Antibacterial shading medical polyvinyl chloride plastic and preparation method thereof

A polyvinyl chloride and plastic technology, applied in the field of medical plastics, can solve problems such as poor transparency, low safety factor, and precipitation of light-shielding additives, and achieve the effects of enhancing safety, ensuring safety in use, and having no effect on transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

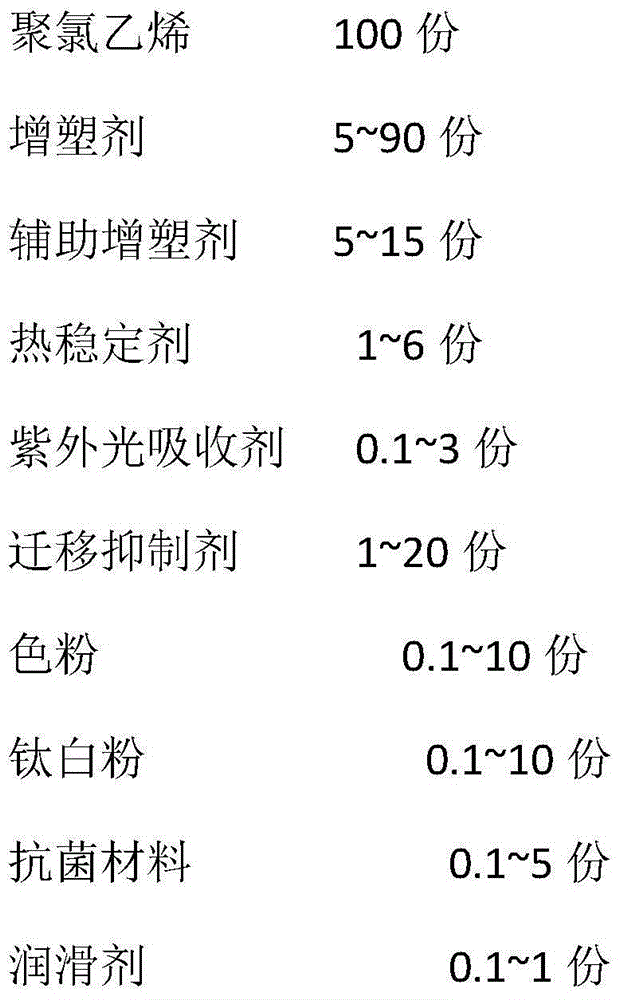

[0026] Proportioning: (parts by weight)

[0027]

[0028]

[0029] The composite color powder is a mixture of red and yellow pigments, and the weight ratio of red and yellow is 1-5;

[0030] Preparation steps:

[0031] (1) Add polyvinyl chloride, plasticizer, auxiliary plasticizer, ultraviolet light stabilizer, migration inhibitor, toner, titanium dioxide, and antibacterial materials into the high-speed mixer in sequence, heat and stir at a low speed of 30rpm to 80°C, and then add antibacterial Material and heat stabilizer, run at 480rpm, add lubricant after the temperature reaches 120°C. Stir continuously to 140°C and discharge to the cooling mixer with a rotation speed of 30rpm. When the temperature of the material is cooled to 45-60°C, the material is discharged.

[0032] (2) The material obtained in step (1) is granulated using a twin-screw extruder. The screw speed of the main engine is 80rpm, the temperature of each section of the extruder: the first section is...

Embodiment 2

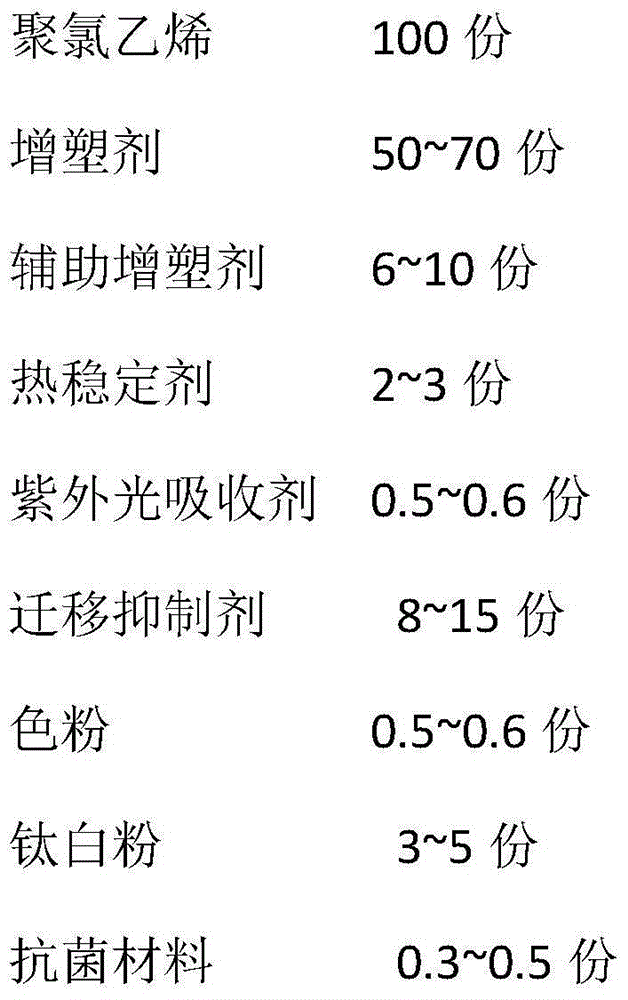

[0034] Proportioning: (parts by weight)

[0035]

[0036]

[0037] The composite color powder is a mixture of blue and green pigments, and the weight ratio of red and yellow is 1-5. The preparation method is the same as in Example 1.

Embodiment 3

[0039] Weigh 100 parts of polyvinyl chloride

[0040] Plasticizer TOTM60 parts

[0041] Auxiliary plasticizer ESO10 parts

[0042] Compound calcium zinc heat stabilizer 2.5 parts

[0043] 0.3 parts of ultraviolet absorber 2,4-dihydroxybenzophenone

[0044] 0.3 parts of ultraviolet absorber 2-(2'-hydroxyl-5'-methylphenyl)benzotriazole

[0045] β-cyclodextrin 15 parts

[0046] Compound color powder 0.6 parts

[0047] Titanium dioxide 5 parts

[0048] Nano silver antibacterial powder 0.5 parts

[0049] Lubricant silicone oil 0.3 parts.

[0050] The composite color powder is a mixture of blue and green pigments, and the weight ratio of red and yellow is 1-5.

[0051] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com