Combustion method and device for pulverized coal hot air furnace

A technology of a combustion device and a pulverized coal burner, which is applied in the combustion method, burner, combustion type and other directions, can solve the problems of high coal quality requirements, black smoke emission, large floor area, etc., and achieves reduction of floor space and structure. Reasonable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

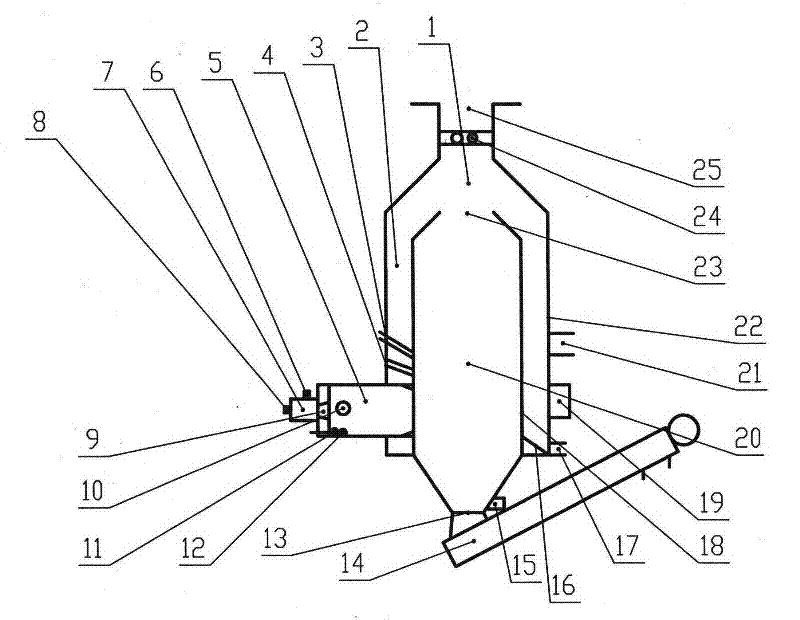

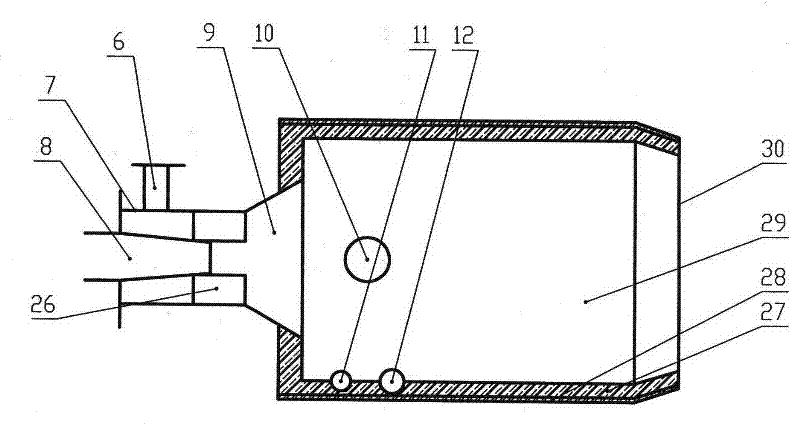

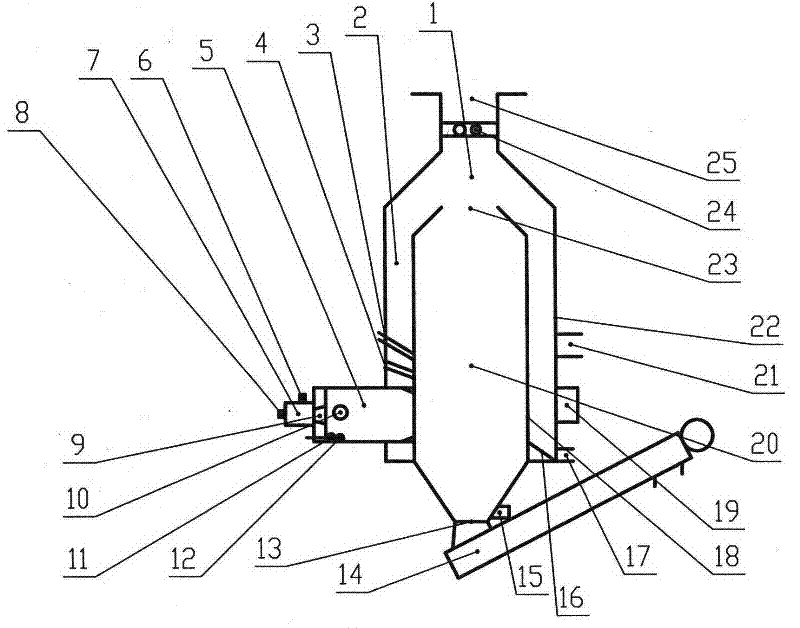

[0014] The gas produced by the gas generator passes through the gas inlet 6, and the air generated by the blower passes through the gas distribution inlet 8 and enters the gas burner 7 at the same time. After the gas is ignited through the ignition hole 10, it heats the pulverized coal burner 5 to above 800°C and starts The coal is ground to 180 mesh coal powder by the coal pulverizer, and input into the pulverized coal burner 5 through the pulverized coal inlet 11, the pulverized coal is ignited and burns continuously in the pulverized coal burner 5, and the gas is always supplied to the pulverized coal burner 5 Heat, strong wind is injected through the pulverized coal air distribution inlet 12, which ensures the continuous combustion of low-priced coal pulverized coal, and at the same time the heat of gas combustion is also fully utilized. Gas, air, and pulverized coal are rotated, fully mixed and burned, prolonging the burning time, and pulverized coal is fully burned, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com