Production method of ceramic chips for ceramic packaging base

A technology of ceramic packaging and production methods, which is applied in the direction of ceramic molding machines and manufacturing tools, can solve the problems of dimensional accuracy and side flatness that cannot meet high-precision requirements, and achieve the effect of high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

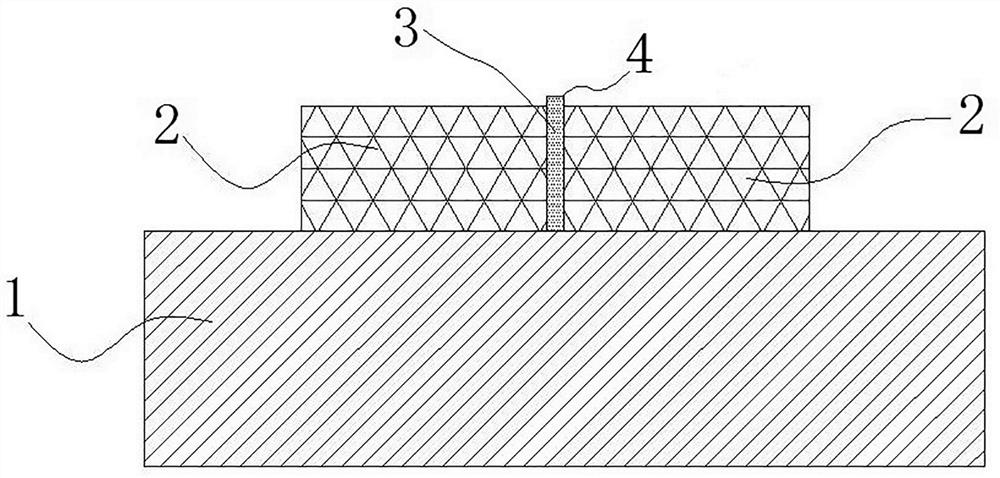

Image

Examples

Embodiment 2

[0046] Embodiment 2 of the method for producing ceramic sheets for ceramic packaging bases in the present invention, the difference between this embodiment and Embodiment 1 is that in this embodiment, only one fixing block is provided, and the fixing block is a stepped fixing block , the fixed block is provided with four cutting reference planes, which are respectively used for cutting and trimming the two sides opposite in the length direction and the two sides opposite in the width direction. When in use, press the ceramic green sheet on the side of the fixed block with fingers Then cut the corresponding sides according to the cutting datum.

Embodiment 3

[0047] Embodiment 3 of the method for producing a ceramic sheet for a ceramic package base in the present invention, the difference between this embodiment and Embodiment 1 is that in this embodiment, when cutting and trimming the ceramic green sheet, the ceramic green sheet The slices are squared, and the corresponding sides are cut and trimmed with a cutter.

Embodiment 4

[0048] Embodiment 4 of the method for producing ceramic sheets for ceramic packaging bases in the present invention, the difference between this embodiment and Embodiment 1 is that in this embodiment, when making ceramic green sheets, the ceramic green sheets are directly cut by a cutter. The green sheet is cut to obtain ceramic green sheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com