High temperature-resistant anti-oxidation filter material and manufacturing method thereof

A manufacturing method and anti-oxidation technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of filter material failure and loss, and achieve the effects of slowing down premature failure, improving oxidation resistance, and delaying aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

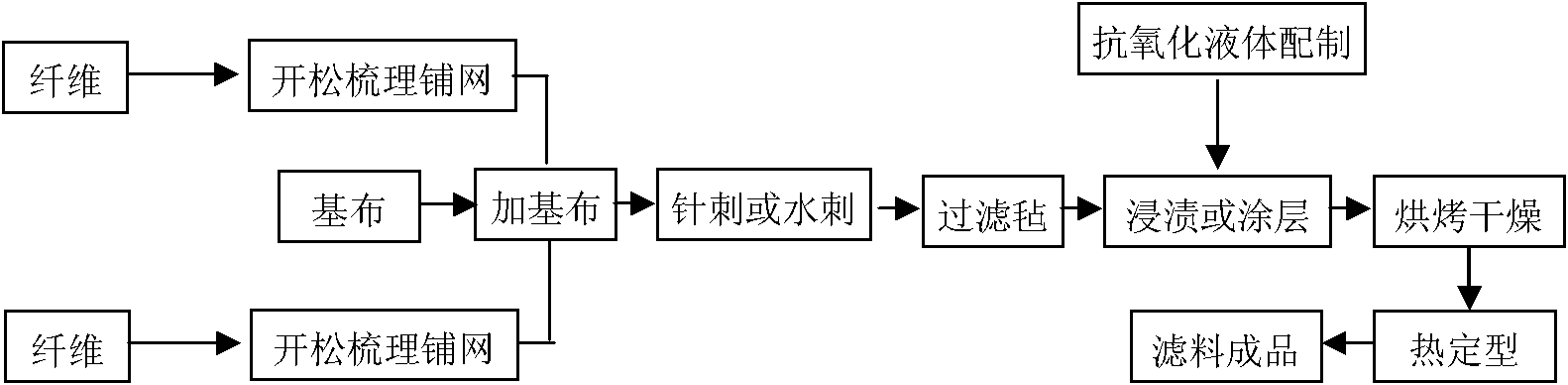

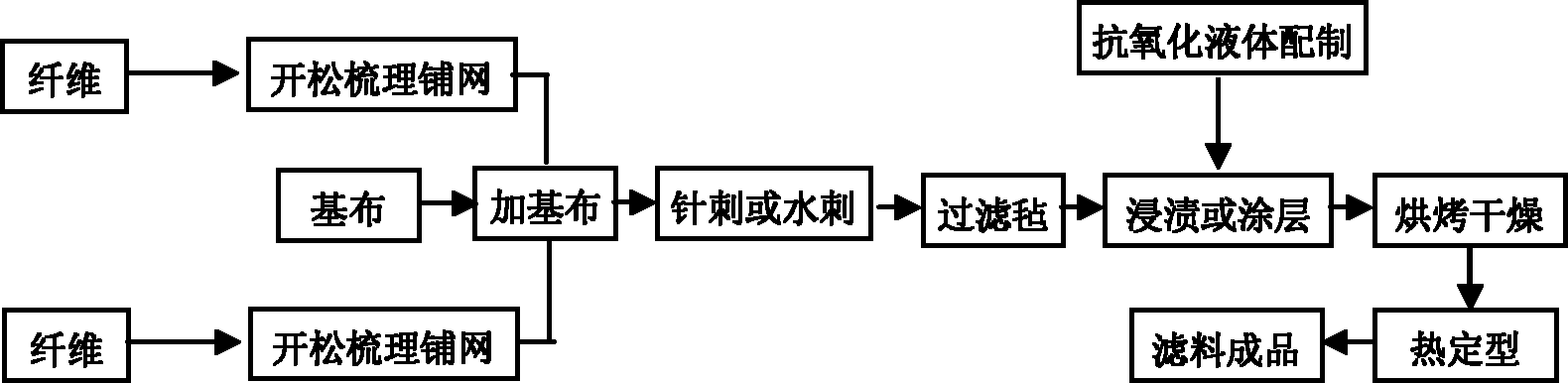

Method used

Image

Examples

example 1

[0011] Using polyphenylene sulfide base cloth and polyphenylene sulfide fiber as raw materials, a 550 g / m2 filter felt is made by needle punching method, and 2,5-di-tert-butylhydroquinone (DTBHO) antioxidant Prepare a solution at a concentration of 10%, and let the needle felt pass through the solution by dipping. It is necessary to ensure that the filter felt is in the solution for at least 15 seconds, so that the coating thickness reaches 1 micron, and then it is passed through a high-temperature steam heating box and a hot pressing roller for baking drying and heat setting line treatment, the temperature is 210°C, and the time is 5 minutes total, after which you get the finished product.

example 2

[0013] With polytetrafluoroethylene base cloth as the base and polyphenylene sulfide fiber as the raw material, a 570 g / m2 filter felt is made by needle punching, and 2,5-di-tert-butylhydroquinone (DTBHO ) Antioxidants were added to 20% polytetrafluoroethylene emulsion at a concentration of 8%, and 3% rosin soap foaming agent was added, and the blower was used to blow out the emulsion at a flow rate of 5L / min, and the formed foam was coated on the needle felt On the surface, make the thickness of the coating reach 1.5 microns, and then make it pass through a high-temperature steam heating box and a hot pressing roller for baking drying and heat setting treatment at a temperature of 210°C for 5 minutes, and then the finished product is obtained.

example 3

[0015] With polytetrafluoroethylene base cloth as the base and aramid fiber as the raw material, a 500 g / m2 filter felt is made by needle punching method, rosemary antioxidant is added to the water at a concentration of 5%, and the needle punched felt is The dipping method passes the liquid. The filter felt is soaked in the liquid for at least 15 seconds, and the coating thickness reaches 1 micron, and then it is baked, dried and heat-set through a high-temperature steam heating box and hot pressing roller at a temperature of 235°C for 5 minutes, and then to get the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com