A kind of repaglinide tablet and preparation method thereof

A tablet and formula technology, applied in the field of pharmaceutical preparations, can solve problems such as content reduction, complicated operation steps, and uneven particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

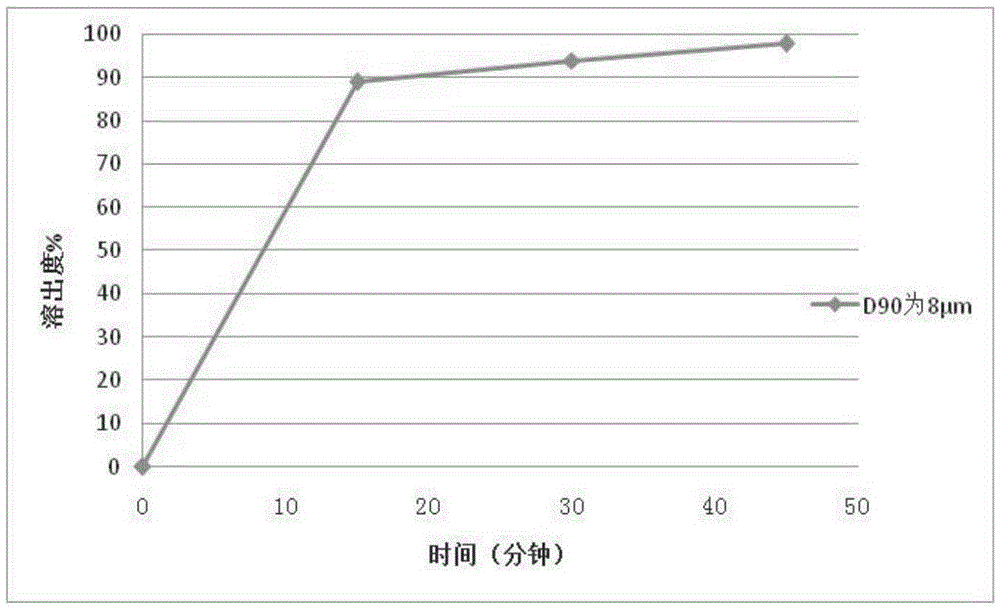

[0101] Example 1 Preparation of Repaglinide Tablets by Powder Direct Compression

[0102] Adopt commercially available repaglinide crude drug, pulverize with a jet mill, and detect the particle size after pulverization; repeat pulverization as required until the particle size is D 90 =8μm. The tablet prescription is shown in Table 1:

[0103] Table 1: Prescription for 1000 repaglinide tablets (2mg / tablet)

[0104] #

Material

1000 prescription quantity (g)

Percentage (%)

1

Repaglinide (8μm)

2

2

2

40

40

3

0.15

0.15

4

Poloxamer 188

2

2

5

Microcrystalline Cellulose PH102

54.15

54.15

6

Crospovidone

1

1

7

0.5

0.5

8

red iron oxide

0.2

0.2

[0105] Described tablet adopts direct compression method to prepare, and concrete steps are:

[0106] A. Pre-...

Embodiment 2

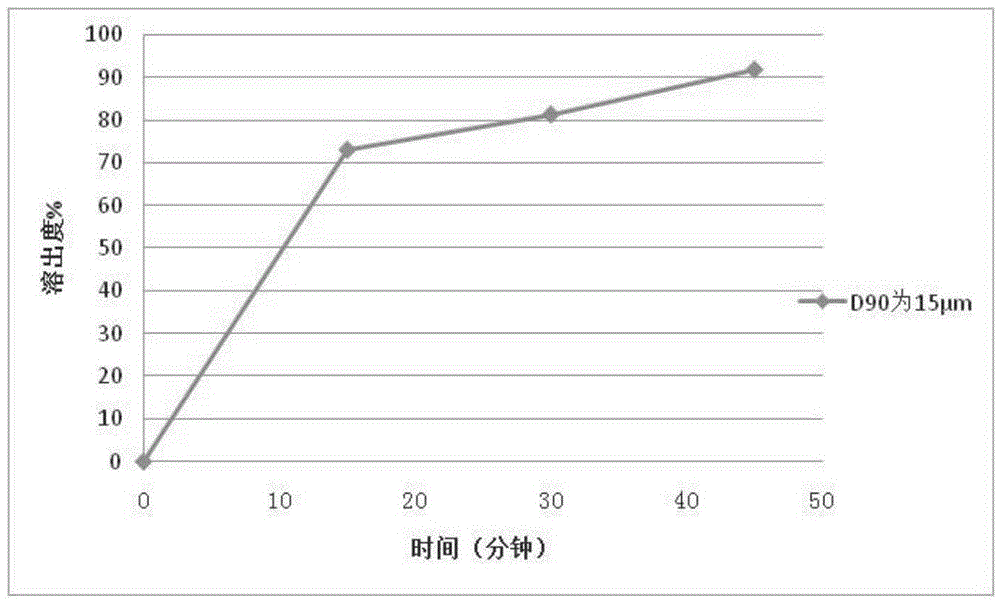

[0113] Example 2 Preparation of Repaglinide Tablets by Powder Direct Compression

[0114] Using the same prescription and process method in Example 1 to prepare 2mg / tablets, the difference is that the particle size D of repaglinide 90 is 15 μm.

Embodiment 3

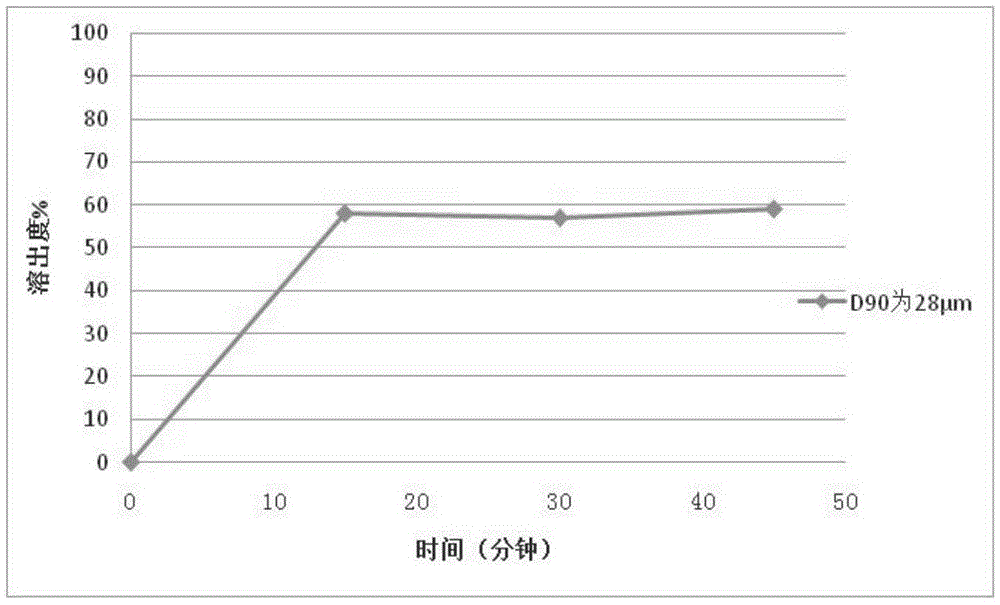

[0115] Example 3 Preparation of Repaglinide Tablets by Powder Direct Compression

[0116] Using the same prescription and process method in Example 1 to prepare 2mg / tablets, the difference is that the particle size D of repaglinide 90 is 28 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com