Patents

Literature

44results about How to "Hardness effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-static polyurethane material for manufacturing shoe soles, shoe sole manufacturing method and manufacturing method of dual-density polyurethane safety shoe soles

ActiveCN102504519AImprove anti-static performanceGood anti-static performanceSolesDefoaming AgentsIsocyanate compound

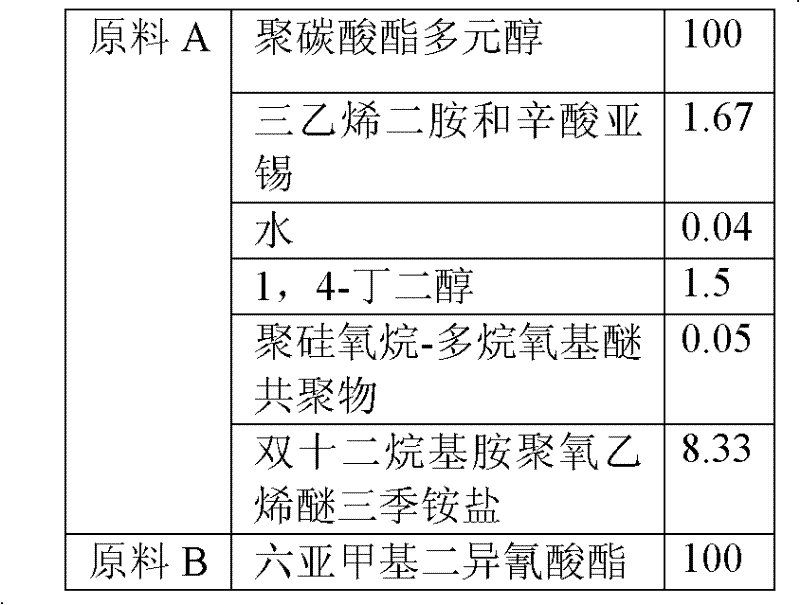

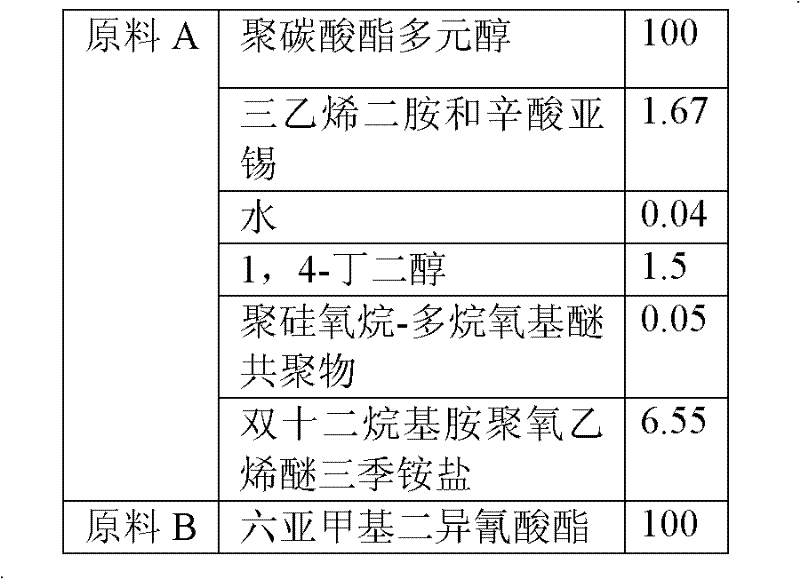

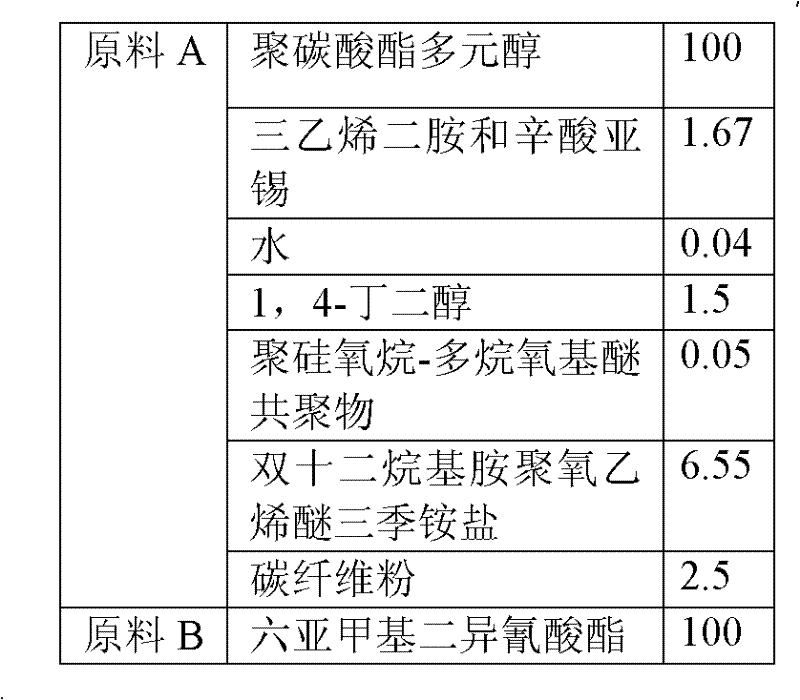

The invention discloses an anti-static polyurethane material for manufacturing shoe soles, a shoe sole manufacturing method and a manufacturing method of dual-density polyurethane safety shoe soles. The anti-static polyurethane material consists of a component A and a component B which are mixed and poured, the component A includes polyatomic alcohol, catalyst, foaming agent, anti-static agent, carbon fiber powder, chain extender and defoaming agent; and the component B is isocyanate. The shoe sole manufacturing method includes steps of baking and drying the polyatomic alcohol and the isocyanate, mixing the rest compositions in the component A and the baked polyatomic alcohol uniformly to form material A, and mixing the material A with the isocyanate of the component B to obtain shoe soles made of anti-static polyurethane materials by pouring forming. The dual-density polyurethane safety shoe soles can be manufactured by secondary pouring by selecting foaming agents in different quantity. The polyurethane materials are high in anti-static performance, and the manufactured shoe soles are proper in hardness. Shoe soles manufactured by the manufacturing methods are fine in demouldingand high in production efficiency.

Owner:深圳市新纶超净科技有限公司

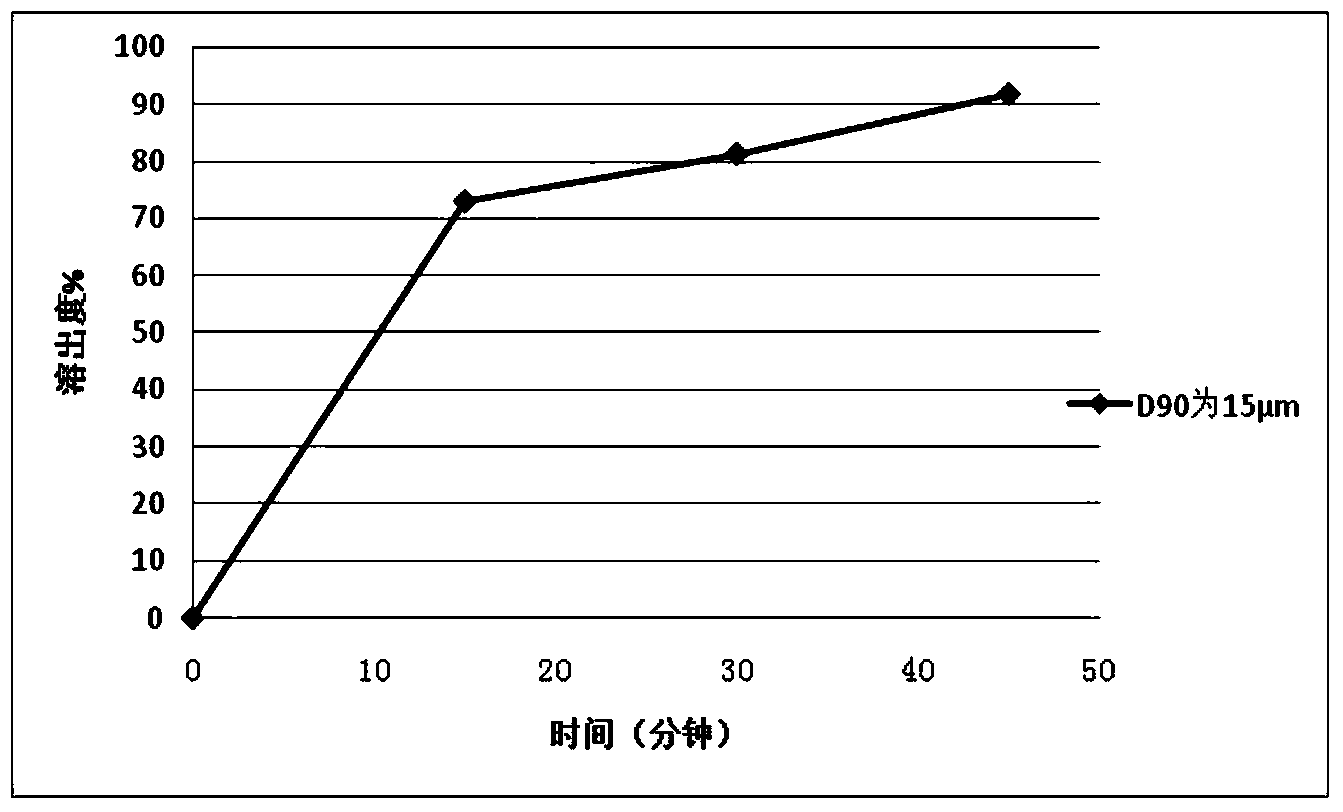

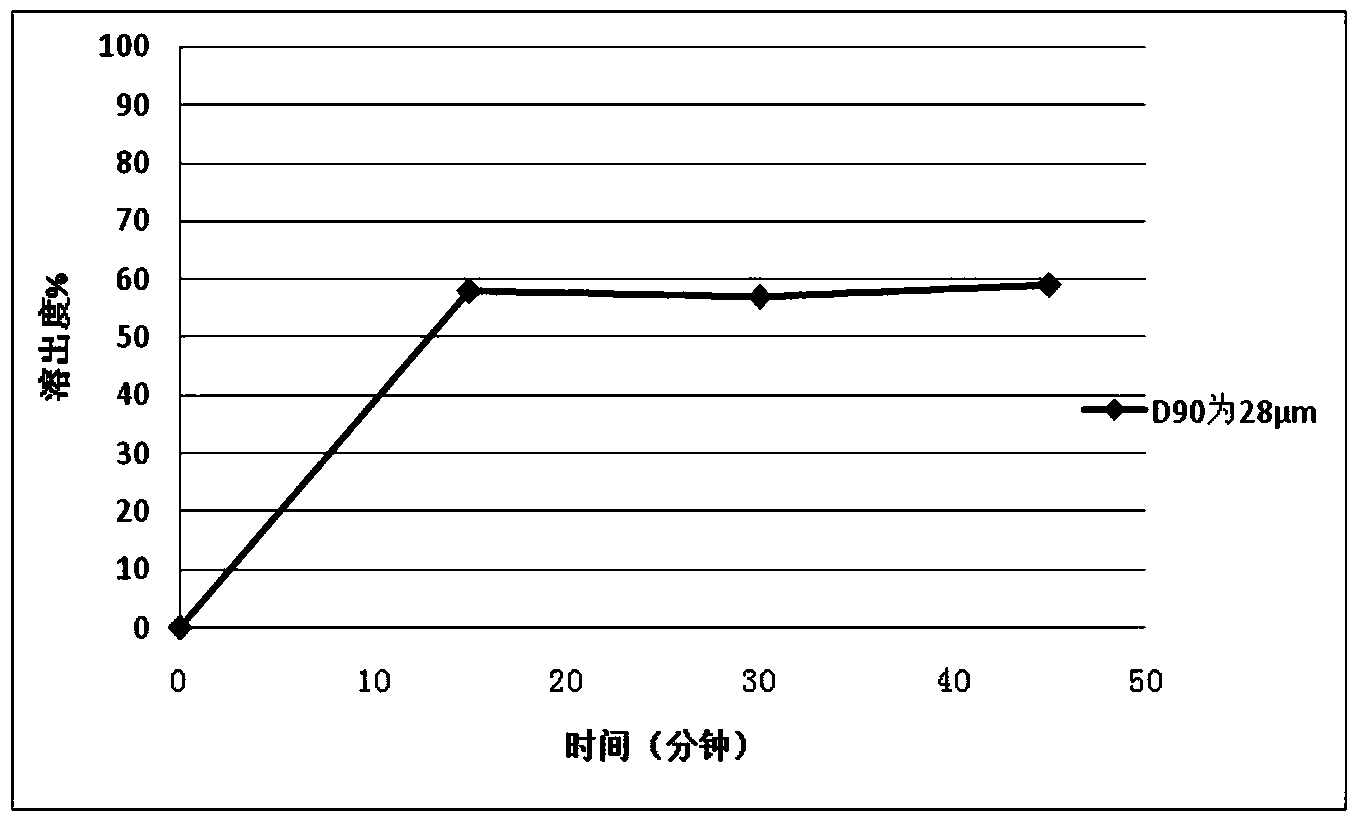

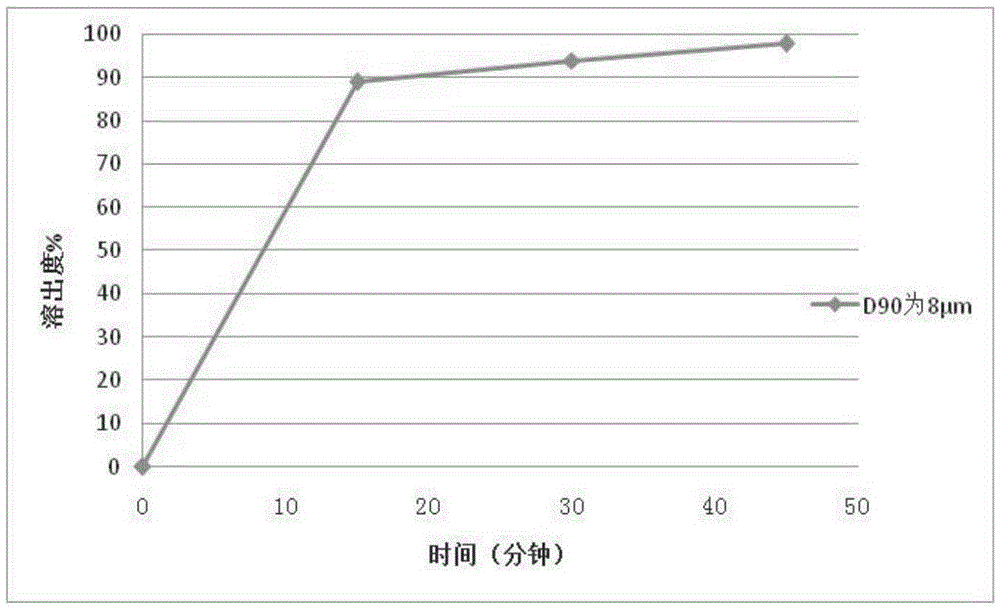

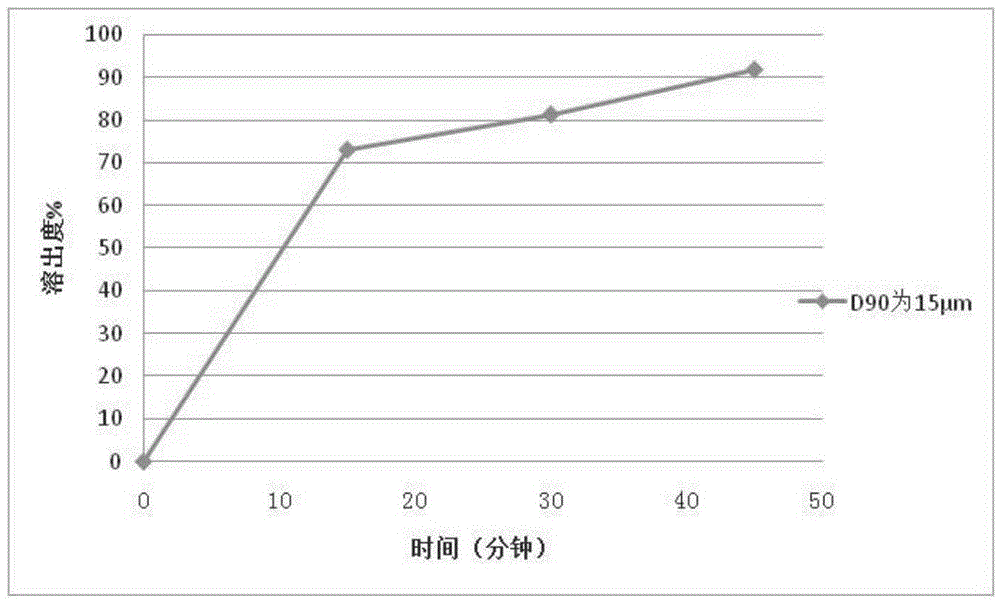

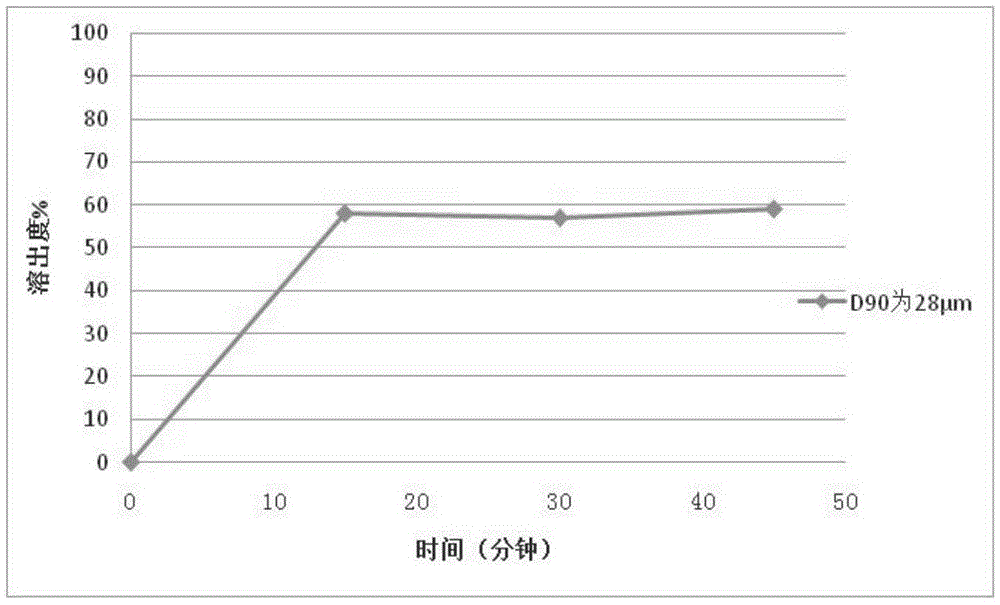

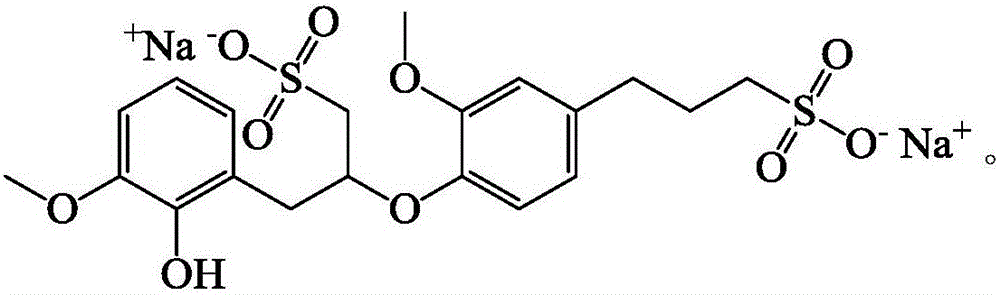

Repaglinide troche and preparation method thereof

ActiveCN103610677AAvoid stickingGood dispersionOrganic active ingredientsMetabolism disorderMedicineDissolution

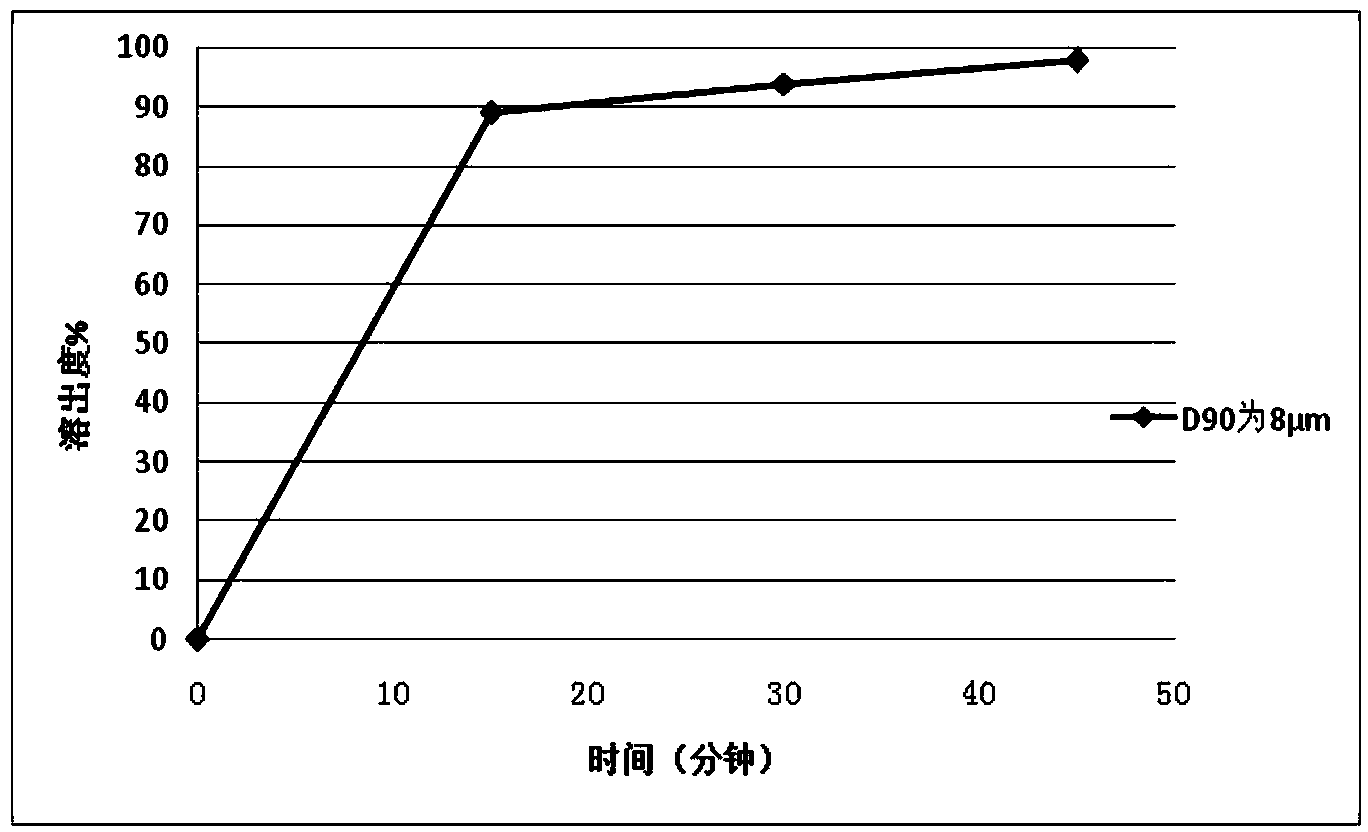

The invention relates to an oral troche which contains repaglinide or pharmaceutically acceptable derivatives of repaglinide as well as a preparation method of the oral troche. According to the preparation method, powder of repaglinide or pharmaceutically acceptable derivatives of repaglinide is directly pressed into troche, so that the production cost is remarkably lowered, and the disintegration and the dissolution rate are greatly improved. The bioavailability and the stability of the medicine can be improved, and the problem of low content uniformity of existing small-dose medicines formed by the direct pressing method is overcome, so that the quality of the troche is better guaranteed.

Owner:华益泰康药业股份有限公司

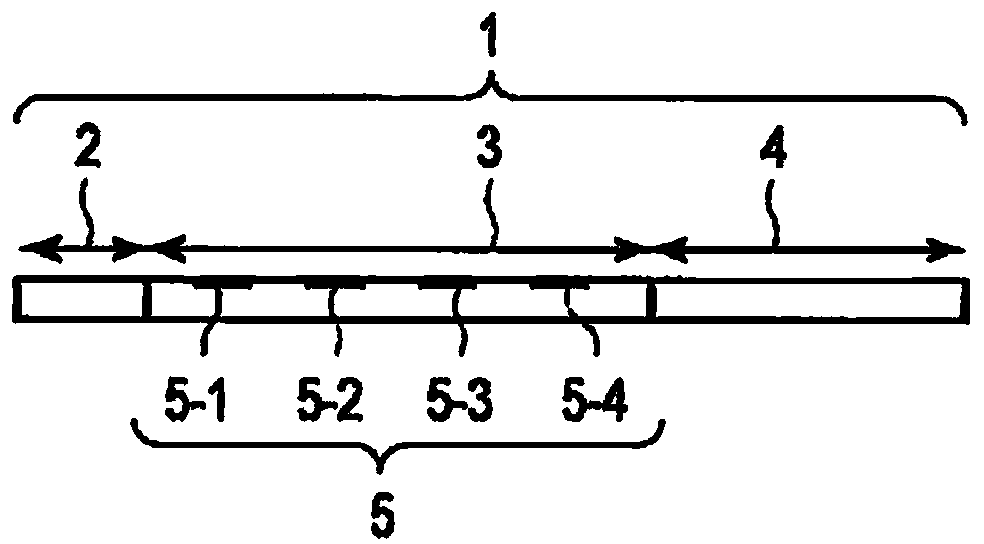

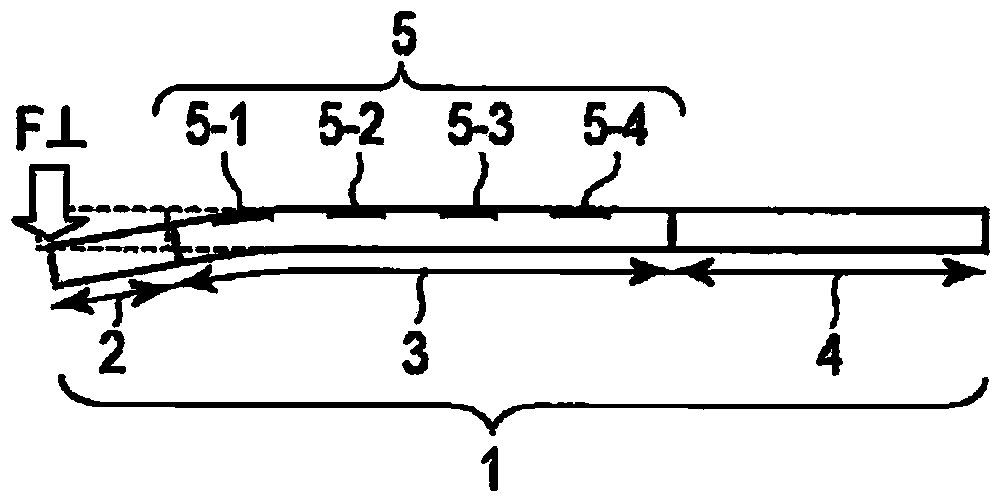

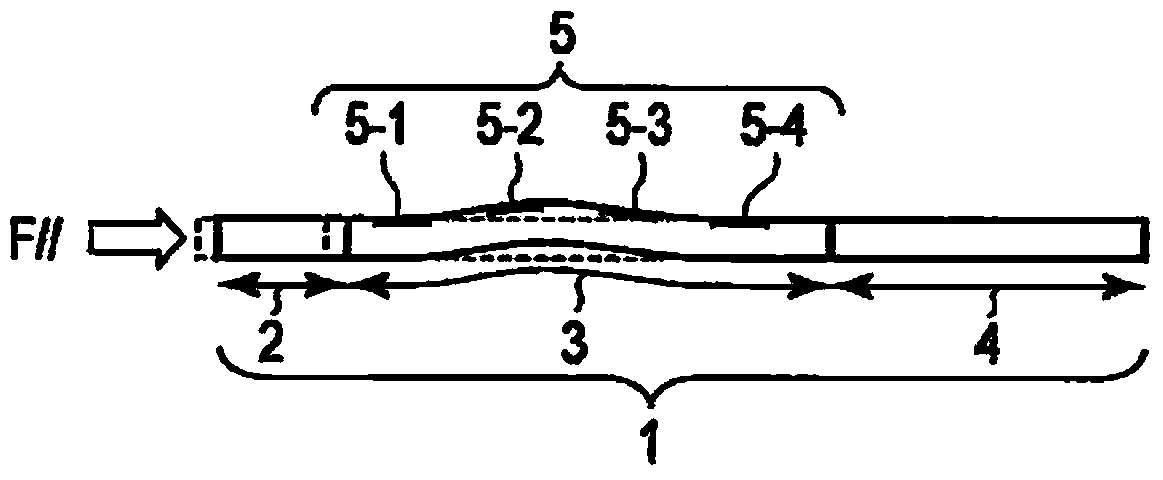

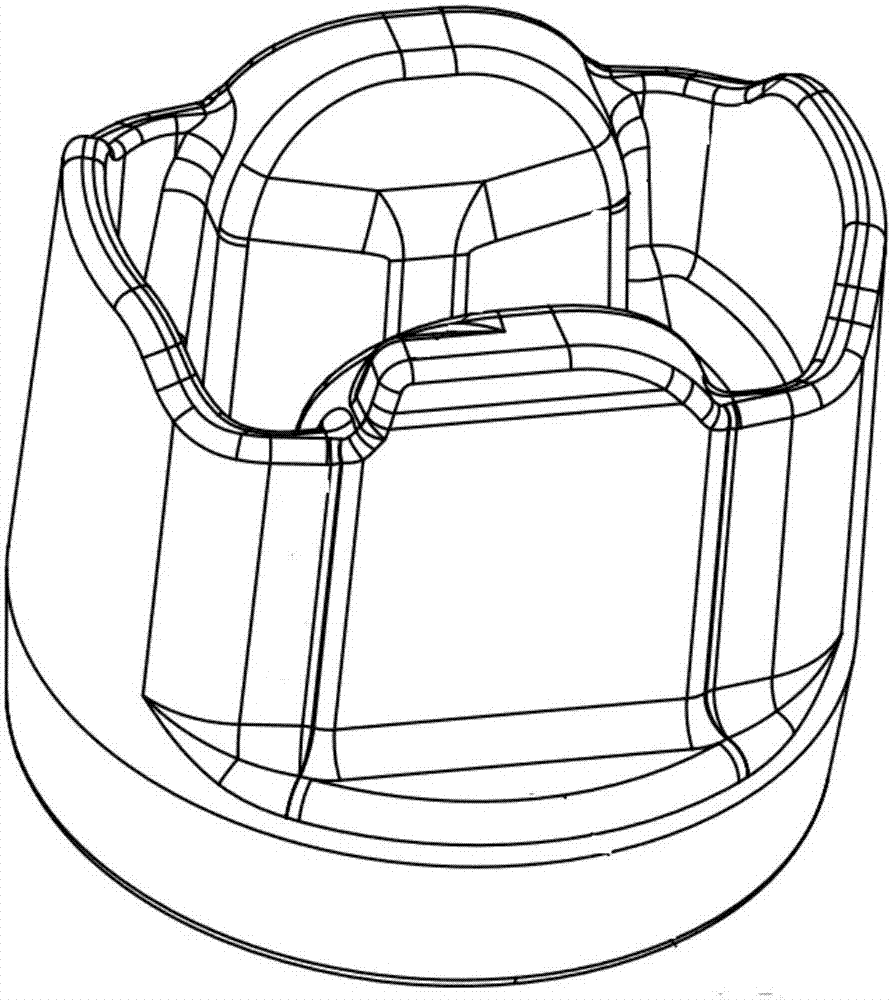

Tubular insertion device

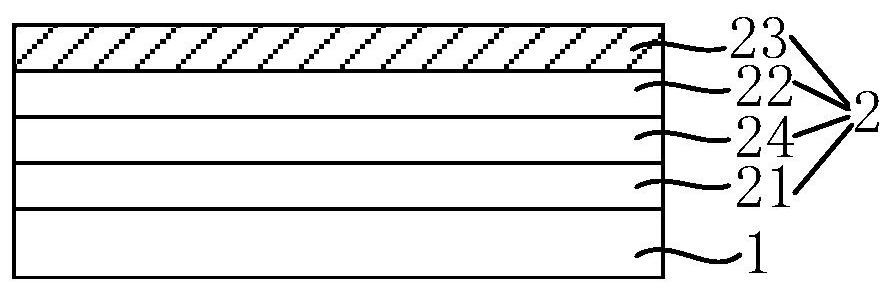

ActiveCN103906459ASize effectHardness effectMaterial strength using steady bending forcesTelescopesBiomedical engineeringInsertion device

A tubular insertion device includes a tubular insertion portion including a flexible portion in a predetermined part, bending sensors distributed and arranged in the flexible portion, and an operation support information calculating unit. The operation support information calculating unit extracts operation support information including at least first external force information regarding an external force applied to the tubular insertion portion by a combinational calculation based on detection information from the bending sensors.

Owner:OLYMPUS CORP

Production method for casting cylinder liner blank for ammonia refrigerator by adopting precoated sand molding

The invention relates to a production method for casting cylinder liner blank for an ammonia refrigerator by adopting precoated sand molding. The method is characterized in that the size of the cylinder liner blank retained with processing amount is determined according to the design requirement, and a semi-open type precoated sand die is manufactured according to the size of the cylinder liner blank; and a cylinder liner metal tyre mold is installed on a centrifugal casting machine, the semi-open type precoated sand die for the cylinder liner blank is loaded in the cylinder liner metal tyre mold for casting, and the iron liquor smelted through a cupola and containing different percentages of various metallic elements is cast in the cylinder liner metal tyre mold of the centrifugal casting machine. The invention is a production method for casting the cylinder liner blank for the ammonia refrigerator by adopting precoated sand molding, because the weight of the cylinder liner blank, the mechanical processing amount and the cost of the products are all reduced, the production efficiency is improved; because the precoated sand is separated on the surface of the cylinder liner blank for water cooling, the chilling is caused by the water cooling, the surface hardness of the cylinder liner blank is less influenced; and the mechanical processing is convenient and the working environment of the workers is improved.

Owner:胡富玲

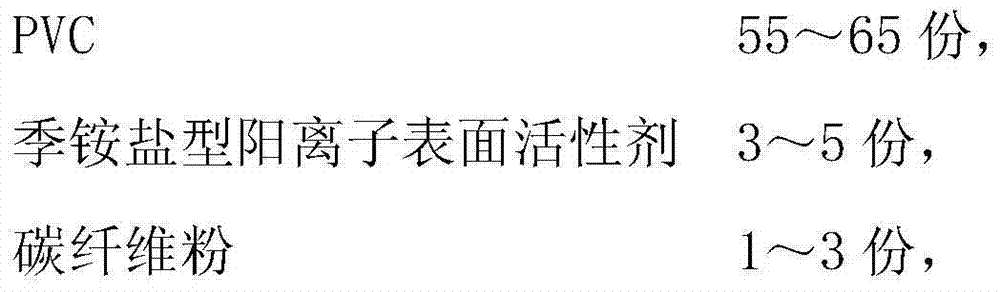

Anti-static PVC sole material and manufacturing method thereof

The invention provides an anti-static PVC sole material, and the anti-static PVC sole material comprises the components in parts by weight as follows; 55-65 parts of PVC, 3-5 parts of quaternary ammonium salt cationic surface active agent, 1-3 parts of carbon fiber powder, 20-30 parts of plasticizer, 2-5 parts of foaming agent, 3-8 parts of white carbon black and 5-10 parts of filler. The manufacturing method for anti-static PVC sole material is also provided. The anti-static PVC sole material has good anti-static performance applied to the anti-static shoes.

Owner:SUZHOU JINGRO TECH

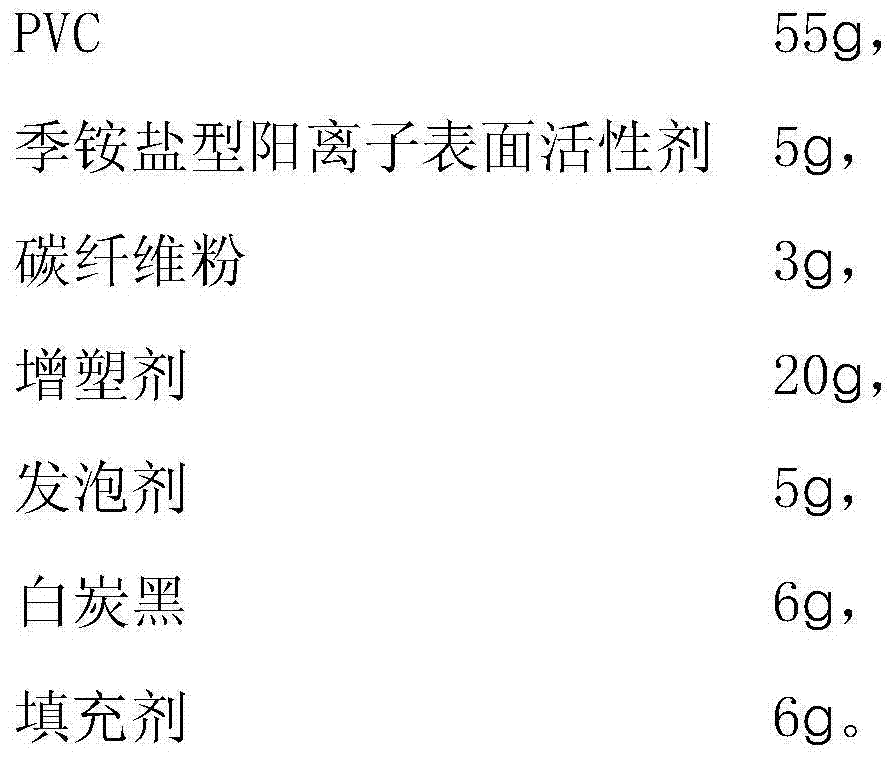

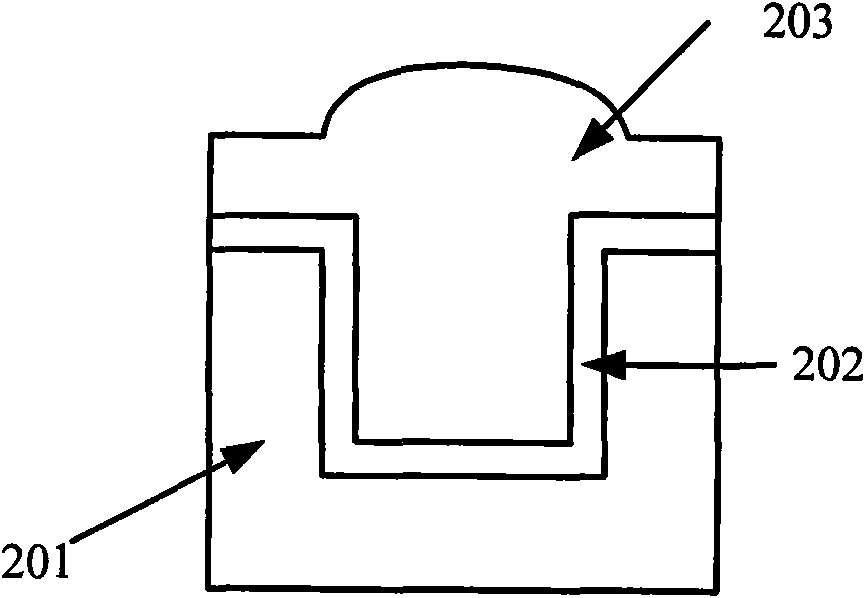

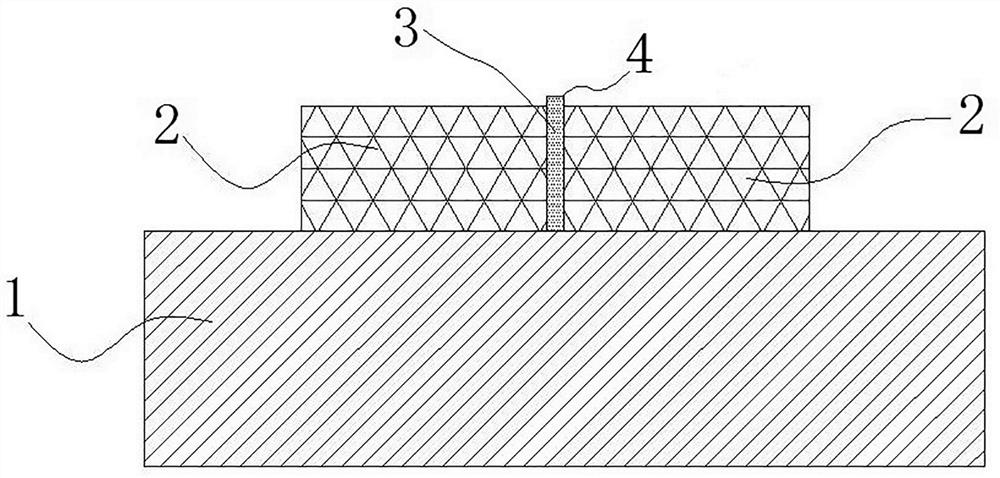

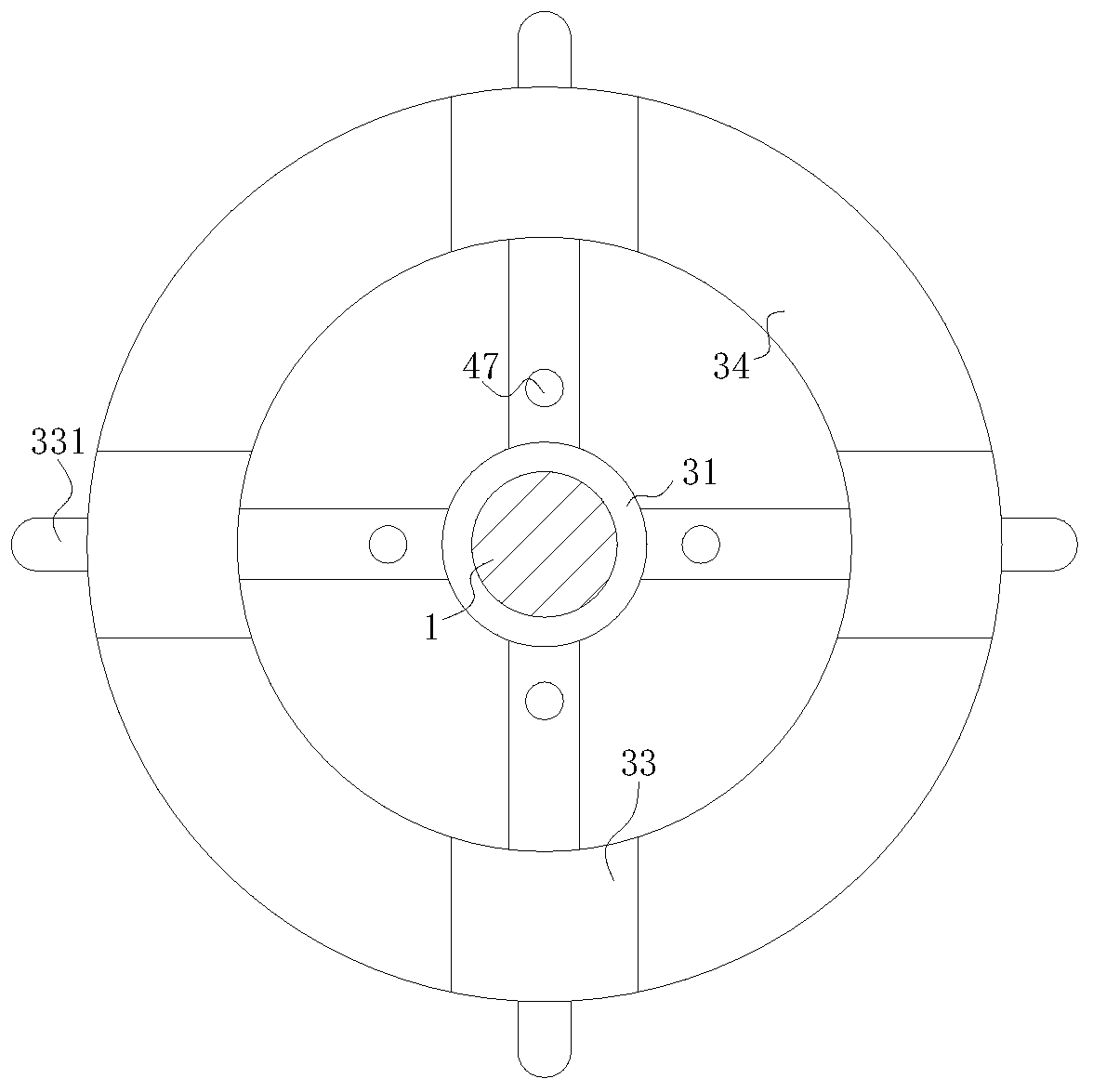

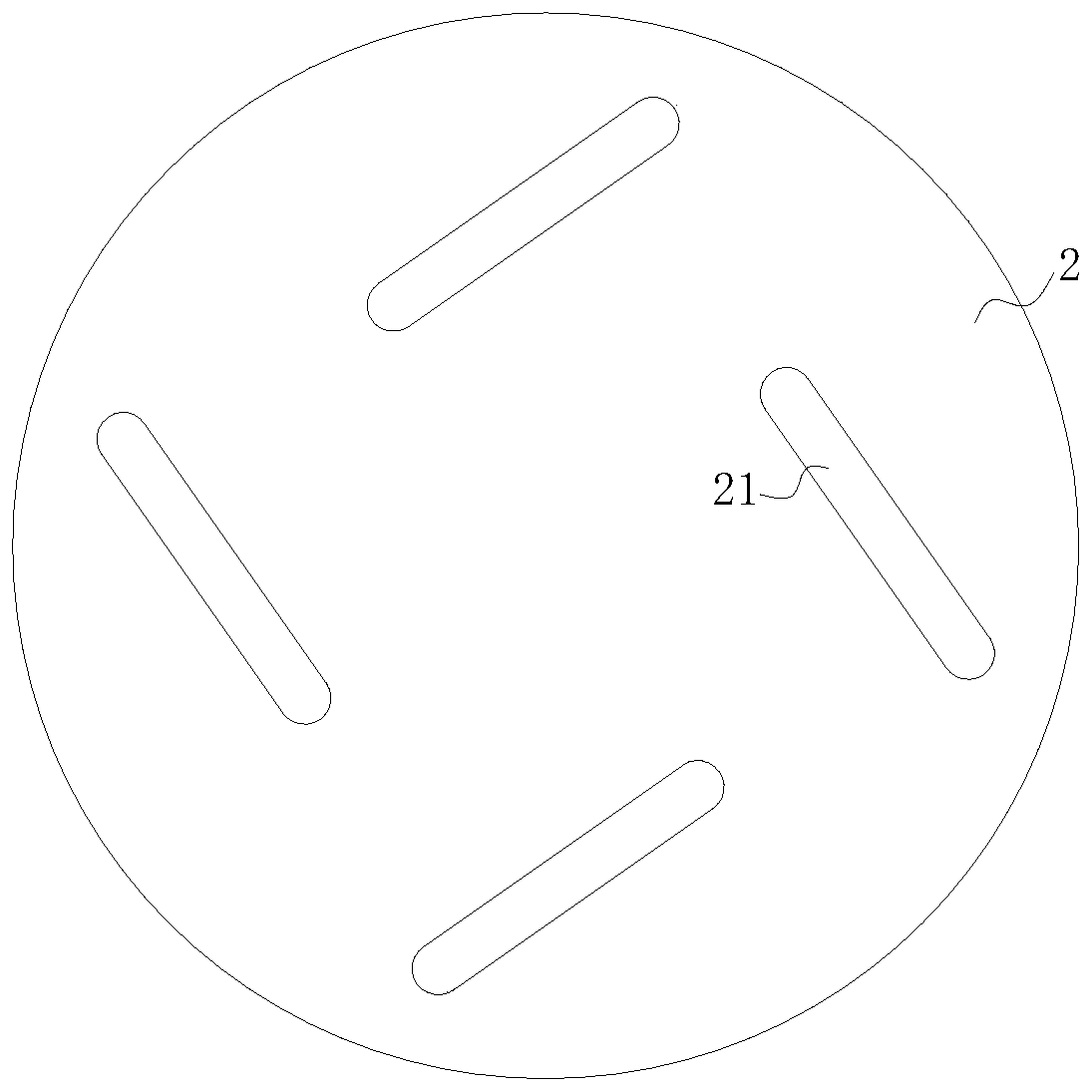

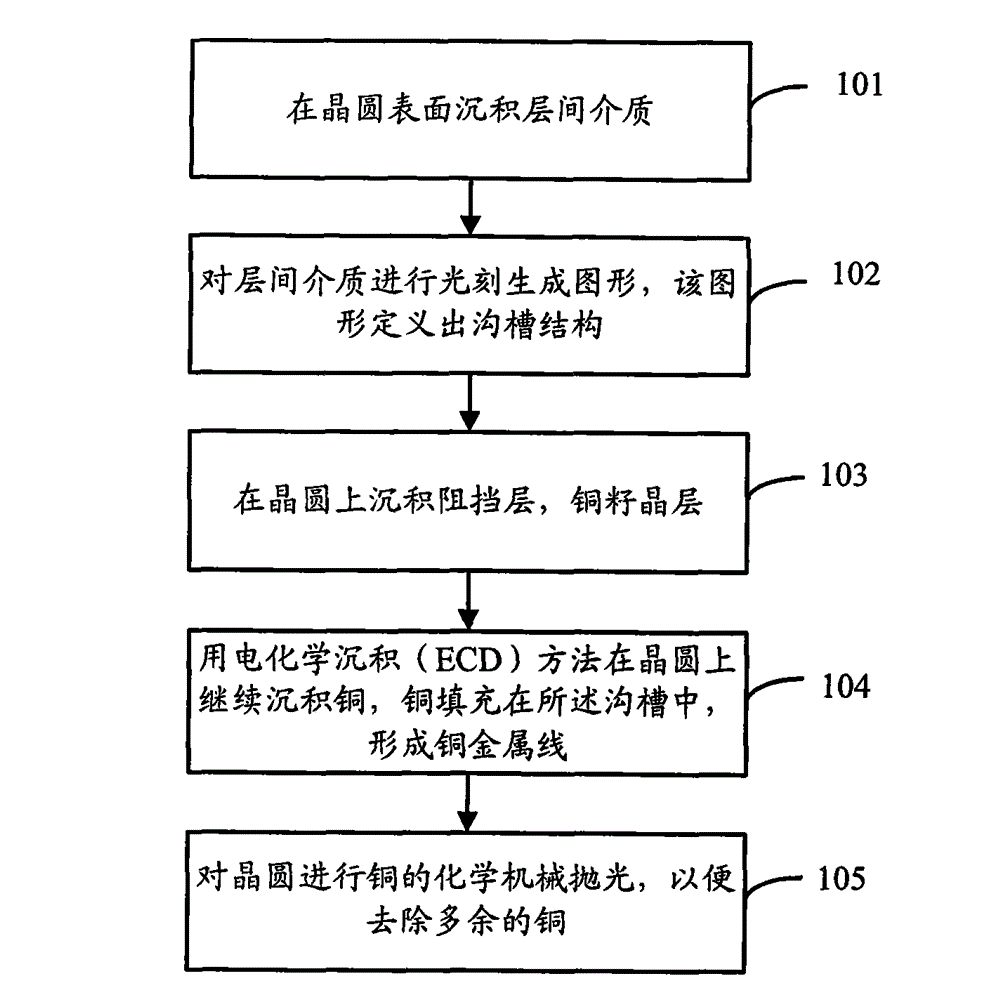

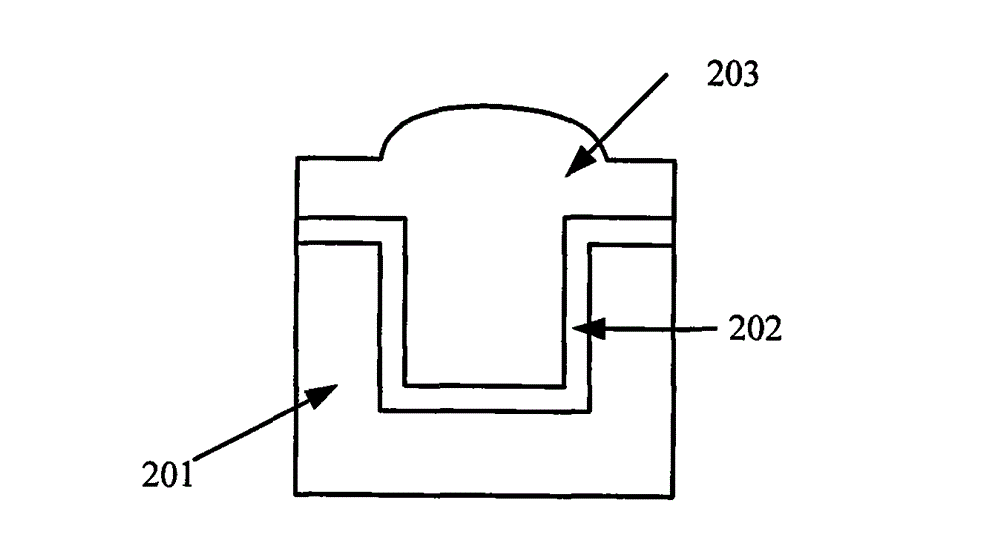

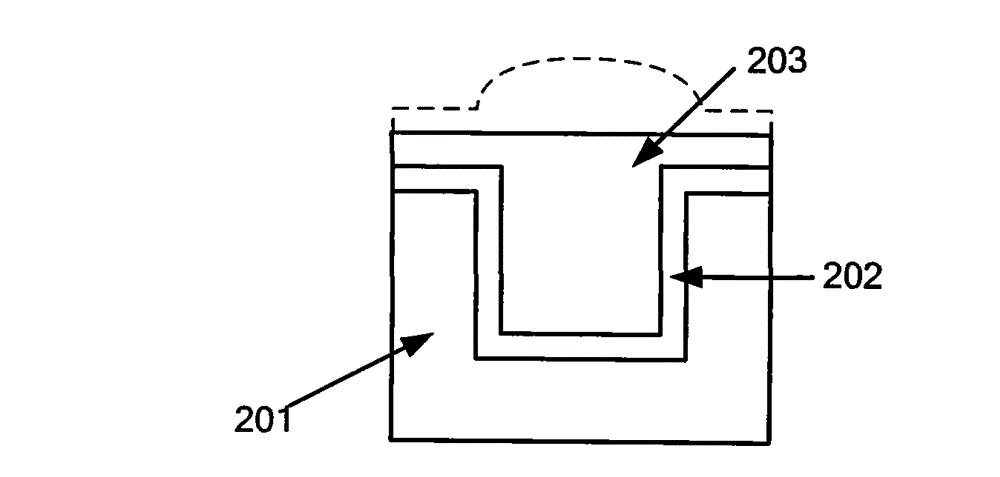

Method for constructing copper wire on wafer and chemical mechanical polishing (CMP) method for copper

ActiveCN101958273AHardness effectReduce sagSemiconductor/solid-state device manufacturingDielectricState of art

The invention discloses a method for constructing a copper wire on a wafer, which comprises the following steps of: depositing a first interlayer dielectric on the upper surface of the wafer; constructing a second interlayer dielectric on the upper surface of the first interlayer dielectric of the wafer, wherein the hardness of the second interlayer dielectric is lower than that of the first interlayer dielectric; photoetching the second interlayer dielectric and the first interlayer dielectric to define a groove structure, wherein the bottom of the groove structure is positioned in the first interlayer dielectric; sequentially depositing a barrier layer and a copper seed crystal layer on the upper surface of the wafer and the inner wall of a groove; depositing copper on the upper surface of the wafer, wherein the copper is filled in the groove to form the copper wire; and performing chemical mechanical polishing (CMP) on the wafer to reach the first interlayer dielectric so as to make the upper surface of the wafer subjected to planarization. The invention also discloses a CMP method for the copper. The sinking degree of the surface of the copper wire constructed by the scheme of the invention is reduced to a certain extent compared with that of the prior art.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

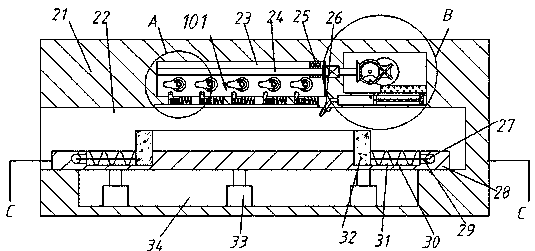

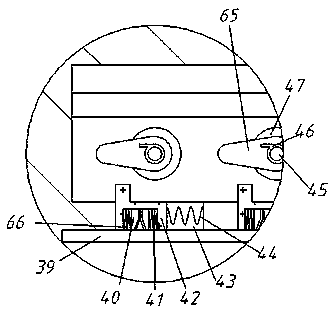

Novel material hardness quantitative analysis instrument

ActiveCN109932261AHardness effectEasy to observeInvestigating material hardnessElectric machineryMotor shaft

The invention discloses a novel material hardness quantitative analysis instrument. The instrument comprises a body, and a testing groove is formed in the body. A through cavity is formed in the upperend wall of the testing groove, and five clamp grooves are formed in the upper end wall of the through cavity. The upper end walls of the clamp grooves are provided with a working cavity, and a linkage groove is formed in the right end of the working cavity. A testing device for measuring hardness is arranged in the working cavity, and the testing device comprises a motor fixedly mounted on the right end wall of the working cavity. A motor shaft rotationally connected with the left end wall of the linkage groove and the left end wall of the working cavity is connected into the motor, and is in threaded connection with a threaded block which is in sliding connection with the upper end wall of the working cavity. According to the invention, the device can achieve the scratch testing of thesurface of a material to be tested through the tools with different hardness, performs the flushing and cooling of the surface of the material to be tested through water while testing is carried out,and prevents the influence of overtemperature on the hardness of the material brings while bringing convenience to an operator for observation.

Owner:台州九桔科技股份有限公司

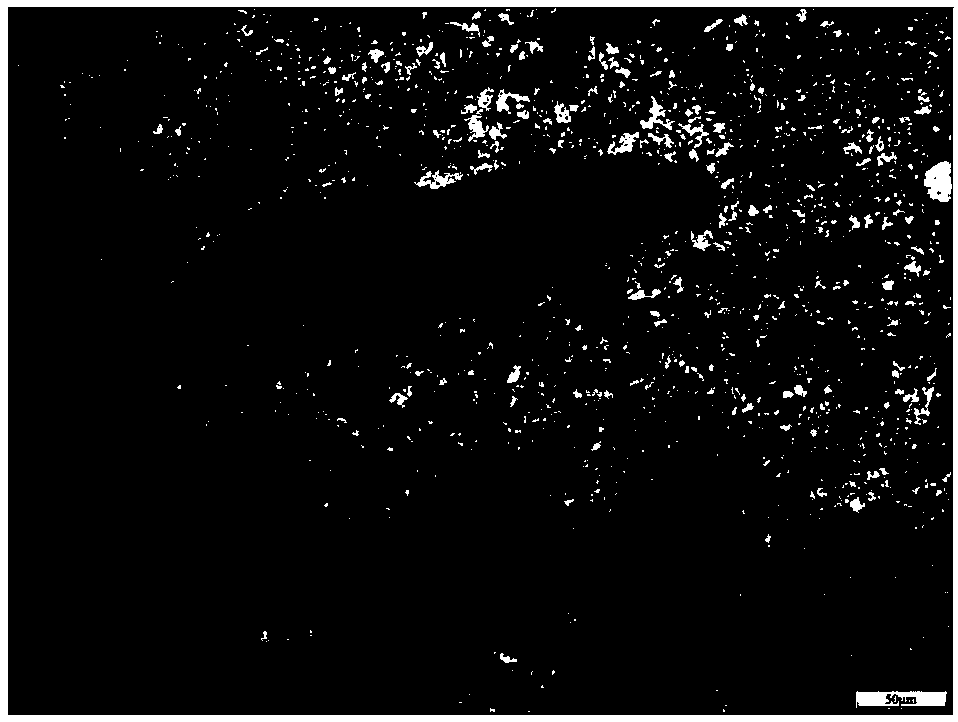

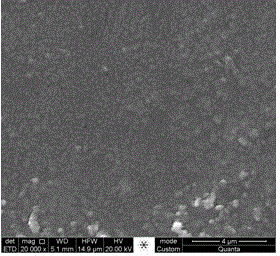

In-situ synthesis chromium diboride-zirconium diboride multiphase ceramic reinforced copper-based composite and preparation method and application thereof

InactiveCN108103342AImprove wear resistanceExtend your lifeTransportation and packagingMetal-working apparatusDiborideBall mill

The invention provides an in-situ synthesis chromium diboride-zirconium diboride multiphase ceramic reinforced copper-based composite and a preparation method of the in-situ synthesis chromium diboride-zirconium diboride multiphase ceramic reinforced copper-based composite. According to the preparation method, chromium elementary substance, zirconium elementary substance and boron elementary substance are ball milled, and then a CrB2-ZrB2 multiphase ceramic precursor is obtained; chemical nickel plating is conducted on the surface of the CrB2-ZrB2 multiphase ceramic precursor, nickel moistenedand reinforced particles are obtained and then mixed with a copper source, the mixture is ball milled, and the ball-milled mixture is obtained; cold pressing is conducted on the ball-mixed mixture, and a pressed blank is obtained; the pressed blank is sintered in an anaerobic atmosphere, and then a sintered body is obtained; and then forging and pressing are conducted, and then the in-situ synthesis CrB2-ZrB2 multiphase ceramic reinforced copper-based composite is obtained. The prepared in-situ synthesis CrB2-ZrB2 multiphase ceramic reinforced copper-based composite is high in hardness, and the hardness is not influenced by coping. The invention further provides the application of the in-situ synthesis CrB2-ZrB2 multiphase ceramic reinforced copper-based composite, wherein the in-situ synthesis CrB2-ZrB2 multiphase ceramic reinforced copper-based composite is used as a spot-welding electrode material.

Owner:HUBEI UNIV OF TECH

Production method of ceramic chips for ceramic packaging base

ActiveCN112589976AHigh dimensional accuracyMeet the precision requirementsCeramic shaping apparatusComposite materialGreen body

The invention relates to a production method of ceramic chips for a ceramic packaging base. The method comprises the following steps of: 1, manufacturing a ceramic green body plate, and dividing the plate-shaped ceramic green body plate into a plurality of ceramic chip green bodies; 2, cutting and trimming process edges of the ceramic chip green bodies; and 3, sintering and hardening the ceramic chip green bodies trimmed in the step 2 to obtain the ceramic chips. In the production process, the ceramic chip green bodies are produced firstly, and the process edges of the ceramic chip green bodies are cut and trimmed based on the characteristic that the hardness of the ceramic chip green bodies is relatively low, so that the size of the produced ceramic chips can conveniently meet the precision requirement.

Owner:瓷金科技(河南)有限公司

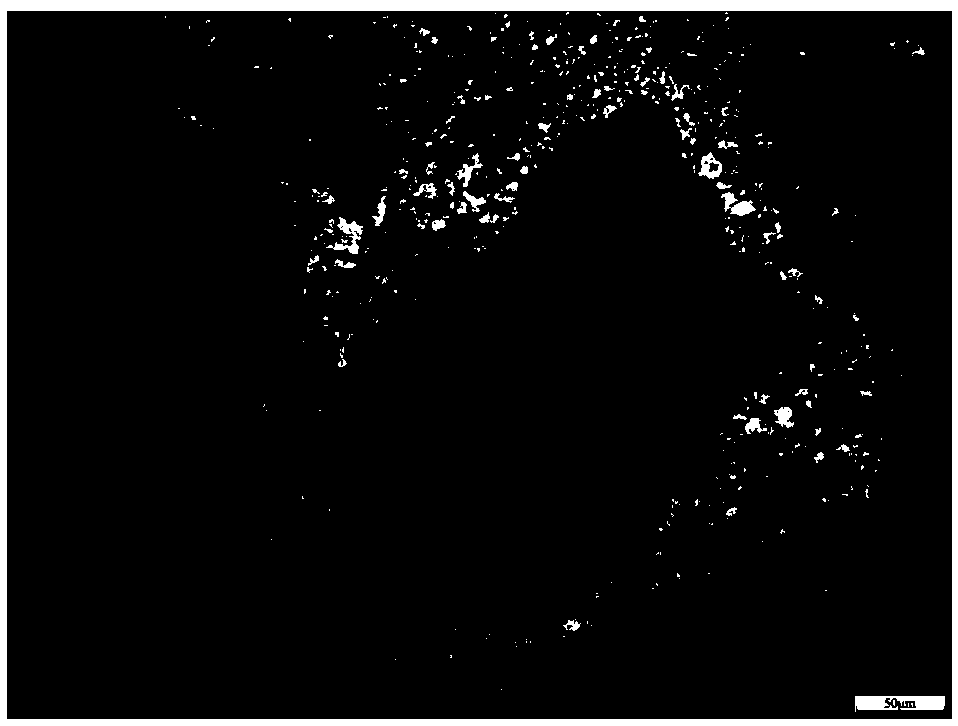

TiB2-ZrB2 composite-phase ceramic reinforced copper-based composite material formed in in-situ synthesis mode according to multi-step method, and preparation method and application thereof

InactiveCN108103340AHardness effectExtend your lifeTransportation and packagingElectrode featuresSpot weldingTitanium boride

The invention provides a TiB2-ZrB2 composite-phase ceramic reinforced copper-based composite material formed in an in-situ synthesis mode according to a multi-step method, and a preparation method andapplication thereof. The composite material comprises a TiB2-ZrB2 composite-phase ceramic reinforcement phase formed in an in-situ synthesis mode, a copper matrix phase and a nickel wetting phase wrapping the surface of the TiB2-ZrB2 composite-phase ceramic reinforcement phase, and the TiB2-ZrB2 composite-phase ceramic reinforcement phase with the surface wrapped with the nickel wetting phase isscattered inside and on the surface of the copper matrix phase. The composite material provided by the invention has excellent conductivity and hardness performance, the reinforcement phase is distributed on the surface of or inside the matrix phase, and when the composite material is applied as a spot welding electrode, even polishing has almost no influence on the service life of the spot welding electrode.

Owner:HUBEI UNIV OF TECH

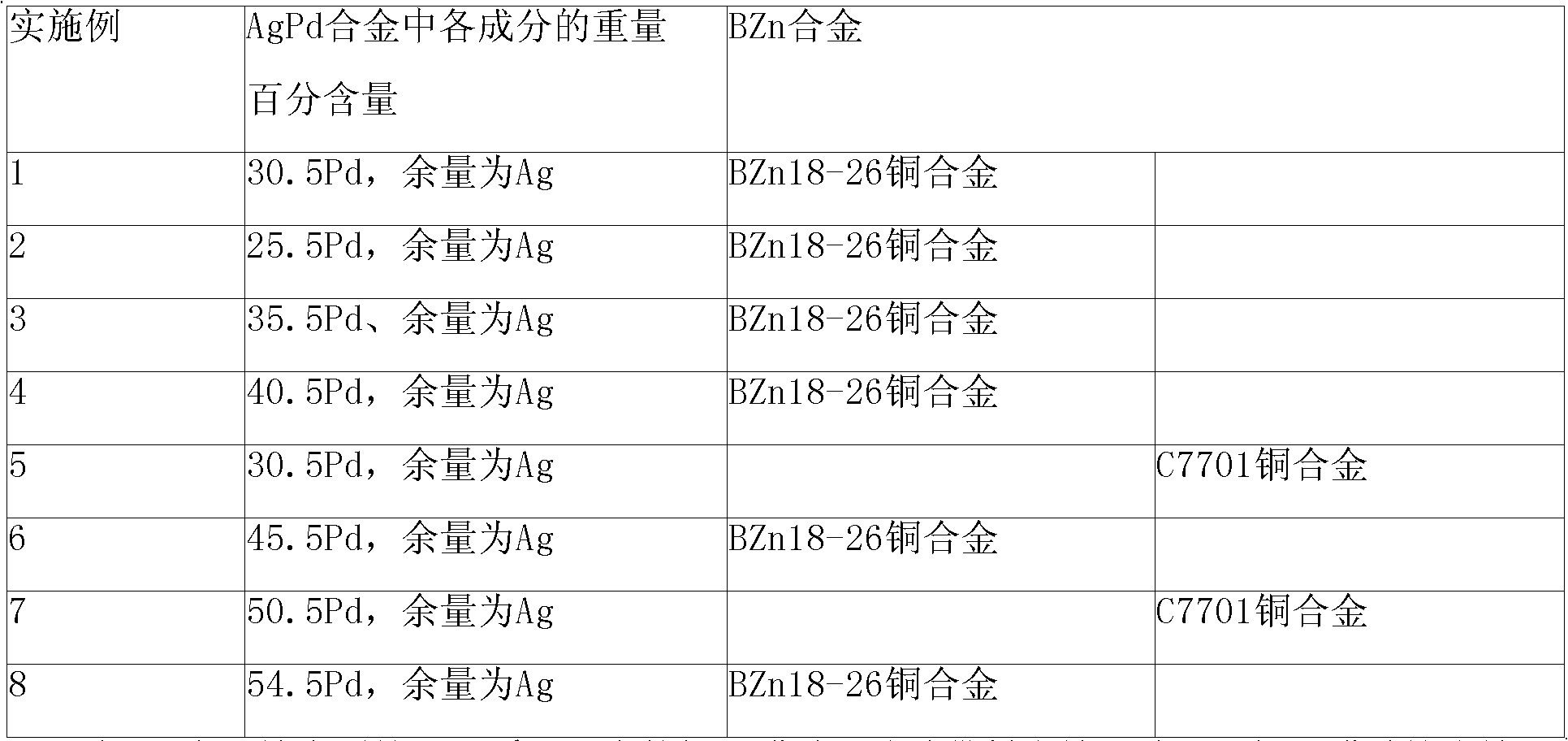

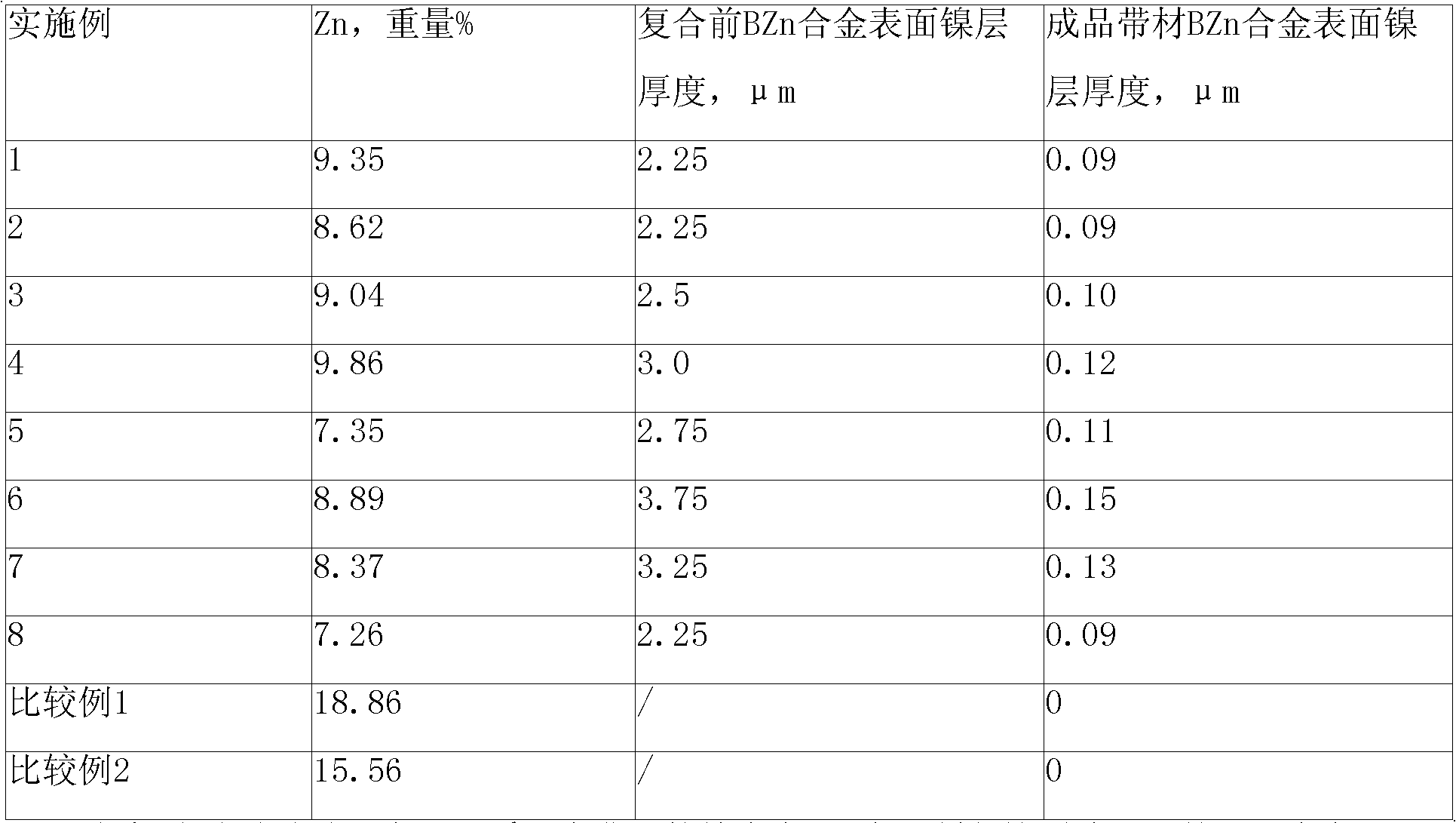

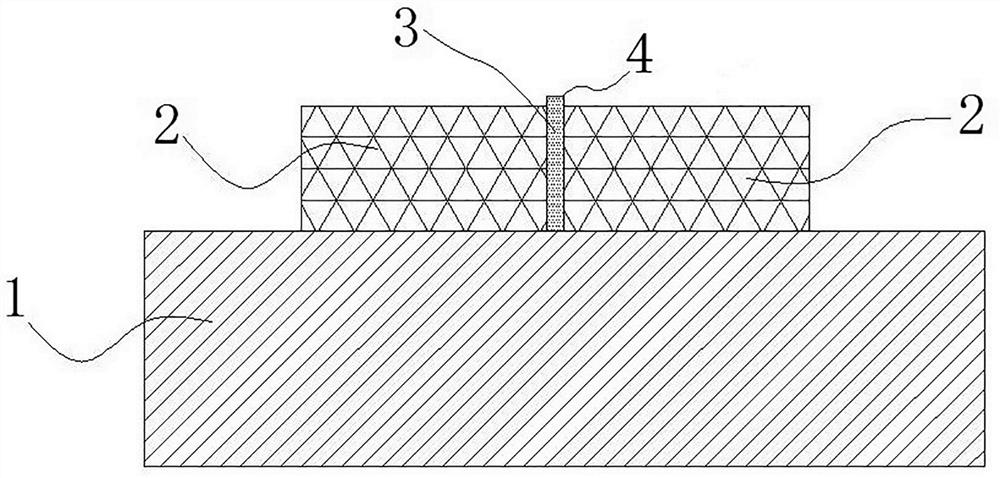

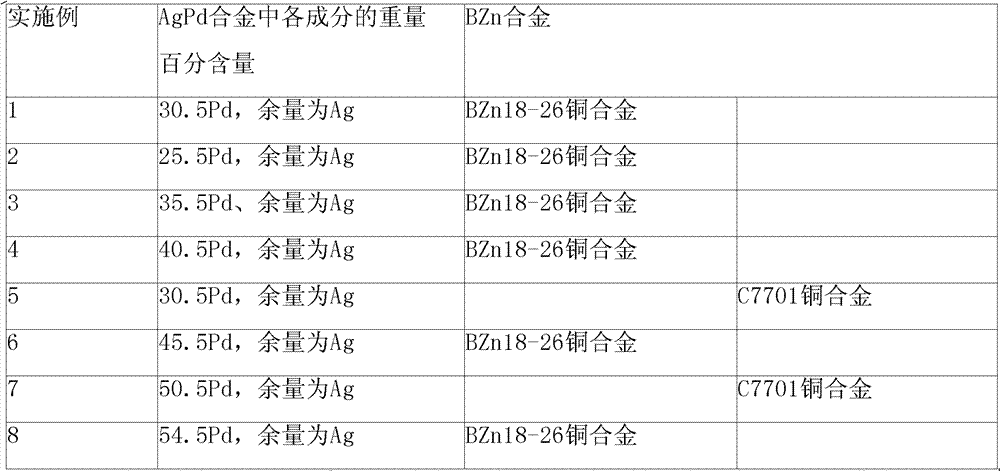

Silver palladium/packfong stratiform composite material and preparation method

ActiveCN101924313AGood interfacial bonding strengthReduce volatilityRotary current collectorBrushes manufactureCupronickelAlloy surface

The invention relates to a silver palladium / packfong stratiform composite material and a preparation method. The silver palladium / packfong stratiform composite material is characterized by being composed of a BZn alloy the surface of which is coated with metallic nickel and AgPd, wherein the AgPd is a work layer and the BZn is a basement layer. The preparation method of the material comprises thefollowing steps: adopting sulfamate continuous strip plating to plate a metal nickel layer on a BZn copper alloy surface; and carrying out hot rolled cladding on the AgPd alloy under the protection of nitrogen or hydrogen or the mixed gas of nitrogen and hydrogen. In the method of the invention, a metal nickel layer is plated on the BZn surface so as to control volatilization of Zn, thereby reducing deposition and enrichment of Zn on the surface of the AgPd layer, improving metal luster thereof, increasing initial usability of a brush material and satisfying requirements from high-end users.

Owner:CHONGQING CHUANYI AUTOMATION

A kind of production method of ceramic sheet for ceramic package base

ActiveCN112589976BMeet the precision requirementsHigh dimensional accuracyCeramic shaping apparatusComposite materialGreen body

The invention relates to a method for producing ceramic sheets for ceramic packaging bases, comprising the following steps: step 1, making ceramic green sheets, and dividing the plate-shaped ceramic green sheets into a plurality of ceramic green sheets; step 2, making ceramic green sheets for each The ceramic green sheet is cut and trimmed during the process; step 3, the ceramic green sheet trimmed in step 2 is sintered and hardened to obtain a ceramic sheet. In the production process, the ceramic green sheet is produced first, and based on the relatively low hardness of the ceramic green sheet, the ceramic green sheet is cut and trimmed during the process, so that the size of the produced ceramic sheet can easily meet the accuracy requirements .

Owner:瓷金科技(河南)有限公司

A kind of repaglinide tablet and preparation method thereof

ActiveCN103610677BAvoid stickingGood dispersionOrganic active ingredientsMetabolism disorderMedicineDissolution

The invention relates to an oral troche which contains repaglinide or pharmaceutically acceptable derivatives of repaglinide as well as a preparation method of the oral troche. According to the preparation method, powder of repaglinide or pharmaceutically acceptable derivatives of repaglinide is directly pressed into troche, so that the production cost is remarkably lowered, and the disintegration and the dissolution rate are greatly improved. The bioavailability and the stability of the medicine can be improved, and the problem of low content uniformity of existing small-dose medicines formed by the direct pressing method is overcome, so that the quality of the troche is better guaranteed.

Owner:华益泰康药业股份有限公司

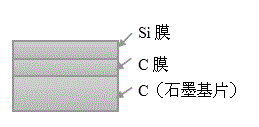

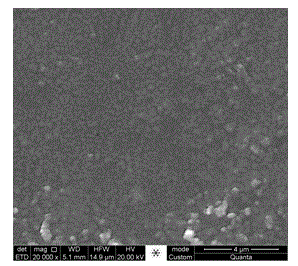

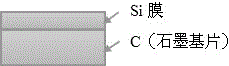

Preparation process of novel C/Si film

InactiveCN104651789AIncrease temperatureSimple structureVacuum evaporation coatingSputtering coatingCarbon layerSputtering

The invention discloses a preparation process of a novel C / Si film. The preparation method comprises the following steps: fixing a graphite substrate in a sputtering cavity for magnetron sputtering; with carbon as a target material, sputtering carbon in an argon atmosphere so that carbon is deposited on the surface of the graphite substrate to form a new carbon layer; then, carrying out thermal evaporation on a sample subjected to sputtering so as to form a Si film in a vacuum deposition way, thus forming a C / Si thin film; and finally annealing in a annealing furnace.

Owner:鞠云

Well salt fruit juice drink and manufacture method thereof

Well salt fruit juice beverage, for each ton of beverage, the amount of sugar 40-45, high fructose syrup 40-45, sodium citrate 0.3-0.5, citric acid 1.1-1.6, D-sodium erythorbate 0.2-0.5, edible well salt 0.55-0.8, Vitamin C 0.2-0.4, potassium sorbate 0.3-0.5, fruit juice concentrate 3.5-12 are prepared by adding water; the above components are in kilograms, and the remaining components are water. The invention also discloses a manufacturing method of a well salt fruit juice drink. The well salt fruit juice drink of the present invention is used, white granulated sugar and fruit juice are added to improve the taste of the drink, and the well salt is used to generate free carbon dioxide gas by utilizing the carbonate therein, and at the same time, the The effect of well salt metal ions on the hardness of beverages, and the iron ions in the juice were also adjusted to facilitate better absorption.

Owner:SICHUAN LUOYUAN FOOD CO LTD

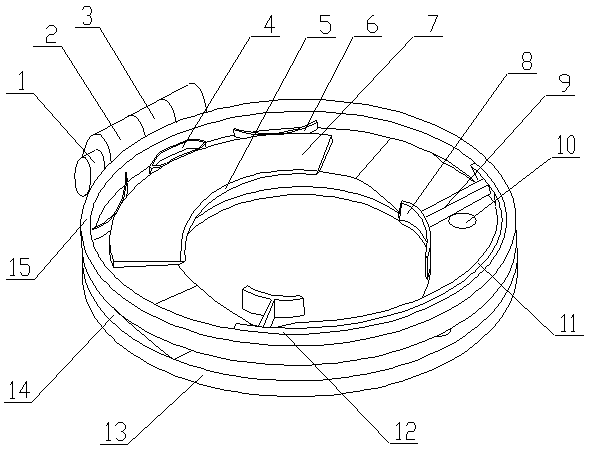

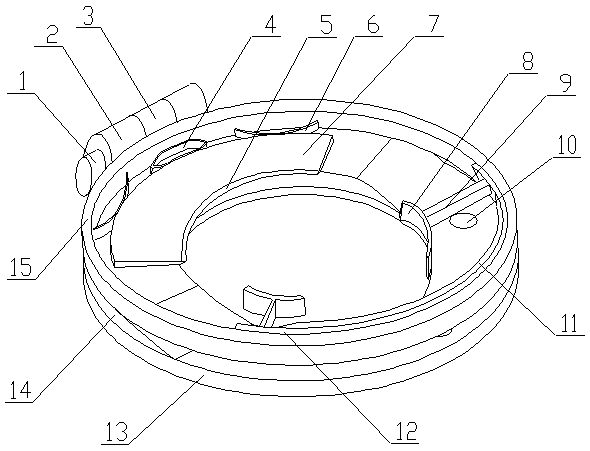

Building construction plastic tube bending device

The invention relates to a building construction plastic tube bending device, and discloses a device for carrying out bending on a single plastic tube by a size of a clamping angle between a base anda towing ring and matching of heating of a heating plate. The building construction plastic tube bending device is characterized in that a base plate is arranged on the base; the base is of a ring-shaped structure; a rubber cushion is arranged in an inner ring of the base; the base is provided with a plurality of fixed holes; the base plate is of a semicircle shape and bevel angles are respectively formed at both ends of the base plate; a thickness of the base plate is equal to that of the base; a power shaft sleeves the outer edge of the base by two connection sleeves and is positioned at themiddle position of the base plate; the outside of the towing ring is hinged with the power shaft by a hinged sleeve; the towing ring is made of a rigid material; a supporting ring is arranged on theinner wall of the towing ring and corresponds to the hinged sleeve; the supporting ring is of a hexagon shape; an inner supporting plate is of an arc structure; the middle part of the outside of the inner supporting plate is arranged on the supporting ring.

Owner:中铁十八局集团北京工程有限公司

Fireproof high-strength plastic floor material and preparation method thereof

The invention discloses a fireproof high-strength plastic floor material. The fireproof high-strength plastic floor material comprises, by weight, 50-70 parts of chlorohydrine rubber, 21-33 parts of silicon resin, 6-13 parts of ultrafine zirconia ceramic powder, 8-17 parts of urea formaldehyde melamine resin, 4-9 parts of zinc powder, 3-10 parts of magnesium silicate, 3-8 parts of sea-foam stone powder, 2-6 parts of antimony trioxide, 3-9 parts of triglycidyl propyl ether, 2-7 parts of phenyl petroleum sulfonate, 4-10 parts of di(tert-butylperoxyisopropyl)benzene, 4-11 parts of dioctyl phthalate, 3-8 parts of terpene resin, 1-4 parts of coupling agent and 1-5 parts of anti-aging agent. The invention further discloses a preparation method of the fireproof high-strength plastic floor material. The prepared fireproof high-strength plastic floor material has the advantages that a hardness value ranges from 51 to 58, abradability is 21.5-25.31 / cm<2>, flame retardant rating is I, and various performance indexes meet practical application requirements, so that the service life of the plastic floor material can be prolonged and customer satisfaction can be improved.

Owner:郑州峰泰纳米材料有限公司

Novel SiC film preparing process

InactiveCN105088174ARelief of residual stressIncreased structural and chemical orderVacuum evaporation coatingSputtering coatingSilicon particleGraphite substrate

The invention discloses a novel SiC film preparing process. The novel SiC film preparing process is characterized in that the process includes the following steps that a resistance-type thermal evaporation device is adopted, silicon particles are evaporated on a graphite substrate, atoms or molecules of the silicon particles can be gasified from the surface under the vacuum condition, a silicon steam flow is formed and enters the graphite substrate with the lower temperature in an incidence manner, and a solid Si film is formed to be annealed in an annealing furnace.

Owner:鞠云

Reaction resin comprising core-shell particles and method for the production thereof and the use thereof

The invention relates to a composition comprising (A) 50 - 99.5 weight % of a reaction resin or a reaction resin mixture that can be processed into a thermosetting material and is liquid at temperatures in the range from 15 to 100 DEG C and has an average molecular weight of 200 to 500,000, and having a sufficient number of suitable reactive groups for the curing process, and (B) 0.5 to 50 weight% of one or more three-dimensionally cross-linked redispersed polyorganosiloxane rubbers, which are homogenously present in the reaction resin or reaction resin mixture in a finely distributed form aspolyorganosiloxane rubber particles having a diameter of 0.001 to 0.4 [mu]m, the polyorganosiloxane rubber particles being made of a core (a) made of a silicone-organic polymer and an organopolymer shell (d) and optionally two inner shells (b) and (c), the inner shell (c) being an organic polymer and the inner shell (b) being a silicone-organic polymer, comprising (a) 20 to 95 weight %, relativeto the total weight of the polyorganosiloxane rubber particle, of a core polymer of the general formula (R3SiO1 / 2)w(R2SiO2 / 2)x.(RSiO3 / 2)y.(SiO4 / 2)z, wherein w = 0 to 20 Mol %, x = 80 to 99.5 Mol%, y =0.5 to 10 Mol%, z = 0 to 10 Mol%, (b) 0 to 40 weight %, relative to the total weight of the polyorganosiloxane rubber particle, of a polydialkylsiloxane shell made of units of the formula (R3SiO1 / 2)w(R2SiO2 / 2) x.(RSiO3 / 2) y.(SiO4 / 2)z, wherein w = 0 to 20 Mol %, x = 0 to 99.5 Mol%, y = 0.5 to 100 Mol%, z = 0 to 50 Mol%, (c) 0 to 40 weight %, relative to the total weight of the polyorganosiloxane rubber particle, of a shell made of organopolymer monoolefinically or polyolefinically unsaturated monomers, and (d) 5 to 95 weight %, relative to the total weight of the polyorganosiloxane rubber particle, of a shell made of organopolymer monoolefinically unsaturated monomers, wherein R means identical or different monovalent alkyl or alkenyl radicals having 1 to 6 carbon atoms, aryl radicals, orsubstituted hydrocarbon radicals.

Owner:WACKER CHEM GMBH

A construction plastic pipe bending device

The invention relates to a building construction plastic tube bending device, and discloses a device for carrying out bending on a single plastic tube by a size of a clamping angle between a base anda towing ring and matching of heating of a heating plate. The building construction plastic tube bending device is characterized in that a base plate is arranged on the base; the base is of a ring-shaped structure; a rubber cushion is arranged in an inner ring of the base; the base is provided with a plurality of fixed holes; the base plate is of a semicircle shape and bevel angles are respectively formed at both ends of the base plate; a thickness of the base plate is equal to that of the base; a power shaft sleeves the outer edge of the base by two connection sleeves and is positioned at themiddle position of the base plate; the outside of the towing ring is hinged with the power shaft by a hinged sleeve; the towing ring is made of a rigid material; a supporting ring is arranged on theinner wall of the towing ring and corresponds to the hinged sleeve; the supporting ring is of a hexagon shape; an inner supporting plate is of an arc structure; the middle part of the outside of the inner supporting plate is arranged on the supporting ring.

Owner:中铁十八局集团北京工程有限公司

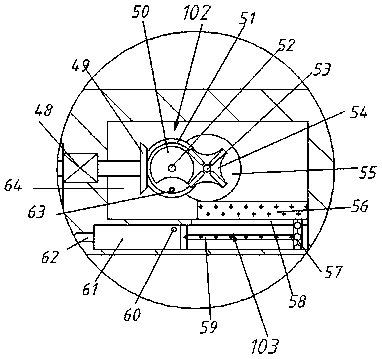

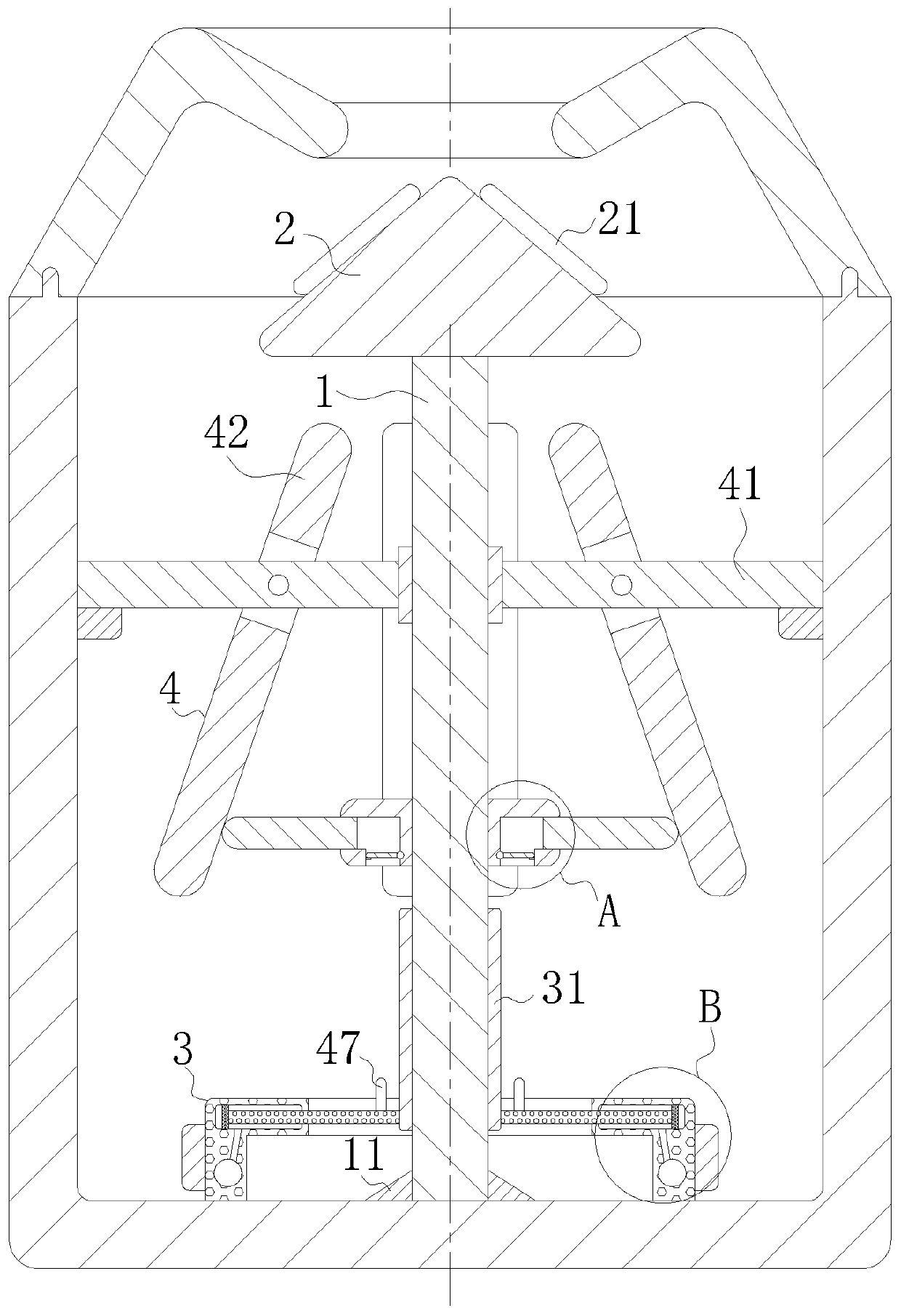

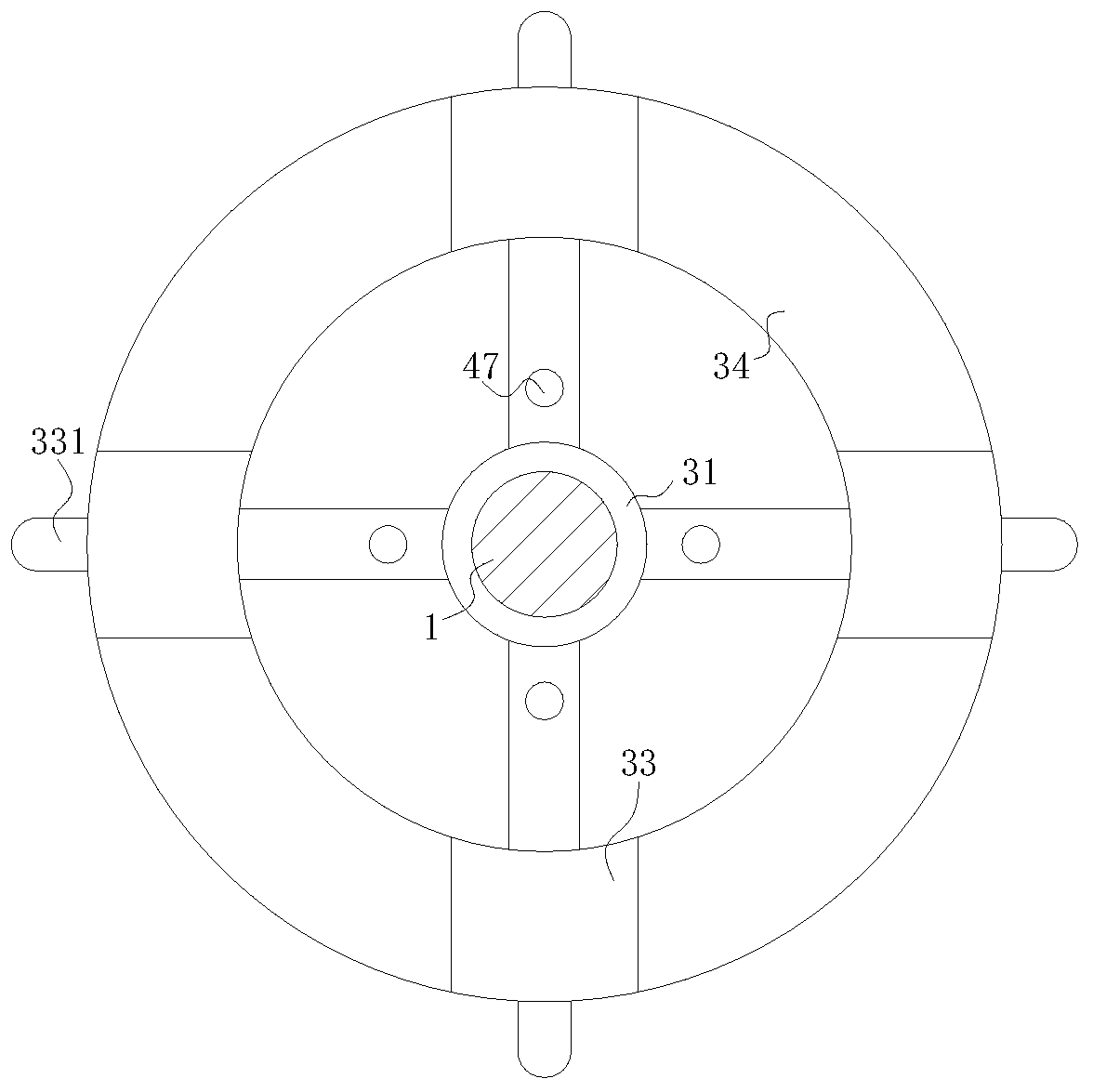

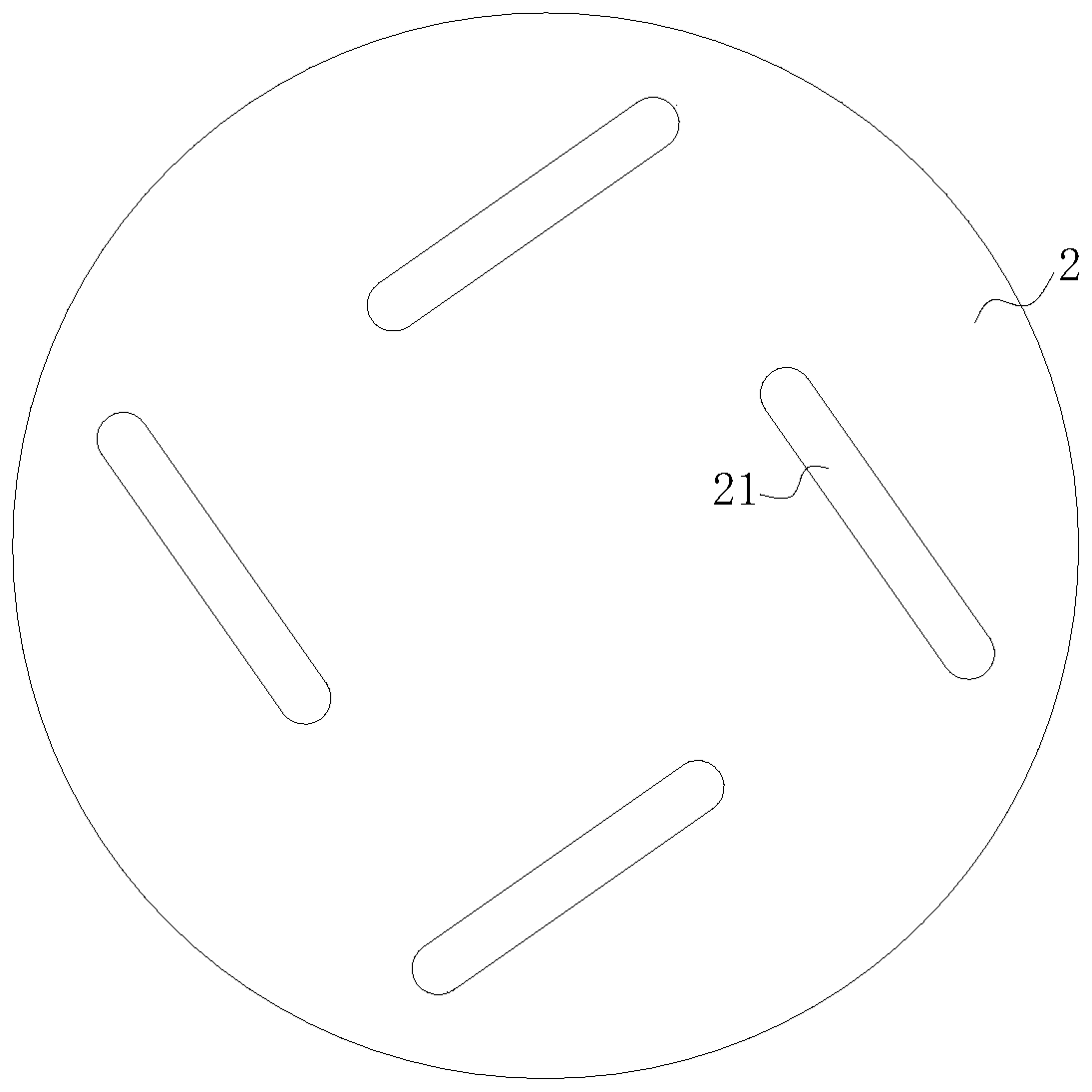

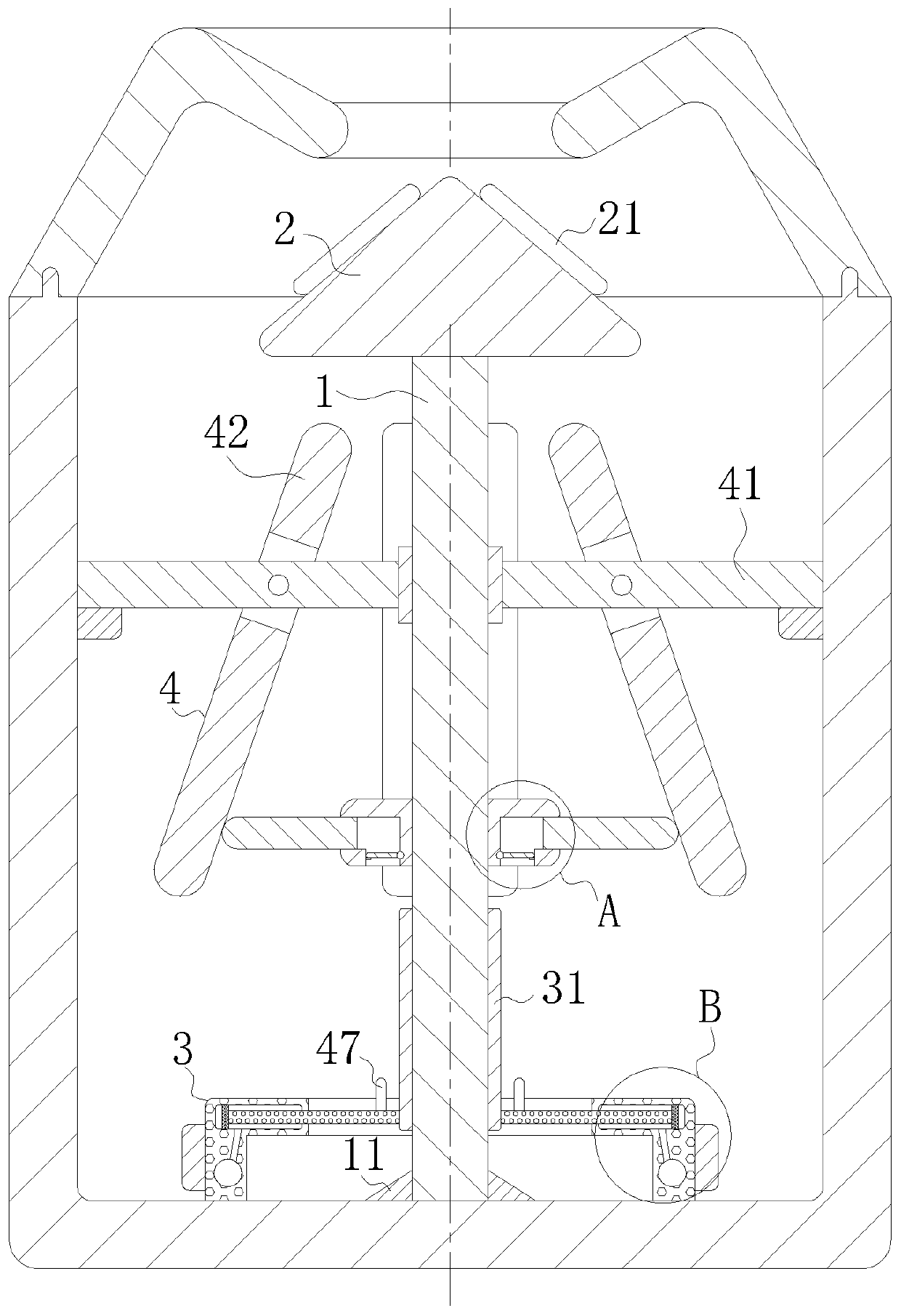

High-creep-ratio and high-strength hydraulic motor body shell blank casting technology

ActiveCN110170621AImprove structural strengthAvoid affecting creep efficiencyProcess efficiency improvementGas emission reductionHydraulic motorControl engineering

The invention belongs to the technical field of motor casting and particularly relates to a high-creep-ratio and high-strength hydraulic motor body shell blank casting technology. A creeping device isincluded and comprises a rotating rod, a rotating block, an isolation mechanism and a scattering mechanism. The rotating rod is arranged in a ladle, and the isolation mechanism is arranged at the lower end of the rotating rod. The rotating block is fixedly connected to the upper end of the rotating rod, and the scattering mechanism is arranged at the middle portion of the rotating rod. The rotating block is arranged at the upper side of the interior of the ladle. The isolation mechanism comprises an installation ring, a connecting rod, a moving block and a connecting block. The connecting rodis fixedly connected to the outer surface of the installation ring. The high-creep-ratio and high-strength hydraulic motor body shell blank casting technology is mainly used for solving the problemsthat in the casting technology at present, when a crushing method is commonly used for producing vermicular graphite cast iron, molten iron and a vermicular agent can generate relative impacts, the vermicular agent is not detonated at the bottom or is detonated too early, the absorption rate of the molten iron on the vermicular agent is reduced, creeping is poor, and tensile strength and hardnessof a hydraulic motor body shell are affected.

Owner:ANHUI DATIAN CASTING

A processing method of an automobile one-axis forging die

ActiveCN105643222BEasy to homogenizeUniform tissueMetal-working apparatusFurnace typesHardnessMechanical property

The invention discloses a method for processing an automobile uniaxial forging die and belongs to the field of die processing. The method comprises the steps of preparing raw materials; performing three-compacting three-pulling forging treatment on bars, and enabling the forging ratio to be 3.8-4; performing annealing treatment and machining treated workblank; after rough machining, performing quenching and three-time tempering to make the die hardness be 46-47; and finally performing finish machining, perform fourth-time tempering to remove cutting stress. According to the technical scheme, through the improvement of material compositions and a heating processing technology, the mechanical property of the forging die is improved, tissue grains are refined, and the service life of the forging die is prolonged.

Owner:MAANSHAN CHANGYE HEAVY IND TECH

A blank casting process for high creep rate and high strength hydraulic motor shell

ActiveCN110170621BImprove structural strengthAvoid affecting creep efficiencyProcess efficiency improvementGas emission reductionHydraulic motorEngineering

Owner:ANHUI DATIAN CASTING

Silver palladium/packfong stratiform composite material and preparation method

ActiveCN101924313BReduce volatilityReduce Zn contentRotary current collectorMetal layered productsHydrogenCupronickel

Owner:CHONGQING CHUANYI AUTOMATION

Method for constructing copper wire on wafer and chemical mechanical polishing (CMP) method for copper

ActiveCN101958273BHardness effectReduce sagSemiconductor/solid-state device manufacturingDielectricCopper wire

The invention discloses a method for constructing a copper wire on a wafer, which comprises the following steps of: depositing a first interlayer dielectric on the upper surface of the wafer; constructing a second interlayer dielectric on the upper surface of the first interlayer dielectric of the wafer, wherein the hardness of the second interlayer dielectric is lower than that of the first interlayer dielectric; photoetching the second interlayer dielectric and the first interlayer dielectric to define a groove structure, wherein the bottom of the groove structure is positioned in the firstinterlayer dielectric; sequentially depositing a barrier layer and a copper seed crystal layer on the upper surface of the wafer and the inner wall of a groove; depositing copper on the upper surfaceof the wafer, wherein the copper is filled in the groove to form the copper wire; and performing chemical mechanical polishing (CMP) on the wafer to reach the first interlayer dielectric so as to make the upper surface of the wafer subjected to planarization. The invention also discloses a CMP method for the copper. The sinking degree of the surface of the copper wire constructed by the scheme ofthe invention is reduced to a certain extent compared with that of the prior art.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A kind of processing method of piston forging die

The invention discloses a machining method for a piston forging mould, belonging to the field of mould machining. The machining method comprises the following machining steps that raw materials are prepared, namely a rod material is subjected to three-upsetting and three-drawing forging process, wherein the forging ratio is 3.8-4; then annealing is performed, and a blank subjected to annealing is machined; then the blank is subjected to four times of electrosparking after rough machining, so that a cavity is machined in place; then quenching and three times of tempering are performed, so that the hardness of the mould reaches 46-47; and finally finish machining is performed, and then a fourth time of tempering is performed, so that cutting stress is removed. According to the technical scheme of the machining method, the components of materials and the machining process are improved, so that the mechanical performance of the forging mould is improved; the machining precision of the mould is improved; the phenomena of fatiguing and cracking of the mould are alleviated; and the service life of the mould is prolonged.

Owner:MAANSHAN CHANGYE HEAVY IND TECH

Mulberry leaf noodles and preparation method thereof

PendingCN114532486AHardness effectSmall granularityClimate change adaptationFood ingredient functionsBiotechnologyWheat starch

According to the mulberry leaf noodles and the preparation method thereof, the wheat flour is subjected to pre-dough kneading through a vacuum dough kneading machine, gluten protein in the wheat flour and wheat starch form a network structure in one step, then the mulberry leaf powder subjected to superfine grinding is added, then dough kneading is conducted through the vacuum dough kneading machine, the mulberry leaf powder is evenly wrapped in the starch-protein structure, and the mulberry leaf noodles are obtained. The noodles prepared by the method are rich in nutrition and moderate in hardness, and meanwhile, a starch-protein structure in the noodles cannot be damaged due to the fact that dietary fibers in the mulberry leaf powder absorb water and swell in the boiling process, so that the breaking rate of the noodles is reduced.

Owner:SICHUAN MOSUN PHARMA LTD

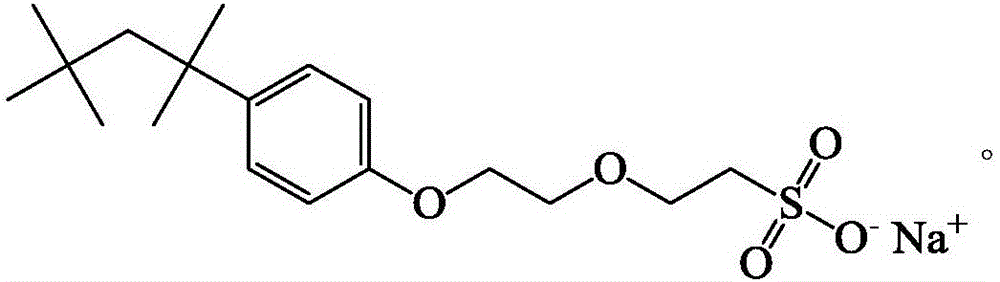

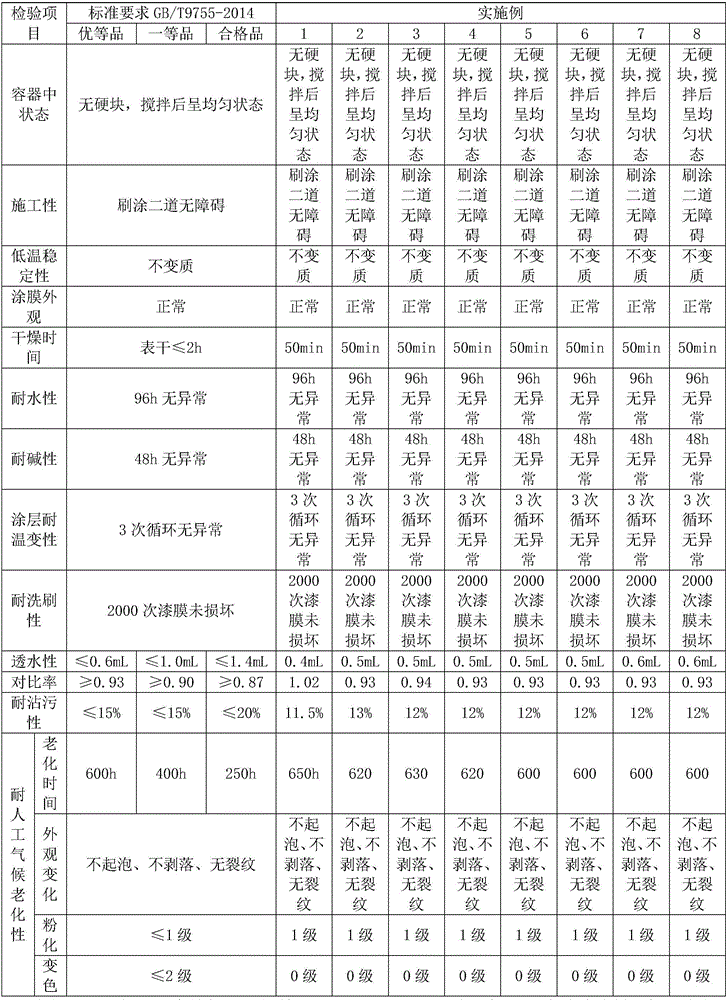

High-strength weather-resistant paint and preparation process thereof

The invention discloses high-strength weather-resistant paint and a preparation process thereof. The high-strength weather-resistant paint comprises the following raw materials in parts by mass: 25-35 parts of waterborne emulsion, 15-25 parts of rutile titanium dioxide, 20-35 parts of high-purity silicon dioxide powder, 15-20 parts of water, 2-5 parts of hydroxyethyl cellulose, 3-7 parts of ethylene glycol, 0.0001-0.0002 part of a dispersing agent, 0.0001-0.0002 part of a wetting agent, 0.0001-0.0002 part of an antifoaming agent, 0.0001-0.0002 part of coalescing agents, 0.0001-0.0002 part of a pH regulator, 0.0001-0.0002 part of a flatting agent and 0.0001-0.0002 part of thickening agent. The paint has high alkali resistance and film hardness.

Owner:北京蓝彬尚科涂料科技有限公司

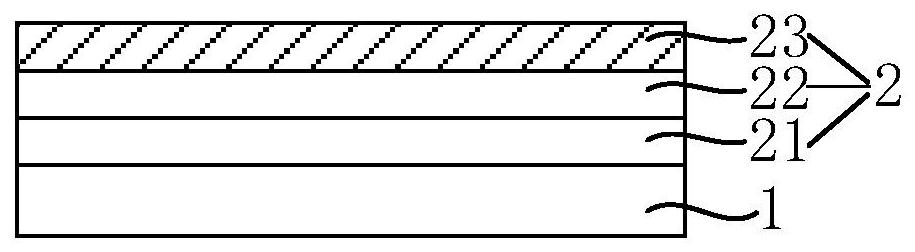

Electronic product part, composition for paint layer of electronic product part and electronic product

PendingCN113913102AImprove wear resistanceReduce coefficient of frictionPolyurea/polyurethane coatingsEpoxy resin coatingsPolymer sciencePhotoinitiator

The invention relates to the technical field of electronic products, in particular to an electronic product part, a composition for a paint layer of the electronic product part and an electronic product. The purpose of the invention is to solve the problems that the brittleness of a paint layer is increased and brittle collapse easily occurs due to the fact that the hardness of the paint layer is changed by changing the crosslinking degree of a resin material and changing the types of the resin material and a photoinitiator in related technologies. The invention provides the composition for the paint layer of the electronic product part. The composition comprises reactant molecules and an additive, the reactant molecules comprise monomer molecules and / or prepolymer molecules, and the monomer molecules and / or prepolymer molecules can be subjected to a cross-linking reaction under preset conditions; the additive comprises a wear-resistant inorganic filler and / or a lubricant, the wear-resistant inorganic filler is powdery or microspherical and can be dispersed in the reactant molecules, and the lubricant does not chemically react with the reactant molecules and other additives except the lubricant in the additive.

Owner:HONOR DEVICE CO LTD

A kind of fireproof high-strength plastic floor material and preparation method thereof

The invention discloses a fireproof high-strength plastic floor material. The fireproof high-strength plastic floor material comprises, by weight, 50-70 parts of chlorohydrine rubber, 21-33 parts of silicon resin, 6-13 parts of ultrafine zirconia ceramic powder, 8-17 parts of urea formaldehyde melamine resin, 4-9 parts of zinc powder, 3-10 parts of magnesium silicate, 3-8 parts of sea-foam stone powder, 2-6 parts of antimony trioxide, 3-9 parts of triglycidyl propyl ether, 2-7 parts of phenyl petroleum sulfonate, 4-10 parts of di(tert-butylperoxyisopropyl)benzene, 4-11 parts of dioctyl phthalate, 3-8 parts of terpene resin, 1-4 parts of coupling agent and 1-5 parts of anti-aging agent. The invention further discloses a preparation method of the fireproof high-strength plastic floor material. The prepared fireproof high-strength plastic floor material has the advantages that a hardness value ranges from 51 to 58, abradability is 21.5-25.31 / cm<2>, flame retardant rating is I, and various performance indexes meet practical application requirements, so that the service life of the plastic floor material can be prolonged and customer satisfaction can be improved.

Owner:郑州峰泰纳米材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com