%, Cd 0.03%, Nd 5%, Si 0.05%, Sb 13% and balance Sn; material C includes the following raw material components in parts by weight: PbO 2 0.2%, Al 2 o 3 0.3%, CaO 0.3%, CdO 0.3%, K 2 O 10% and balance SiO 2 ; Material D includes the following raw material components in parts by weight: PbO 2 0.3%, Mn 2 o 3 17%, CdO 0.3%, Nd 2 o 3 0.3% and balance Fe 2 o 3 ; The weight ratio of material A, material B, material C and material D is 0.3:0.015:0.015:10; the weight ratio of material B and material C is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com