Patents

Literature

343results about How to "Efficiency is not affected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

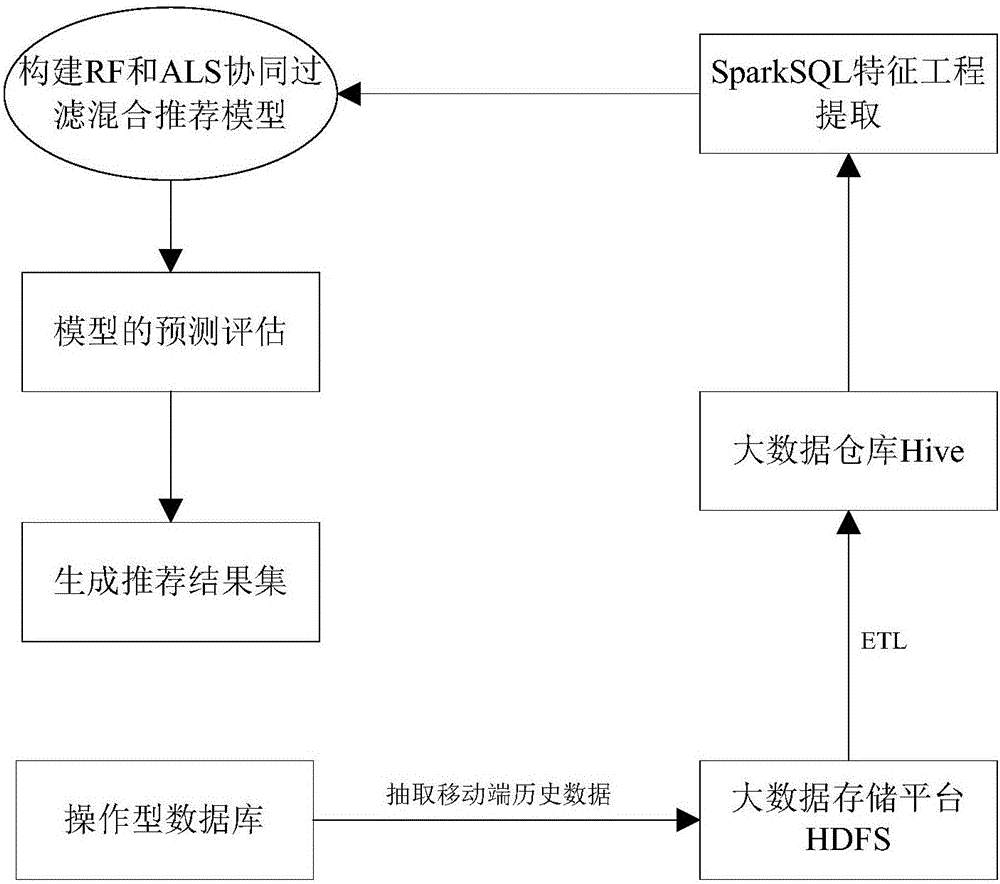

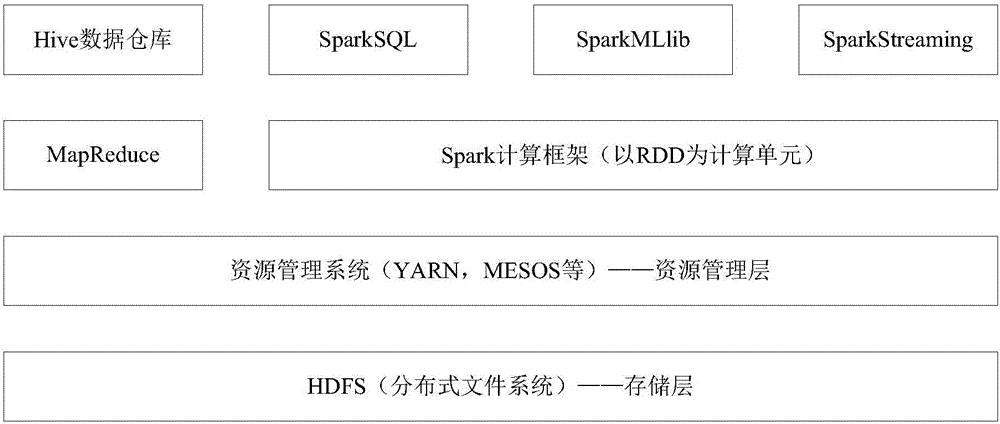

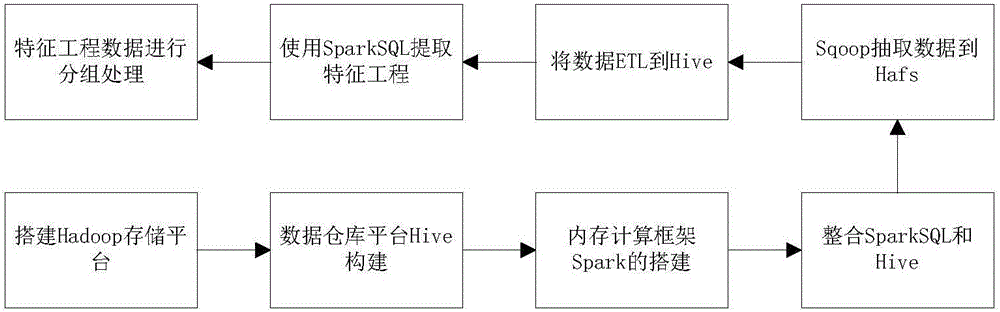

Spark-based big data hybrid model mobile recommending method

InactiveCN106056427AAvoid the pitfalls of using it aloneEfficiency is not affectedCharacter and pattern recognitionBuying/selling/leasing transactionsData setData platform

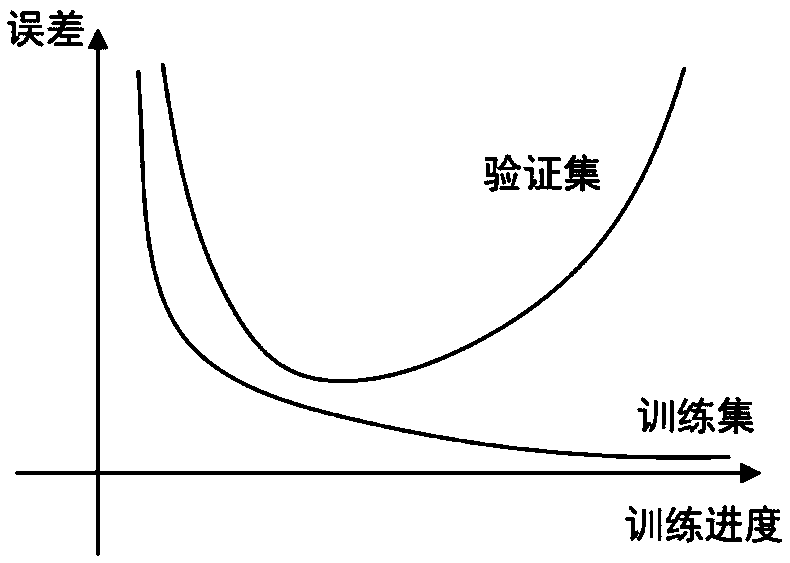

The invention puts forward a Spark-based big data hybrid model mobile recommending method comprising four steps as follows: firstly, getting a user's commodity purchase data at a mobile end; secondly, extracting user historical data from a database and importing the user historical data to an HDFS, and extracting features, such as user behavior features, brand features, user's personal consumption features and cross features; thirdly, packaging a hybrid model on a Spark platform using an RDD operator, and embedding the model interface into a big data platform for calling; and fourthly, calling the hybrid model interface to extract feature data, setting training parameters of the model, and training the hybrid model. The model is estimated using a test data set and optimized, the trained hybrid model is saved, and relevant recommendation is made. The method can effectively improve the efficiency of recommendation under the condition of a larger amount of data and higher data sparseness.

Owner:CENT SOUTH UNIV

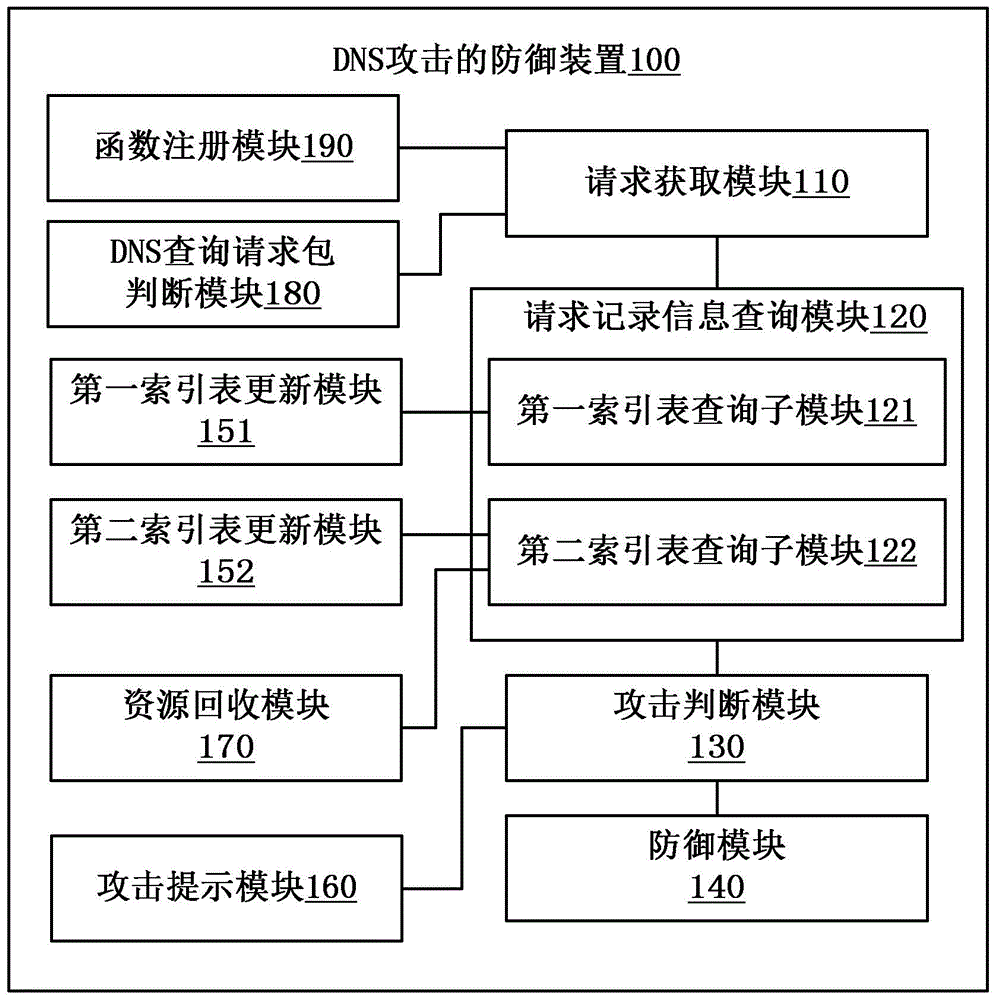

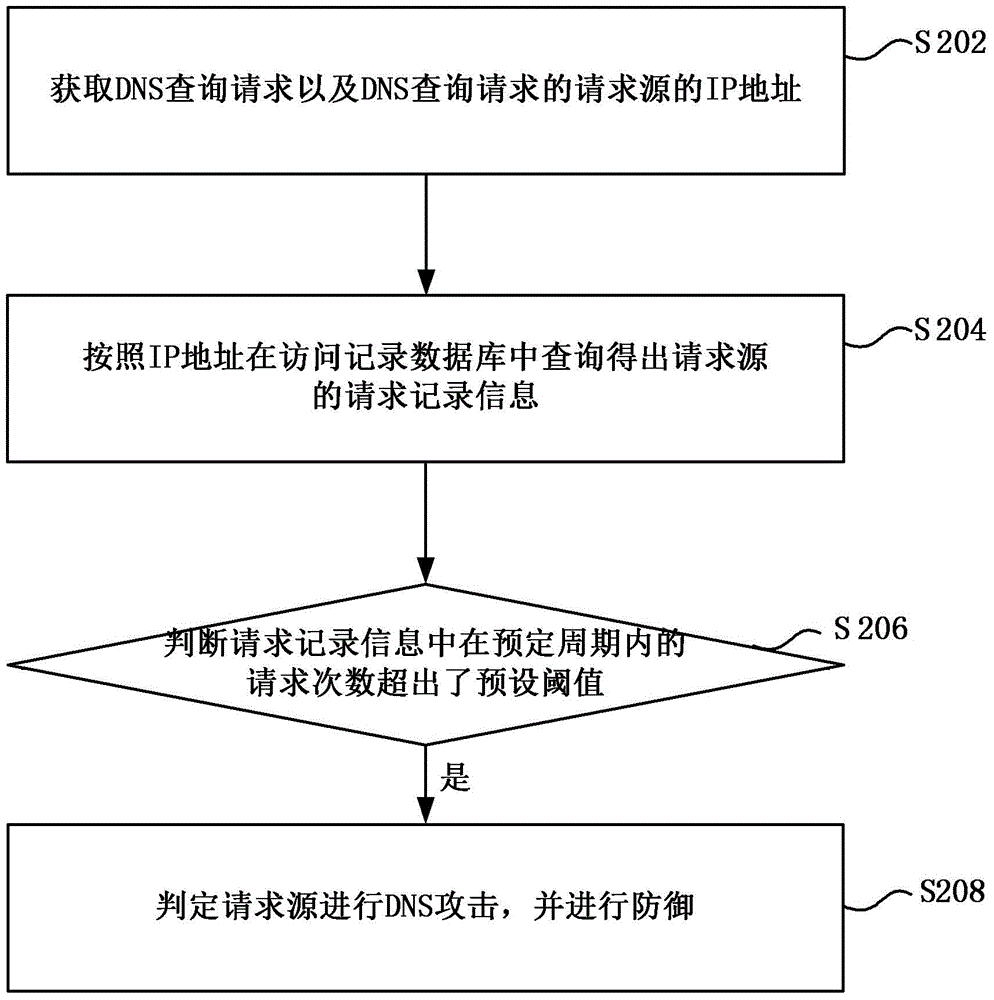

DNS system and defense method and device for DNS attack

ActiveCN103957195AWill not affect normal accessPrecision Attack DefenseTransmissionIp addressData library

The invention provides a DNS system and a defense method and device for a DNS attack. The defense method includes the steps that a DNS inquiry request and an IP address of a request source of the DNS inquiry request are obtained; according to the IP address, request record information where the request source is located is inquired in an access record database; whether the number of times of requests within a predetermined cycle in the request record information exceeds a preset threshold value or not is judged; if yes, the request source is judged to perform the DNS attack, and accordingly defense is performed. Because IP addresses of all the request sources are judged without affecting normal access of other request sources, precise attack defense is achieved.

Owner:BEIJING QIHOO TECH CO LTD +2

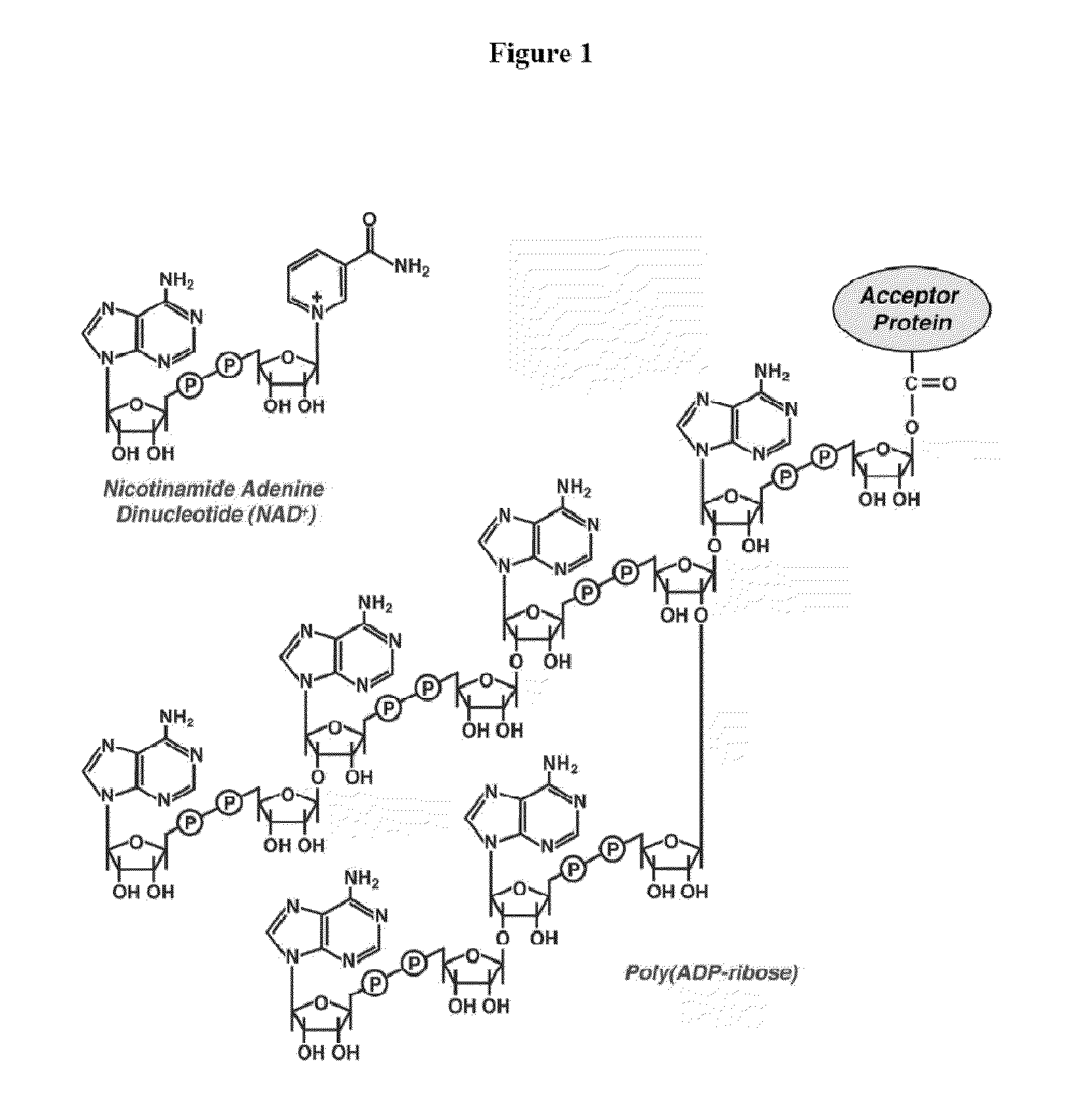

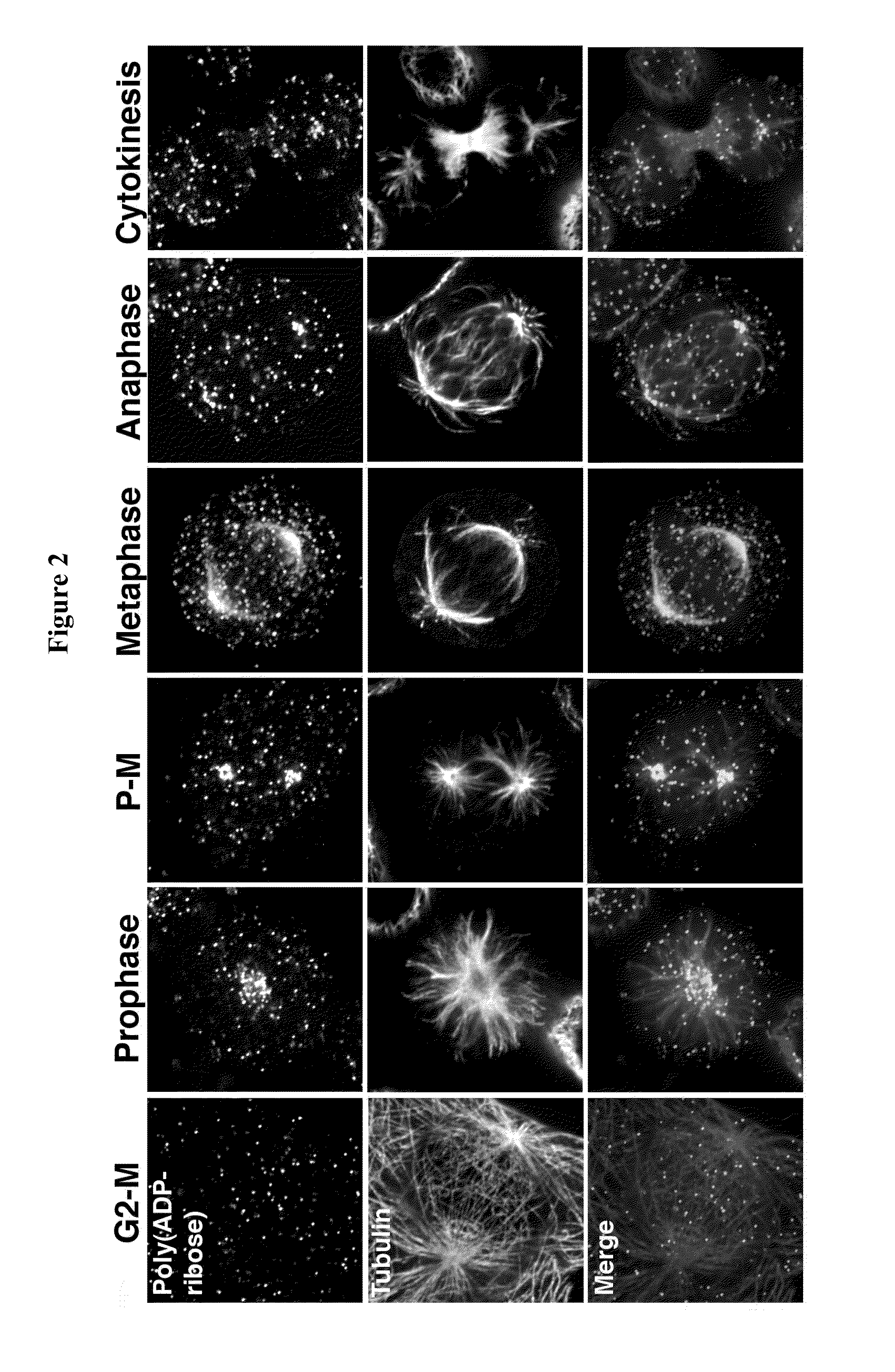

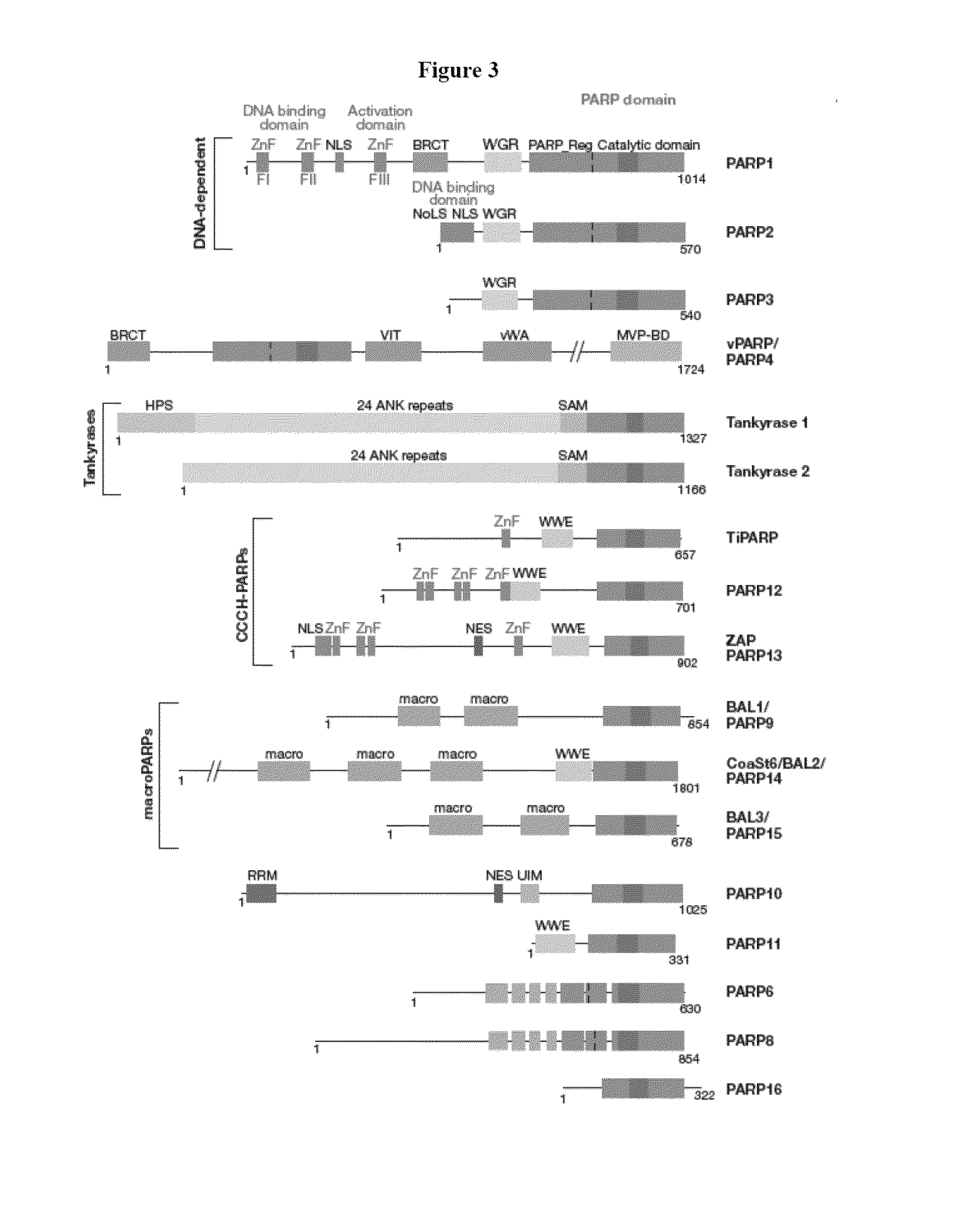

Compositions and methods for treating cancer and modulating stress granule formation

ActiveUS20130156776A1Reduce the possibilityImprove stabilityCompound screeningOrganic active ingredientsEnzyme activatorPharmaceutical drug

The invention provides methods for treating or decreasing the likelihood of developing a stress-granule related disorder and / or cancer by administering one or more poly-ADP-ribose polymerase (PARP) inhibitors, one or more PARP activators, one or more poly-ADP-ribose glycosylase (PARG) activators, and / or one or more poly-ADP-ribose glycohydrolase ARH3 activators. The invention also provides corresponding methods of decreasing stress granule formation and / or proliferation in a cell or a population of cells. The invention further provides methods of increasing the number of stress granules and proliferation in a cell or a population of cells by administering one or more PARP activators, one or more PARP inhibitors, one or more PARG inhibitors, and / or one or more ARH3 inhibitors. The invention also provides methods for screening for agents for treating or decreasing the likelihood of developing a stress granule-related disorder or cancer, and methods for determining the propensity for developing a stress granule-related disorder or cancer, as well as compositions and kits containing one or more PARP inhibitors, one or more PARP activators, one or more PARG activators, and one or more ARH3 activators.

Owner:MASSACHUSETTS INST OF TECH

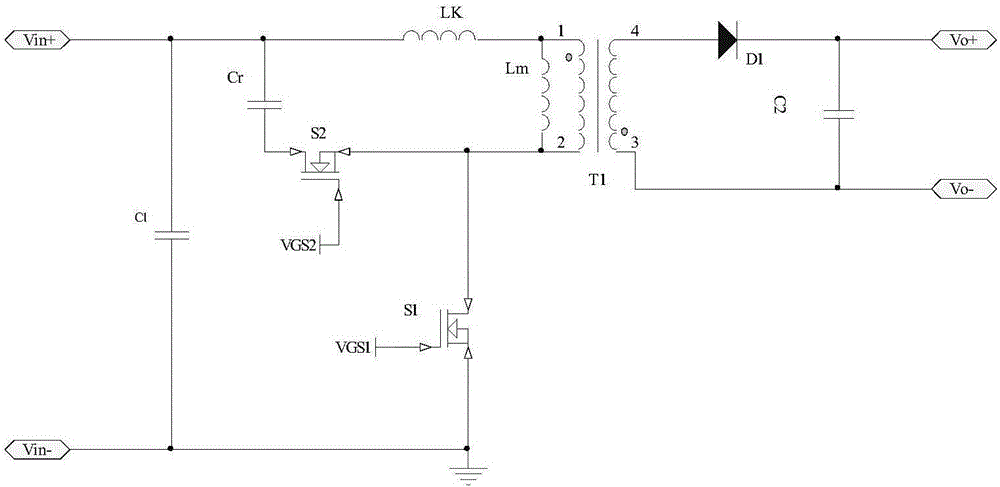

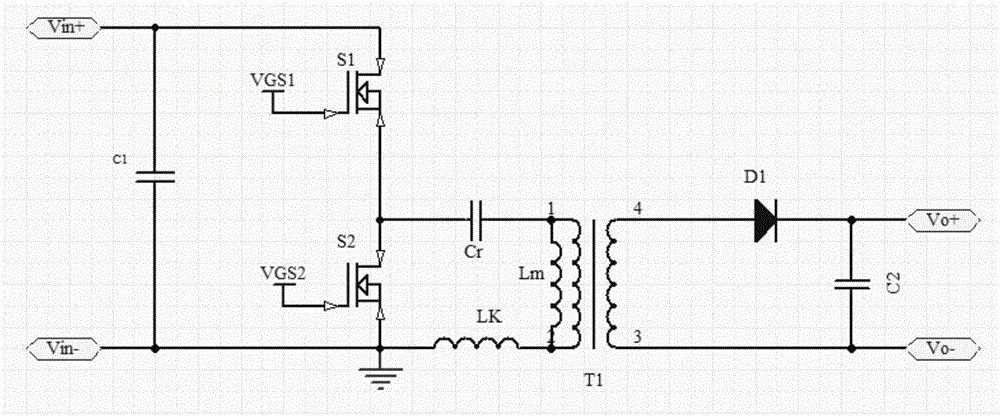

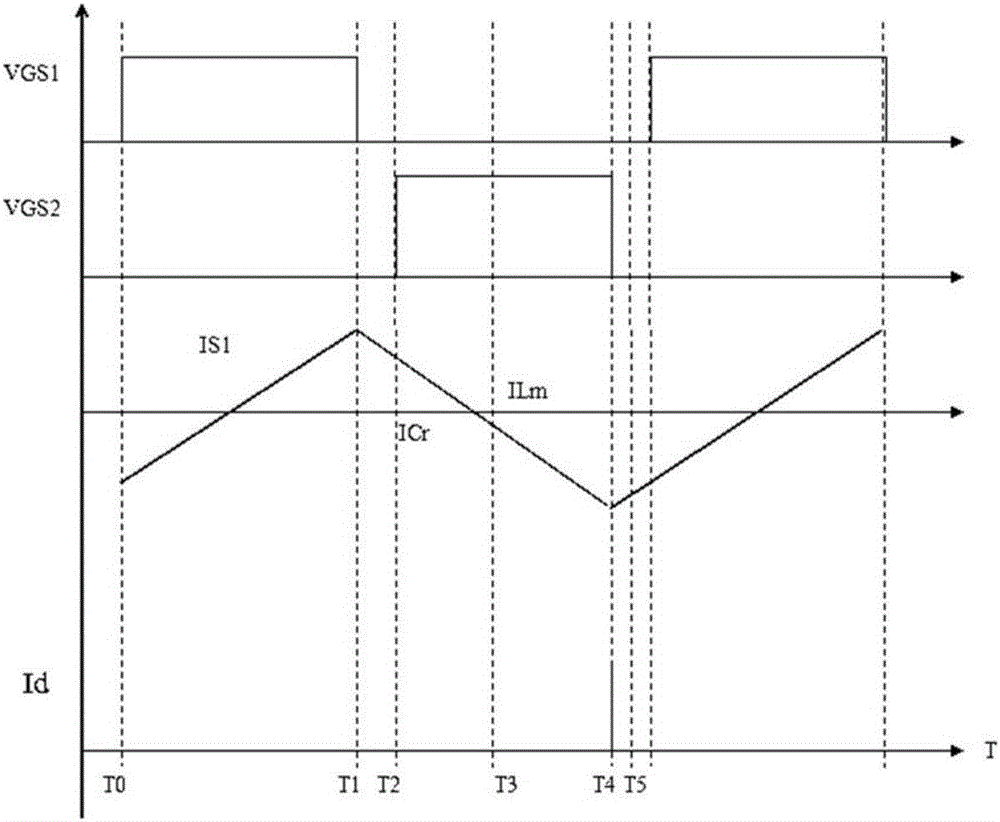

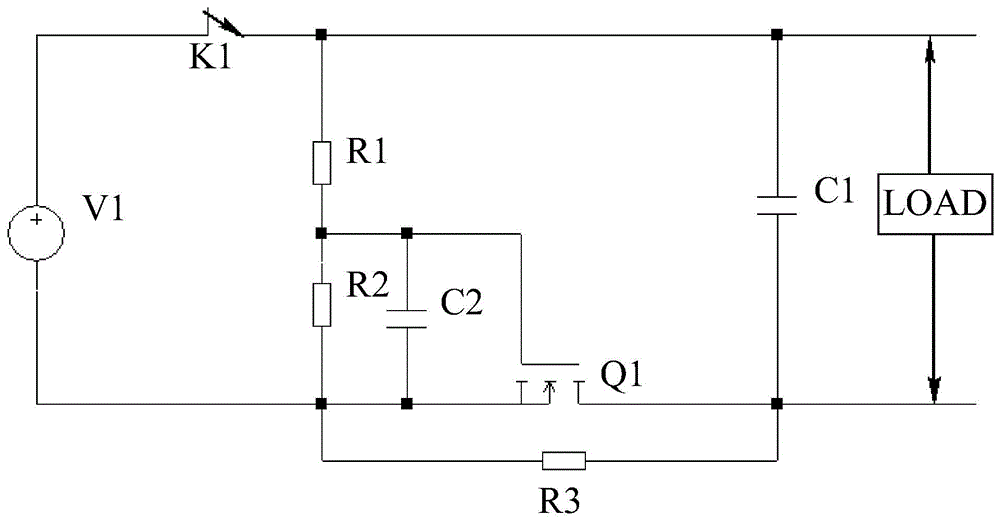

Flyback control circuit and control method

ActiveCN106100352AEfficiency is not affectedReduce no-load power consumptionEfficient power electronics conversionDc-dc conversionActive clampWork cycle

The invention in particular relates to a flyback active-clamp, asymmetrical half-bridge switching converter control circuit and control method. According to the technical scheme of the circuit, a flyback control circuit is provided and controls an integrated control circuit controlling a switch tube and a clamping tube. The integrated control circuit comprises a driving unit of the switch tube, a driving unit of the clamping tube, and a turn-off holding driving unit. When the load is light or zero, the total of a turn-on time of the switch tube, a turn-on time of the clamping tube and a dead zone therebetween forms a single period. The time length of the single period is a fixed value. The turn-on time of the switch tube and that of the clamping tube are in a complementary relation in the single period. The time of the single period and a turn-off holding time form a total working period. Compared with the prior art, while ensuring the efficiency of a conventional circuit and the EMI advantage under a load no less than a light load, the circuit improves the light load efficiency and reduces the zero load power consumption.

Owner:MORNSUN GUANGZHOU SCI & TECH +1

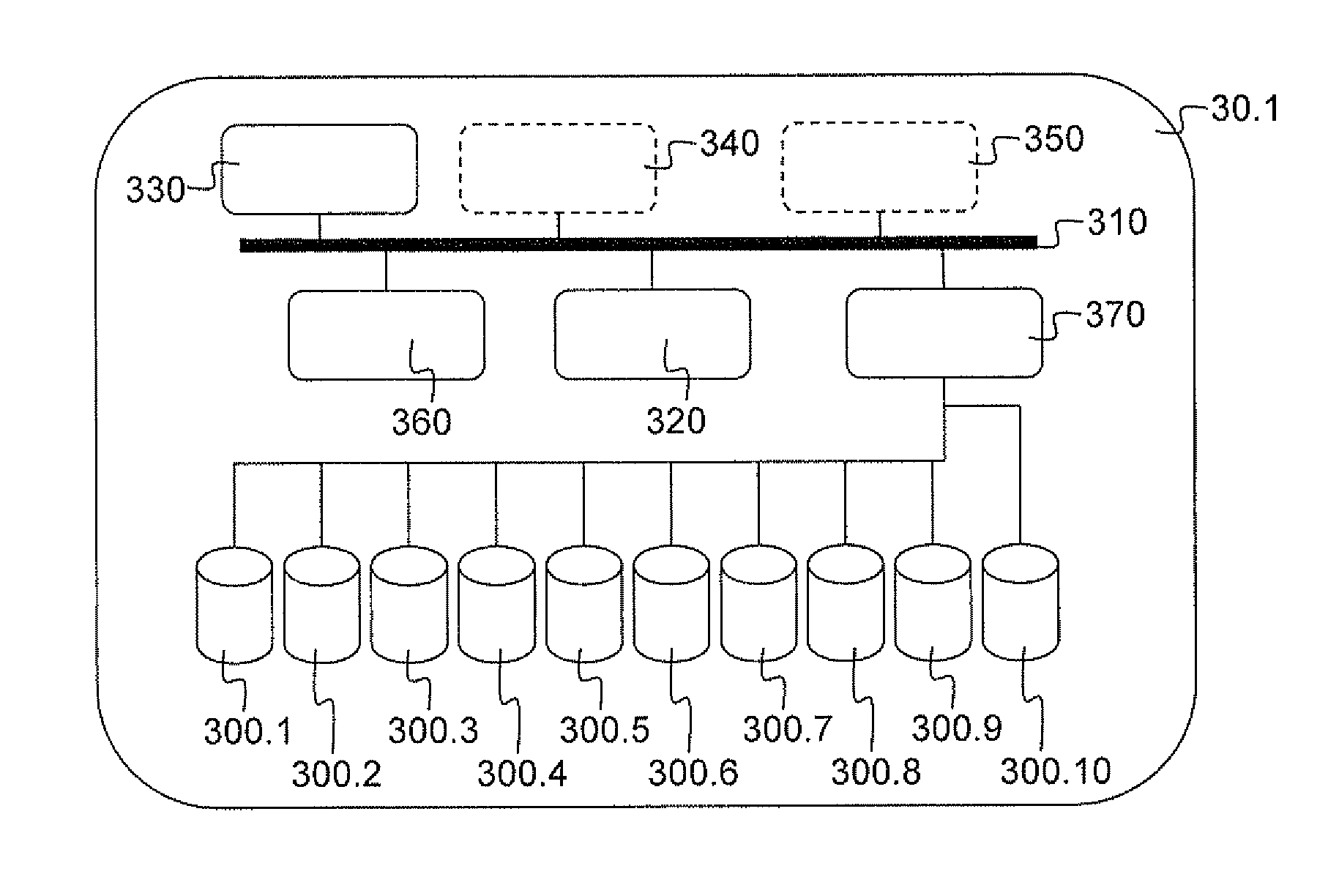

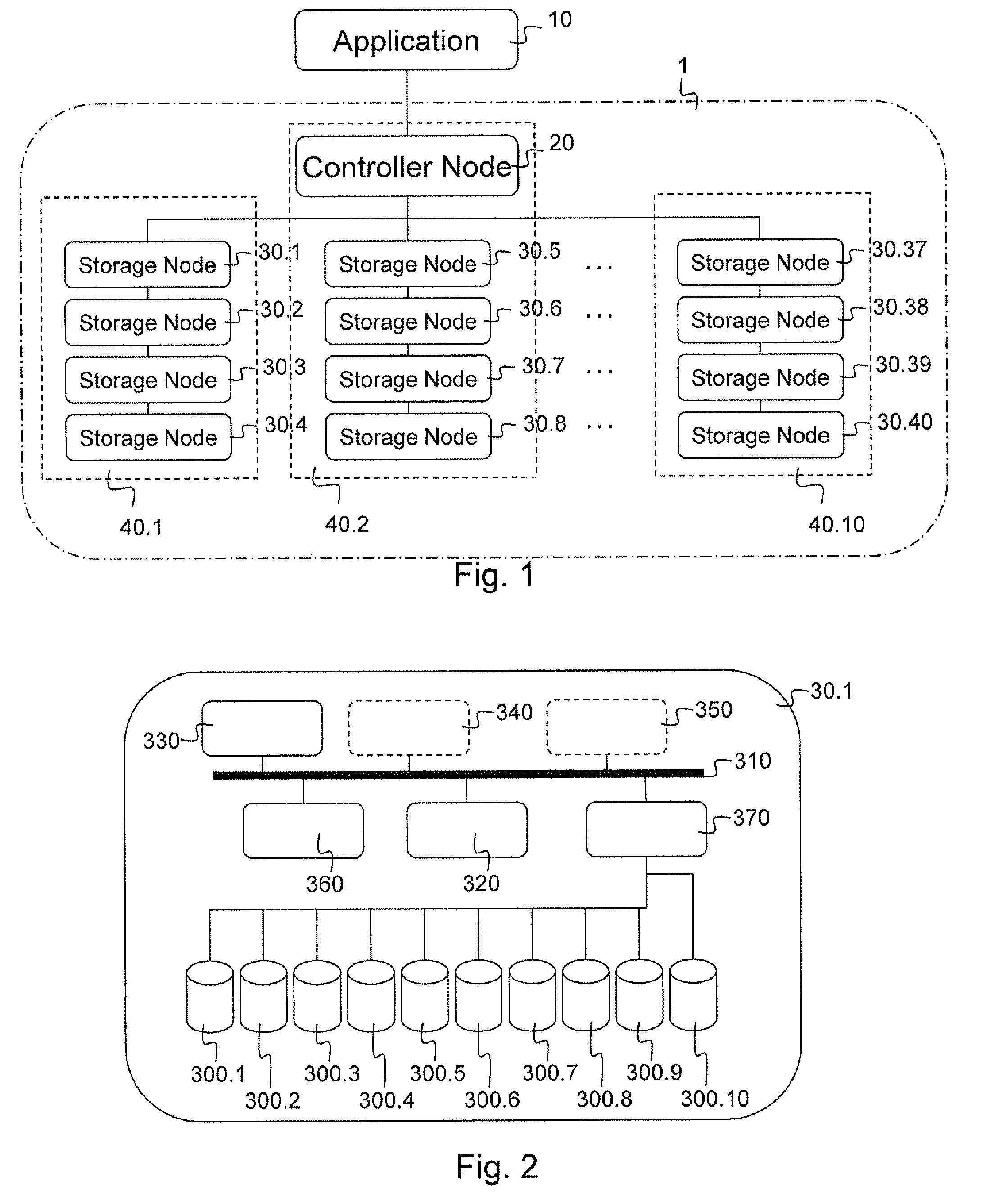

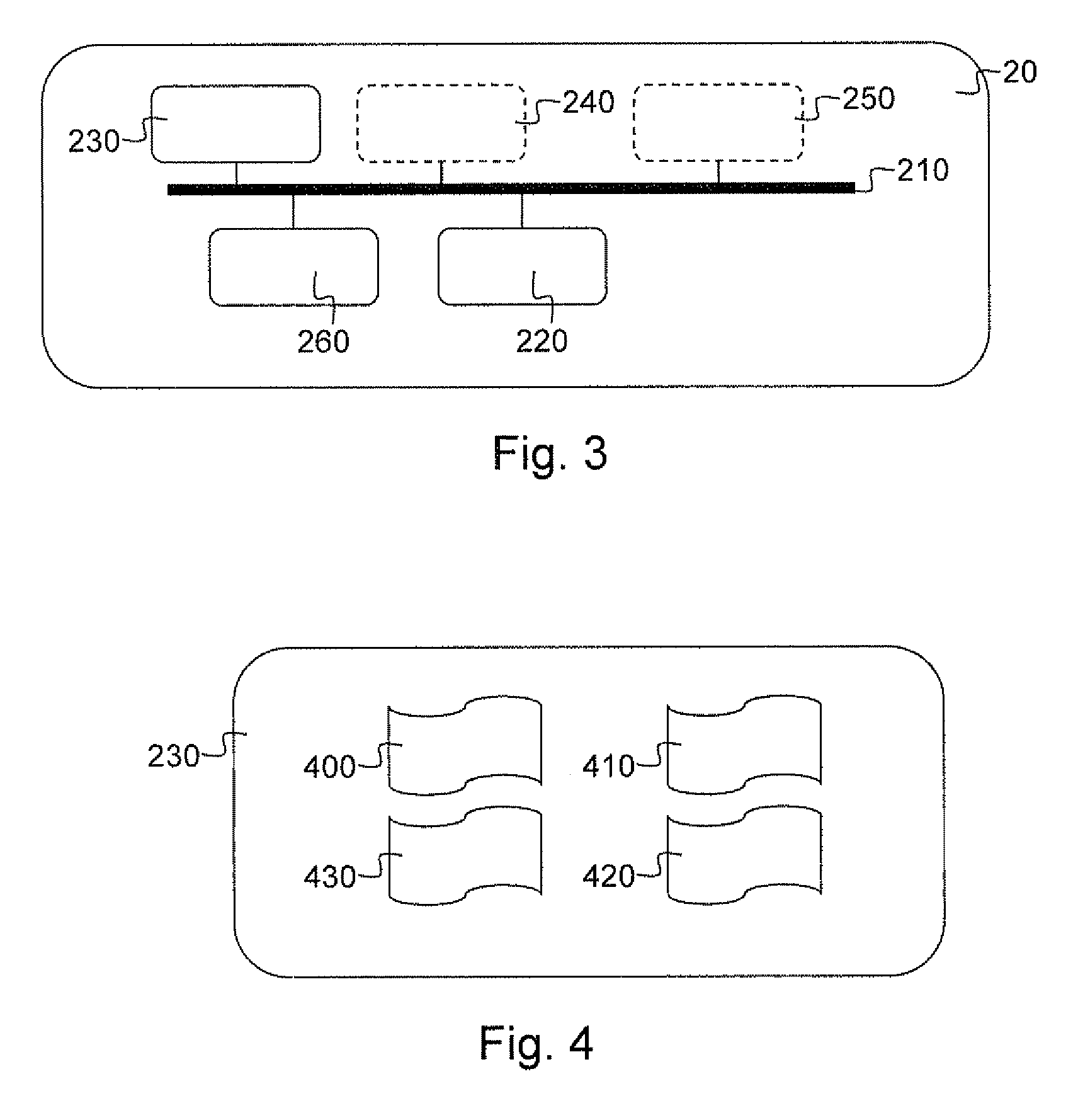

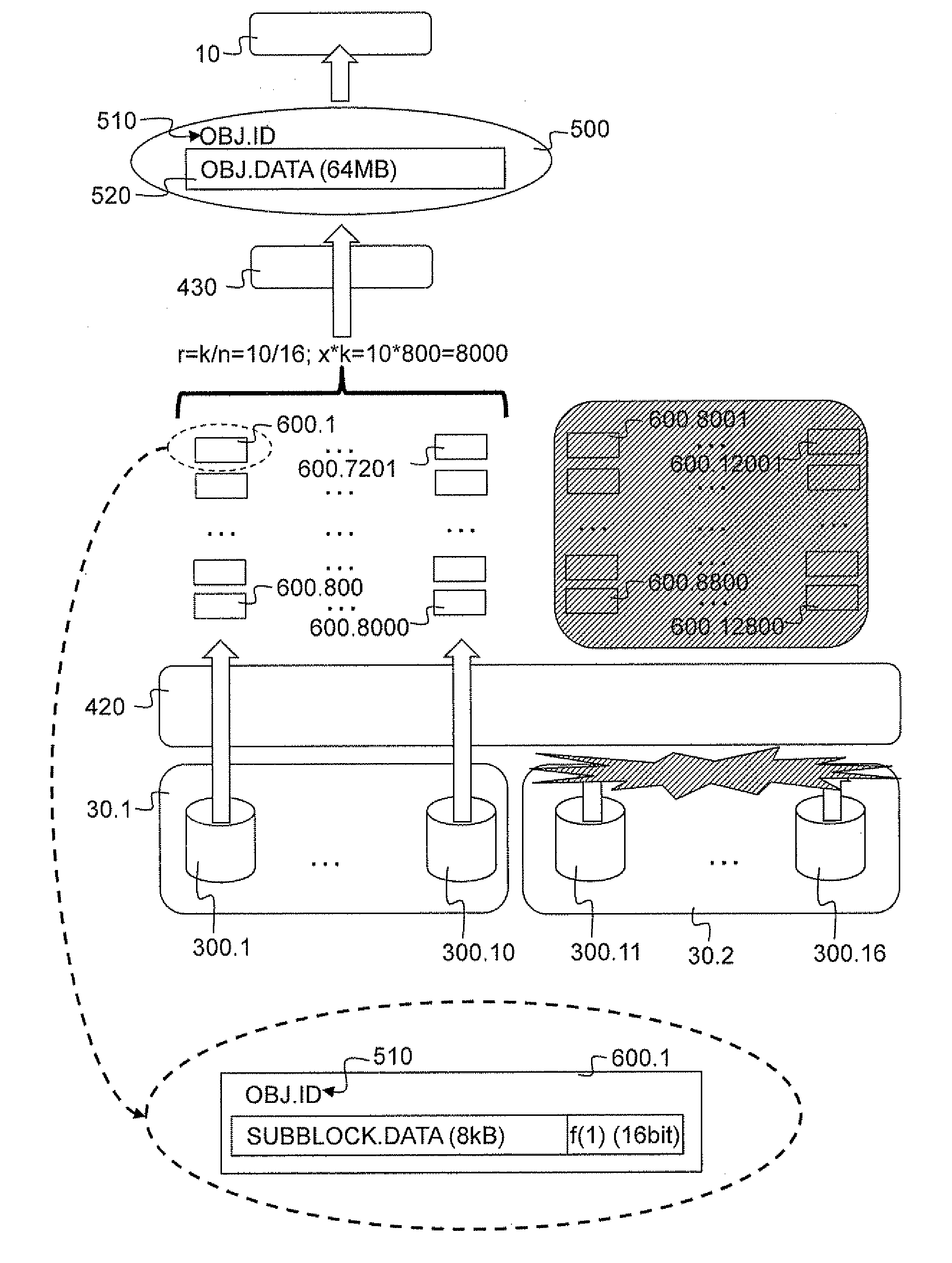

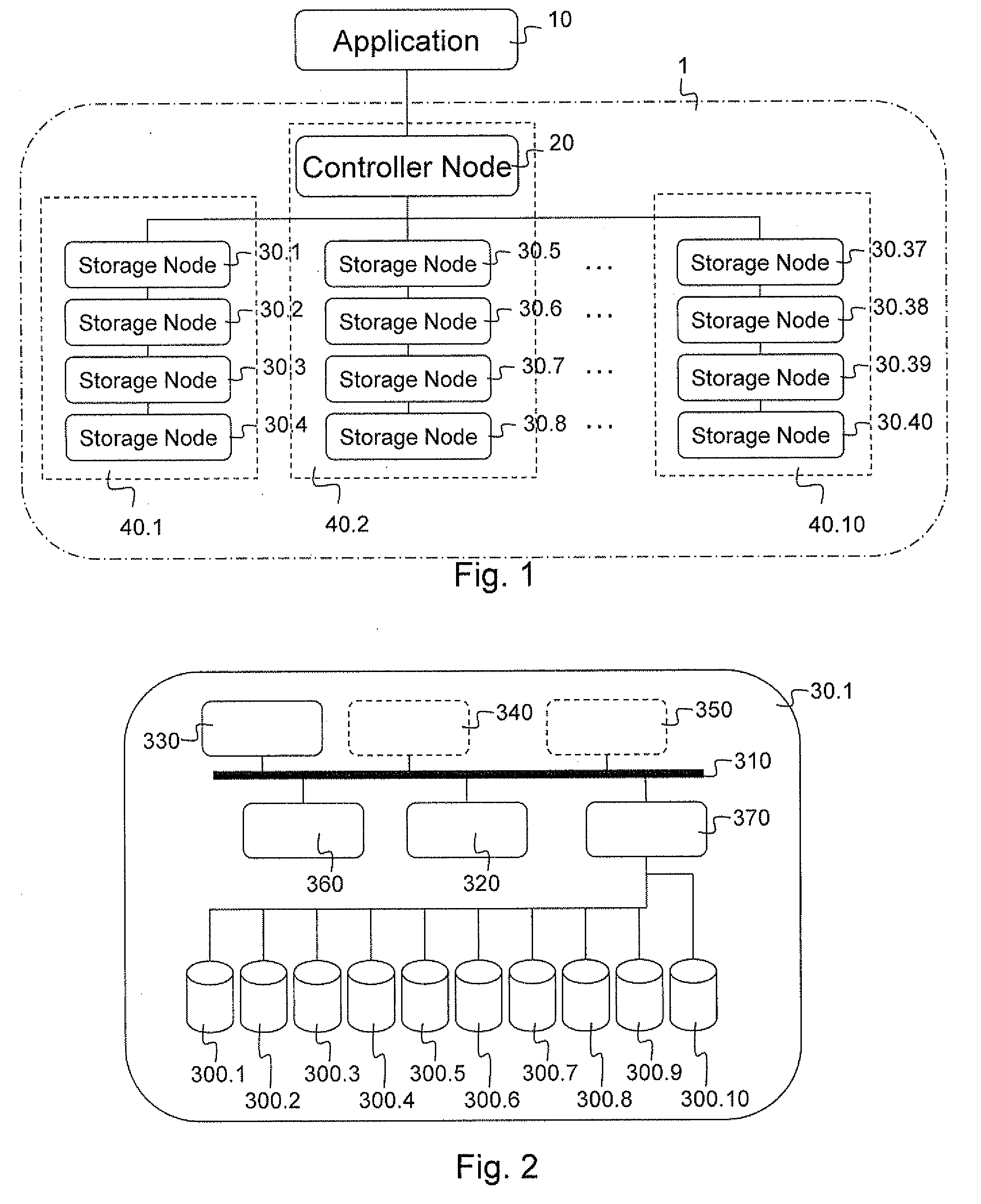

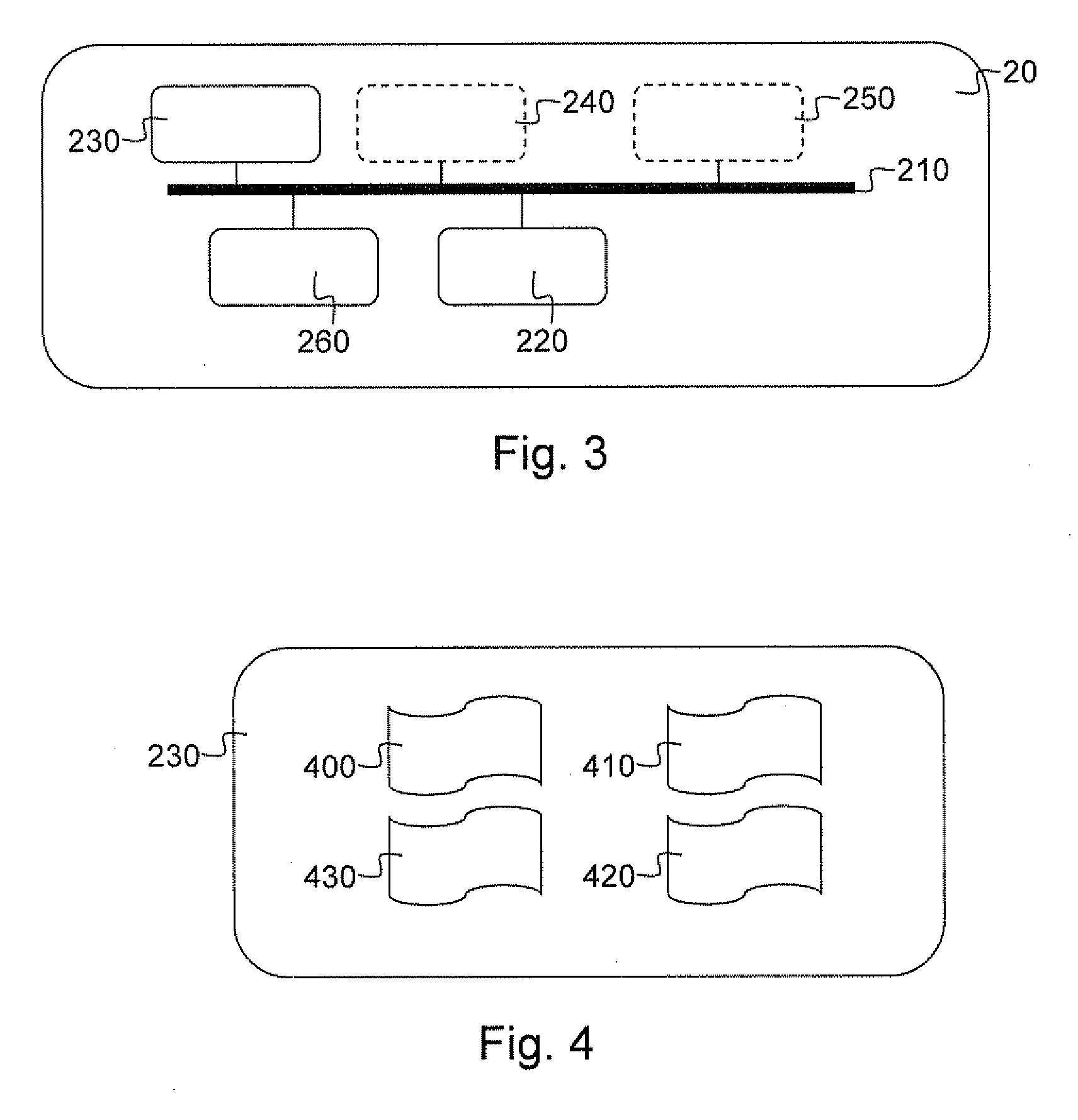

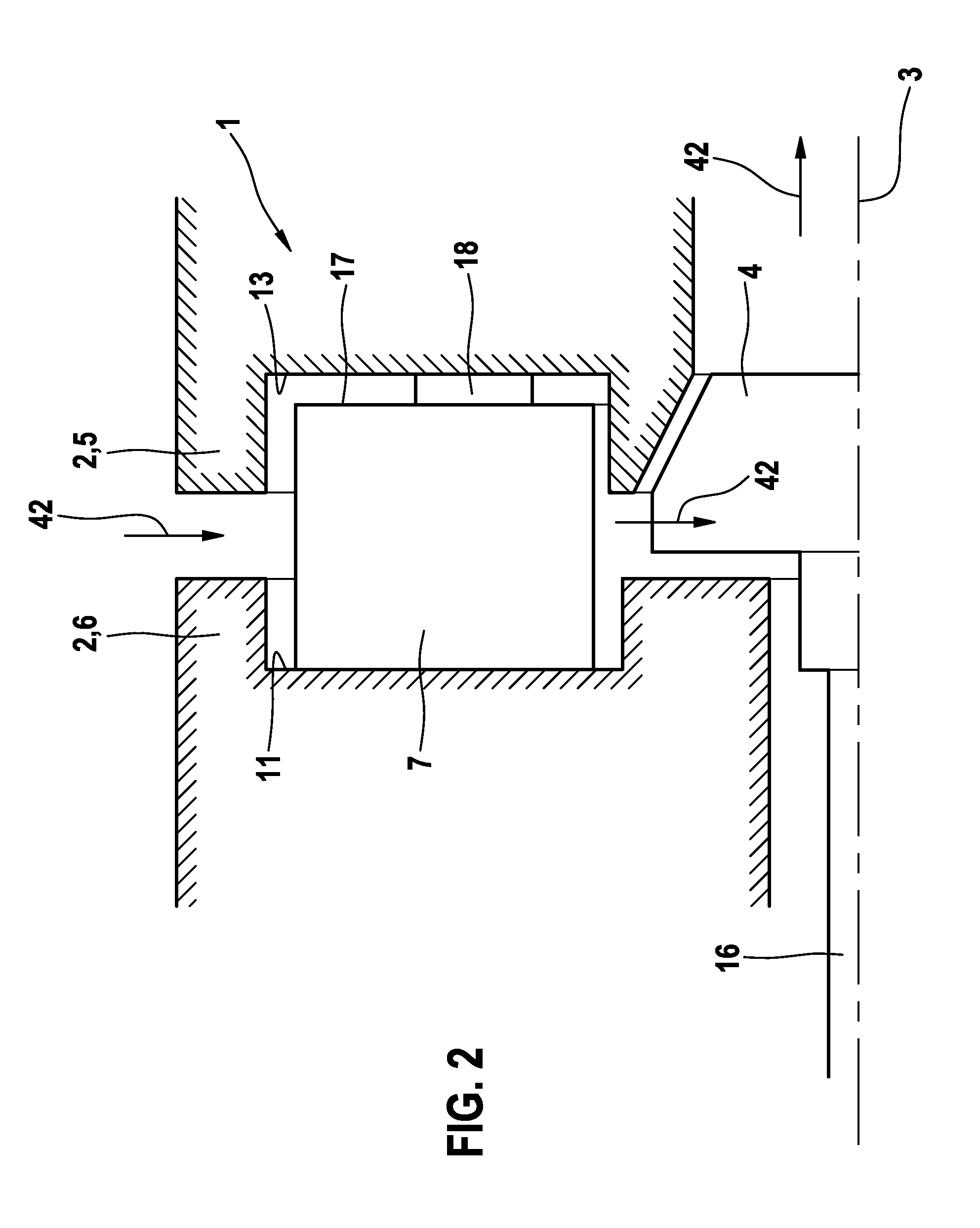

Hierarchical, distributed object storage system

InactiveUS8433849B2Easy to implementEfficiency is not affectedError detection/correctionMemory systemsDistributed objectObject storage

The invention concerns a distributed object storage system (1) that comprises a spreading module (410) which makes a selection of a number of storage elements (300) being larger or equal to a desired spreading width by means of a spreading policy that comprises rules for selecting storage elements (300) in function of a first hierarchy level identifier (70.1) and / or a second hierarchy level identifier (70.2).

Owner:WESTERN DIGITAL TECH INC

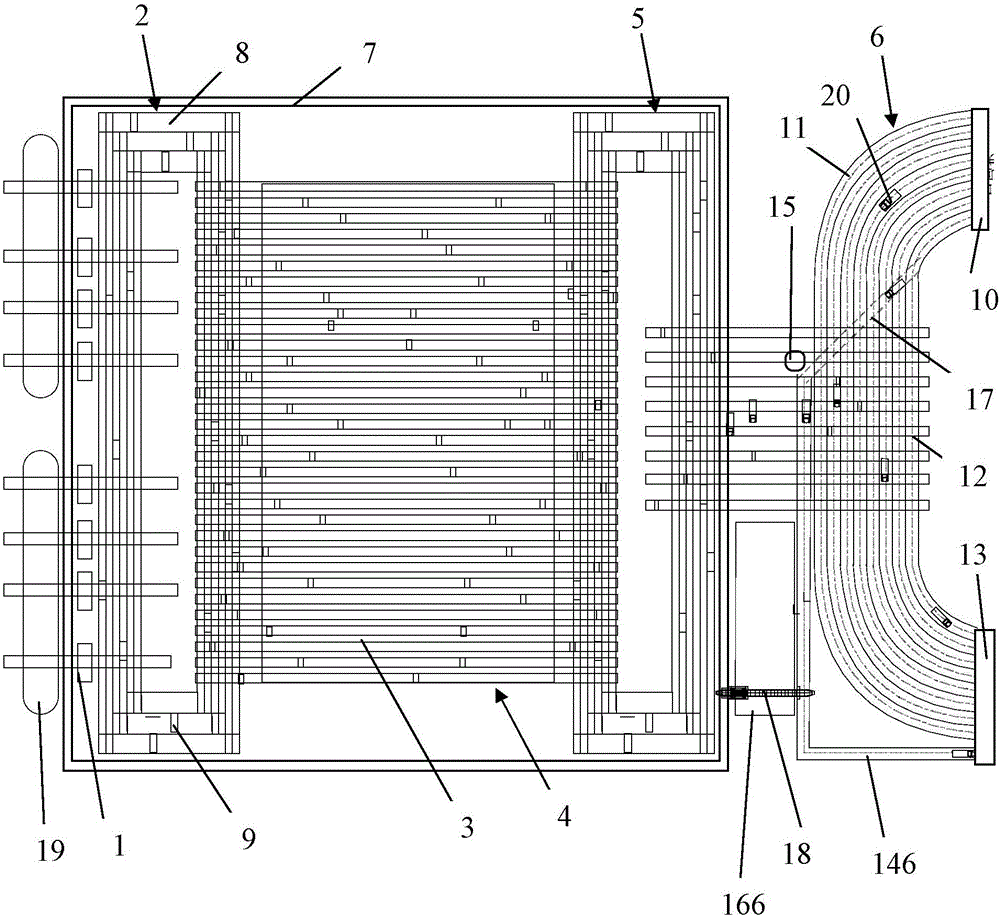

Loading and unloading system for distribution center type automated container terminal

The invention relates to a loading and unloading system for a distribution center type automated container terminal. The loading and unloading system comprises a plurality of quay cranes, a nearshore multipath rectangular-ambulatory-plane automatic transportation system, an elevated container automatic loading and unloading system, a storage yard, a container evacuating port side multipath rectangular-ambulatory-plane automatic transportation system, a container evacuating port transportation system, an annular special container channel and a control system. Compared with the scheme of an existing automated container terminal, the loading and unloading system for the distribution center type automated container terminal is advantaged in that the loading and unloading system is creative and unique, and is high in production efficiency, safety, automation degree and stability, and is simple in structure, simple to control and complete in scheme.

Owner:TIANJIN PORT CONTAINER TERMINAL

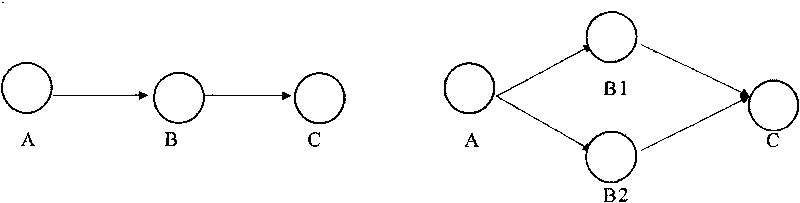

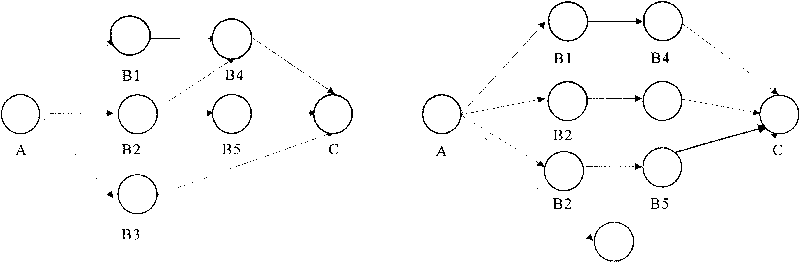

Dynamic cross-domain access control method based on trust valuation mechanism

InactiveCN101729321ATroubleshoot access control issuesAvoid deceitful behaviorData switching networksExtensibilityData access control

The invention discloses a dynamic cross-domain access control method based on a trust valuation mechanism, belonging to the technical field of network security. The method is based on the subjective logic theory and sets a credit value for each entity in a grid by introducing the trust valuation mechanism into access control, wherein different entity credit values correspond to different roles, and each role is provided with the relative authority. According to the historic access activities of the entities in the grids and the trust policy, when the credit values of the entities are changed, roles of the entities in the grids are changed, thereby dynamically changing the access authorities of the entities. The dynamic cross-domain access control method based on the trust valuation mechanism is reliable, dynamic and extendable, and can effectively achieve safe and dynamic resource sharing among the grid entities under the grid environment.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

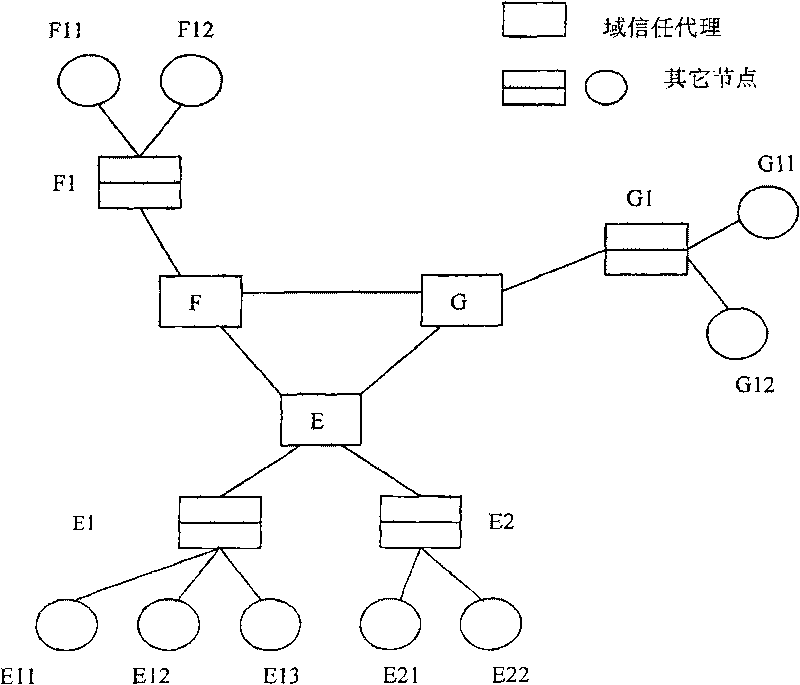

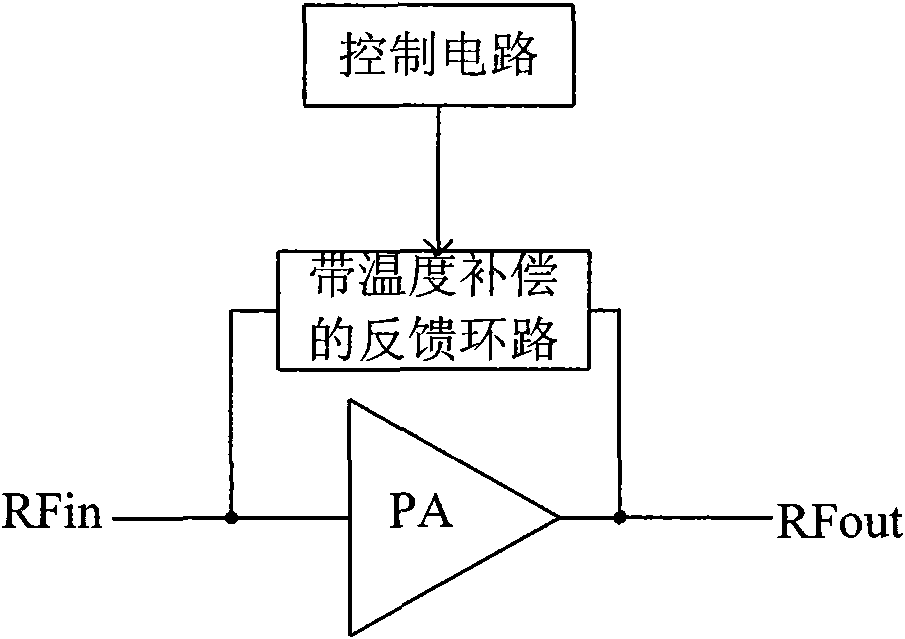

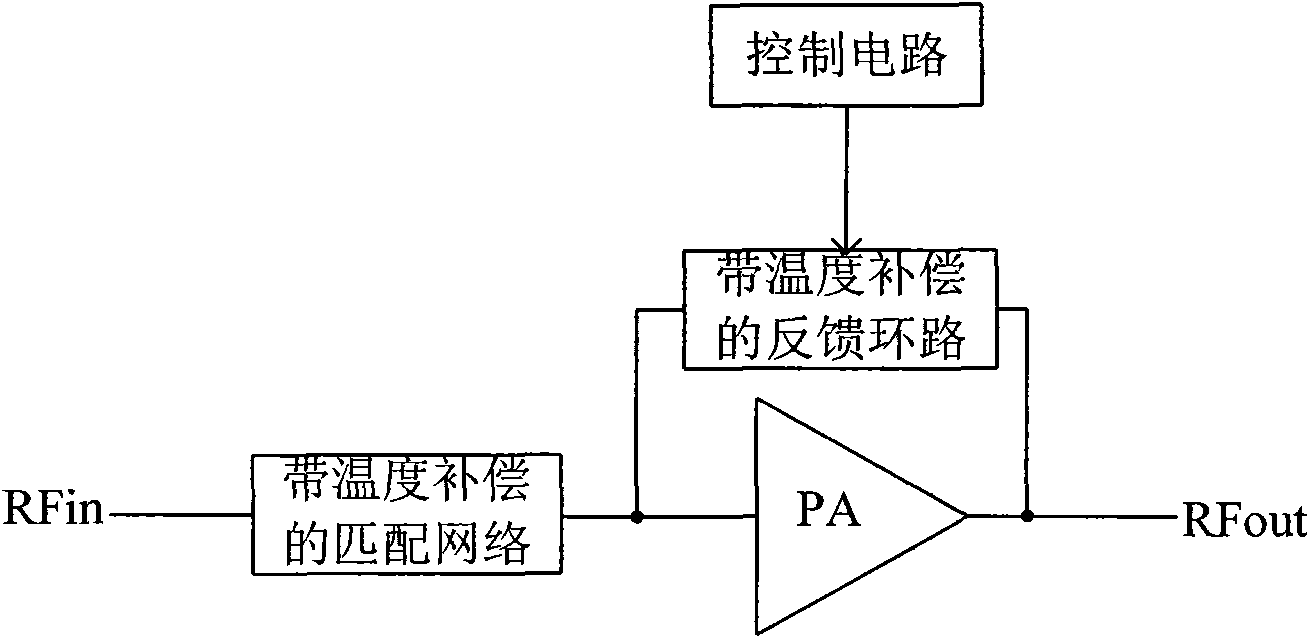

Temperature compensating circuit of radio frequency power amplifier

InactiveCN101656511AEfficiency is not affectedImprove linearity metricsNegative-feedback-circuit arrangementsHigh frequency amplifiersAudio power amplifierControl circuit

The invention discloses a temperature compensating circuit of a radio frequency power amplifier with stable gain function. The temperature compensating circuit comprises a control circuit, wherein thecontrol circuit generates control voltage V<tf> which can be changed along with the change of the chip temperature of the radio frequency power amplifier so as to regulate the feedback quantity of afeedback loop of the radio frequency power amplifier, the feedback loop is connected between the input end and the output end of the radio frequency power amplifier or the control circuit generates control voltage V<bias> which can be changed along with the change of the temperature of the radio frequency power amplifier to regulate the bias current of a bias circuit of the radio frequency power amplifier, and the bias circuit is connected with the input end of the radio frequency power amplifier. On the premise that the indexes of efficiency, and the like of the radio frequency power amplifier are not influenced, the temperature compensating circuit can reduce the grain change along with temperature change, change the feedback quantity of the feedback loop, improve the linearity index ofthe amplifier simultaneously and achieve simple structure and low cost.

Owner:ZYW MICROELECTRONICS

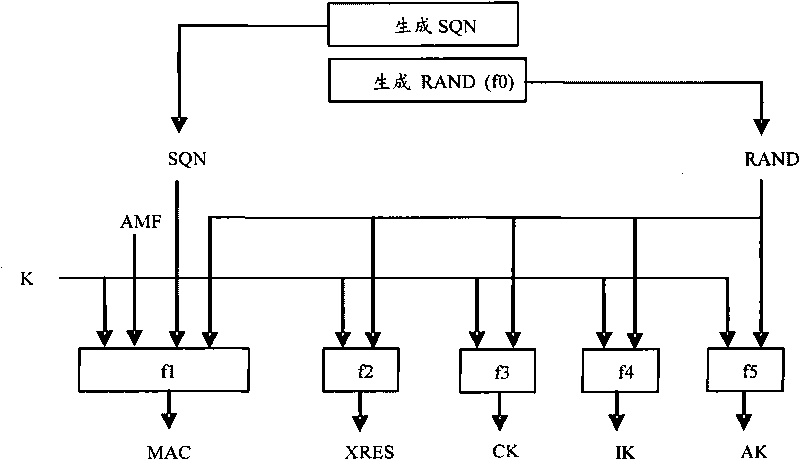

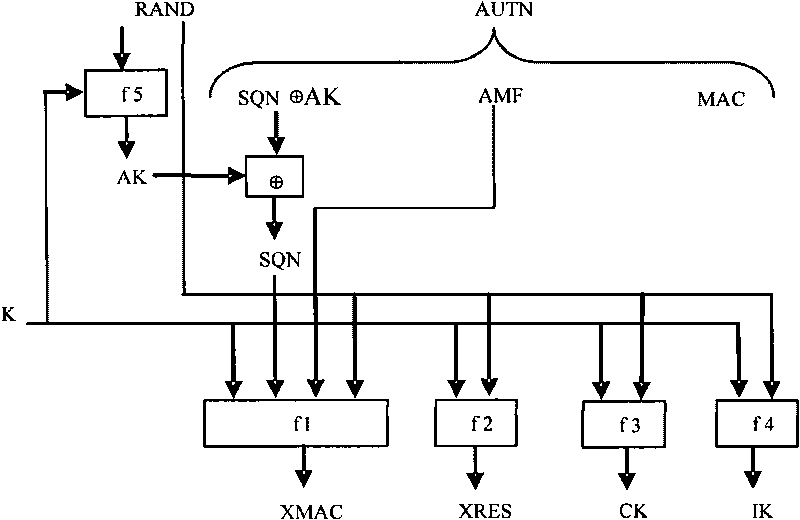

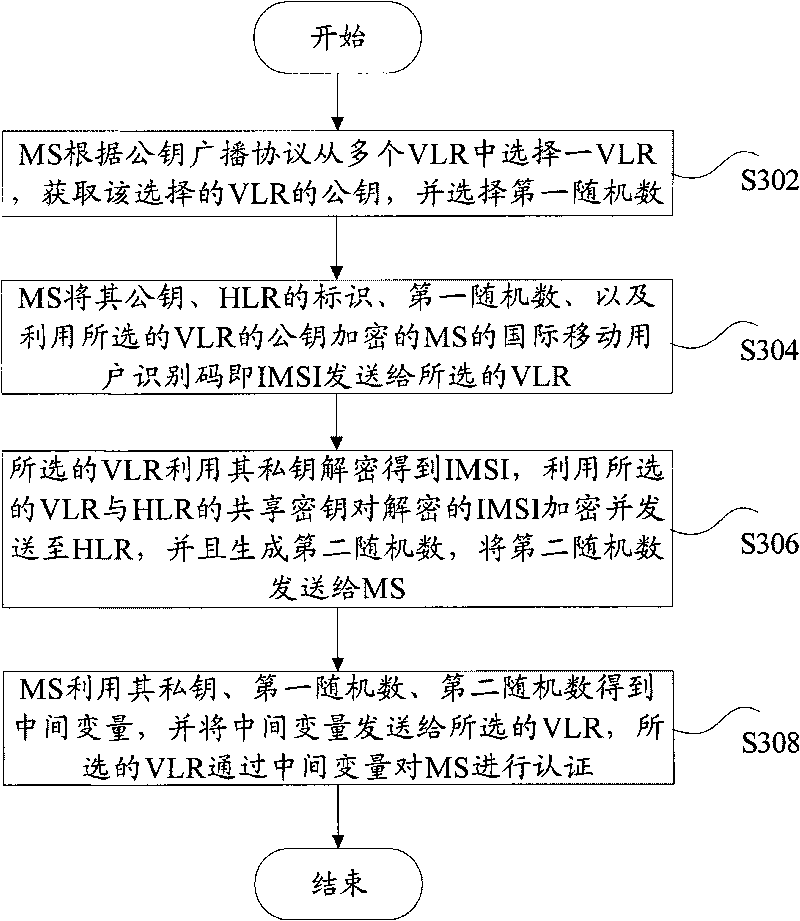

Method and system for identity authentication and key agreement

InactiveCN101741555AAvoid safety hazardsEnsure safetyKey distribution for secure communicationUser identity/authority verificationIntermediate variableInternational mobile subscriber identity

The invention discloses a method and a system for identity authentication and key agreement. The method comprises the following steps that: an MS chooses a VLR from a plurality of VLRs according to a key broadcast protocol to acquire a public key of the chosen VLR, and then chooses a first random number; the MS sends the public key, an identifier of the HLR, the first random number and an international mobile subscriber identity, namely an IMSI of the MS which is encrypted by the public key of the chosen VLR to the chosen VLR; the chosen VLR uses a private key thereof to decrypt and acquire the IMSI, a shared key of the chosen VLR and an HLR is used for encrypting the decrypted IMSI, the IMSI is sent to the HLR, a second random number is generated, and then the second random number is sent to the MS; and the MS uses a private key thereof, the first random number and the second random number to construct an intermediate variable, and sends the intermediate variable to the chosen VLR, and then the chosen VLR performs authentication on the MS through the intermediate variable.

Owner:ZTE CORP

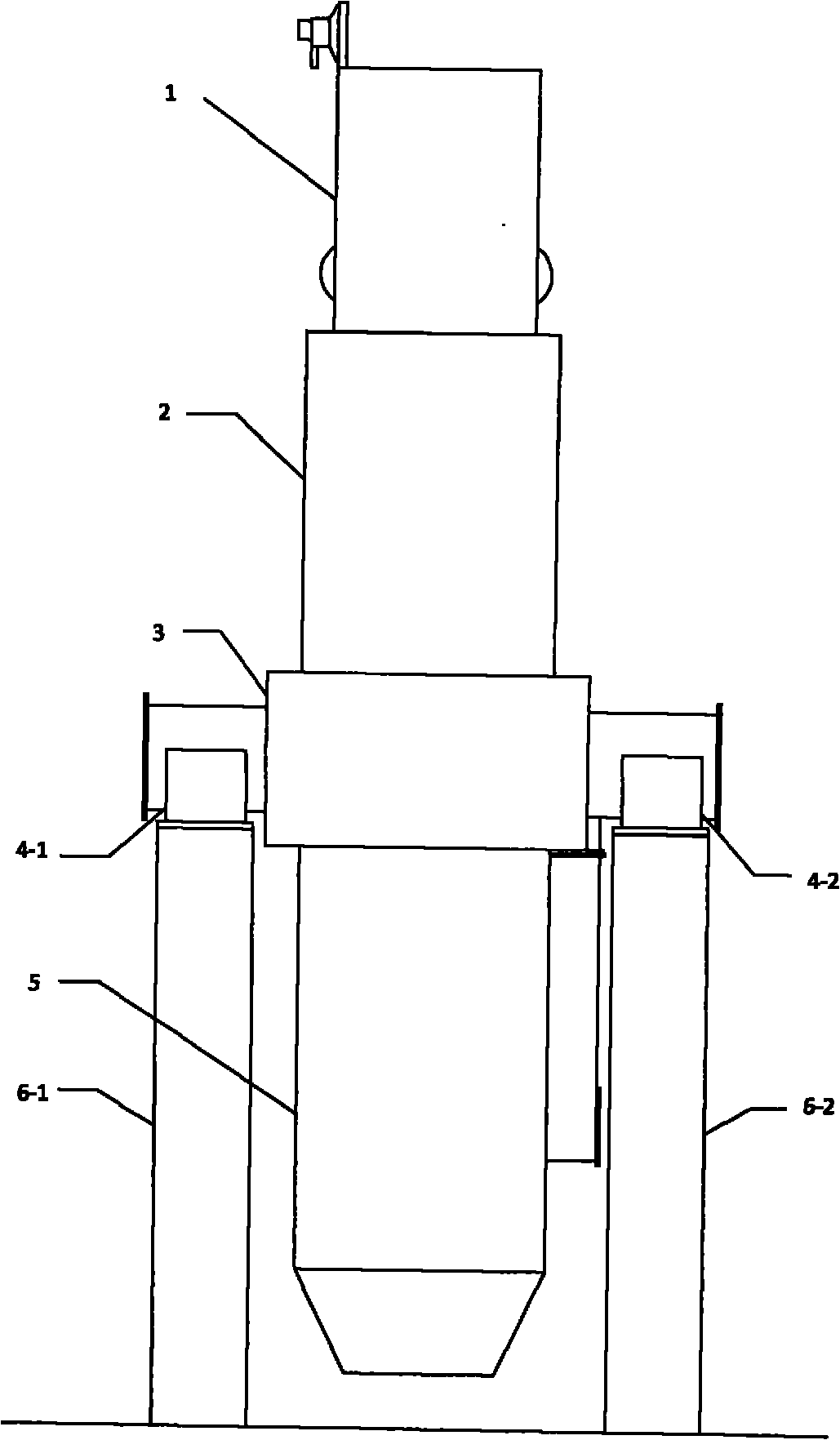

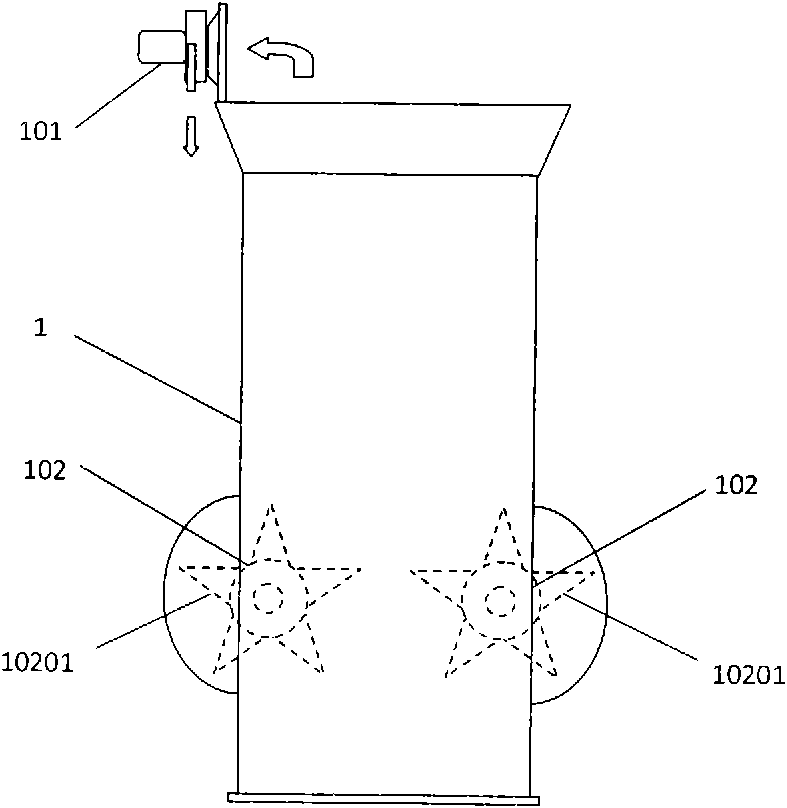

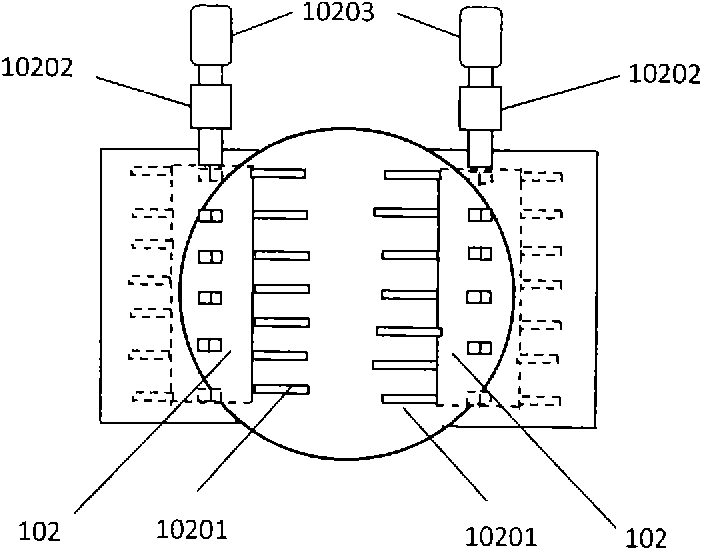

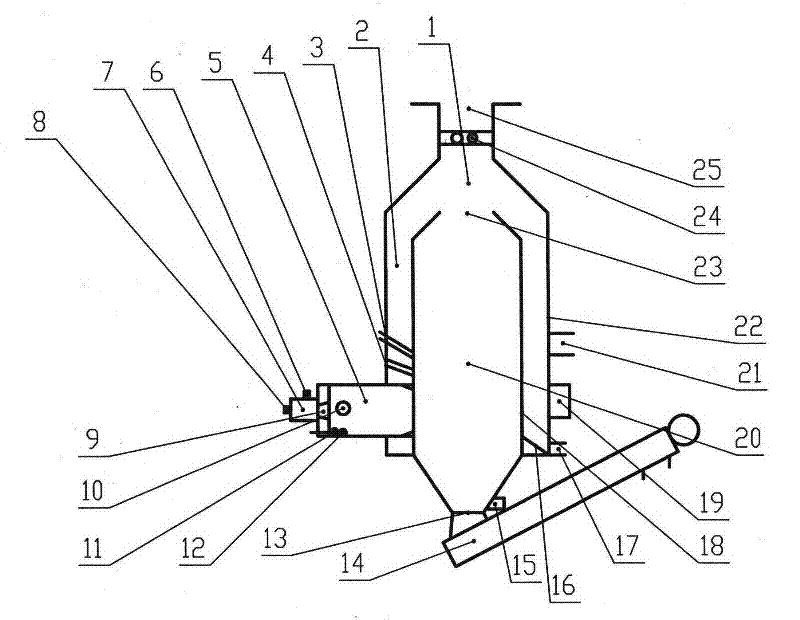

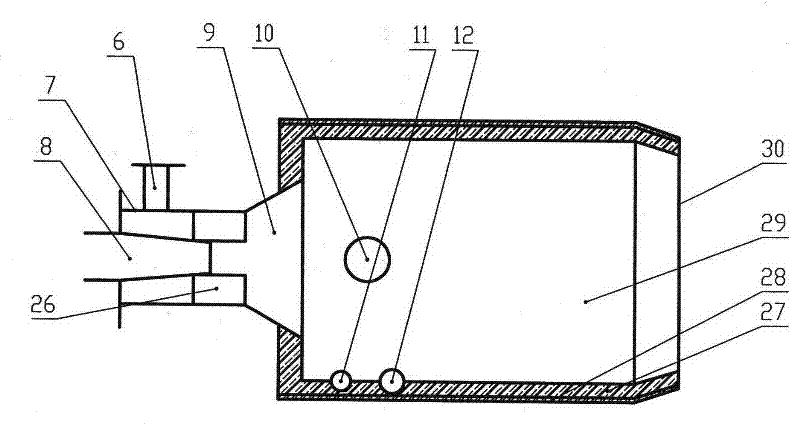

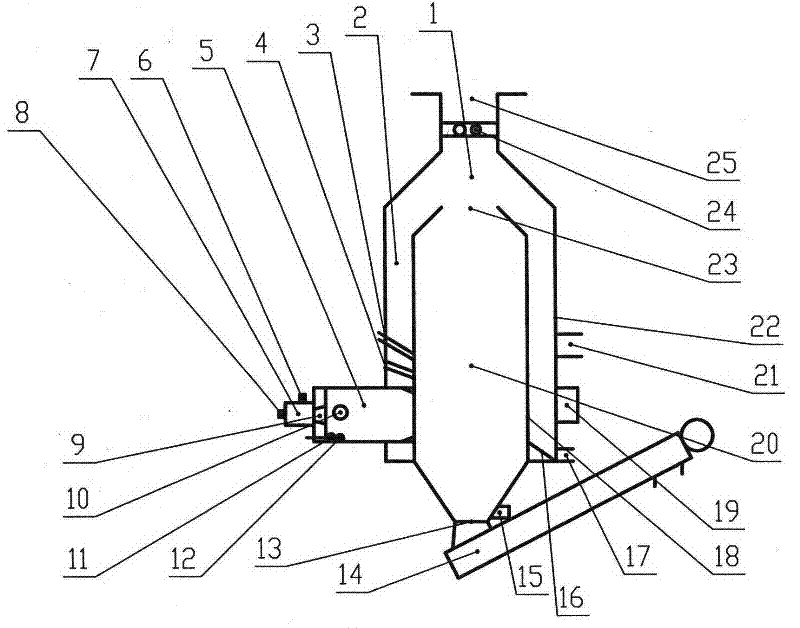

Two-stage plasma gasifying, melting and cracking method and device of waste containing organic matters

ActiveCN102000691ANo emissionsComplete gasificationSolid waste disposalGlass furnace apparatusGeneration rateHigh energy

The invention relates to a treatment method of waste containing organic matters, in particular to two-stage plasma gasifying, melting and cracking method and device of the waste containing organic matters, belonging to the field of gasifying, melting and cracking techniques. In the invention, the serious defects of high energy consumption of the waste containing organic matters and more flying ash during the plasma arc melting and cracking are solved, thereby thoroughly utilizing the energy of the organic matters and maximizing the treating efficiency, thoroughly cracking the tar, reducing the generation rate of Dioxin, obtaining synthesis gas with high quality and high heat value as much as possible, providing guarantee for the subsequent gasification power generation, the hydrogen energy recovery or the production of green liquid fuel, simultaneously finishing one-step recovery of noble metals and direct utilization of glass bodies in the field of building materials, laying foundation for the large-scale commercial development and application of the energy of the waste containing organic matters, and thoroughly solving the possible pollutant discharging problem in the gasifying process of the organic matters, particularly the dangerous waste.

Owner:HOOTECH

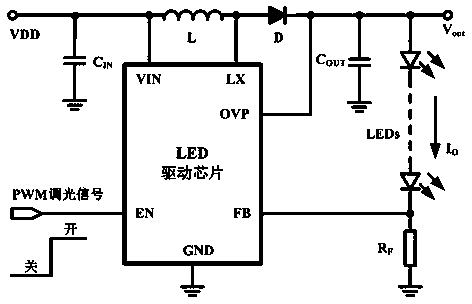

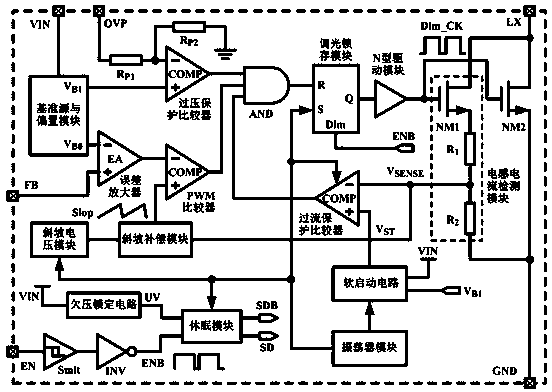

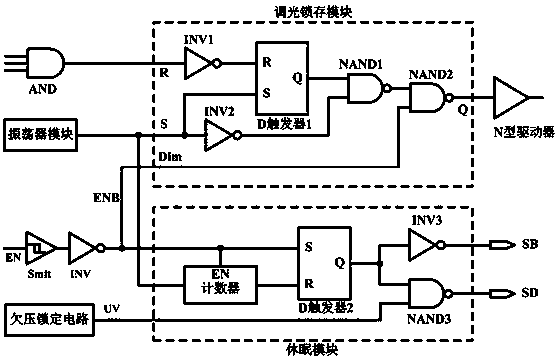

Dimmable LED driver chip provided with soft start and under-voltage lock-out circuits

ActiveCN103929860ASimple structureEfficiency is not affectedElectric light circuit arrangementEnergy saving control techniquesLed driverEngineering

The invention belongs to the field of LED drivers, and relates to a dimmable LED driver chip, in particular to a dimmable LED driver chip provided with soft start and under-voltage lock-out (UVLO) circuits. The chip is based on a current PWM mode DC-DC boost converter. A switch type PWM dimming strategy is adopted for the interior of the chip so that the brightness of an LED lamp can be adjusted smoothly in a wide-range and dispersion-free mode without influencing the efficiency of the chip. Furthermore, the novel soft start circuit is integrated with the chip and can restrain surge currents and overshoot voltages during starting to protect the LED lamp and the driver chip from damage. Finally, the novel UVLO circuit is integrated with the chip to guarantee the working stability of the LED driver chip when the voltage of a power supply changes while the area of the chip is reduced, and the reliability of light emission of the LED is ensured.

Owner:WUHAN UNIV

Hierarchical, distributed object storage system

InactiveUS20120166726A1Not compromise efficiencyEasy to implementError detection/correctionMemory systemsObject storageDistributed object

The invention concerns a distributed object storage system (1) that comprises a spreading module (410) which makes a selection of a number of storage elements (300) being larger or equal to a desired spreading width by means of a spreading policy that comprises rules for selecting storage elements (300) in function of a first hierarchy level identifier (70.1) and / or a second hierarchy level identifier (70.2).

Owner:WESTERN DIGITAL TECH INC

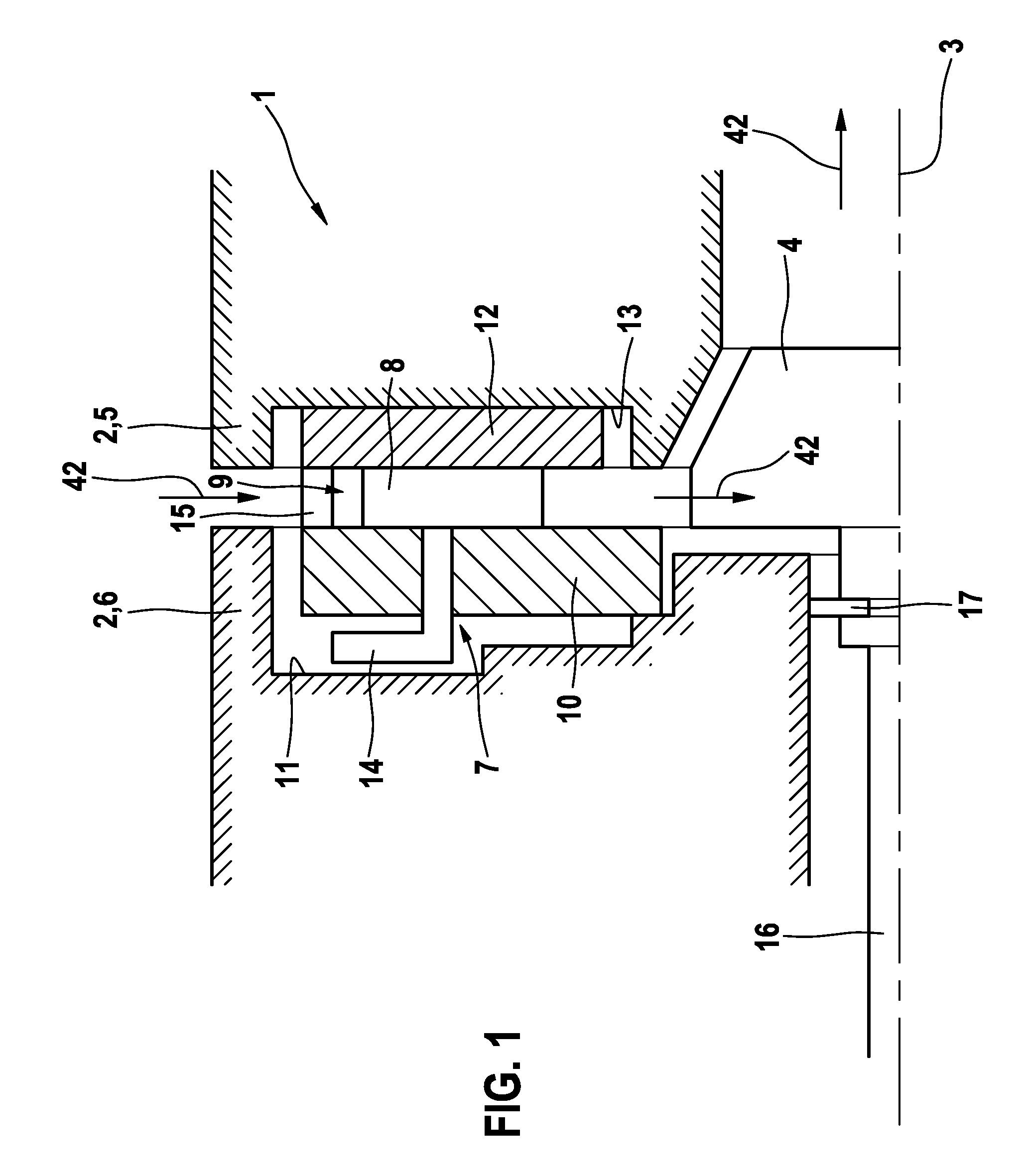

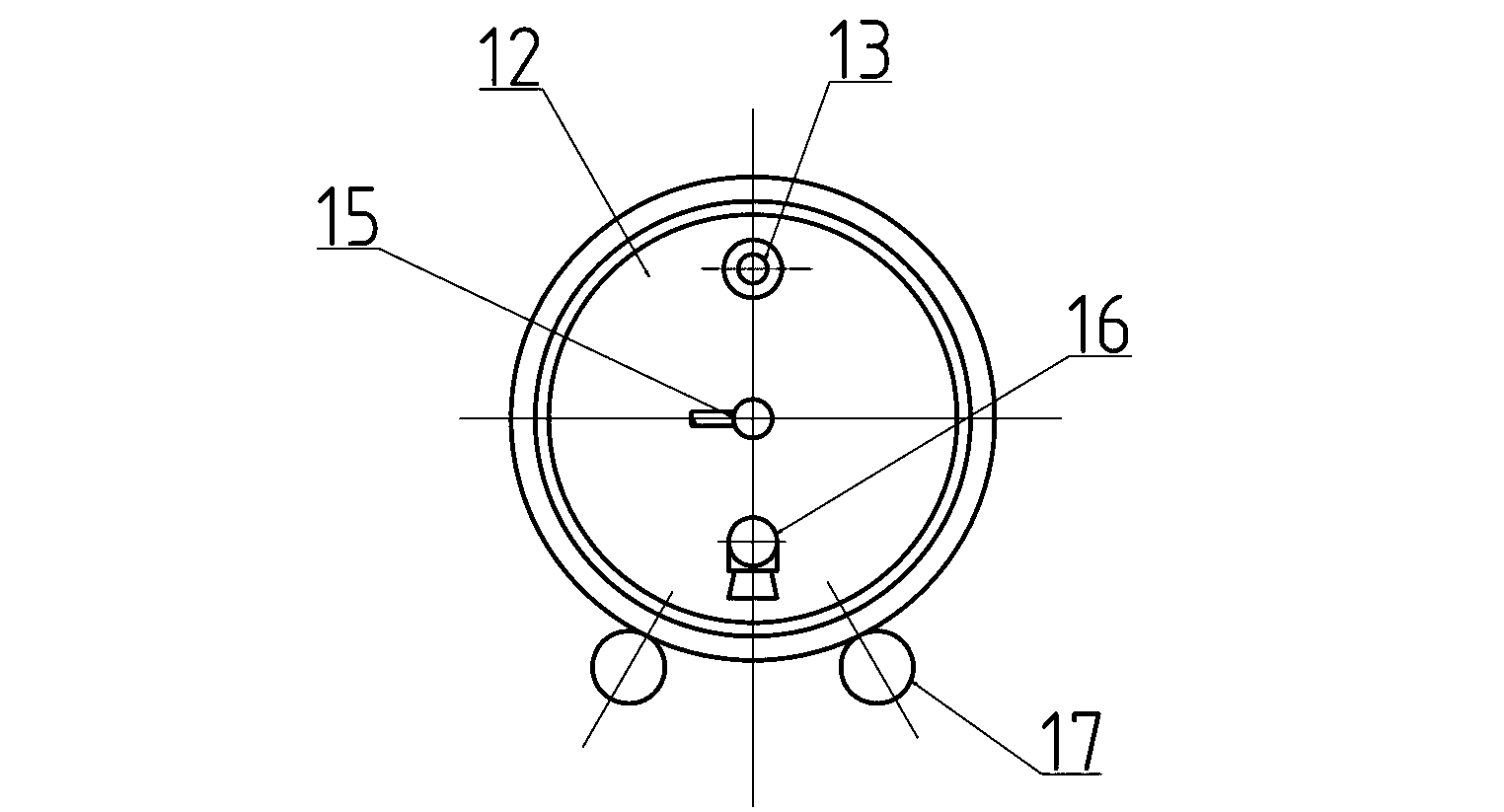

Turbine, in particular for an exhaust gas turbocharger, and exhaust gas turbocharger

ActiveUS20110038742A1Easy to assembleSimple and cost-effectiveEngine manufactureGas turbine plantsRotational axisInlet channel

An exhaust gas turbocharger, comprising: a turbine rotor rotatably mounted in a housing, which is associated with at least one guide apparatus forming a radial inlet channel, wherein the guide apparatus includes at least one of a guide vane bearing ring, a plurality of guide vanes radially surrounding the turbine rotor and located in the inlet channel and a guide vane cover ring. The inlet channel is axially delimited by the guide vane bearing ring and the guide vane cover ring wherein the guide vane bearing ring and the guide vane cover ring are moveably mounted at least one of axially and radially relative to each other and to the housing. The guide apparatus is subjected to at least one of an axial and radial preload, wherein a line of axial preload flux runs through the guide apparatus substantially parallel to the rotational axis of the turbine rotor.

Owner:BOSCH MAHLE TURBO SYST GMBH & CO KG

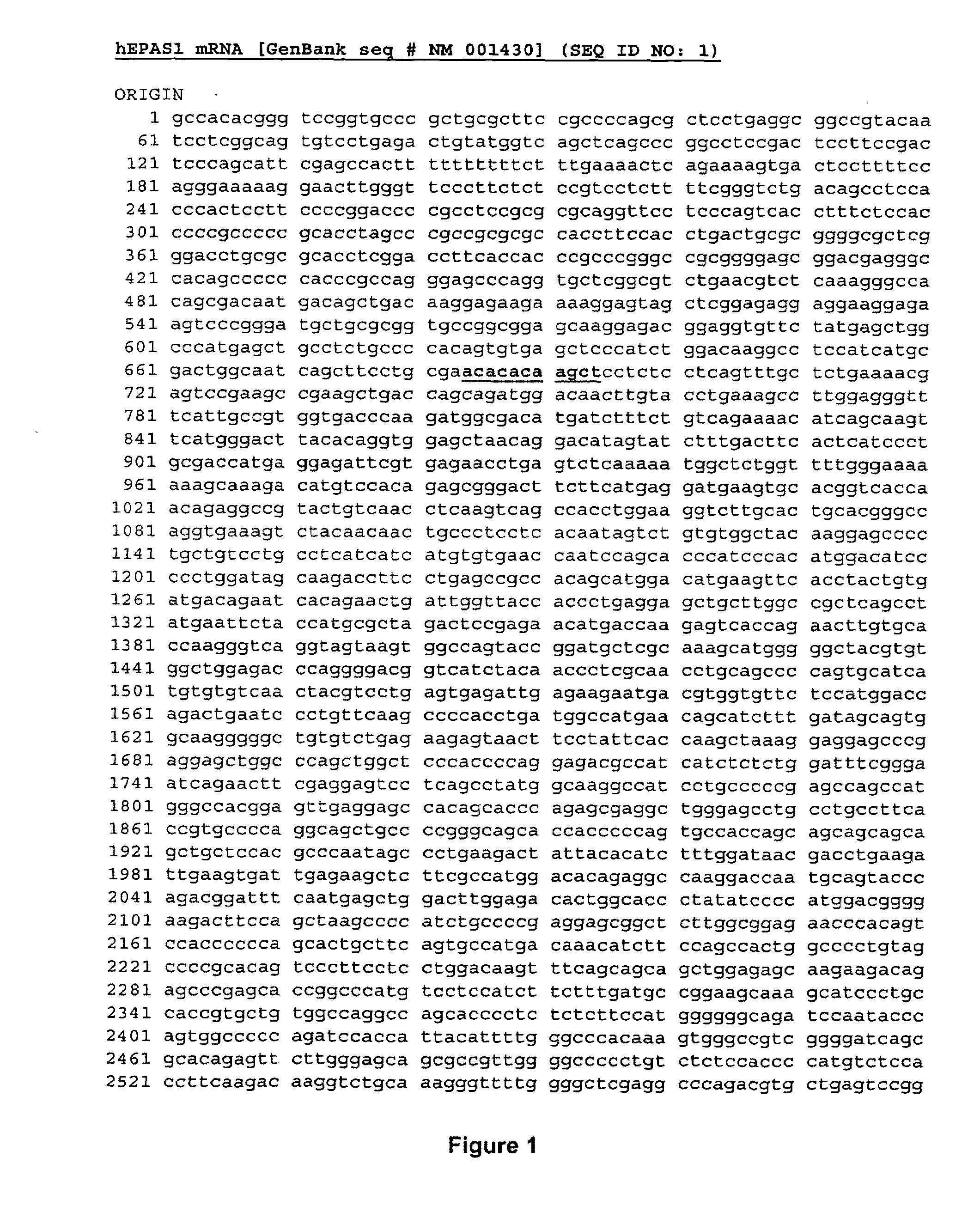

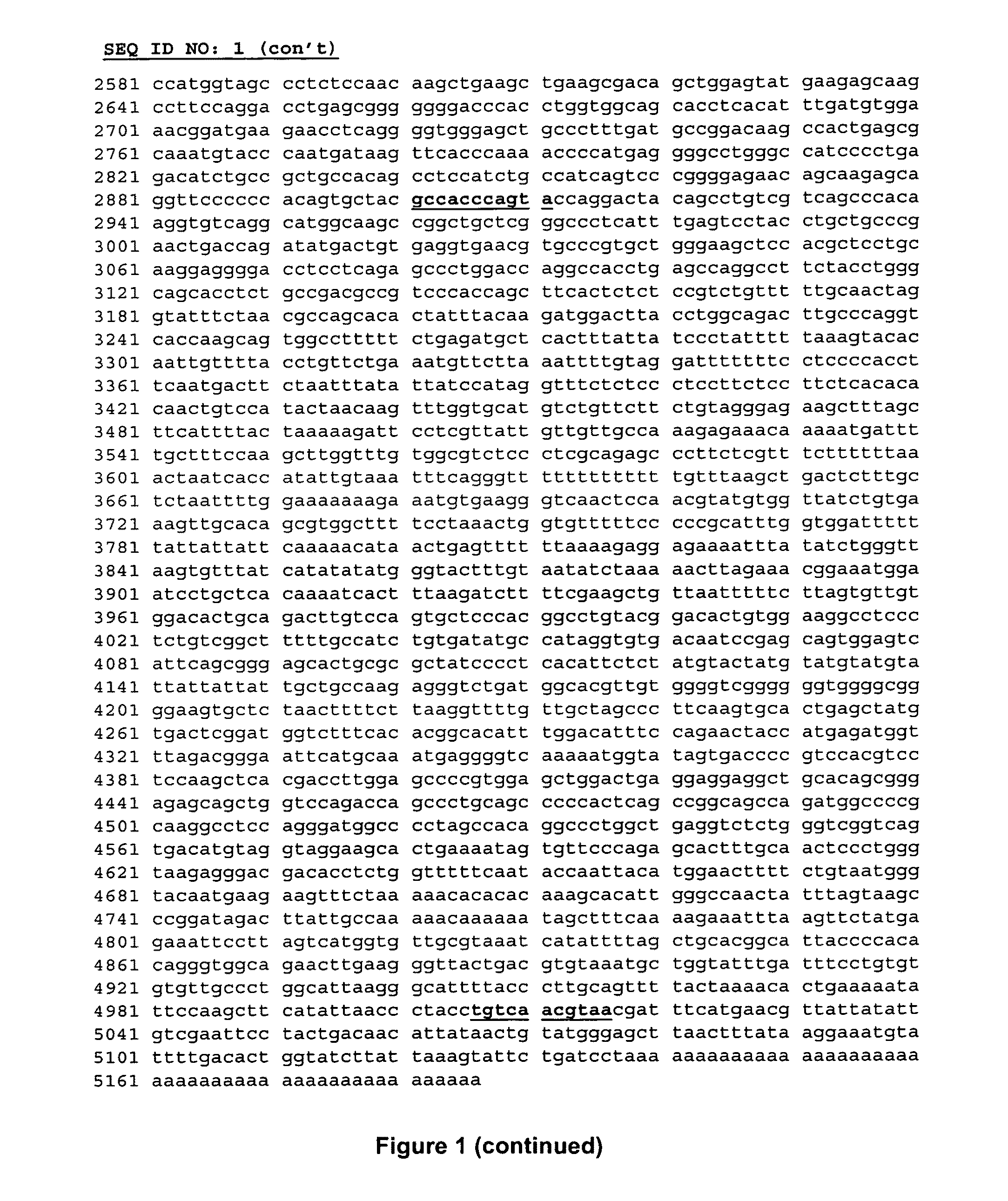

Compositions and use of EPAS1 inhibitors

InactiveUS20100010071A1RNA degradationImprove stabilityOrganic active ingredientsSugar derivativesPAS domainEPAS1

The present invention relates to inhibitors of endothelial PAS domain protein 1 (EPAS1), and methods and compositions related to the EPAS1 inhibitors. In certain embodiments, the EPAS1 inhibitors include nucleic acids, such as for example siRNAs.

Owner:CALANDO PHARMA INC

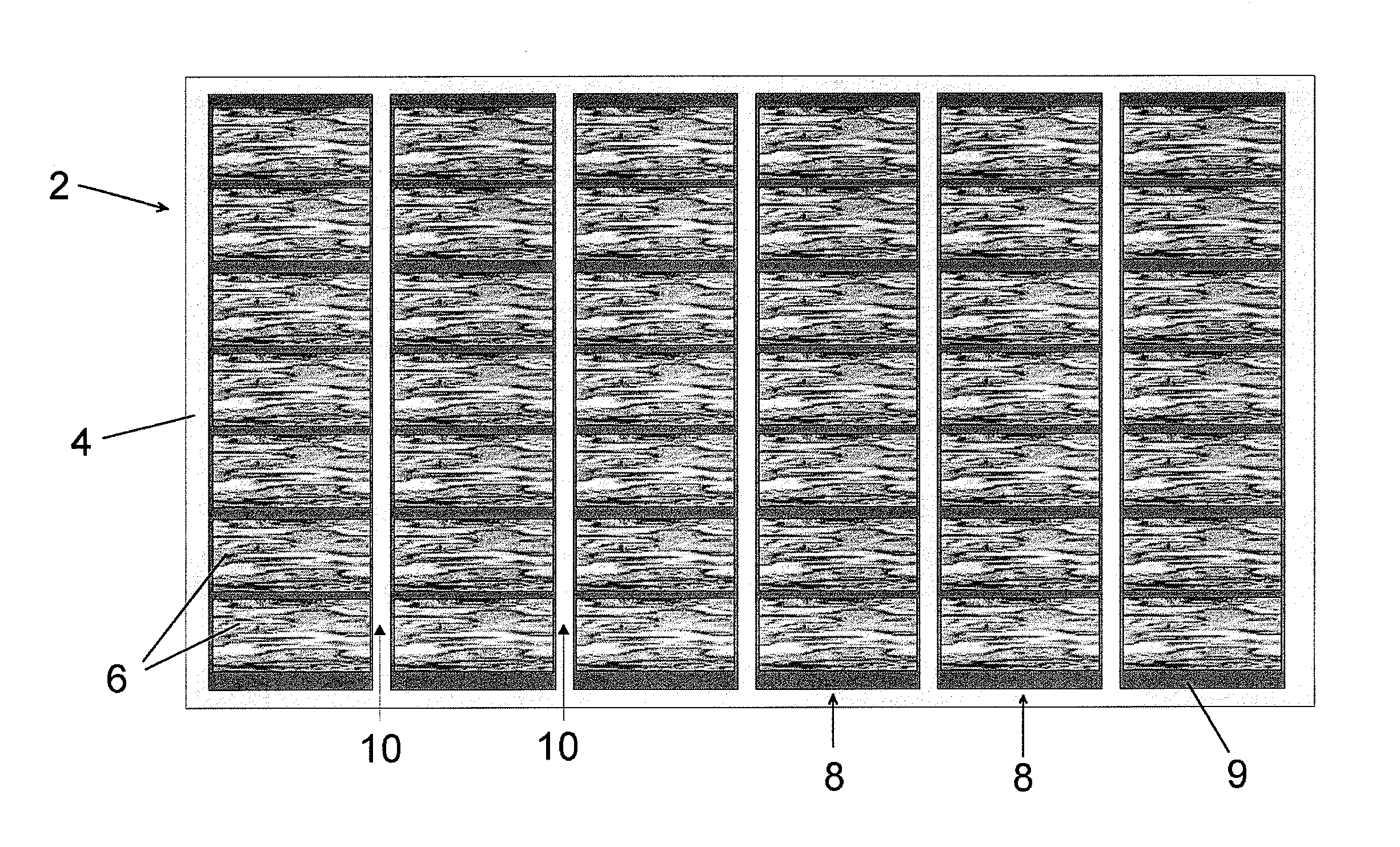

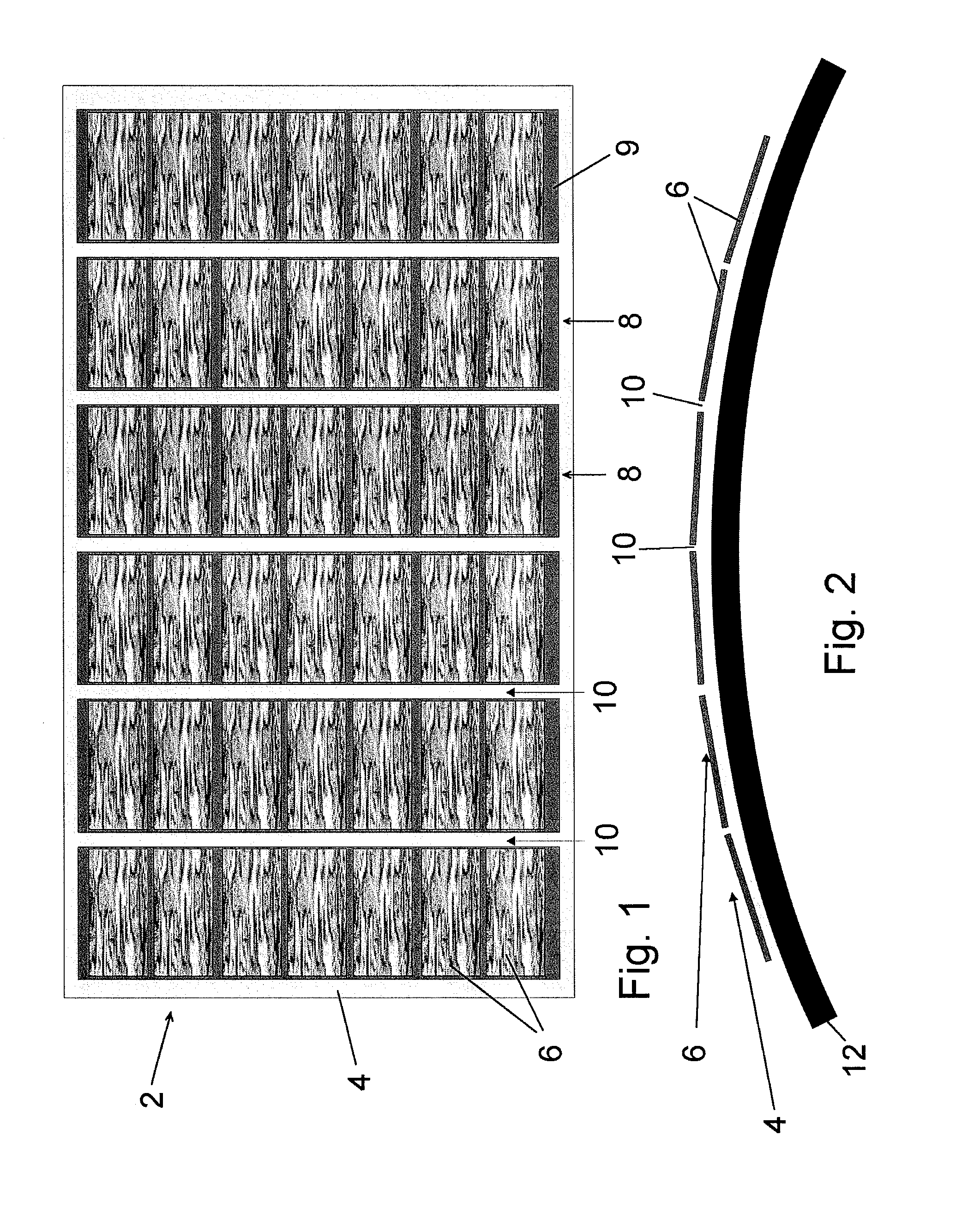

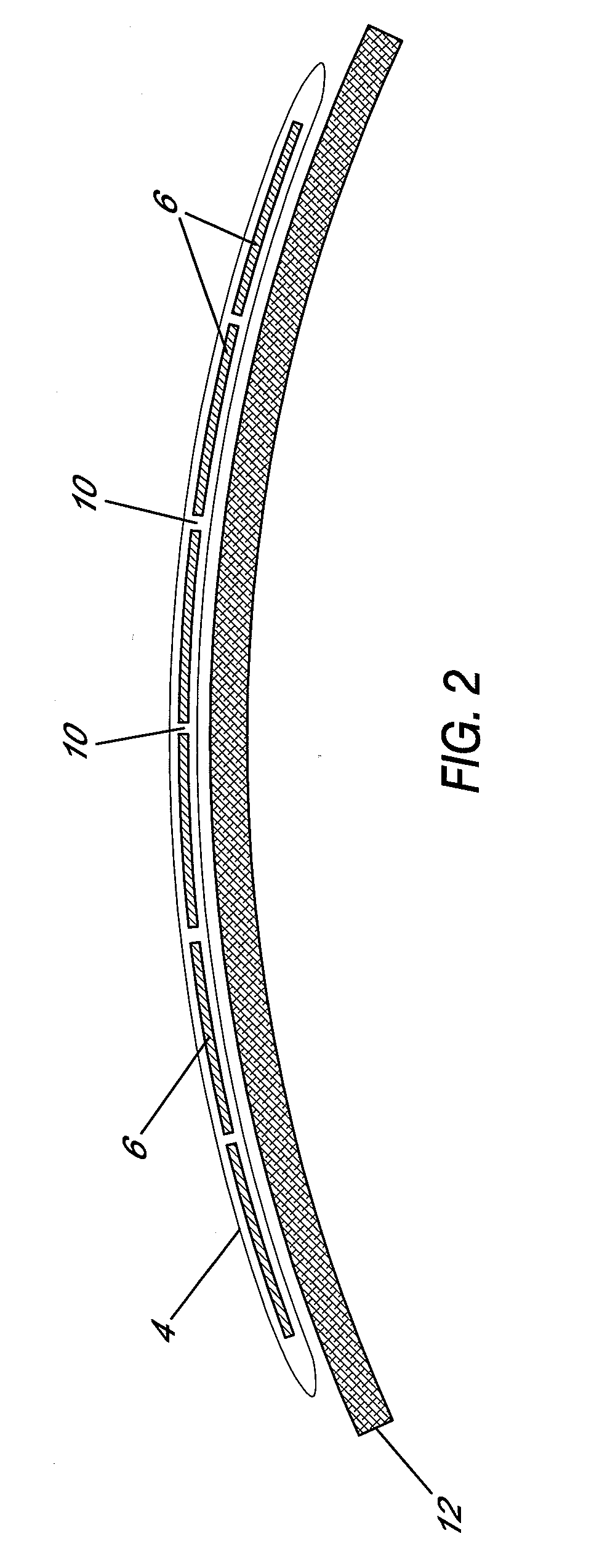

Solar panel

InactiveUS20090044852A1Not affect performance of photovoltaicEfficiency is not affectedPV power plantsPhotovoltaic energy generationEngineeringElectrical current

A solar panel including a flexible polymeric support element and a plurality of photovoltaic cells supported by the support element. At least some of the photovoltaic cells are spaced apart such that the flexible support element provides a hinge between the spaced apart photovoltaic cells. A plurality of bypass diodes are connected in parallel with the cells, so that if one of the cells ceases to operate, electrical current generated by the other cells is able to bypass the inoperative cell.

Owner:ZETA CONTROLS LTD

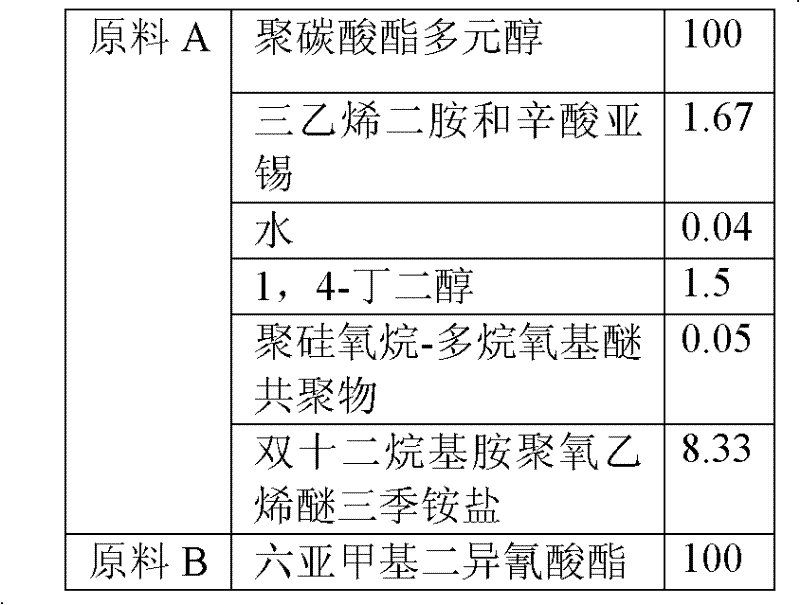

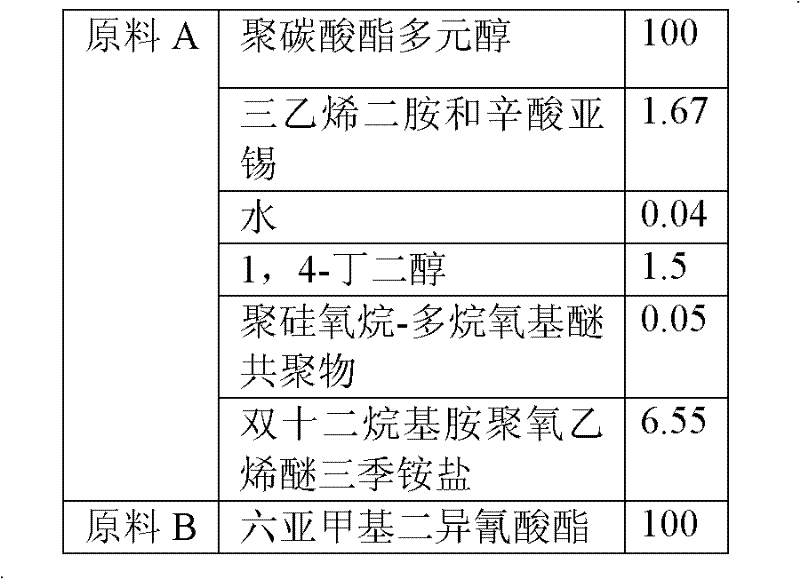

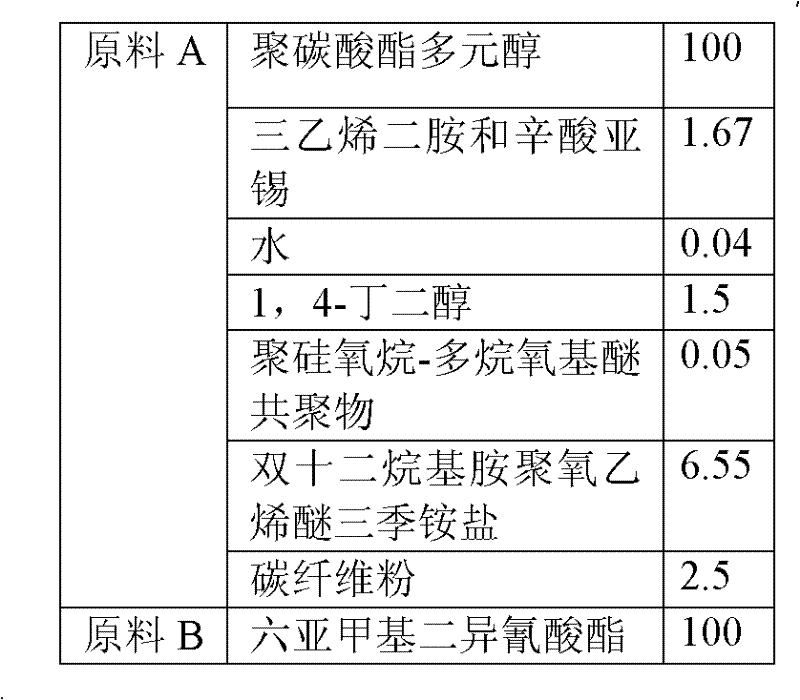

Anti-static polyurethane material for manufacturing shoe soles, shoe sole manufacturing method and manufacturing method of dual-density polyurethane safety shoe soles

ActiveCN102504519AImprove anti-static performanceGood anti-static performanceSolesDefoaming AgentsIsocyanate compound

The invention discloses an anti-static polyurethane material for manufacturing shoe soles, a shoe sole manufacturing method and a manufacturing method of dual-density polyurethane safety shoe soles. The anti-static polyurethane material consists of a component A and a component B which are mixed and poured, the component A includes polyatomic alcohol, catalyst, foaming agent, anti-static agent, carbon fiber powder, chain extender and defoaming agent; and the component B is isocyanate. The shoe sole manufacturing method includes steps of baking and drying the polyatomic alcohol and the isocyanate, mixing the rest compositions in the component A and the baked polyatomic alcohol uniformly to form material A, and mixing the material A with the isocyanate of the component B to obtain shoe soles made of anti-static polyurethane materials by pouring forming. The dual-density polyurethane safety shoe soles can be manufactured by secondary pouring by selecting foaming agents in different quantity. The polyurethane materials are high in anti-static performance, and the manufactured shoe soles are proper in hardness. Shoe soles manufactured by the manufacturing methods are fine in demouldingand high in production efficiency.

Owner:深圳市新纶超净科技有限公司

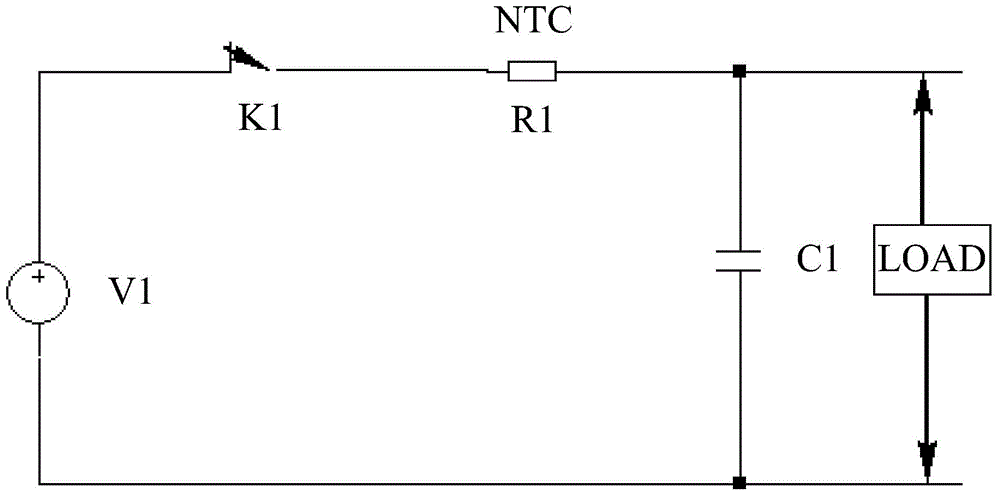

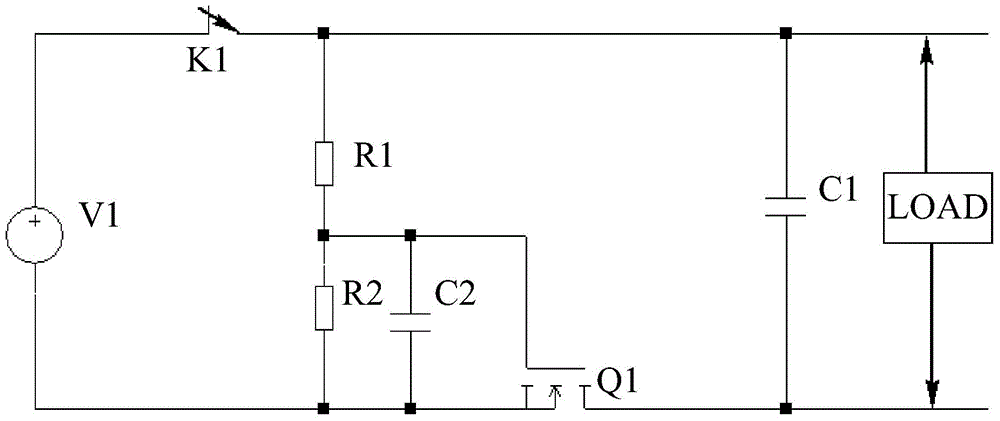

Method and circuit for restraining surge current of DC electrical source

InactiveCN105322522AEasy to implementImprove reliabilityBatteries circuit arrangementsPower supply for data processingCapacitancePower flow

The present invention discloses a method and a circuit for restraining surge current of a DC electrical source. The method includes the steps as follows: a secondary electric power supply is connected to a power supply, and charges an energy storage unit through a constant-current source circuit; a voltage detection circuit drives a time delay circuit when the voltage detection circuit detects that the voltage of an energy storage capacitor in the energy storage unit reaches to a preset voltage value; the time delay circuit drives a switch unit to be opened slowly until the switch unit is fully conducted; the switch unit bypasses the constant-current source circuit and charges the energy storage unit. According to the technical scheme of the present invention, the impact current can be restrained, and the voltage drop of a slow startup switch during starting can be reduced.

Owner:ZTE CORP

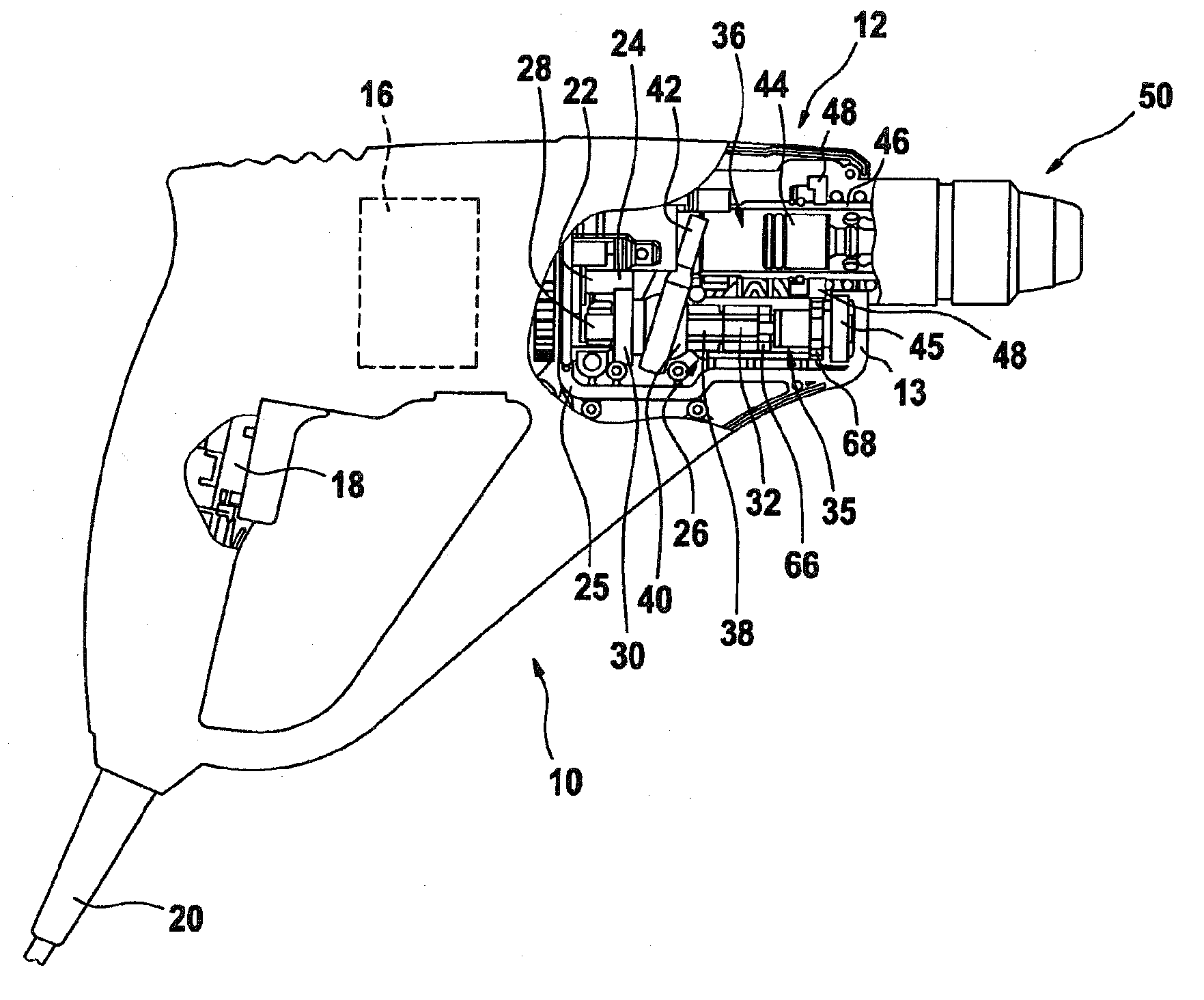

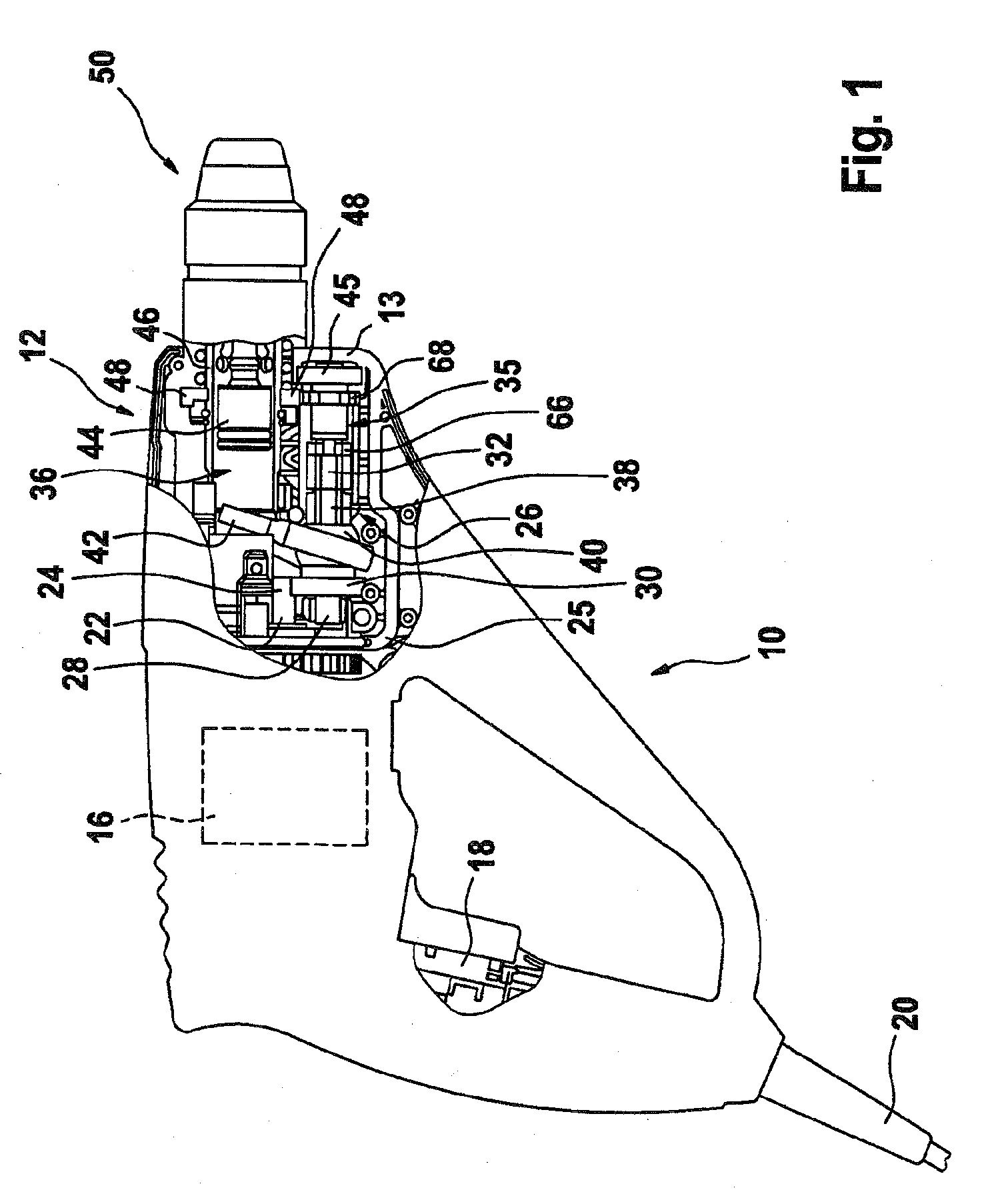

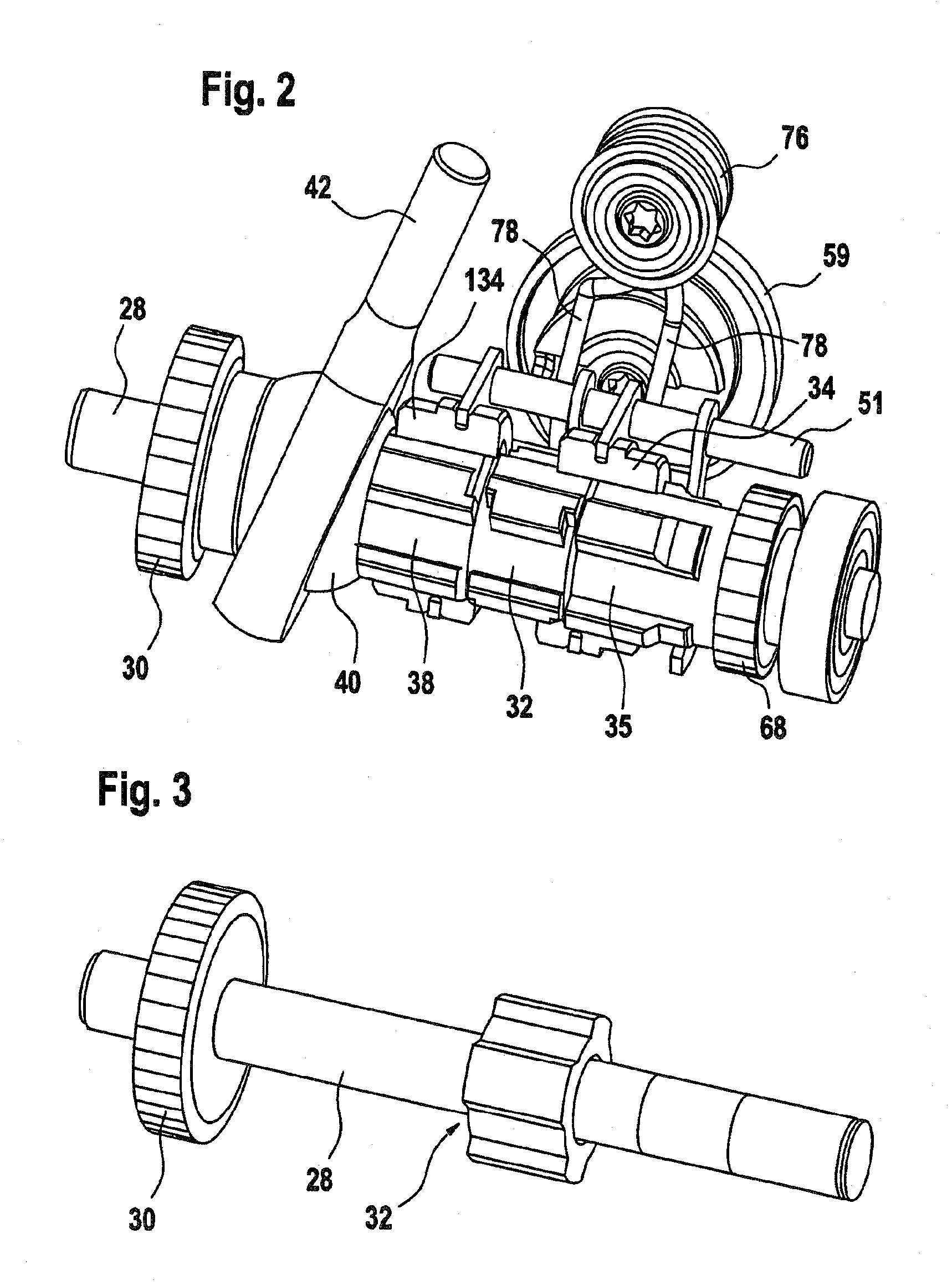

Drill Hammer With Three Modes of Operation

ActiveUS20080169111A1Promote conversionReduce friction lossDrilling rodsReciprocating drilling machinesGear wheelElectric machine

A hammer drill (10), consisting of a housing (12), accommodating the parts mentioned below and assembled in particular from half shells (13, 14), a motor (16) with an on / off switch (18) and with a motor shaft (22) with motor pinion (24), a gear unit (26) with an intermediate shaft (28), with a drive gear (30), with a splined driving shaft (32), with a shifting sleeve (34) and with an output gear (35), a percussion mechanism (36), in particular with a wobble plate (40), with a wobble gear (38) with wobble finger (42), and with a percussion element (44), an output shaft (46) with a drive gear (48), and a drill chuck (50), wherein the motor (16) meshes with the drive gear (30) of the intermediate shaft (28) via its motor pinion (24), wherein the rotary driving of the wobble plate (40) with the intermediate shaft (28) can be set or stopped via coupling or release of the shifting sleeve (34), in particular with the splined driving shaft, preferably by displacing with shifting means (52), and wherein the rotary driving of the output shaft (46) with the intermediate shaft (28) can be set or stopped via separate means, in particular independently of the shifting sleeve (34), can be produced cost-effectively and works at a high efficiency by virtue of the fact that a second shifting sleeve (134) serves to set the rotation of the output shaft (46), said shifting sleeve (134) enclosing the splined driving shaft (32) and / or the output gear (35) in a positive-locking and axially displaceable shiftable manner.

Owner:ROBERT BOSCH GMBH

Antibacterial shading medical polyvinyl chloride plastic and preparation method thereof

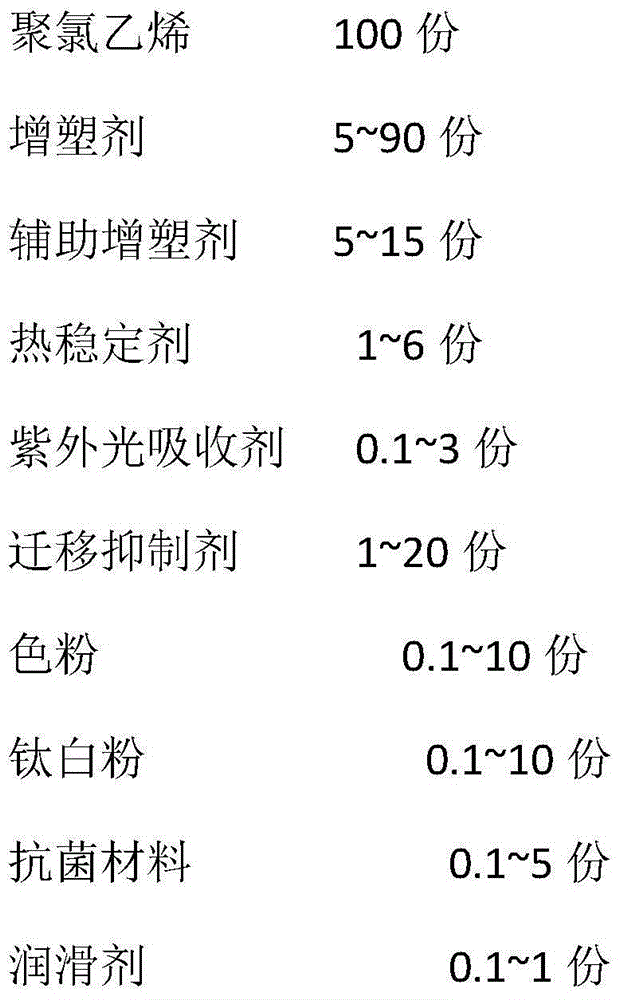

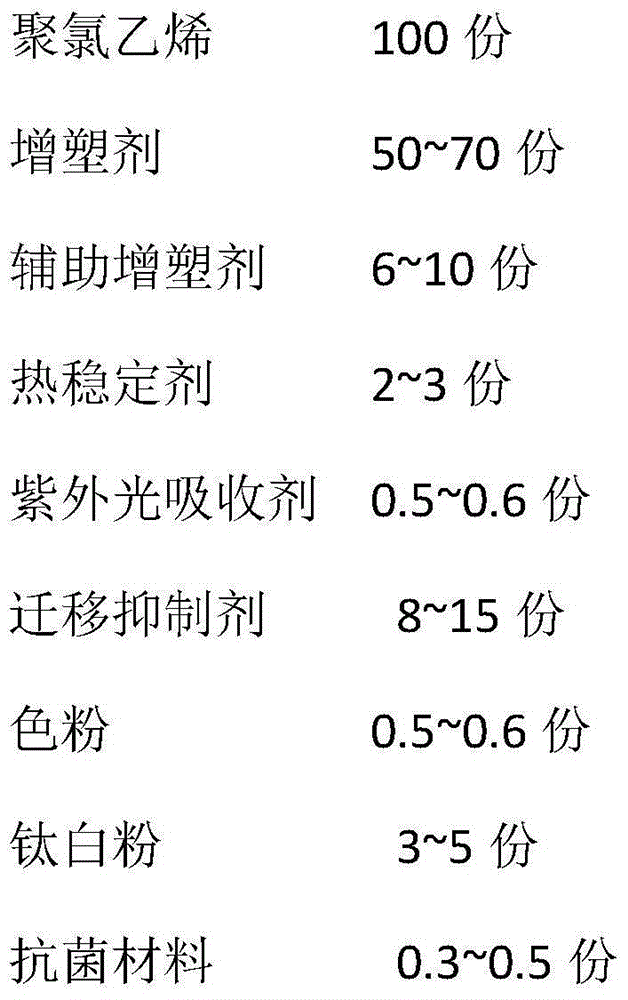

The invention discloses antibacterial shading medical polyvinyl chloride plastic and a preparation method thereof. The antibacterial shading medical polyvinyl chloride plastic comprises, by weight, 100 parts of polyvinyl chloride, 5-90 parts of a plasticizer, 5-15 parts of an auxiliary plasticizer, 1-6 parts of a heat stabilizer, 0.1-3 parts of a ultraviolet light absorbent, 1-20 parts of a migration inhibitor, 0.1-10 parts of toner, 0.1-10 parts of titanium dioxide, 0.1-5 parts of an antibacterial material and 0.1-1 part of a lubricant. The migration inhibitor is beta-cyclodextrin. The antibacterial shading medical polyvinyl chloride plastic can effectively inhibit migration or decoloring of micromolecule substances such as a plasticizer and toner, can improve transfusion apparatus safety after disinfection, can guarantee patient usage safety, can thoroughly prevent light-avoiding agent migration and illumination-caused influence on a medical agent, does not influence drug use efficiency, has excellent dyeing resistance and anti-tarnishing performances in processing or use and does not influence PVC material transparency.

Owner:上海新上化高分子材料有限公司

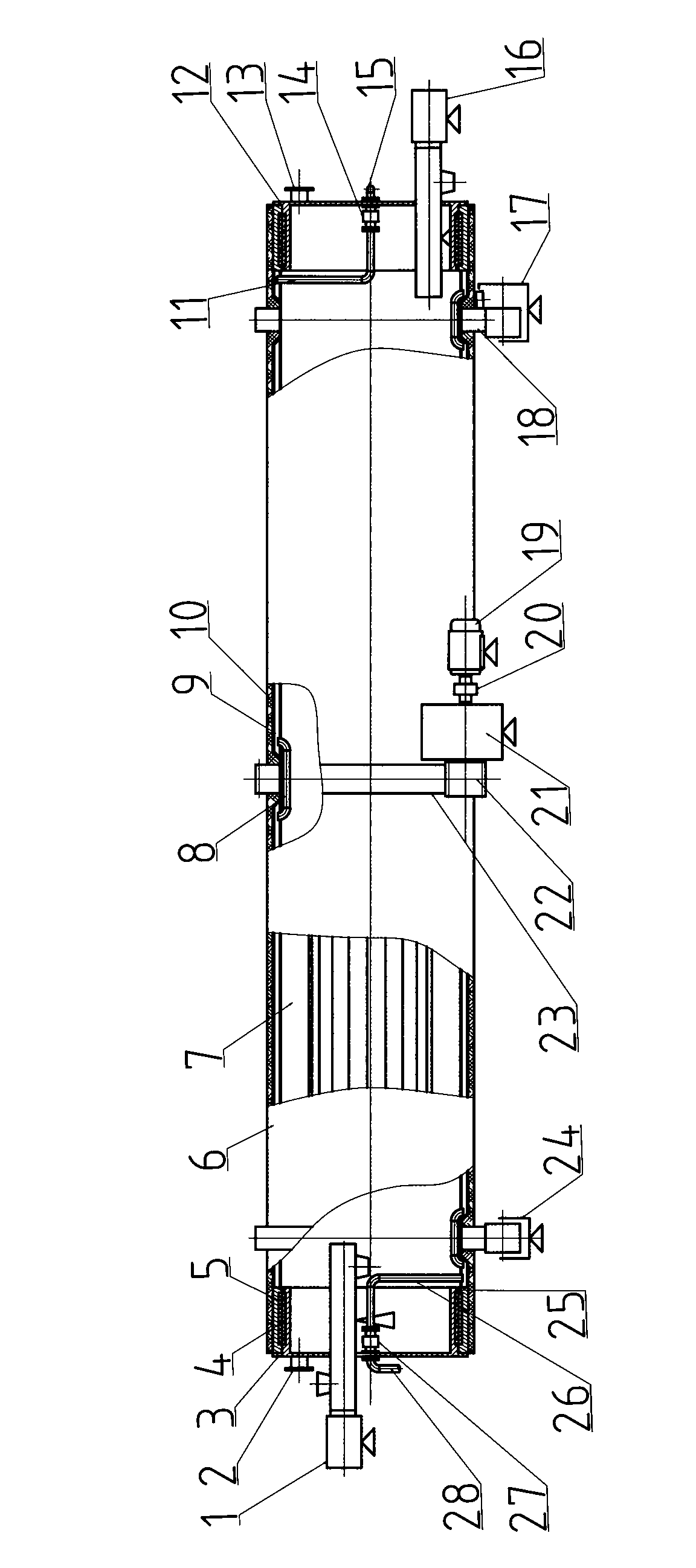

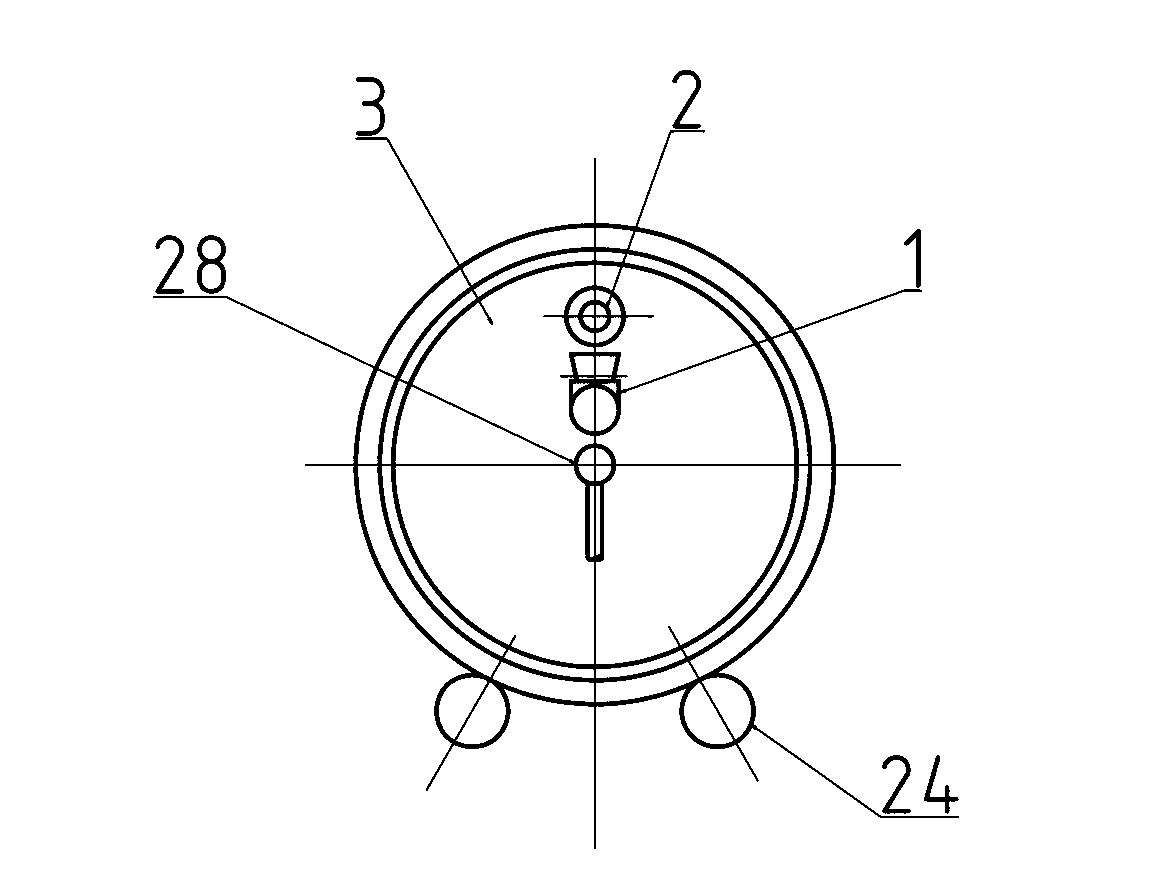

Horizontally-arranged cylinder rolling type aerobic fermentation apparatus with heat exchange function

ActiveCN102757270ARealize resource utilizationHigh-speed fermentation reactionBio-organic fraction processingOrganic fertiliser preparationReducerSmall footprint

The invention relates to a horizontally-arranged cylinder rolling type aerobic fermentation apparatus with a heat exchange function. A horizontally-arranged cylinder fermentation tank is supported by supporting roller sets. Bearings are arranged on left and right ends of the cylinder fermentation tank. The cylinder fermentation tank is connected to left and right side sealing caps through bearing outer rings and bearing inner rings. The fermentation tank, the bearings and the sealing caps form a sealed space. A spiral feeder and an exhaust pipe, and a spiral discharging machine and a gas inlet pipe are respectively arranged on the left and right side sealing caps. A coaxial cylindrical heat exchange water sleeve is arranged outside the cylinder fermentation tank. A motor, a coupler, a speed reducer, and a pinion are sequentially connected. The pinion is engaged with an outer gear ring on the cylinder fermentation tank. The apparatus provided by the invention is advantaged in small land occupation, high fermentation efficiency, and no secondary pollution. The apparatus is not affected by environment factors and low-temperature conditions. A finished product is advantaged in low water content, and can be commercialized as high-quality organic fertilizer. Therefore, excrement reduction, harmless modification and recycling and utilization can be realized. No odor or heat is discharged outside, and an environment protection effect is good.

Owner:HUNAN SCIENTOP AUTOMATIC EQUIP SHARES +1

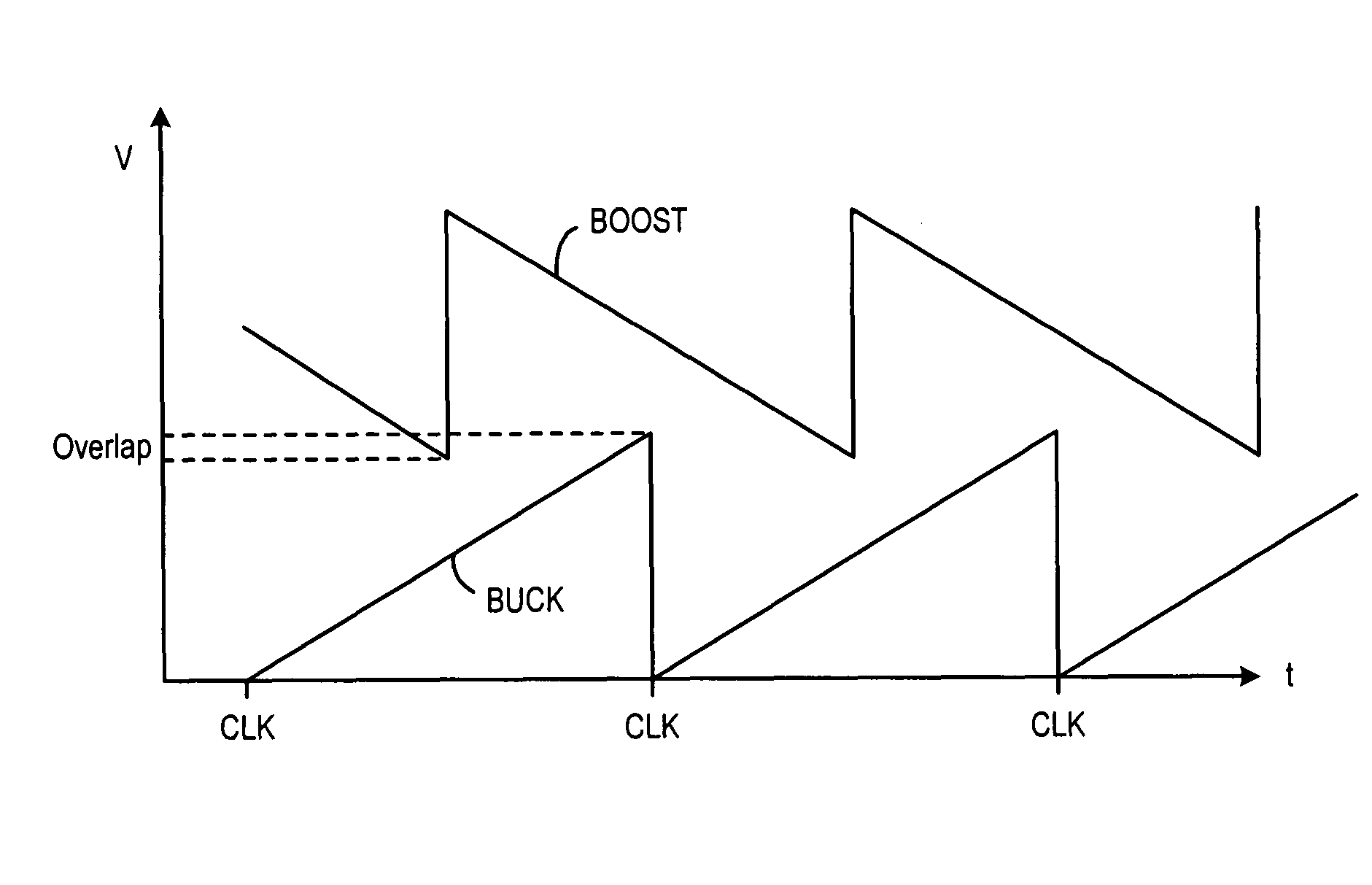

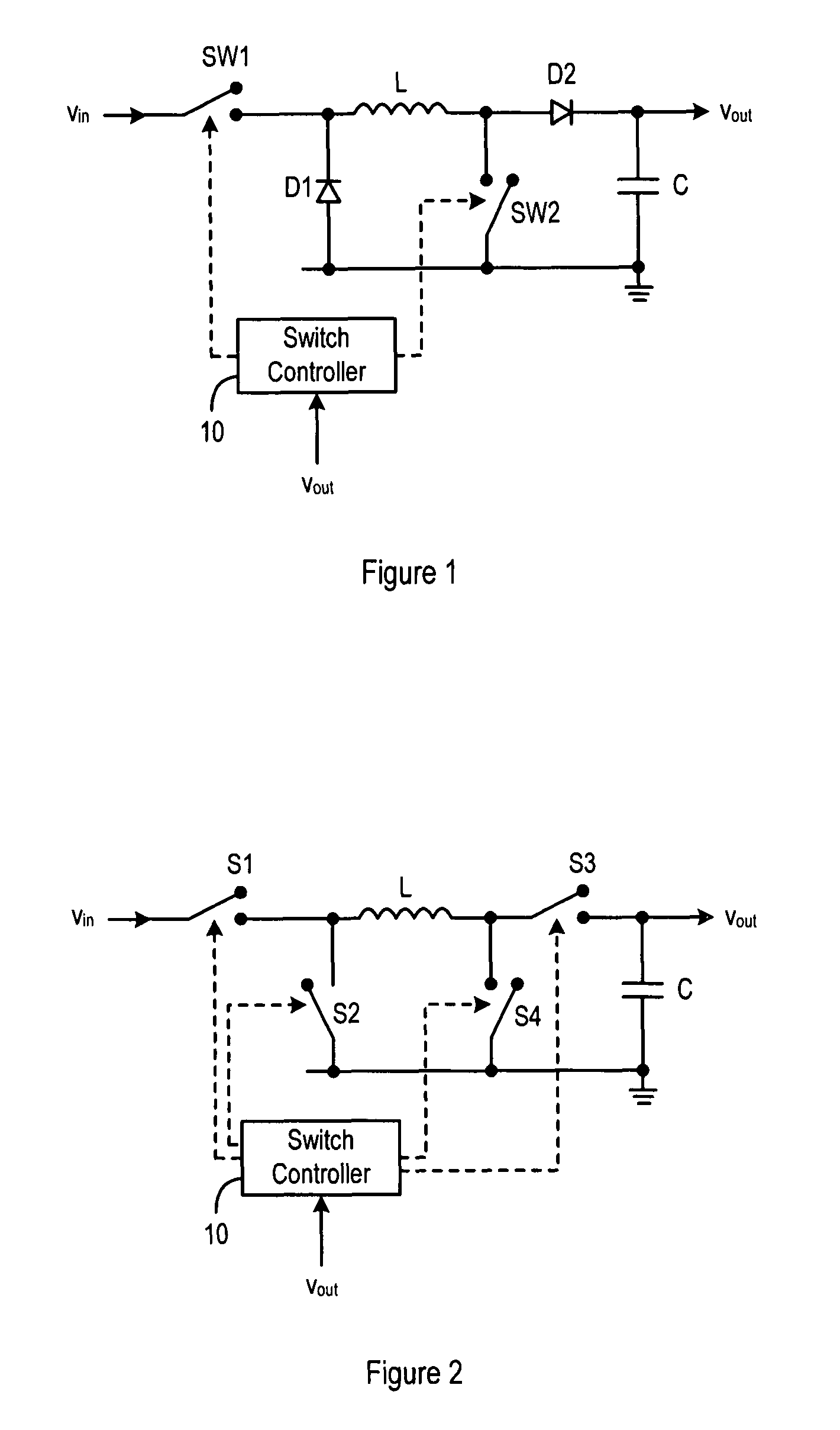

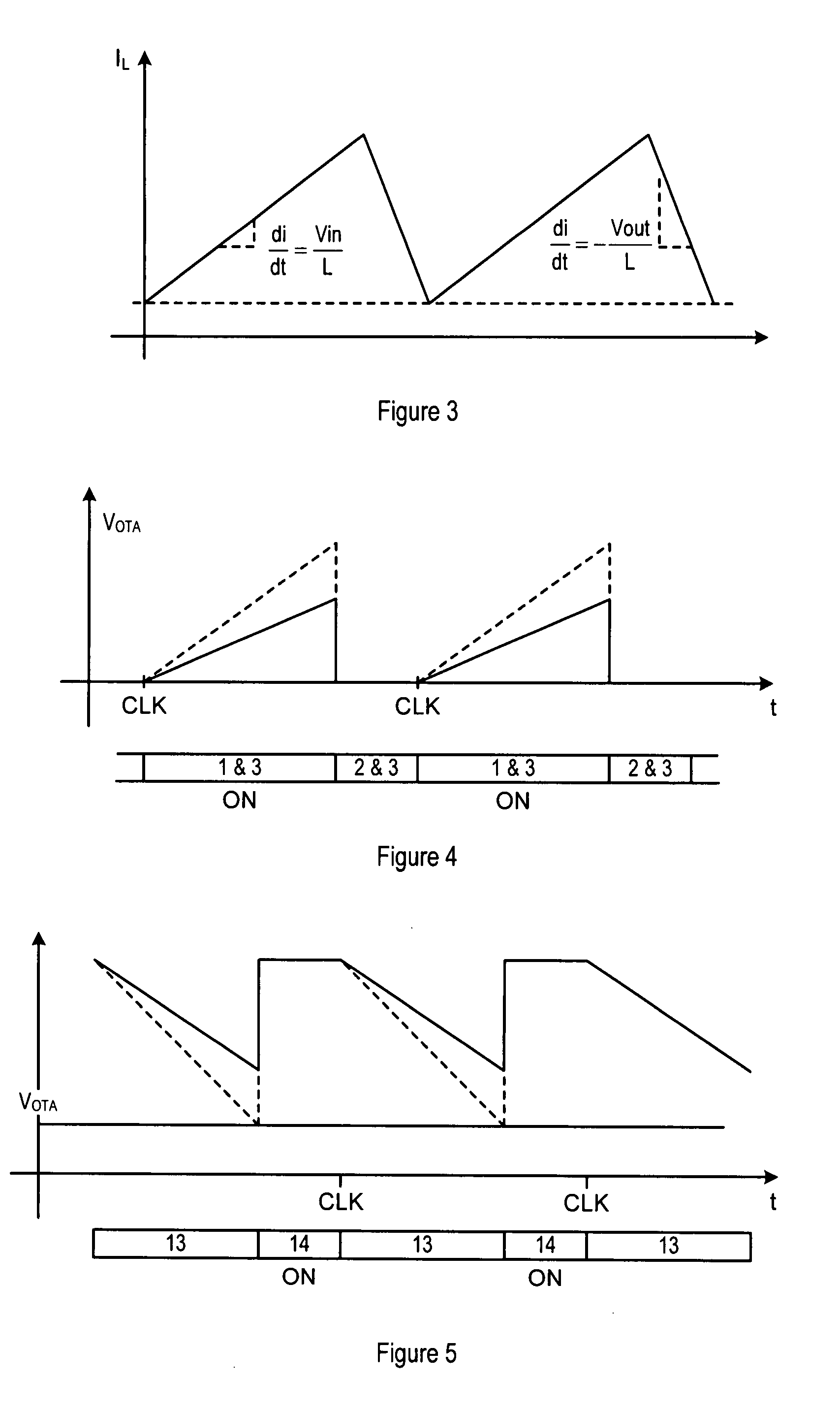

Constant frequency current-mode buck-boost converter with reduced current sensing

ActiveUS7777457B2Efficiency is not affectedConstant output voltageDc-dc conversionElectric variable regulationConstant frequencyCurrent sensor

A converter including an inductor (L), a first switch (SW1, S1) connected between an input terminal (Vin) and the inductor, a diode / switch (D1, S2), connected between the first end of the inductor and ground, a diode / switch (D2, S3) connected between the inductor and an output terminal (Vout), and a second switch (SW2, S4) coupled between inductor and ground. A current sensor senses current in the first switch (SW1, S1) as a measure of inductor current. Waveform generators (31, 32) generate buck and boost slope compensation ramps (RMP-BUCK, RMP-BOOST). Control logic (10) opens and closes the switches every clock period at individual duty cycles determined using a feedback signal derived from the output terminal, the sensed current and the slope compensation ramps. The slope compensation ramps are mutually offset such that current sensing is needed only while the first switch (SW1, S1) is closed.

Owner:CIRRUS LOGIC INC

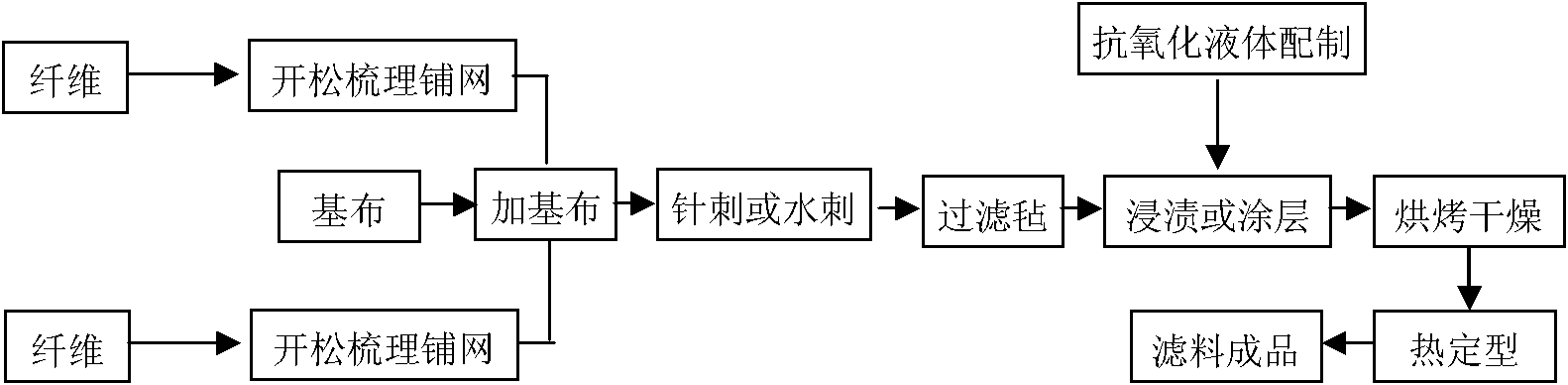

High temperature-resistant anti-oxidation filter material and manufacturing method thereof

ActiveCN102151436ADoes not affect resistanceEfficiency is not affectedLayered productsFiltration separationNeedle punctureOxidation resistant

The invention relates to a high temperature-resistant anti-oxidation filter material and a manufacturing method thereof, belonging to the technical field of high-temperature filter materials. 1%-10% of 2,5-di-tert-butylhydroquinone or rosemary antioxidant liquid is utilized for performing impregnation or coating treatment on a 300-1000g / square meter filter felt produced by the needle puncture method or the spunlacing method for coating an anti-oxidation coating layer with 0.5-50 microns on the surface of the filter felt, and then high-temperature baking treatment and thermosetting with steam or hot oil are performed for 1-60 minutes at the temperature of 100-235 DEG C for forming the high temperature-resistant anti-oxidation filter material for filtering high-temperature smoke dust. In order to solve the defects of the filter material for a bag dust collector in the anti-oxidation aspect, the invention provides the high temperature-resistant anti-oxidation filter material and the manufacturing method thereof, by using the high-temperature antioxidant to perform the impregnation or the coating on the filter material and further performing the baking and the thermosetting treatment,the filter material has the anti-oxidation property, and the too early aging failure of the filter material under a high-temperature oxidation environment can be avoided.

Owner:NORTHEASTERN UNIV

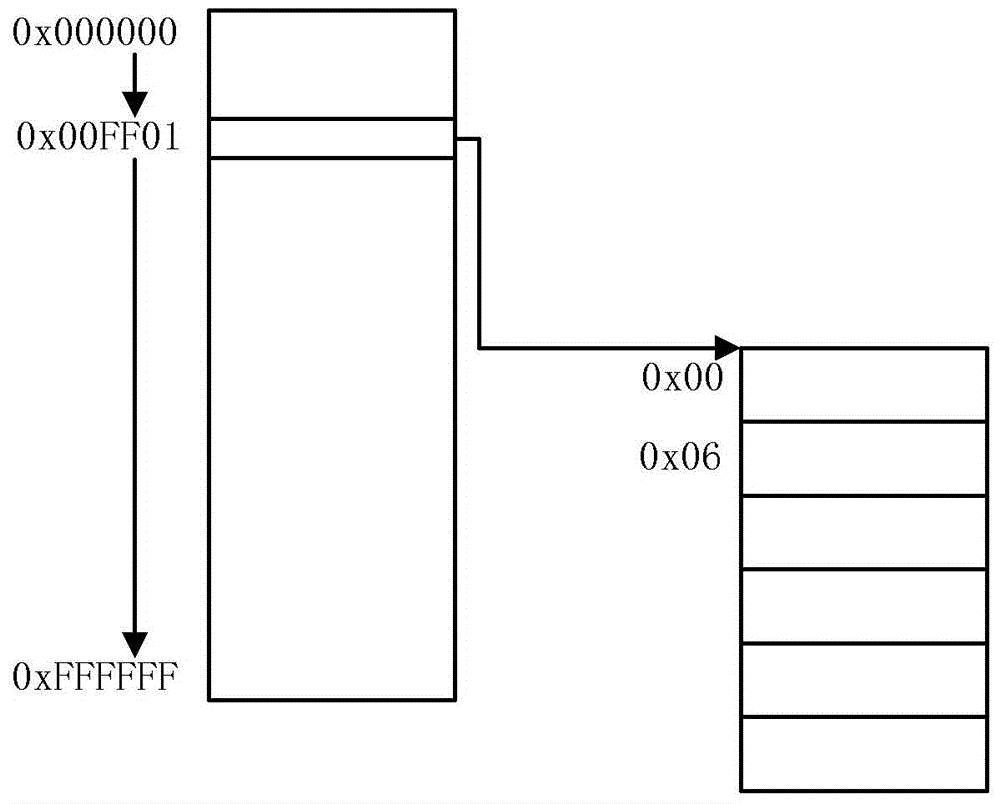

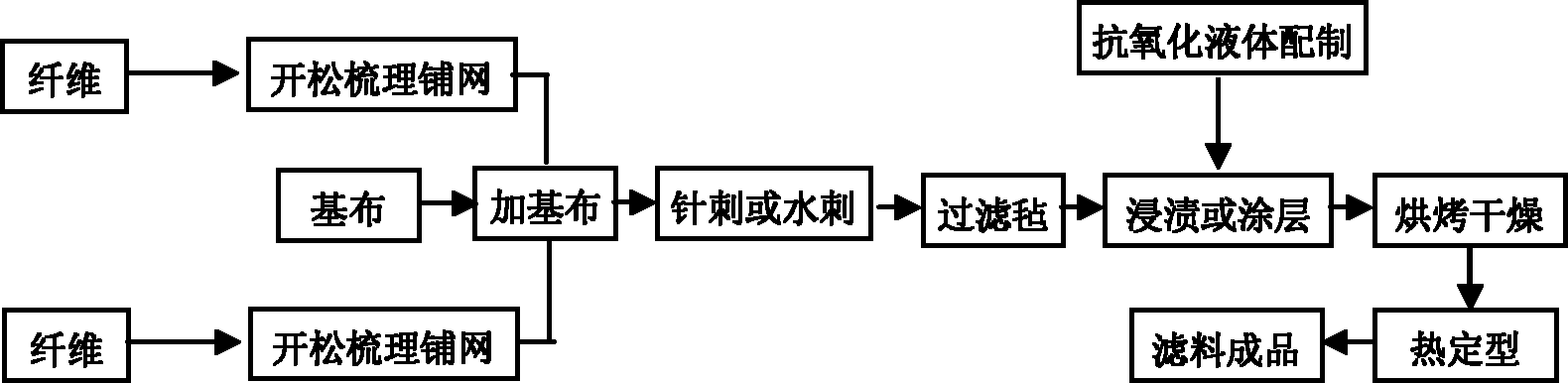

Method for searching data base ciphertext

InactiveCN1786963AEnsure consistencyGuaranteed correctnessSpecial data processing applicationsDaily operationCiphertext

The invention is a method for realizing fast cryptograph inquiry in database by auxiliary data structure, comprising the steps of establishing an auxiliary data structure, maintaining the auxiliary data structure and making cryptograph inquiry and its technical key points: by establishing a list-stored auxiliary data structure in the database for the fields to realize cryptograph inquiry, inserting the maintaining operation on the auxiliary data structure in the daily operation of the database and using the auxiliary data structure to inquire the cryptographic fields. The invention makes the database system originally not supporting cryptograph inquiry able to make high efficiency cryptograph inquiry on the cryptographic fields and can select encryption algorithms and secret keys by users and can assure the consistency of the whole database system and the accuracy and integrity of the cryptograph searching and other database operations. The invention can be applied to the database systems of the governments, armies and large-scale enterprises to be able to improve the system safety and strengthen the system practicality.

Owner:曾致中

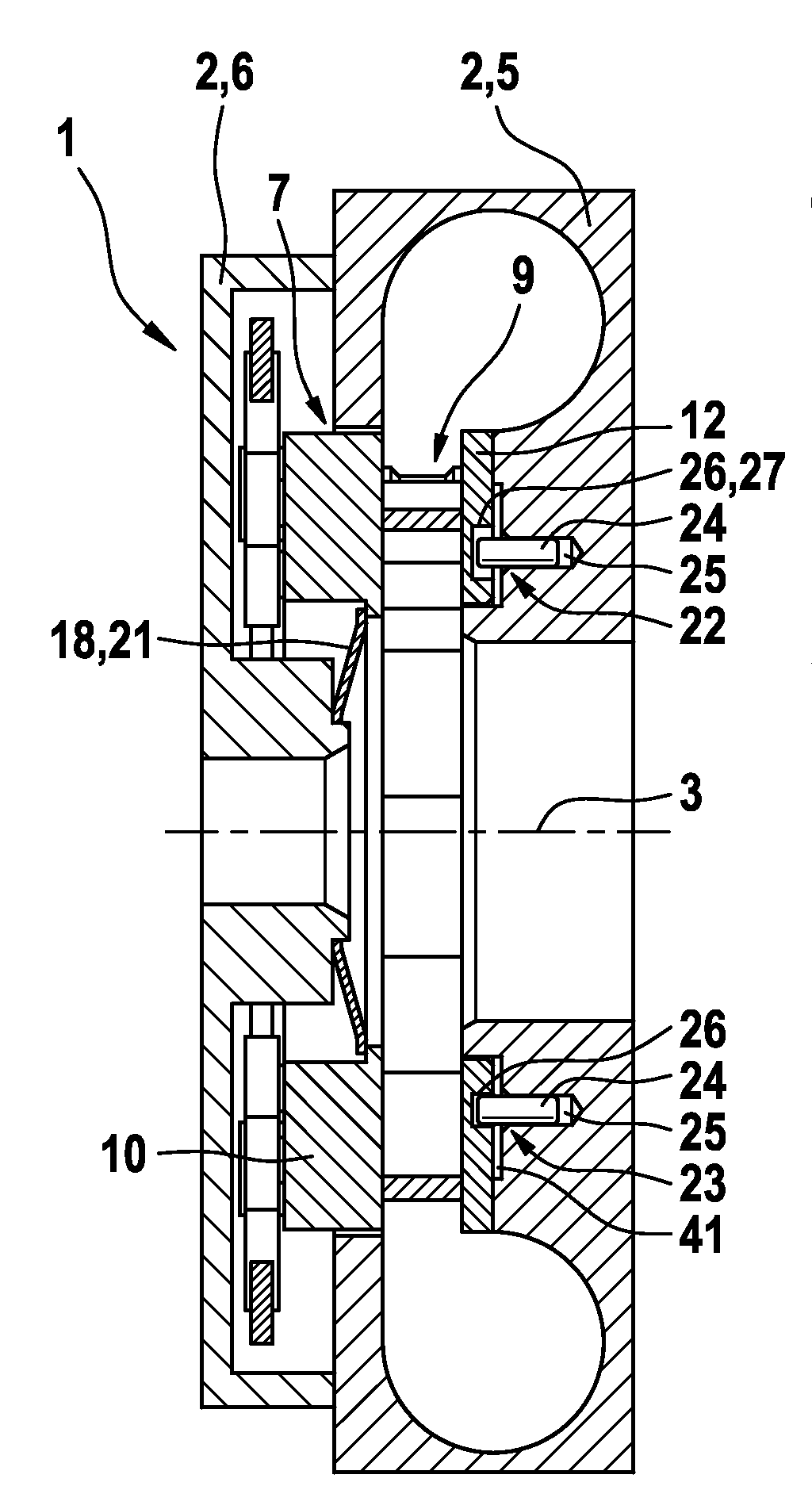

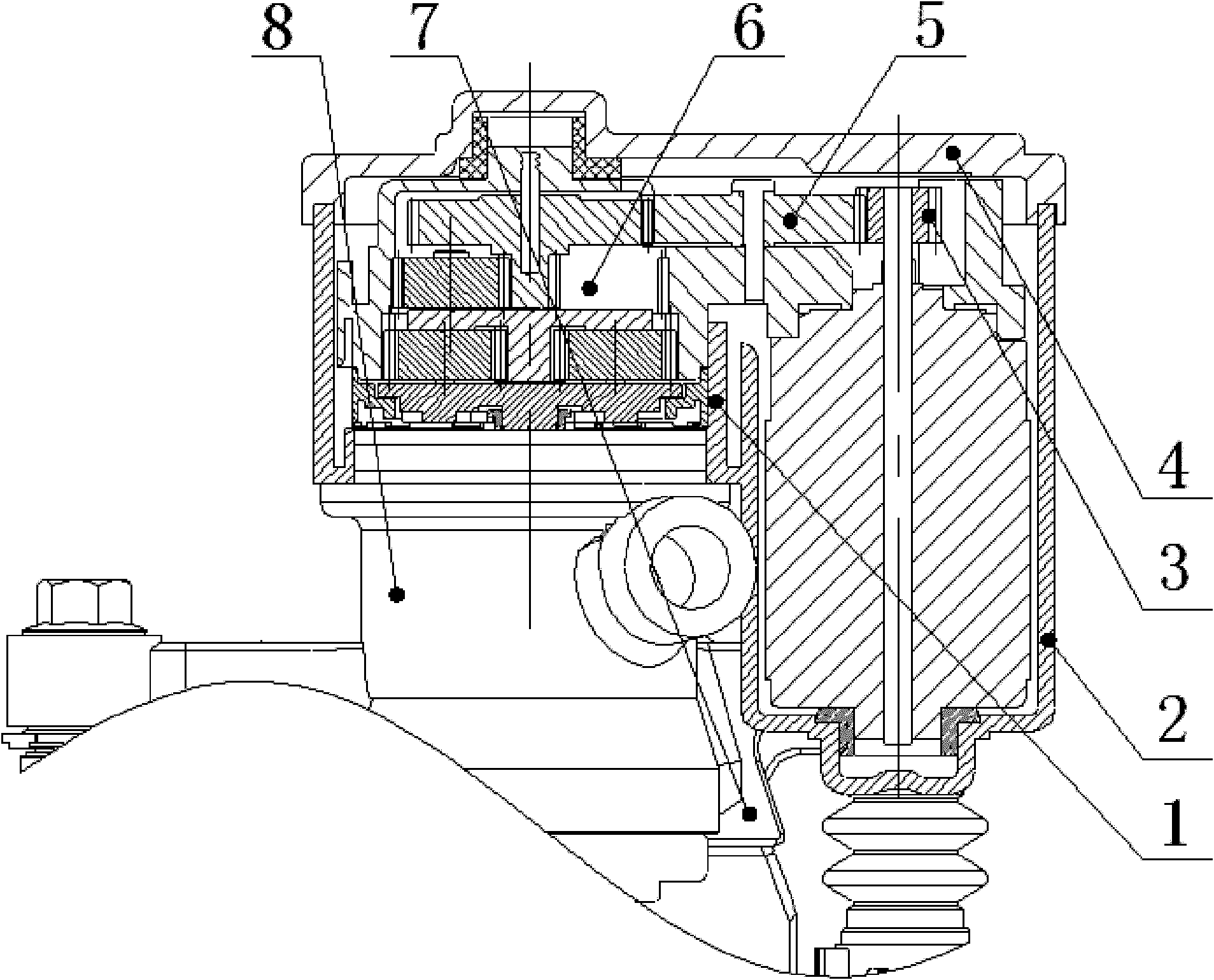

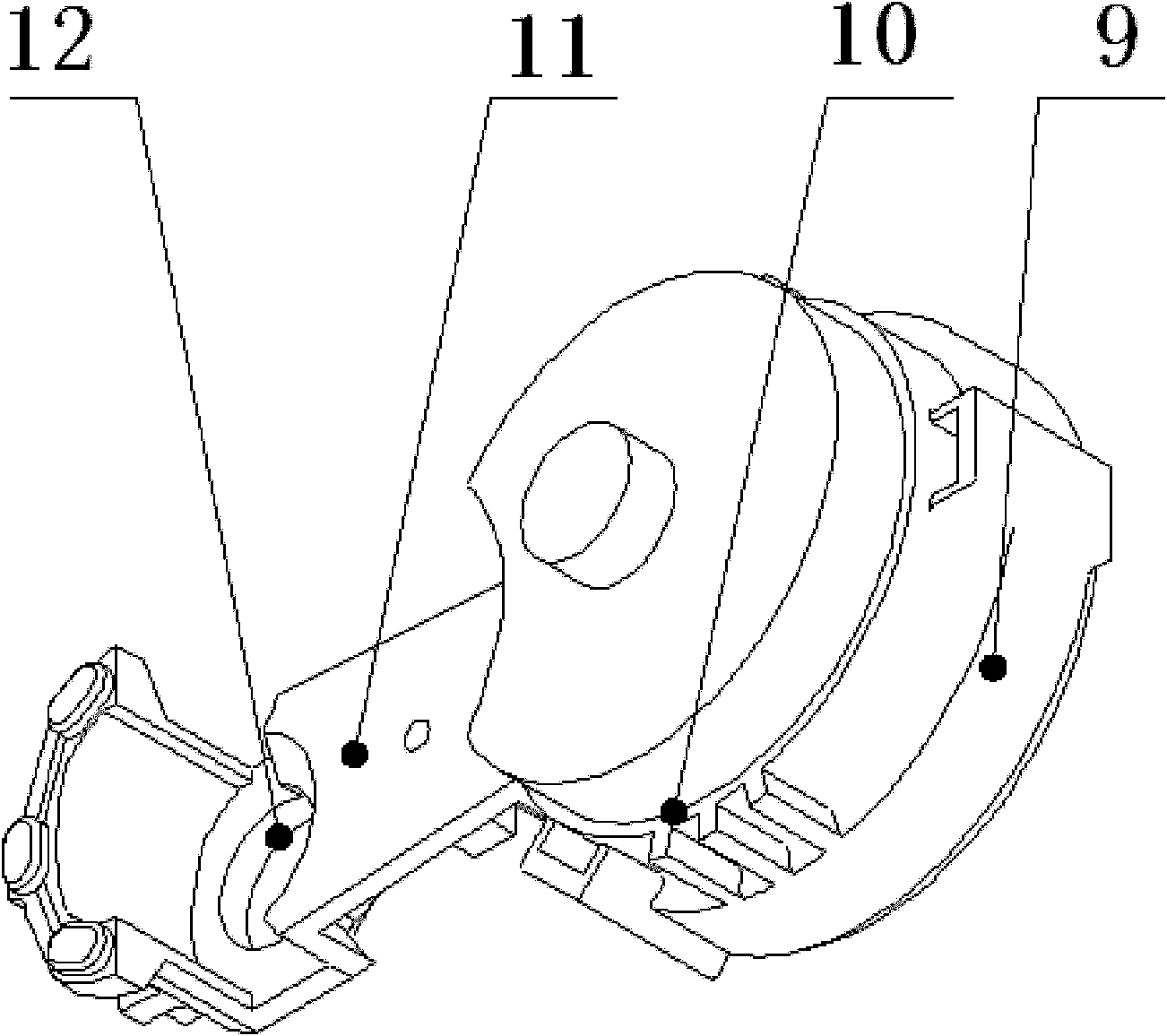

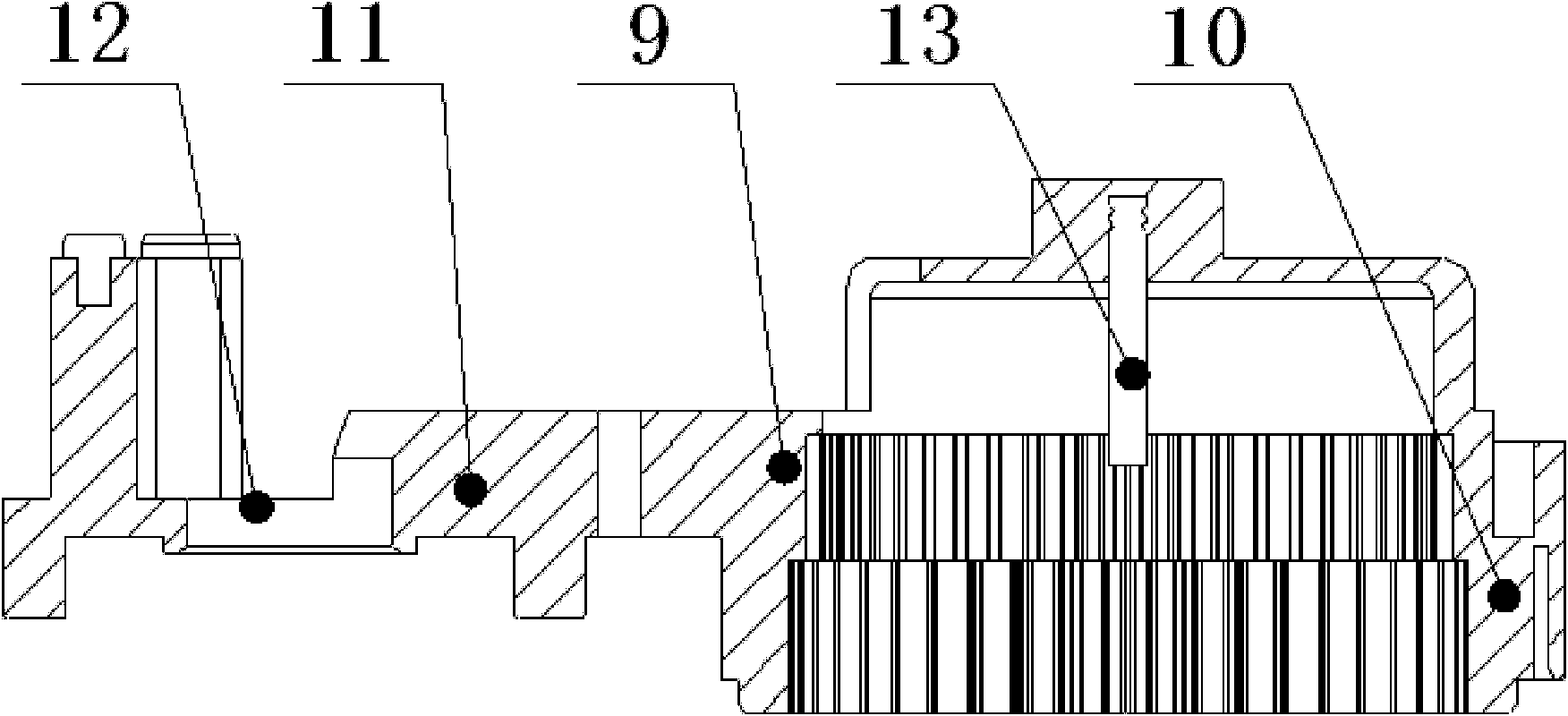

Electronic parking executor applied to motor vehicle brake system

ActiveCN102001334AImprove meshing accuracyIncrease product costBraking action transmissionBraking componentsGear transmissionMotor shaft

The invention discloses an electronic parking executor 1 applied to a motor vehicle brake system, which comprises a shell, a cover, a motor, motor accessories, a planetary gear transmission mechanism, parking brake calipers and the like. The electronic parking executor also comprises an integrated transmission mechanism frame, wherein a transmission mechanism and a planetary gear transmission mechanism from a motor shaft and a planetary gear main shaft are installed on a body in the integrated transmission mechanism frame, and the power transmission route of the transmission mechanism is from the motor shaft to the planetary gear main shaft. The technical scheme provided by the invention can effectively solve the problems of inconsistent assembly between rigid spacers and the motor shaft and the main shaft of the planetary gear transmission mechanism, axial nonparallelism and easy deformation of the rigid spacers after stressing in the prior art; meanwhile, the invention also has the characteristics of increasing the stability of internal transmission mechanism and the performance consistency after being connected with braking, reducing assembly cost, increasing assembly quality, benefiting tests, having good batch consistency and the like.

Owner:WUHU BETHEL AUTOMOTIVE SAFETY SYST

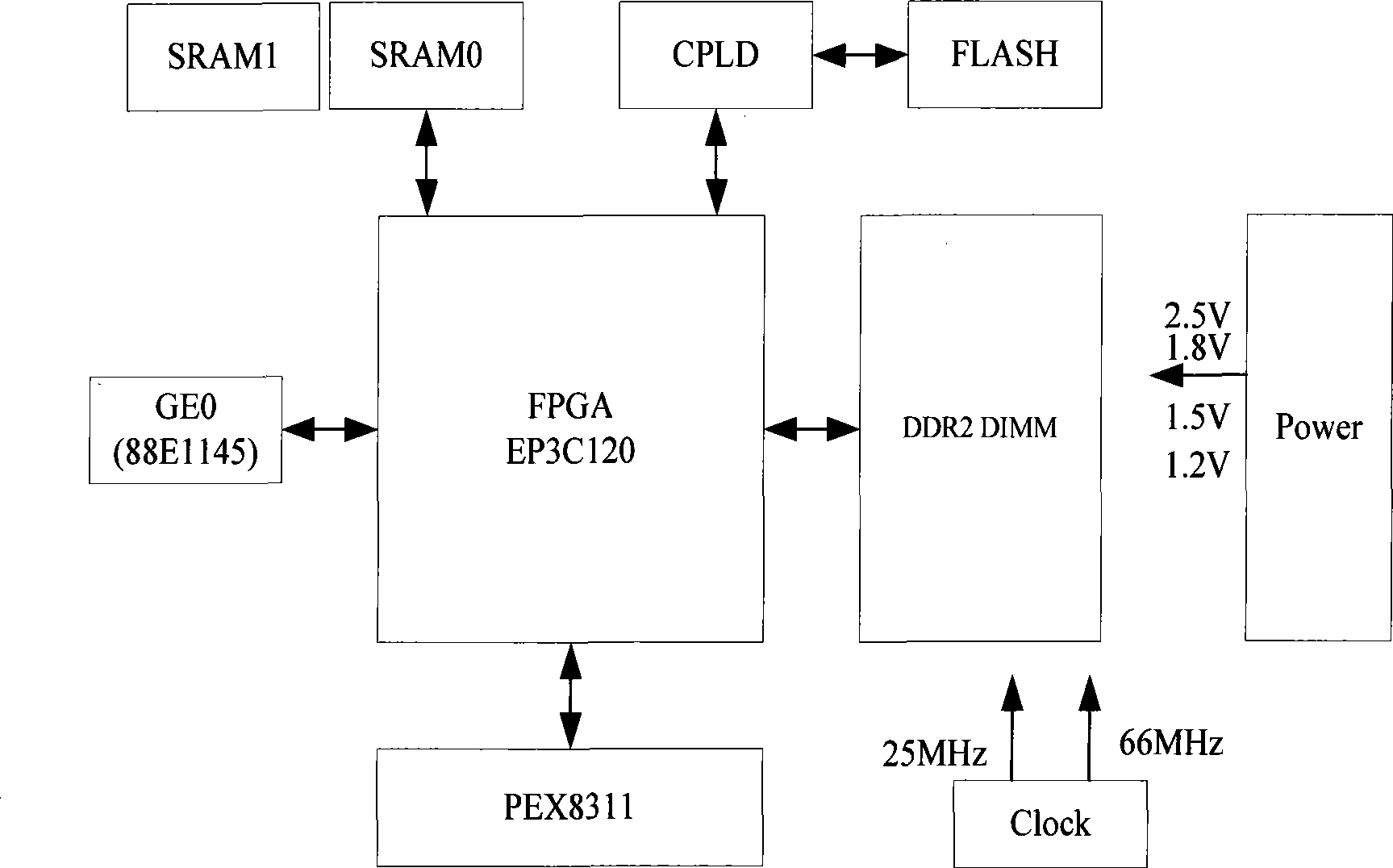

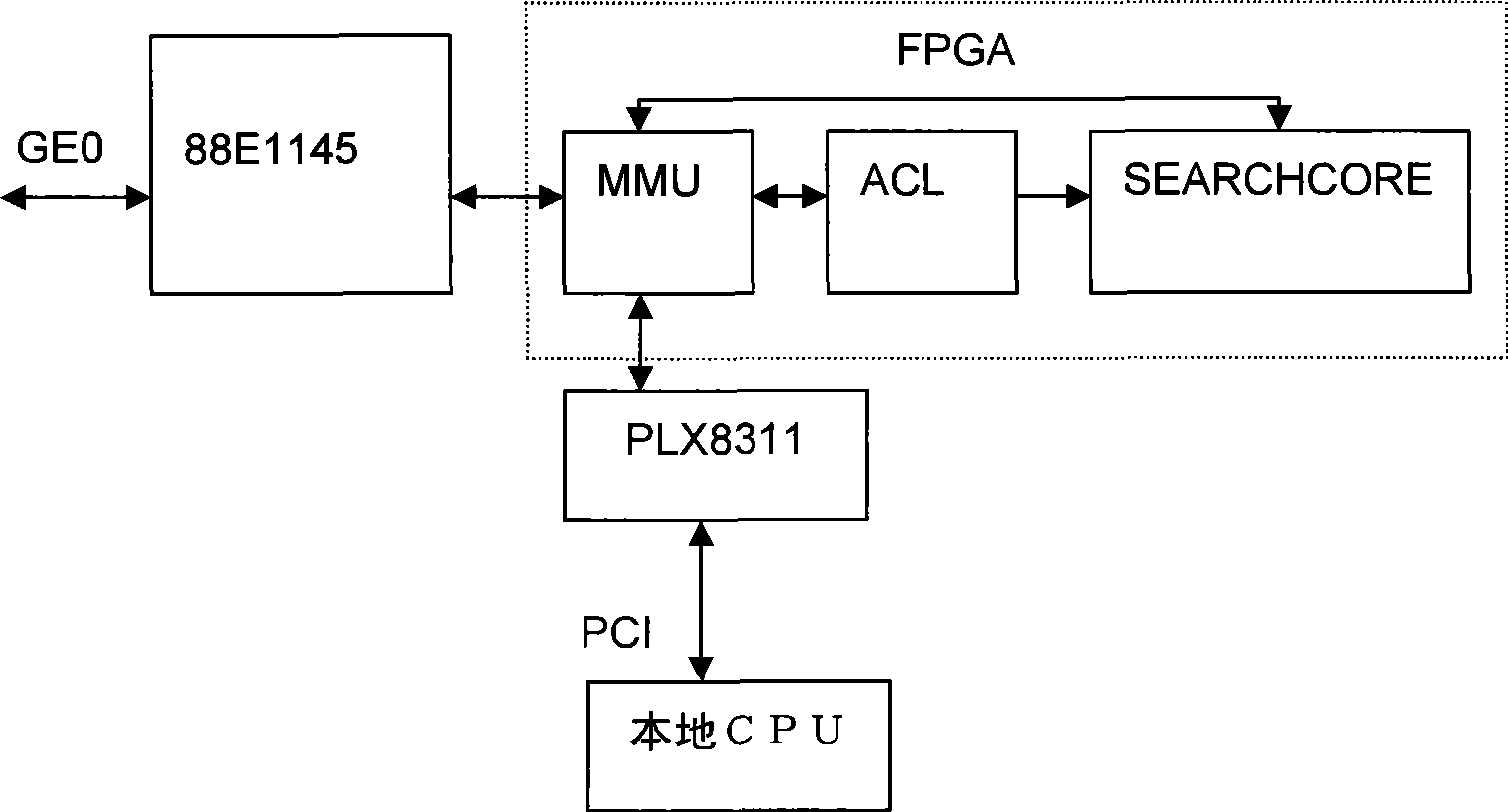

Network safe content processing card based on FPGA

InactiveCN101483649AHigh Content Processing CapabilityEfficiency is not affectedTransmissionWire speedNetwork packet

The invention relates to a network safety content processing card based on FPGA (field programmable gate array). The invention provides a method for solving the problem that contradiction between network safety and network speed and contradiction between network management and network cost are becoming serious. The method comprises giving first place to an FPGA safety chip, adopting a PCI card inserted into a PCI slot of a server, performing data communication with the server by using a PCI express interface protocol, connecting with an outer network through kilomega network ports for completing data receiving and sending, realizing byte-by-byte content detection, content labeling, and flow recombination of the server data under a kilomega line speed, and at the same time, realizing functions of network flow real-time controlling, blocking, inbreak detecting and log auditing. By adopting the invention, networking cost can be reduced, CPU resources of servers can be saved, a CPU can focus on completing other functions, and therefore, the integral performance of the system is improved.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Display system and display method applied to embedded digital entertainment on-demand system

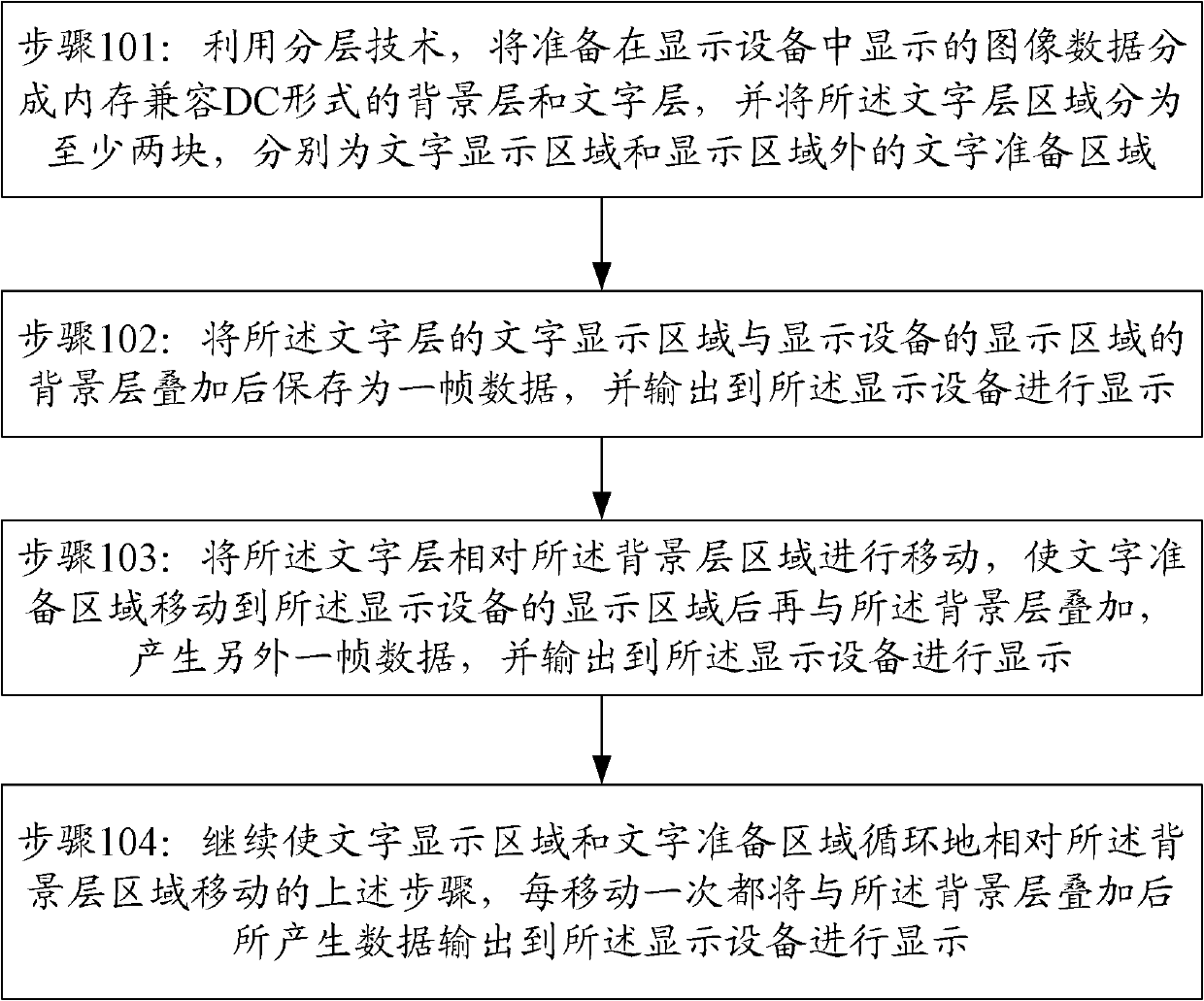

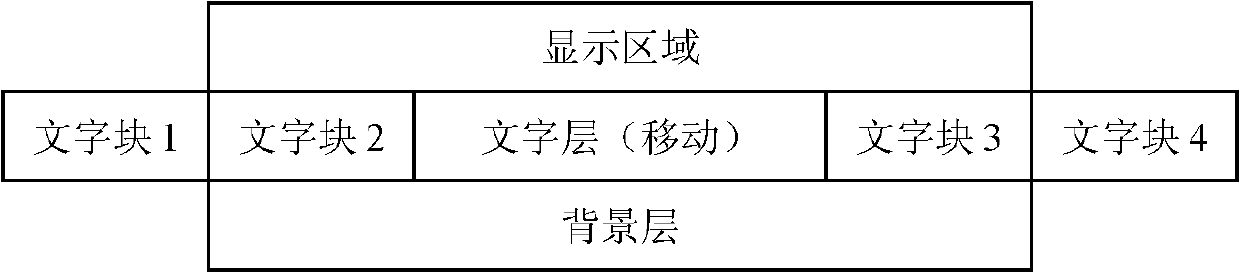

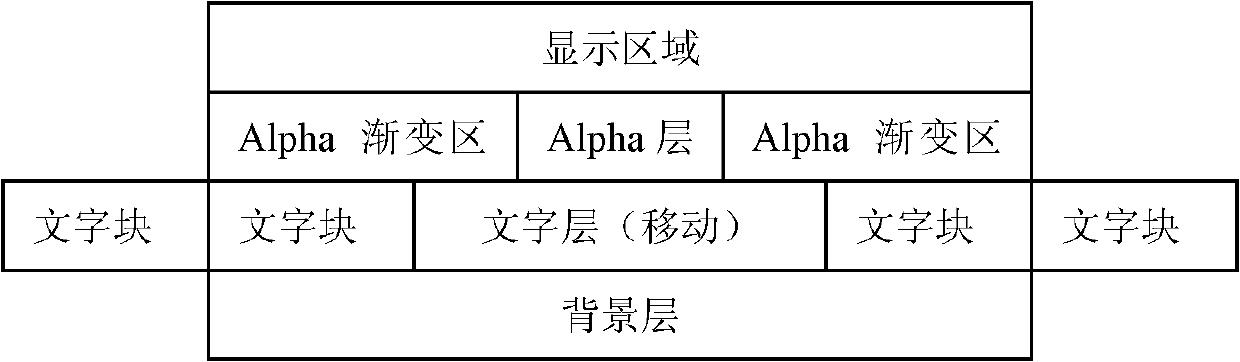

ActiveCN102566952AImprove smooth performanceReduce text and drawing processingDigital output to display deviceText displayImaging data

The invention discloses a display system and a display method applied to an embedded digital entertainment on-demand system. The method includes the steps: dividing image data about to be displayed in display equipment into a background layer and a text layer by means of layering technology, and dividing a text layer area into at least two blocks including a text display area and a text preparation area outside the display area respectively, wherein each of the background layer and the text layer is in a memory compatible DC (dual channel) form; stacking the text display area of the text layer with the background layer of a display area of the display equipment, storing the stacked text display area and the background layer into a frame, and outputting the frame to the display equipment for display; and moving the text layer relative to a background layer area, generating data after the text layer is moved every time to be stacked with the background layer and outputting the data to the display equipment for display. The display system and the display method are capable of improving efficiency of scroll captions in the embedded digital entertainment on-demand system.

Owner:FUJIAN STAR NET EVIDEO INFORMATION SYST CO LTD

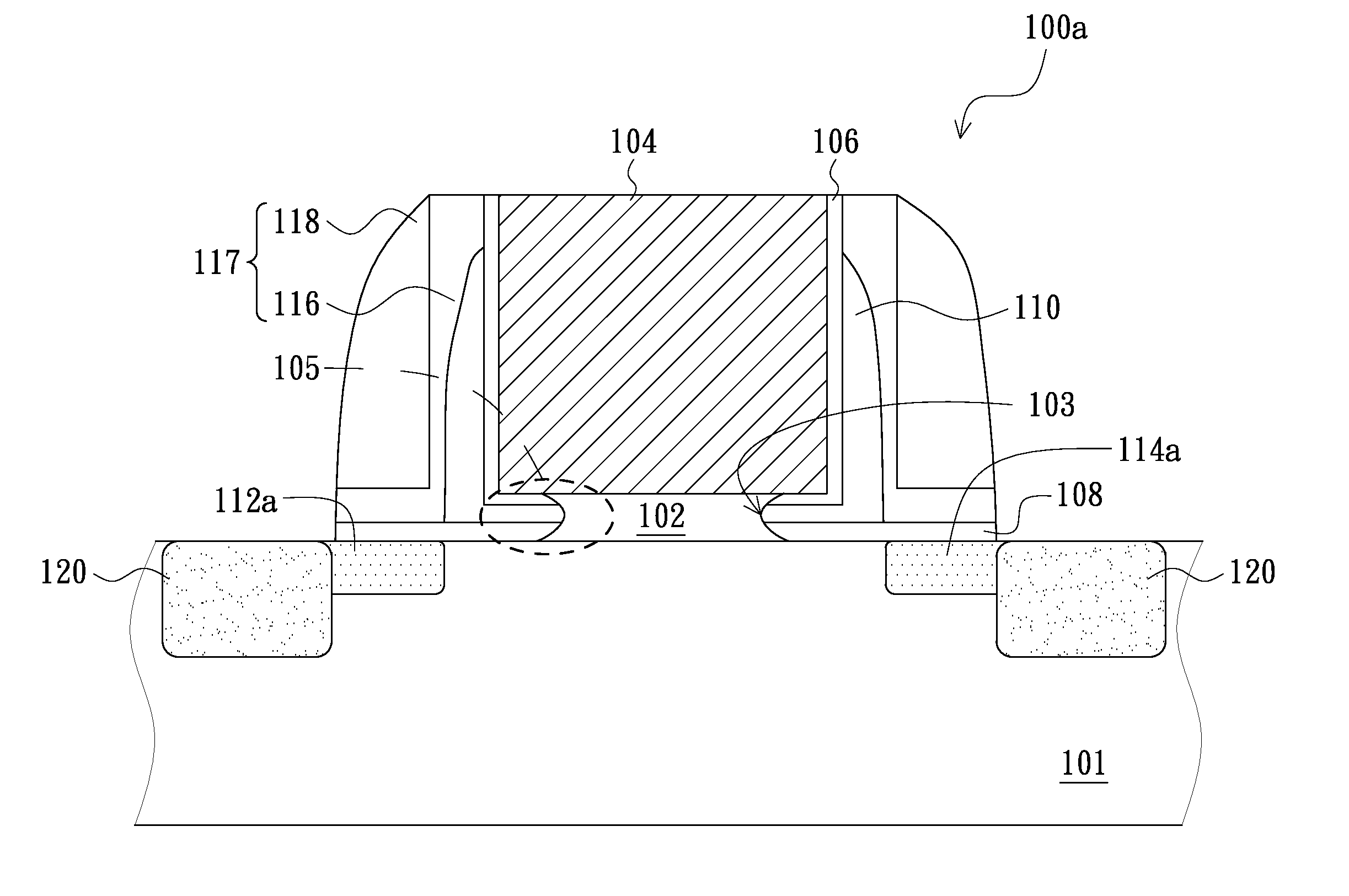

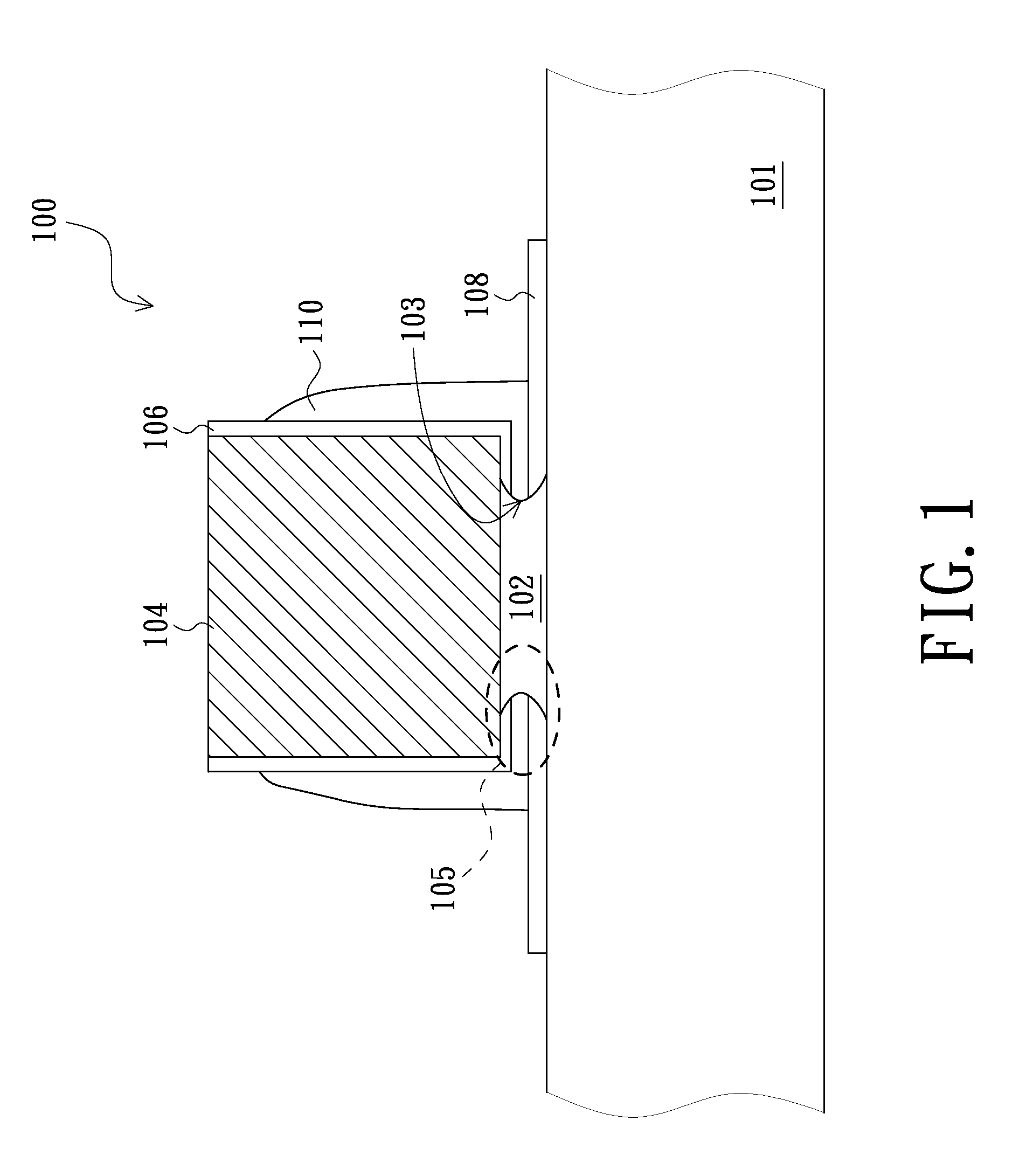

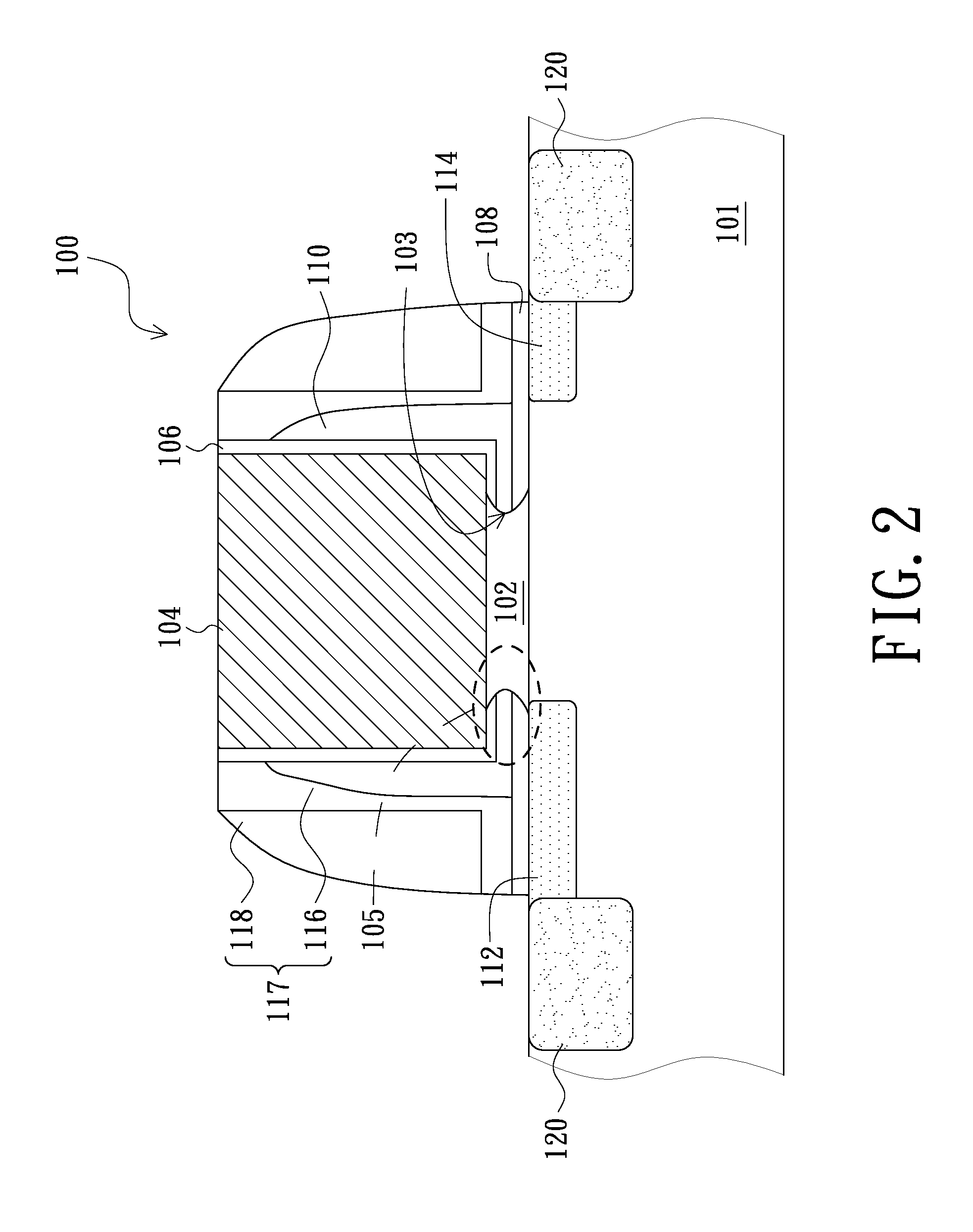

Non-volatile memory and manufacturing method thereof

ActiveUS20120018795A1Efficiency is not affectedHigh efficiency of programming/erasingSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricNitride

A manufacturing method of a non-volatile memory is disclosed. A gate structure is formed on a substrate and includes a gate dielectric layer and a gate conductive layer. The gate dielectric layer is partly removed, thereby a symmetrical opening is formed among the gate conductive layer, the substrate and the gate dielectric layer, and a cavity is formed on end sides of the gate dielectric layer. A first oxide layer is formed on a sidewall and bottom of the gate conductive layer, and a second oxide layer is formed on a surface of the substrate. A nitride material layer is formed covering the gate structure, the first and second oxide layer and the substrate and filling the opening. An etching process is performed to partly remove the nitride material layer, thereby a nitride layer is formed on a sidewall of the gate conductive layer and extending into the opening.

Owner:UNITED MICROELECTRONICS CORP

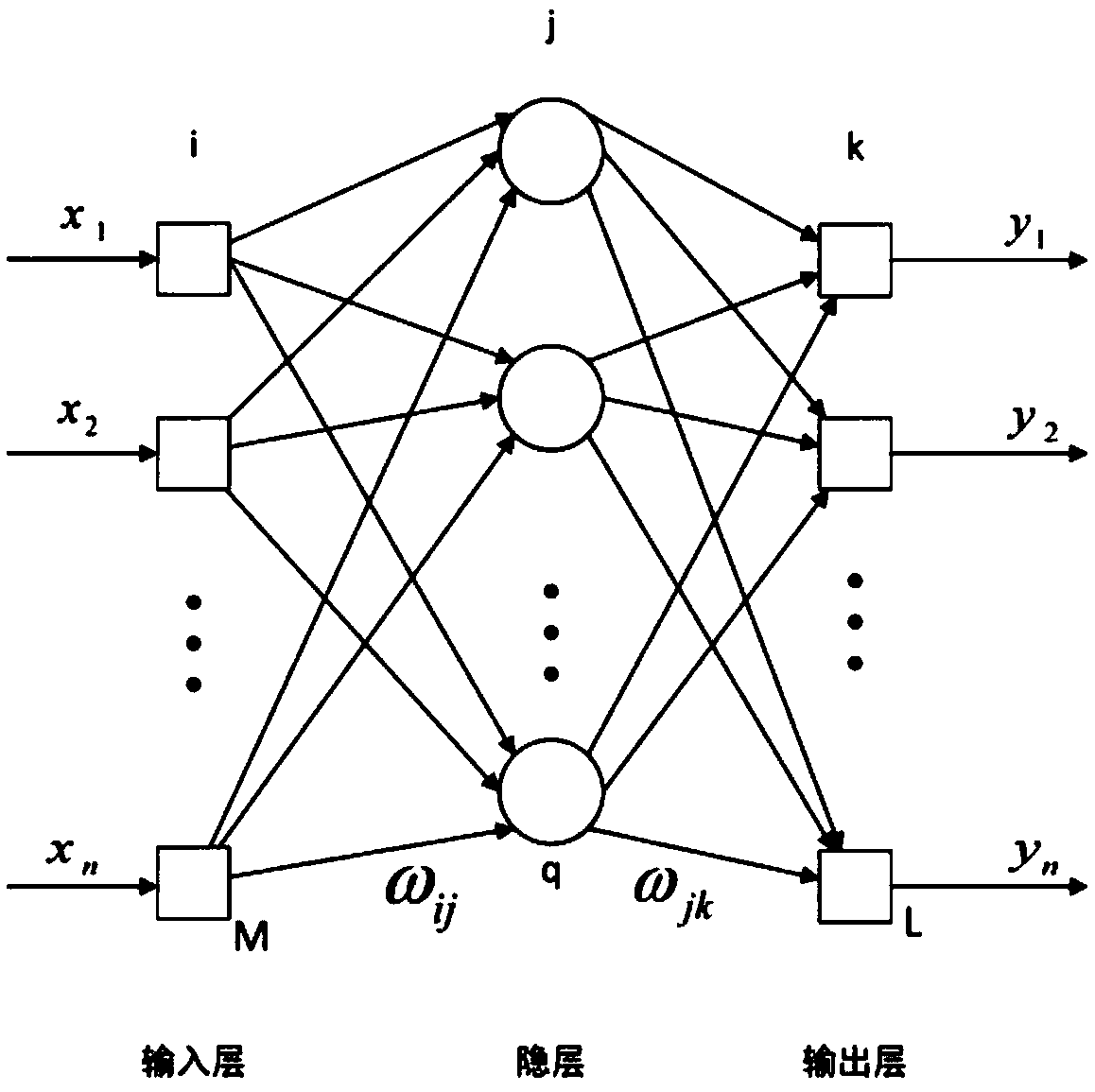

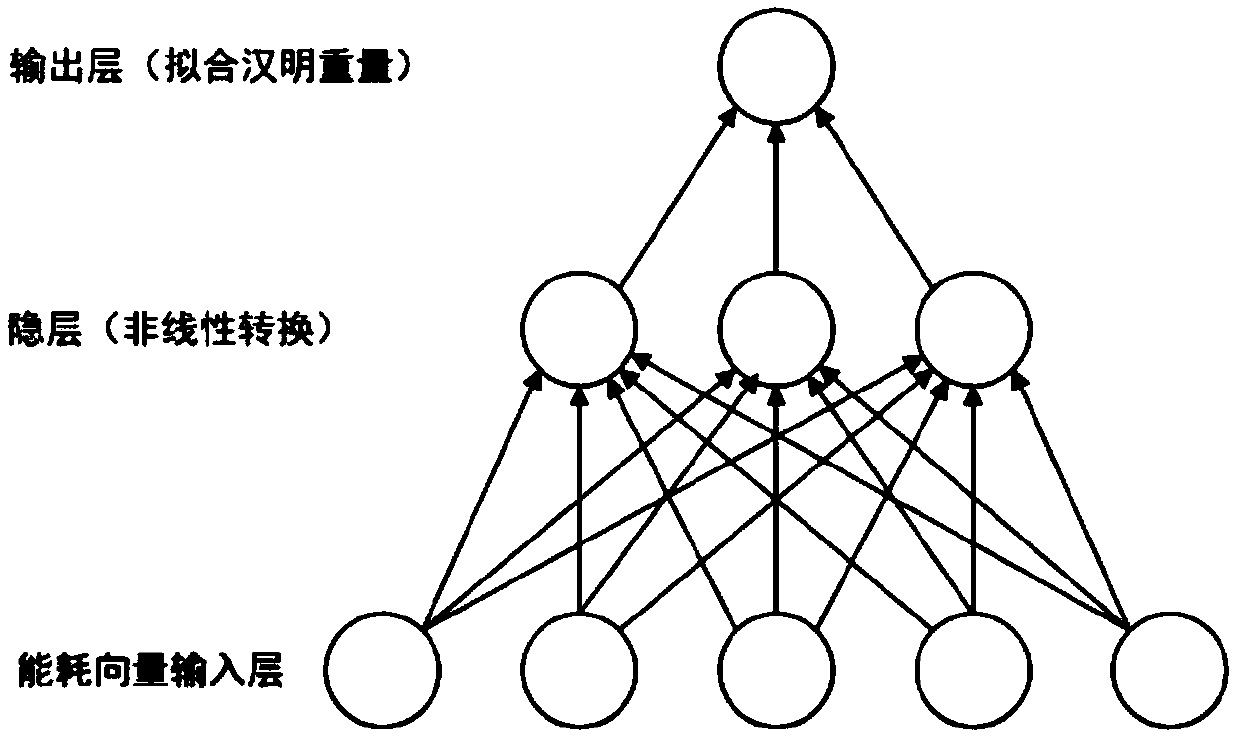

DPA attack method for carrying out fitting by utilizing neural network, system and terminal

InactiveCN109525384AImprove attack efficiencyImprove time and efficiencyCryptographic attack countermeasuresNeural learning methodsFeature vectorNerve network

The invention belongs to the field of cipher algorithm analysis and detection and discloses a DPA attack method for carrying out fitting by utilizing a neural network, a system and a terminal. In thetraining stage, a predictive neural network automatically learns and obtains a mapping relationship between an energy consumption characteristic vector and an intermediate combination value accordingto a training energy consumption set; and in high-order DPA attack, the predictive neural network is used to predict the intermediate combination value of the attack energy trace, and the correlationcoefficient between a predictive intermediate combination value and a conjecture intermediate combination is calculated, thus the device key is attacked. The method of the invention eliminates the requirement that the mask must be understood in the learning stage, simultaneously avoids the requirement of the high-order DPA on the energy consumption cross-combination, reduces the attack condition,and improves the attack efficiency. Experimental results show that the attack algorithm is feasible and efficient.

Owner:CHENGDU UNIV OF INFORMATION TECH

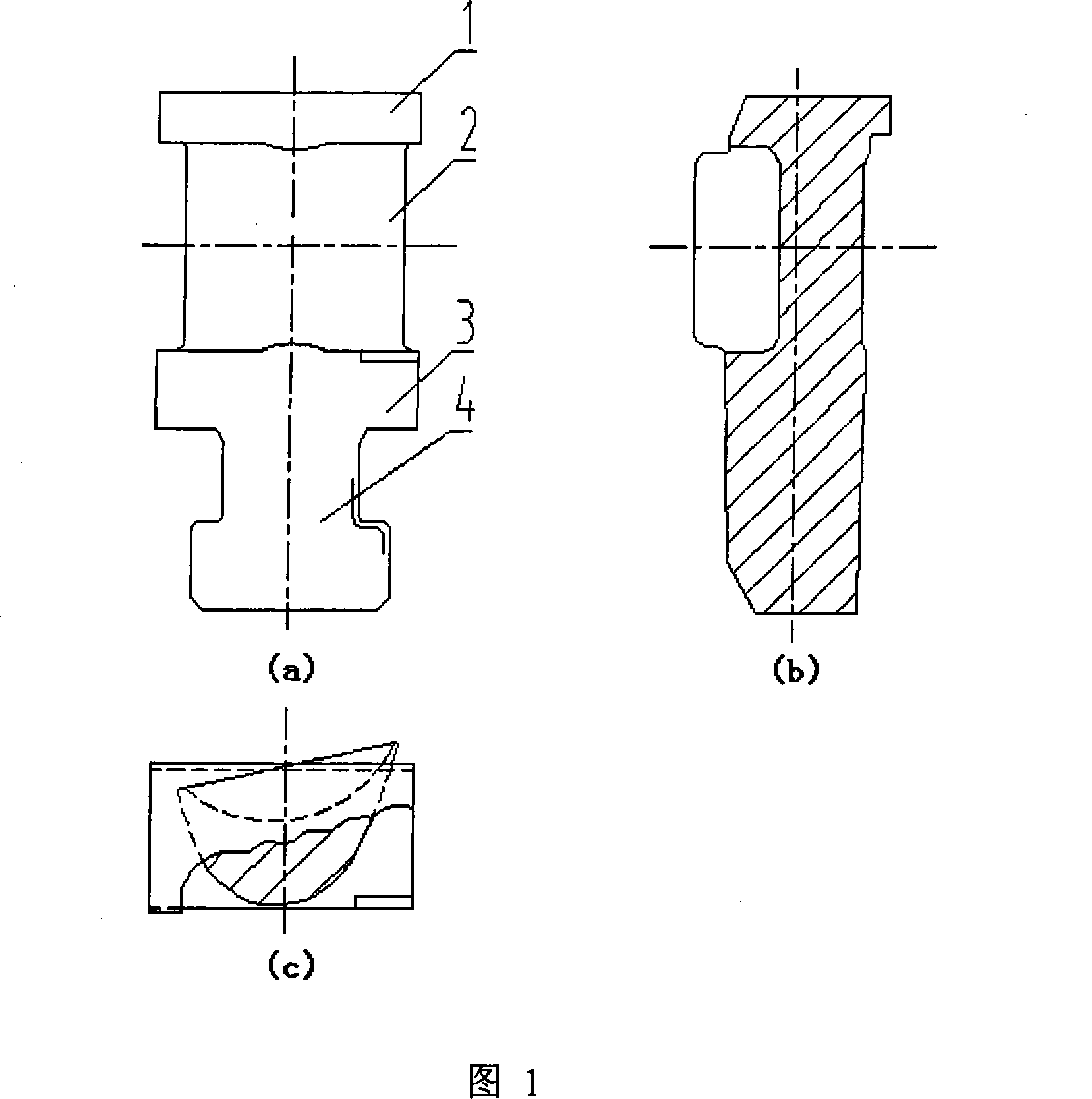

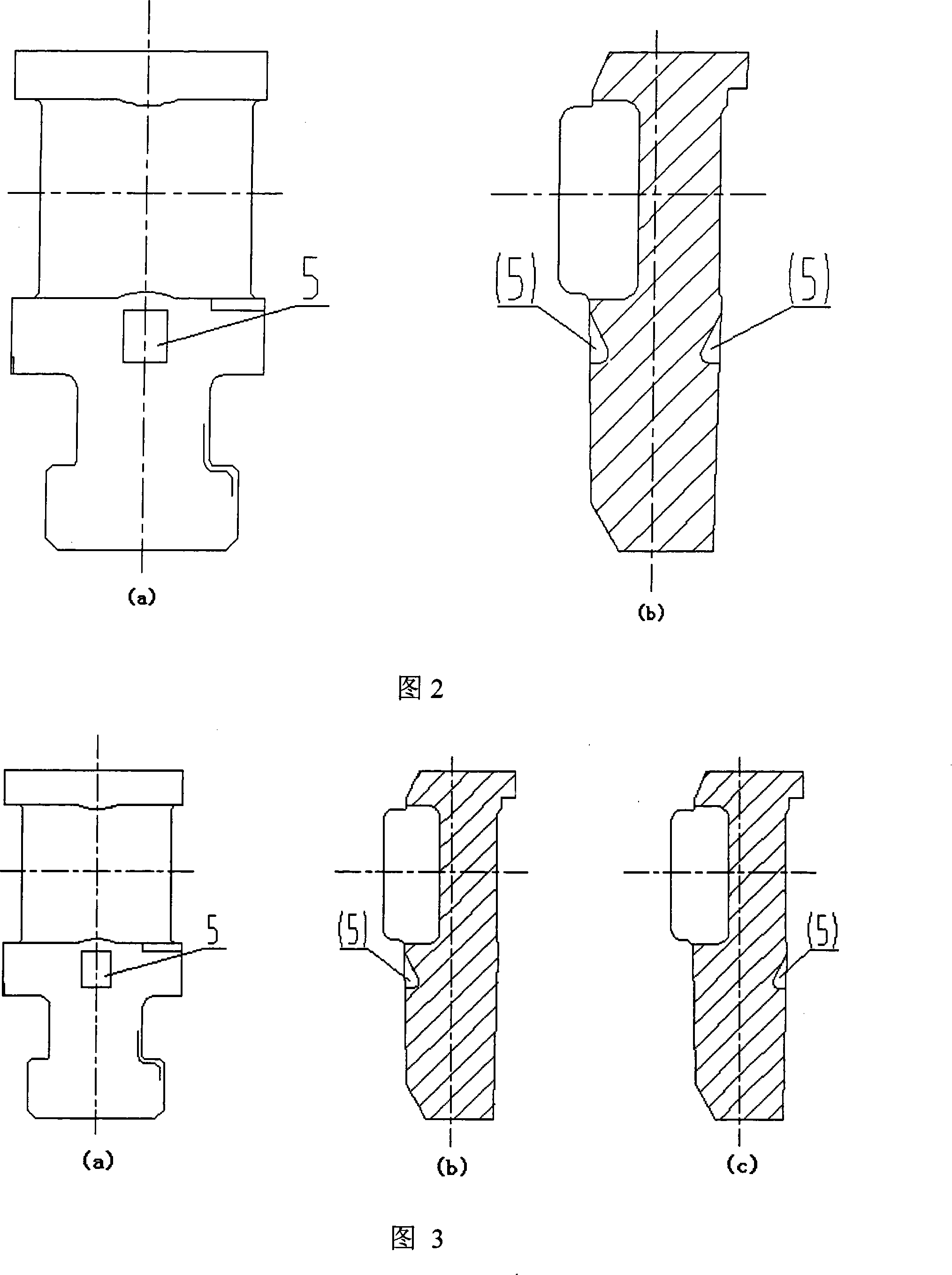

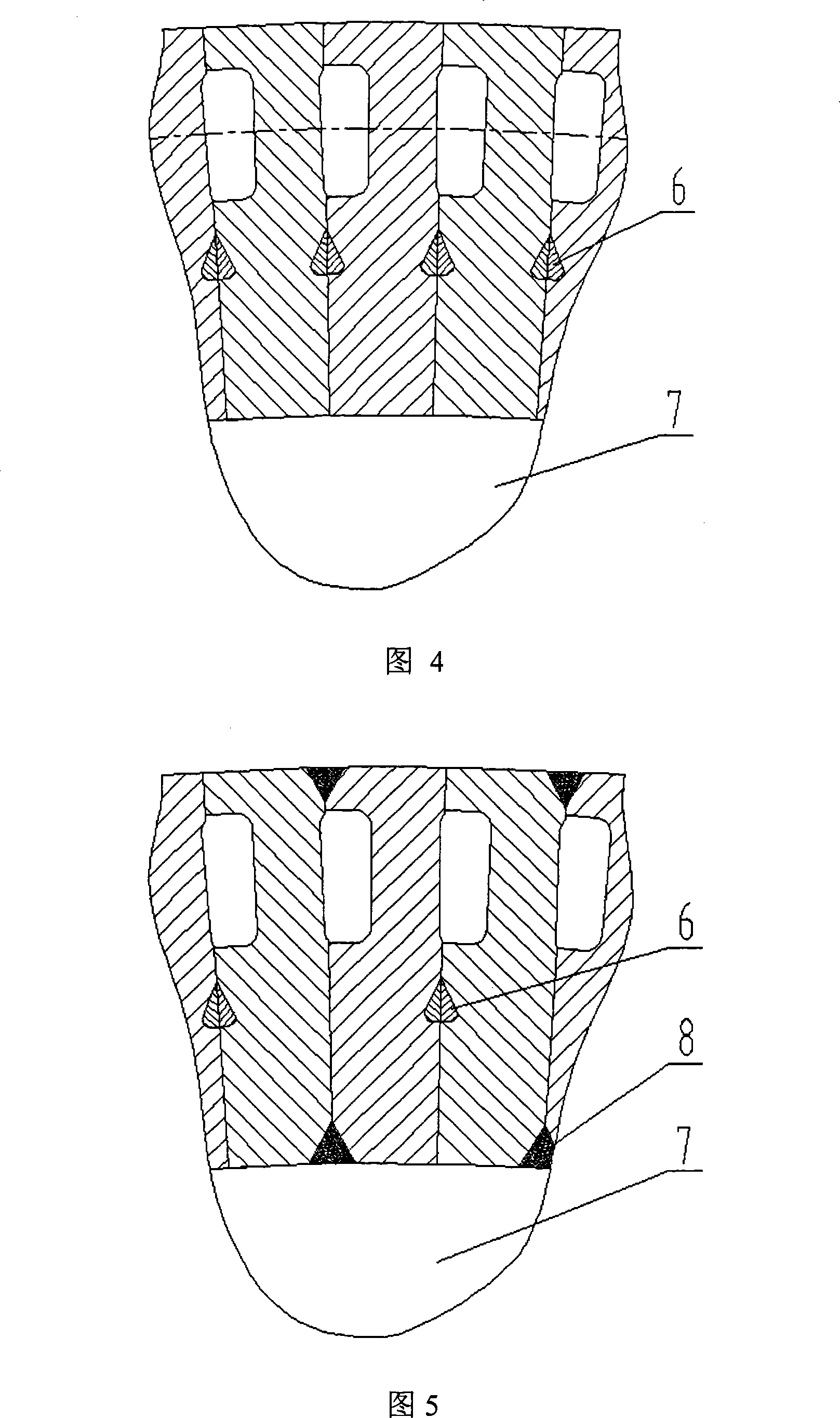

Bucket root platform double wedge shape blocks damping structure of turbine bucket

InactiveCN101158290AImprove rigidityGuaranteed tightnessBlade accessoriesMachines/enginesEngineeringDouble wedge

The invention discloses a vane-root platform double-wedge damp structure used for a turbine dynamic vane. The invention comprises a dynamic vane consisting of a round-belt, a vane body, a vane-root platform and a vane-root. Gaps are arranged on two circle side faces of the vane-root platform of the vane, and the wedge damp blocks are arranged in the gaps, and an outer end face and a radial face of the wedge damp block are equal in height. When the dynamic vane revolves, one face of the wedge damp block firmly presses an upper surface of the vane-root platform gap under an effect of the centrifugal force, and the other face firmly clings to the wedge damp block of a neighboring dynamic vane, and the positive pressure and the friction force on an interface of the wedge damp block lead the vane to form a damp wreathing structure. The structure can consume the energy of the vibration, and can ease and eliminate the vibration of the vane, and also can enhance the rigidity of the vane-root and reduce the dispersal of the proper frequency of the vane. The structure needs a little manufacturing work, and the manufacturing, assembling and disassembling are convenient. And the structure has good universal property for the quantity of the lock-port vanes, the static-stress strength of the vane and the general size are not increased.

Owner:XI AN JIAOTONG UNIV

Combustion method and device for pulverized coal hot air furnace

InactiveCN102418997AAvoid crackingLow costAir heatersPulverulent fuel combustion burnersBrown coalCombustion chamber

The invention relates to a combustion method and a combustion device for a pulverized coal hot air furnace. The method comprises the following steps of: simultaneously introducing gas and air into a gas burner, igniting the gas and heating a pulverized coal combustor to the temperature of more than 800 DEG C; feeding pulverized coal with the granularity of 180 meshes into the pulverized coal combustor, igniting the pulverized coal and continuously combusting the pulverized coal in the pulverized coal combustor; raising the temperature of an inner cavity of the pulverized coal combustor to be between 1,000 and 1,350 DEG C, injecting flames into a combustion chamber through a flame outlet of the pulverized coal combustor, and supplying the air through a secondary air inlet for full combustion; exhausting the burned fine particles which are carried by high-temperature hot air through an outlet of the combustion chamber, making the air pass through an adjustable air inlet, and making backflow flue gas pass through a backflow flue gas inlet and rotate and rise in an air sleeve from the lower part of an outer sleeve; and recovering waste heat, arranging a natural mixed air pipe and introducing the air in the center of high-temperature flue gas for mixing, and conveying the hot air to users through a hot air furnace outlet when the hot air is adjusted to the needed temperature. The invention has the characteristics that: the cost is reduced by utilizing low-price coal and brown coal, the combustion chamber and a mixed air chamber are mixed into a whole, the pulverized coal is fully combusted, carbon residues are about 1 percent of ash, the thermal efficiency is over 90 percent, and the like.

Owner:舒瑞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com