Abrasion generator

A generator and abrasion technology, applied in instruments, scientific instruments, testing wear resistance, etc., can solve problems such as the inability to measure the effect of sediment abrasion on material abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The silt is selected from the Yangtze River silt, and the particle size of the silt is: 0.300~0.600mm, 0.038~0.054mm and 0.013~0.018mm; the sediment content is 20kg / m 3 .

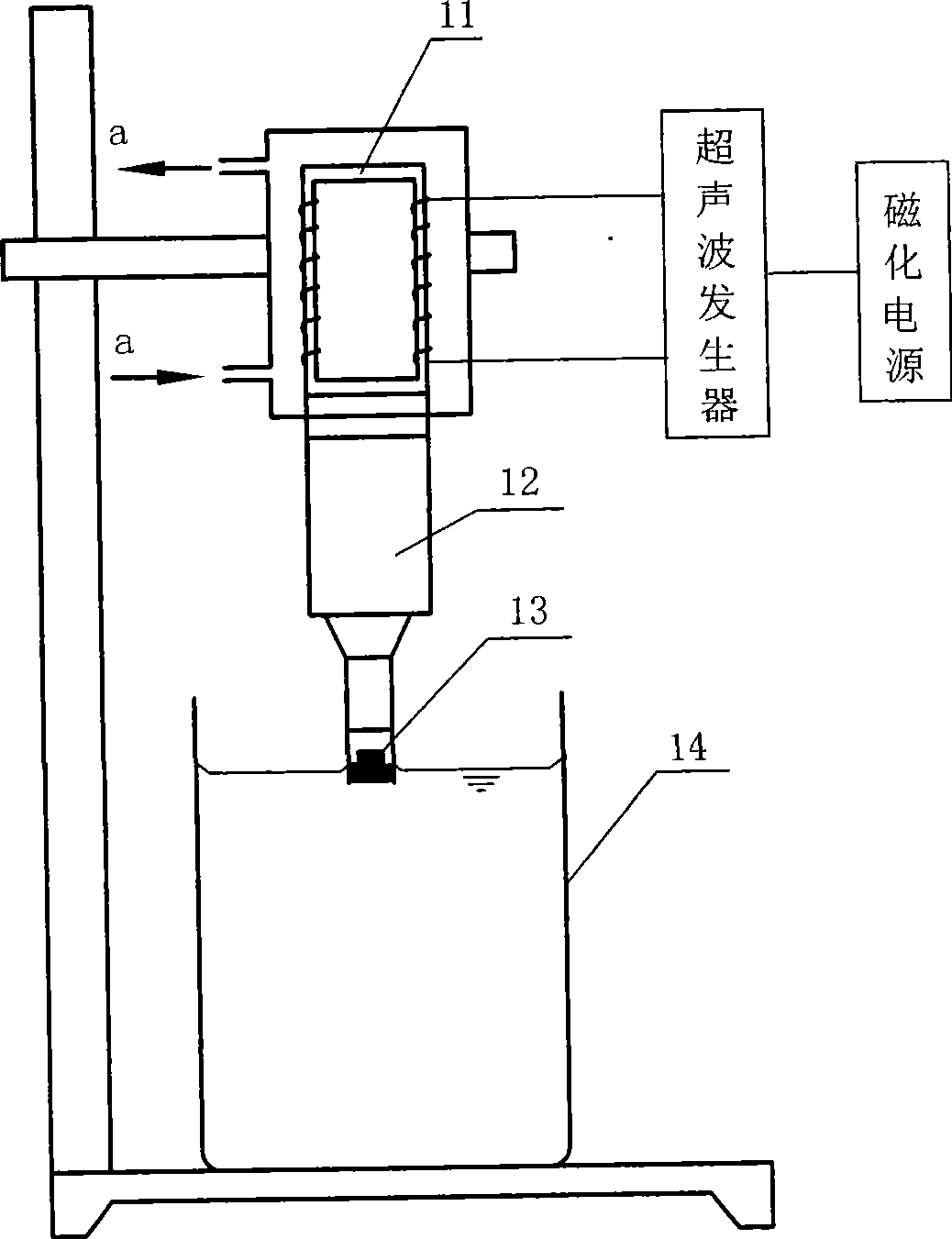

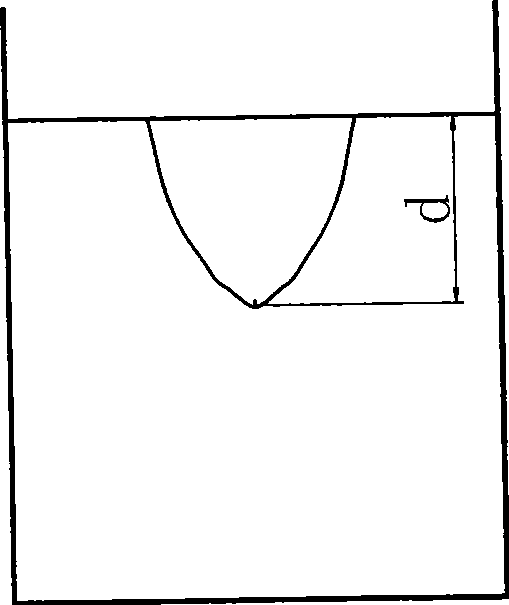

[0030] The vibration frequency of the magnetostrictive oscillator used in this embodiment is 19.6 kHz, the amplitude is 50 μm, the power is 1100 W, the test piece is No. 45 steel, and the test solution used is water. Before the test, first clean the test piece with acetone solution in an ultrasonic cleaner, then dry it, and when it is naturally cooled to room temperature, weigh it on an electronic analytical balance with an accuracy of 0.1 mg, and record the measurement results. Such as Figure 5Shown, in the container 14 that test solution is housed of the present invention, put into certain content (the sand content of this test is all 20%), the silt of certain grain size, then add certain water again, open controller 23 Turn on the power switch, adjust the controller 23, observe the effect of th...

Embodiment 2

[0033] The specimen used in the test is still No. 45 steel. The sediment is selected from the Yangtze River sediment, and the sediment content is: 5kg / m 3 、50kg / m 3 and 85kg / m 3 . The particle size of the sediment is 0.300-0.600mm. Test method and test condition are exactly the same as embodiment one.

[0034] According to the measured data of the test, the relationship curve of the mass loss by abrasion of the test piece, the sand concentration and the test time is drawn, see Figure 7 , where C1>C2>C3. Depend on Figure 4 It can be seen that for this sediment particle size, the greater the sediment content, the greater the mass loss per unit time.

[0035] As can be seen from the above two embodiments, the device has the following advantages:

[0036] It can measure the effect of different particle sizes and different contents of sediment on abrasion;

[0037] It overcomes the disadvantage that the traditionally used magnetostrictive oscillator can only measure the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com