Patents

Literature

390 results about "Tert-Butylhydroquinone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tert-Butylhydroquinone (TBHQ, tertiary butylhydroquinone) is a synthetic aromatic organic compound which is a type of phenol. It is a derivative of hydroquinone, substituted with a tert-butyl group.

Preparing method for tert-butyl group hydroquinol

InactiveCN1583698AReduce usageReduce pollutionOrganic chemistryOrganic compound preparationAlkyl transferOrganic solvent

A process for preparing tert-butyl hydroquinone (TBHQ) includes such steps as dewatering alkylation reaction between hydroqainone and tert-butanol under catalysis of acid to obtain TBHQ, and purifying by reducing agent and acid.

Owner:GUANGZHOU YOUBAO IND

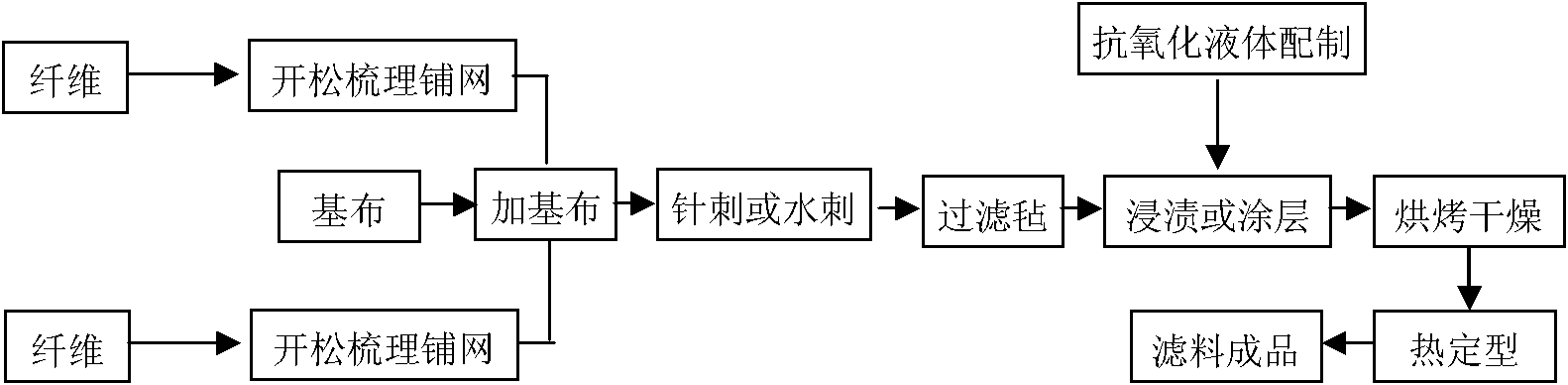

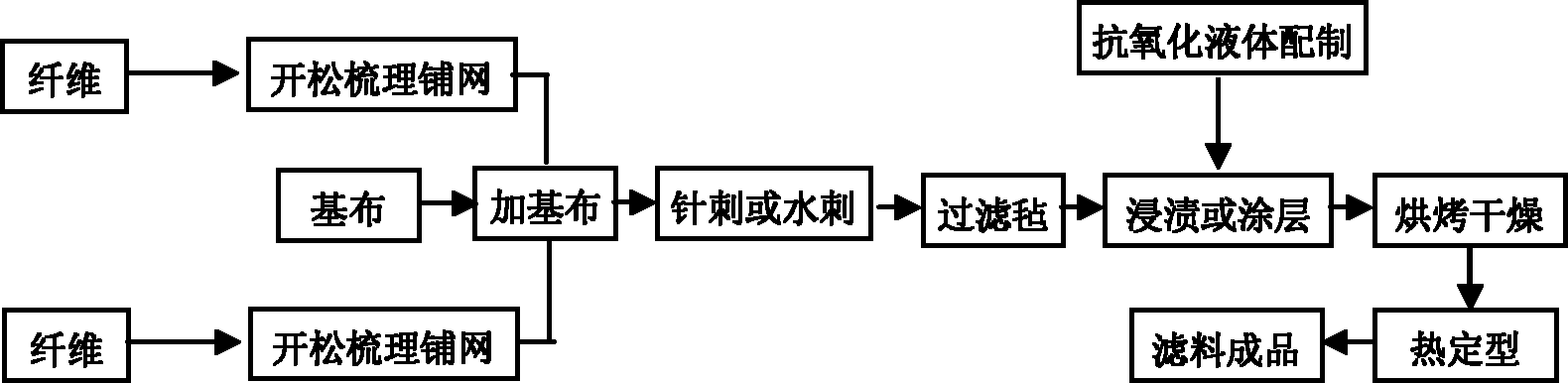

High temperature-resistant anti-oxidation filter material and manufacturing method thereof

ActiveCN102151436ADoes not affect resistanceEfficiency is not affectedLayered productsFiltration separationNeedle punctureOxidation resistant

The invention relates to a high temperature-resistant anti-oxidation filter material and a manufacturing method thereof, belonging to the technical field of high-temperature filter materials. 1%-10% of 2,5-di-tert-butylhydroquinone or rosemary antioxidant liquid is utilized for performing impregnation or coating treatment on a 300-1000g / square meter filter felt produced by the needle puncture method or the spunlacing method for coating an anti-oxidation coating layer with 0.5-50 microns on the surface of the filter felt, and then high-temperature baking treatment and thermosetting with steam or hot oil are performed for 1-60 minutes at the temperature of 100-235 DEG C for forming the high temperature-resistant anti-oxidation filter material for filtering high-temperature smoke dust. In order to solve the defects of the filter material for a bag dust collector in the anti-oxidation aspect, the invention provides the high temperature-resistant anti-oxidation filter material and the manufacturing method thereof, by using the high-temperature antioxidant to perform the impregnation or the coating on the filter material and further performing the baking and the thermosetting treatment,the filter material has the anti-oxidation property, and the too early aging failure of the filter material under a high-temperature oxidation environment can be avoided.

Owner:NORTHEASTERN UNIV

Energy bar and preparation method thereof

The invention discloses an energy bar, which belongs to the field of food. The preparation method comprises the following steps: adding corn oil, VE (Vitamin E), malic acid, citric acid, water and grapefruit essence in the process of treating citron tea by a colloid mill; in the frying process of nuts, adding TBHQ (tert-Butylhydroquinone); adding and evenly mixing white sesame seed, konjak puffed grain, puffed sticky rice, puffed oat, dried cranberry, dried yangtao, dried plum tomato, Gllan gum, guar gum and Pullulan; adding prepared citron tea and fully mixing; and then, putting into a mould, shaping, demoulding, drying by cold air, and packaging in vacuum to obtain the energy bar. The energy bar has the advantages of small product volume, light weight, good taste and balanced nutrition, is convenient to carry, is rich in unsaturated fatty acid, does not contain cane sugar and other sugar products which consume insulin, and is especially suitable for patients with diabetes mellitus and people wanting to lose weight.

Owner:天津北洋百川生物技术有限公司

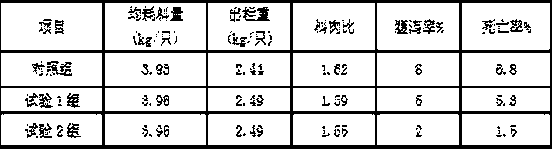

Nitrite-free Chinese-style sausage and production method

The invention relates to a nitrite-free Chinese-style sausage and a production process. The production process comprises the steps of selecting and preprocessing raw meat, mixing materials and salting, filling and bundling sausages, putting the sausages on a bar, putting the sausages in an oven, baking the sausages, cooling, packaging and warehousing, thereby obtaining the nitrite-free Chinese-style sausage. By using monascus color, tert-butylhydroquinone, sodium erythorbate, nisin and sodium diacetate to substitute for nitrite and nitrate and by adjusting the original material mixing and salting and baking process, effects of colorizing, anti-oxidation and anticorrosion are taken in the nitrite-free Chinese-style sausage, and the nutrient, delicious and healthy nitrite-free Chinese-style sausage is produced. According to physical and chemical inspection, the results show that the sausage does not contain residual nitride, the color and the flavor of the nitride-free sausage are superior to the color and the flavor of a nitride-containing sausage and the color of the nitride-free sausage is not changed after the nitride-free sausage is stored for one month in a incubator at 37 DEG C.

Owner:湖南唐人神肉制品有限公司

Quality modifier for pre-treatment of aquatic product before drying and its prepn and application

InactiveCN101066066APrevent oxidationProblems preventing muscle fiber contractionMeat/fish preservation using chemicalsMyofibrilAdditive ingredient

The present invention provides one kind of quality modifier for dried aquatic product and its composition and usage. The quality modifier consists of white spirit, antioxidant, phosphate, gluconic acid-delta-lactone, ascorbic acid and mycose, and may also have enzyme, such as glucose oxidase, added to further raise antioxidant effect. The quality modifier may be used to prevent oxidation, myofibril contraction and microbe propagation during drying aquatic product, eliminate fish smell and raise rehydration property. When the quality modifier is used, aquatic product and the quality modifier in the weight ratio of 2-15 to 1 are set in a basin, and the aquatic product is soaked for 30-60 min before being dried at 50 deg.c to obtain dried aquatic product.

Owner:ZHEJIANG UNIV OF TECH

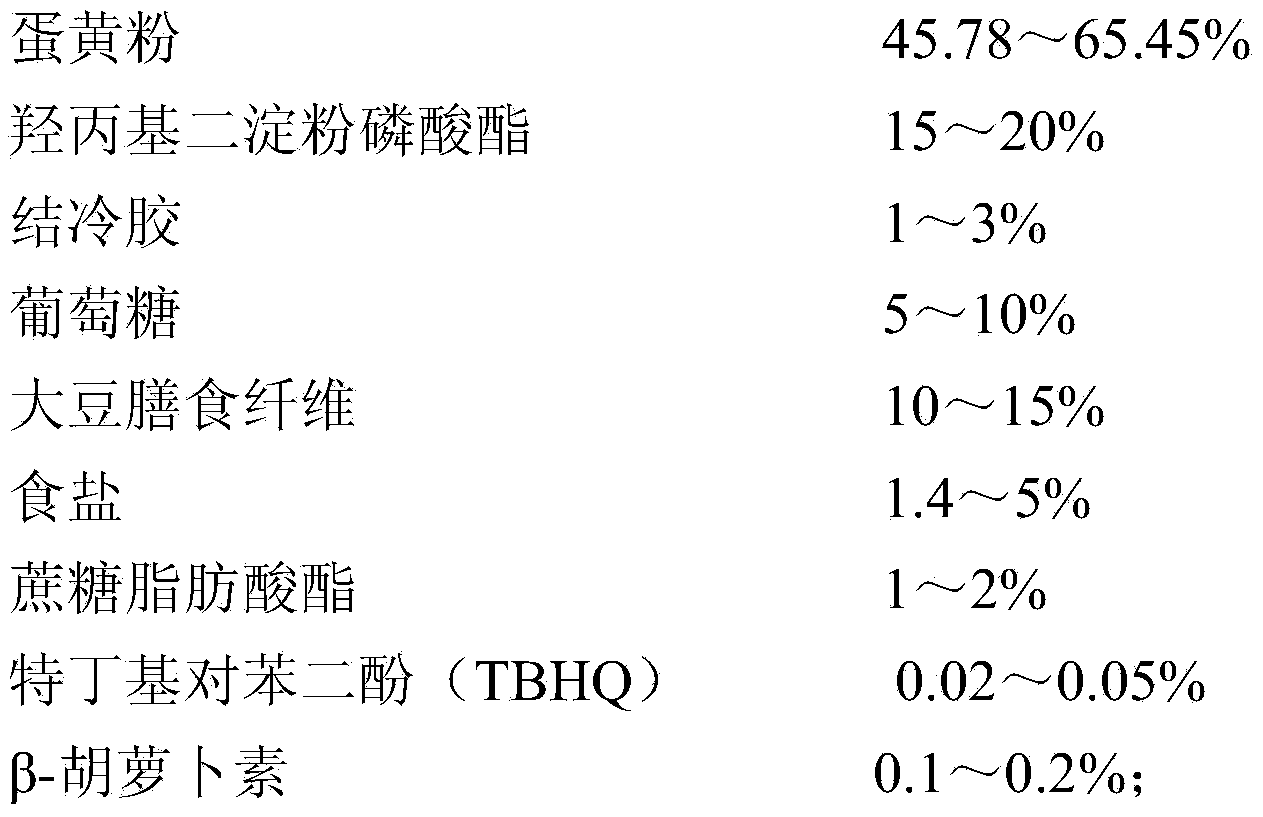

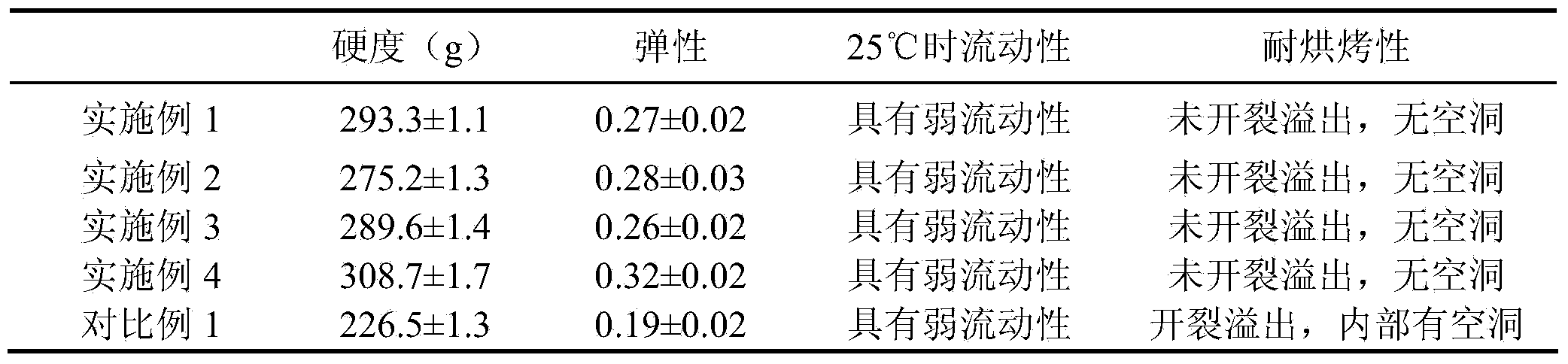

Quicksand-type stuffing with long shelf life and resistant to bake and premixed flour and manufacturing method thereof

The invention provides quicksand-type stuffing with a long shelf life and resistant to bake and premixed flour and a manufacturing method thereof. The premixed flour of the quicksand-type stuffing comprises, by mass percent, 45.78-65.45% of egg yolk powder, 15-20% of hydroxy propyl distarch phosphate, 1-3% of gellan gum, 5-10% of glucose, 10-15% of soybean dietary fibers, 1.4-5% of salt, 1-2% of sucrose fatty acid ester, 0.02-0.05% of tertiary butylhydroquinone and 0.1-0.2% of beta-carotene. The ingredients are mixed to obtain the premixed flour of the quicksand-type stuffing. The premixed flour is combined with malt syrup, anhydrous ghee, edible glycerol and citric acid so that the quicksand-type stuffing can be manufactured. The quicksand-type stuffing has taste and egg yolk flavor approximate to traditional golden quicksand-type stuffing, and is resistant to bake and long in shelf life.

Owner:广州合诚实业有限公司

Process for producing conjugated linoleic acid by using rubber seed oil

InactiveCN102086427AImprove securityHigh development valueFatty acid isomerisationFatty acids production/refiningIsomerizationPEG 400

The invention discloses a process for producing conjugated linoleic acid by using rubber seed oil, comprising the following steps of: undergoing an isomerization reaction between the rubber seed oil containing linoleic acid with higher content and a polyethylene glycol 400 solution of alkali under the protection of nitrogen gas, carrying out molecular distillation purification, and adding tertbutylhydroquinone with stronger antioxidation to the product to produce the conjugated linoleic acid. In the invention, the utilized base oil is the rubber seed oil, and the content of the linoleic acid of the rubber seed oil is as high as 32.8%, thus the rubber seed oil is an excellent oil source for preparing the conjugated linoleic acid; and the utilized solvent is a pharmaceutic adjuvant, thus the safety of the products is ensured. The purification process is a molecular distillation technique, thus the conjugated linoleic acid products with higher purification can be obtained. The invention has the advantages of high yield of the reaction, simple process flow and good product quality.

Owner:海南省粮油科学研究所

Release agent and preparation method thereof

ActiveCN103305325AImprove antioxidant capacityWon't happenLubricant compositionFatty acid glycerol estersPOLYOXYETHYLENE ETHER

The invention discloses a release agent and a preparation method thereof, belongs to the field of release agent and solves the problem of environment pollution caused by irritant gas generated during application of the release agent. The release agent comprises long-chain alkyl aryl silicone oil, machine oil, Span 80, nonylphenol polyoxyethylene ether, fatty glyceride, triethanolamine borate, triethanolamine and 2, 5-ditert-butylhydroquinone. The preparation method of the release agent comprises the following steps of: mixing Span 80 with nonylphenol polyoxyethylene ether to obtain an emulsifier; adding water, heating up and adding the emulsifier; mixing long-chain alkyl aryl silicone oil, machine oil, oxidized polyethlene wax and fatty glyceride; slowly adding the mixture into hot water and stirring, forming emulsion after adding all the mixture into the hot water; and orderly adding cholamine borate, 2, 5-ditert-butylhydroquinone and triethanolamine, mixing and forming the release agent. The triethanolamine is used for regulating the PH value, the 2, 5-ditert-butylhydroquinone is used for enhancing the oxidation resistance, and the two constituents both cannot generate irritant gas to pollute environment.

Owner:CHAOWEI POWER CO LTD

Scaling powder for low-temperature halogen-free low-solid-content lead-free tin soldering

InactiveCN103785973AEnhanced spread rate effectHigh spreading rateWelding/cutting media/materialsSoldering mediaDiethylene glycol diethyl etherSalicylic acid

The invention discloses scaling powder for low-temperature halogen-free low-solid-content lead-free tin soldering. The scaling powder comprises 12 percent to 16 percent of activating agents, 8-10 percent of colophony, 2-3 percent of surface active agents, 0.05-0.1 percent of antioxidants, 5-8 percent of organic amine and the balance organic solvents. The activating agents comprise compound components of 40-57 parts of anhydrous citric acid, 7-14 parts of salicylic acid, 0.6-3.6 parts of lactic acid and 36-43 parts of DL-malic acid, the surface active agents comprise compound component Tween 60 and a Span, the organic amine is one or more of monoethanolamine, diethanol amine and triethanolamine, the antioxidants are tertiary butylhydroquinone, and the organic solvents are mixed solvents of ethylene glycol, diethylene glycol diethyl ether, nitroethane, tetrahydrofurfuryl alcohol and propylene glycol by mass. According to the method, the scaling powder for low-temperature halogen-free low-solid-content lead-free tin soldering has the advantages of improving the coverage rate of the welding materials and reducing the cost.

Owner:SUZHOU LOTTE CHEM TECH

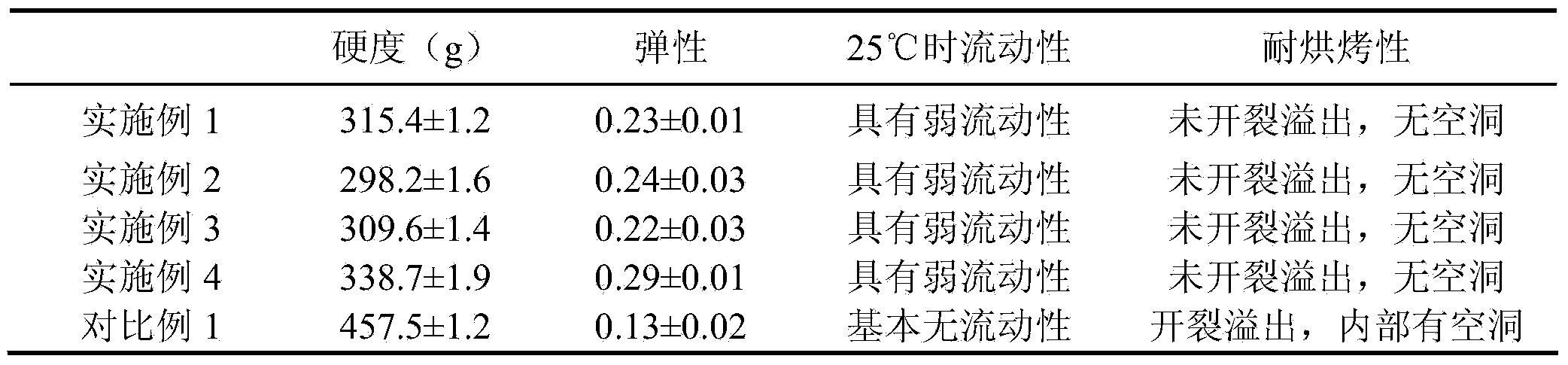

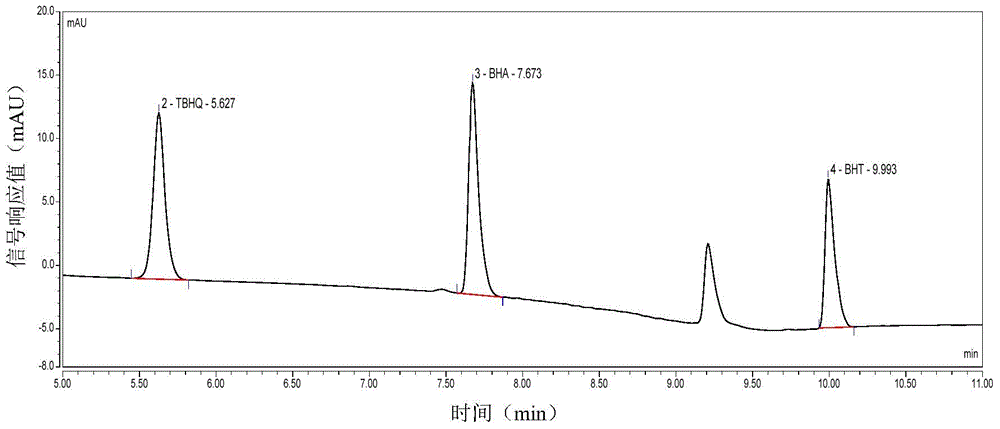

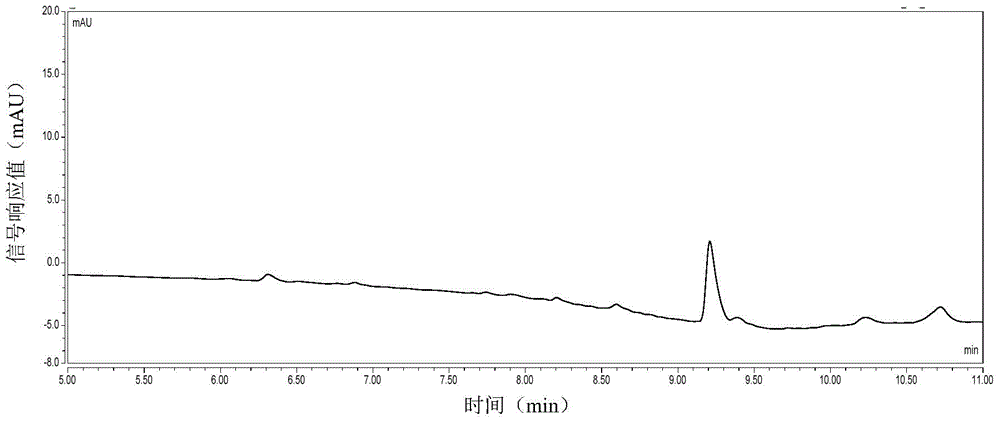

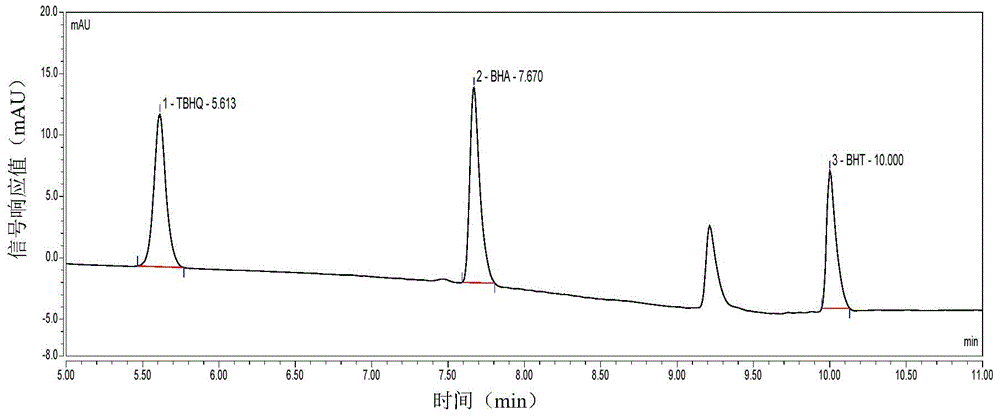

Method for fast detection of butylated hydroxyanisole (BHA), 2, 6-ditertbutyl-4 methylphenol (BHT) and tert-butylhydroquinone (TBHQ) of plant oil sample and pre-treatment method

The invention relates to the field of food additive detection. The invention relates to a pre-treatment method for fast detection of butylated hydroxyanisole (BHA), 2, 6-ditertbutyl-4 methylphenol (BHT) and tert-butylhydroquinone (TBHQ) in a plant oil sample. The pre-treatment method comprises 1, mixing a plant oil sample, an adsorbent and an extraction solvent to obtain a mixture, 2, carrying out vortex oscillation on the mixture obtained through the step 1 to obtain a supernatant and 3, concentrating the supernatant obtained through the step 2 to obtain a solution to be detected. The invention also relates to a method for fast detection of BHA, BHT and TBHQ in a plant oil sample through the pre-treatment method. The pre-treatment method has a high BHA, BHT and TBHQ yield, fast and simple processes, small process pollution and a low cost.

Owner:COFCO GROUP +1

Cooling solution for machining

InactiveCN105368547AEnvironmental protection is goodImprove rust resistanceHeat-exchange elementsLubricant compositionPotassium hydroxideRust

The invention discloses a cooling solution for machining. The cooling solution comprises, by weight, 100 parts of plant oil, 15-25 parts of triethanolamine, 3-7 parts of potassium hydroxide, 4-8 parts of sodium benzoate, 3-6 parts of tert-butylhydroquinone, 0.5-1.5 parts of fluorboric acid, 0.5-1.5 parts of a methanol-isopropanol mixture, 5-10 parts of sodium chloride, 0.1-1 part of an antirust agent and 0.1-1 part of an antiwear lubricant. The plant oil is conjugated triene-containing tung oil. The antiwear lubricant is dry molybdenum disulfide. The antirust agent is a silane coupling antirust agent. The cooling solution for machining has good environmental protection performances, skid resistance and good antirust performances, does not contain harmful substances such as nitrite and heavy metals, can be recycled for 6 months, does not go bad and produce odor, does not corrode a machine tool and a workpiece, does not produce foam and odor, is convenient for product cutting, does not produce rust in work for 15 days, has a good antirust function, is convenient for use and can be stored for two years or more.

Owner:ANHUI MENGLING PRECISION ELECTRONICS

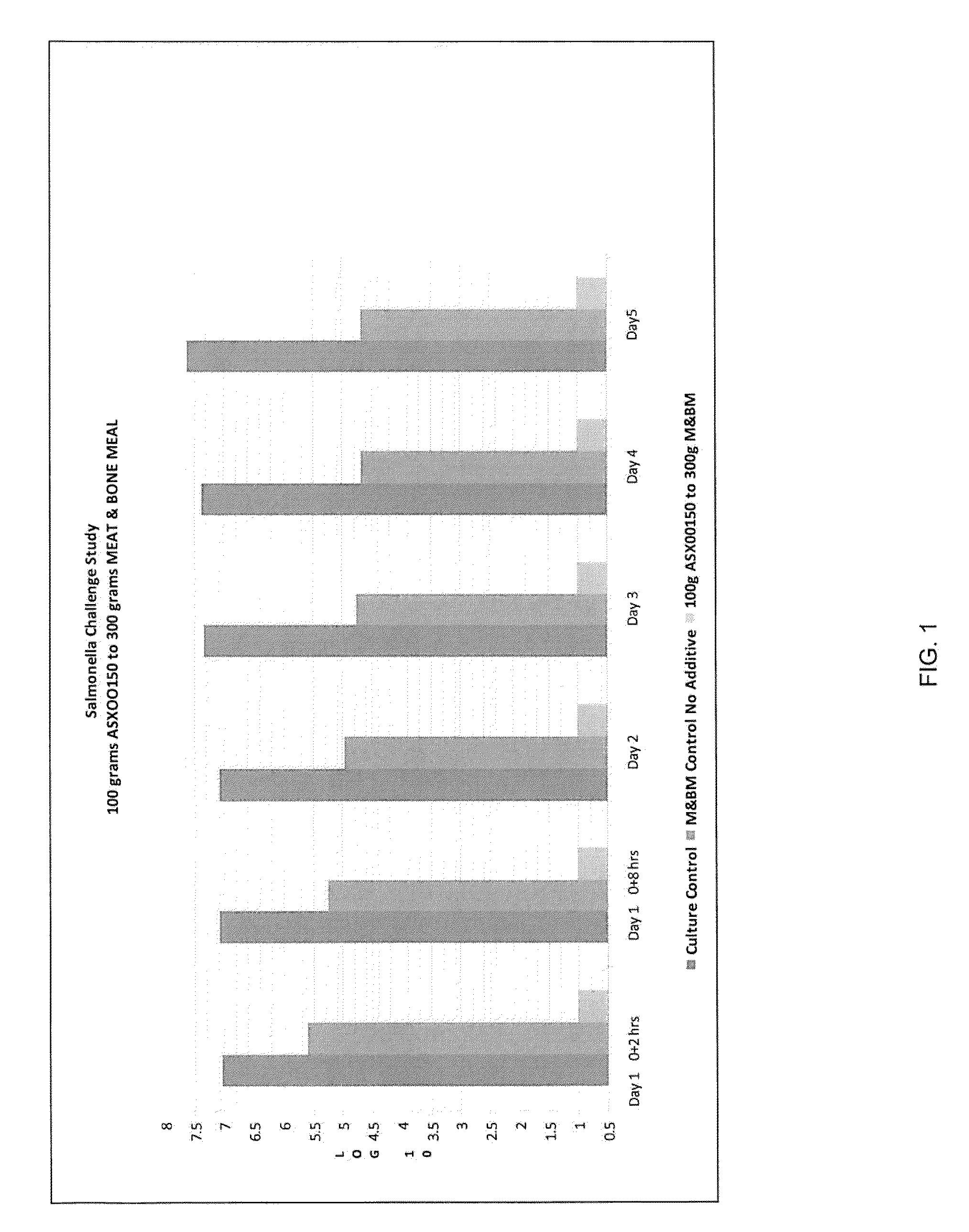

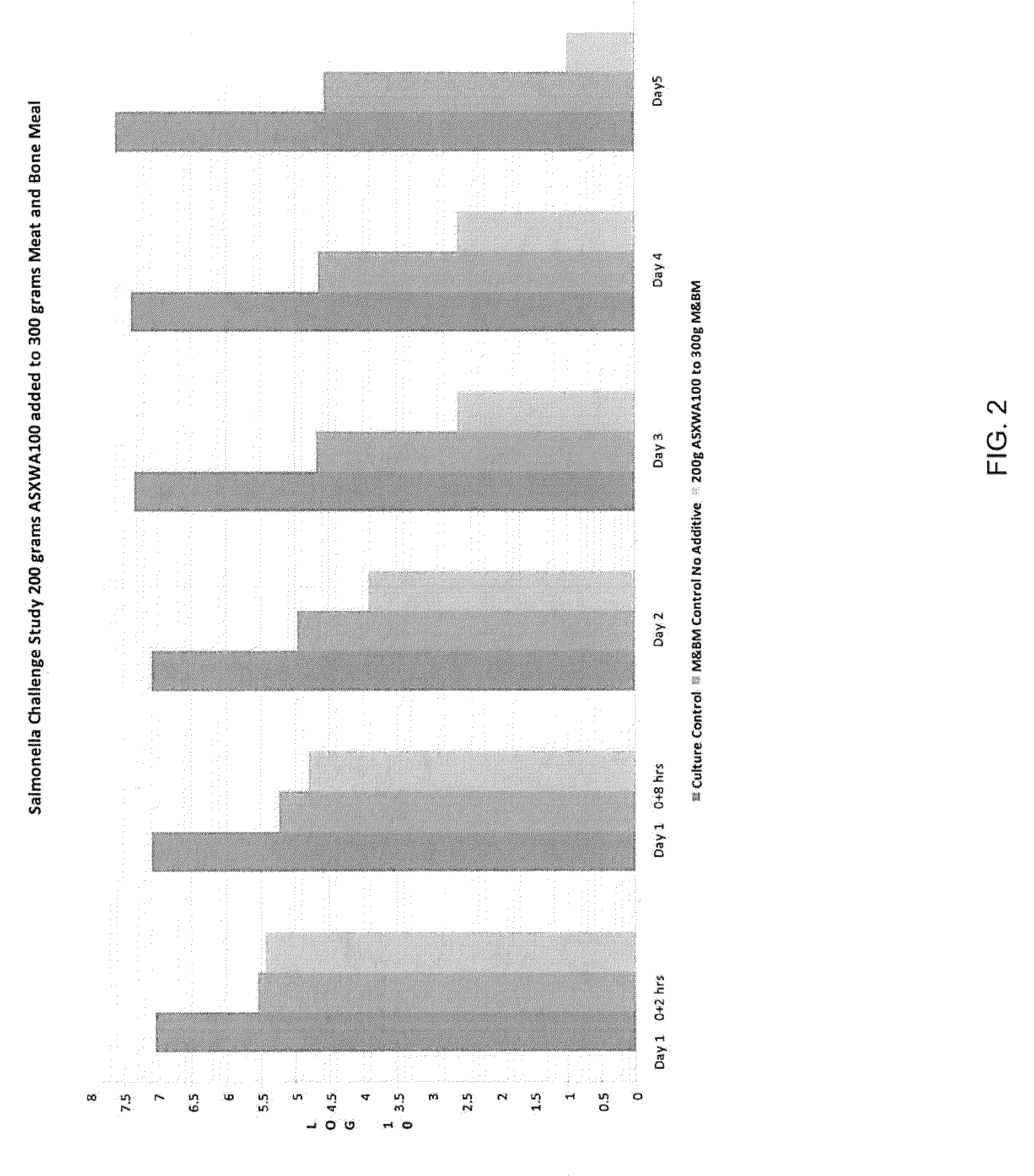

Antimicrobial compositions within antioxidant solutions used to protect whole protein foods

An antimicrobial composition within an antioxidant solution and used to protect whole protein food source is provided. The antimicrobial compound of the composition is selected preferably from a medium chain fatty acid (MCFA), a long chain fatty acid (LCFA), a phenolic acid, and derivatives or mixtures thereof, and has a pH between about 2 and 6. Antioxidant compounds for the composition are composed preferably from phenolic based compounds such as butylated hydroxyanisole (BHA), butylated hydroxytoluene (butylhydroxytoluene, BHT), propyl gallate (propyl 3,4,5-trihydroxybenzoate), tert-butylhydroquinone (TBHQ, tertiary butylhydroquinone), mixed tocopherols (tocopherols, Vitamin E), rosemary extract, oregano oil (origanum oil) and vegetable oil; other antioxidant compounds such as calcium propanoate (or calcium propionate) and ethyoxyquin; and derivatives or mixtures thereof.

Owner:FRASERMICH

High-DF (dietary fiber) maize germ flour and preparation method thereof

InactiveCN105995551AIncrease intakeGuaranteed nutritional functionFood shapingFood ingredient functionsFiberNutritive values

The invention discloses high-DF (dietary fiber) maize germ flour and a preparation method thereof. After maize bran, maize germ dregs and rice bran dregs are soaked in an acetic acid solution, a sodium bicarbonate solution is used for neutralization, a mixture with the pH value being 6.7+ / -0.2 is obtained through water washing, and filtration, drying and milling are performed to prepare mixed powder; tert-butylhydroquinone is dissolved in vegetable oil, and then the obtained oil is added into the mixed powder to form a mixture, the mixture is poured into a moisture conditioner, the water mass content in the mixed powder is adjusted to be 15%-25% by spraying water or steam at the room temperature, conditioned powder is obtained and sent into a twin-screw extruder, extruding-expansion is performed to obtain a granular semi-finished product, the granular semi-finished product is dried and crushed, maltodextrin and white granulated sugar are added and mixed uniformly, and the high-DF maize germ flour is obtained. The high-DF (dietary fiber) maize germ flour has the advantages that the nutritive value is relatively high, rich DFs can be provided for a human body and are beneficial to the health of the human body, the taste and the resolvent quality are excellent, and the high-DF maize germ flour has excellent wettability and dispersity in warm water and cold boiled water, is convenient to eat and has a wide applicable crowd.

Owner:BOHAI UNIV

Complex antioxidant and preparation method thereof

ActiveCN102640968AImprove antioxidant capacitySingle performance solutionClimate change adaptationFood preservationHydroquinone CompoundTert-Butylhydroquinone

The invention discloses a complex antioxidant and a preparation method thereof. The complex antioxidant is mainly prepared by using the following components by weight percent: 2-66 percent of ethoxyquinoline, 2-50 percent of dibutylhydroxytoluene, 0.5-30 percent of tertiary butyl hydroquinone, 1-33 percent of white carbon black and 10-80 percent of calcium carbonate. The preparation method comprises the steps of: (1) weighing the components according to the formulation proportion, spraying ethoxyquinoline to a mixture of white carbon black and calcium carbonate, and stirring while spraying; and (2) uniformly mixing and stirring the mixture subjected to stirring and spraying with the other remained components. The complex antioxidant prepared by using the method has the advantages of high comprehensive effectiveness, good antioxidation effect, high safety, low preparation cost, wide application range and the like, is long in lasting effect after a small quantity of complex antioxidantsis added, and is suitable for popularization and application on additives.

Owner:宁波它世界生物科技有限公司

Environmental protection type thread steel surface antirust treatment agent

ActiveCN103276383AGuaranteed performanceQuality assuranceMetallic material coating processesWater basedMaterials science

The present invention discloses an environmental protection type thread steel surface antirust treatment agent, which comprises, by weight, 5-15% of a zirconium salt, 2-8% of sodium hypophosphite, 0.5-5% of an alkali, 0.1-0.5% of a corrosion inhibitor, 0.1-0.5% of a stabilizer, 0.05-0.08% of nickel fluoride, 0.5-0.8% of phenyl ethylene glycol ether, 0.05-0.1% of tert-butylhydroquinone, 0.05-0.08% of glycerol monostearate, 0.05-0.08% of 4-sulfo phthalic acid, 0.02-0.05% of 2-sulfo phenylpropionic acid, and the balance of water. With the present invention, the commonly existing problem of easy rust during a storage and transportation process of the thread steel is solved, wherein a common water base antirust agent can heavily pollute an environment, and antirust oil can affect bounding stress between the thread steel and concrete. Compared with the antirust treatment agent in the prior art, the antirust treatment agent of the present invention has characteristics of significant antirust effect, long antirust time, low cost, no pollution and high safety.

Owner:合肥华清高科表面技术股份有限公司

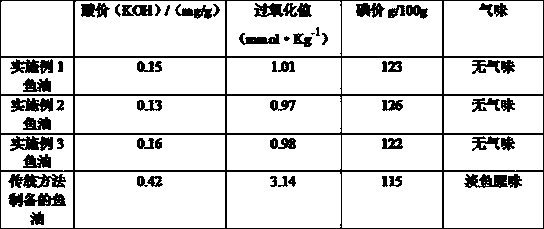

Preparation method of fish oil

InactiveCN107586591ANo off-flavor phenomenonImprove qualityFatty substance preservation using additivesFatty-oils/fats refiningWater bathsGlucosamine Sulfate

The invention provides a preparation method of fish oil and belongs to the technical field of preparation of fish oil. The preparation method comprises preparation steps as follows: 1) raw material treatment: discarded internal organs during fish processing are taken, cleaned, minced and mixed with water, and homogenate is obtained and subjected to ultrasonic treatment; 2) crude extraction of thefish oil: the pH value of the homogenate is adjusted, the homogenate is stirred and heated, table salt is added, the mixture is stirred, homogenized, and filtered, filter residues are pressed, filtrate and a pressed liquid are mixed, and crudely extracted fish oil is obtained; 3) fine extraction of the fish oil: the crudely extracted fish oil is taken and mixed with tert-butylhydroquinone and glucosamine sulfate, the mixture is subjected to water-bath heating, a degelation agent and hot water are added with stirring, the mixture is stirred and centrifuged, upper fish oil subjected to degelation is taken, deacidified, decolored, deodorized and cooled, and fine extracted fish oil is obtained. Oxidation of the prepared fish oil by unsaturated fatty acid is avoided, and the extraction rate isincreased on the premise that the extraction purity is guaranteed.

Owner:ZHEJIANG OCEAN UNIV

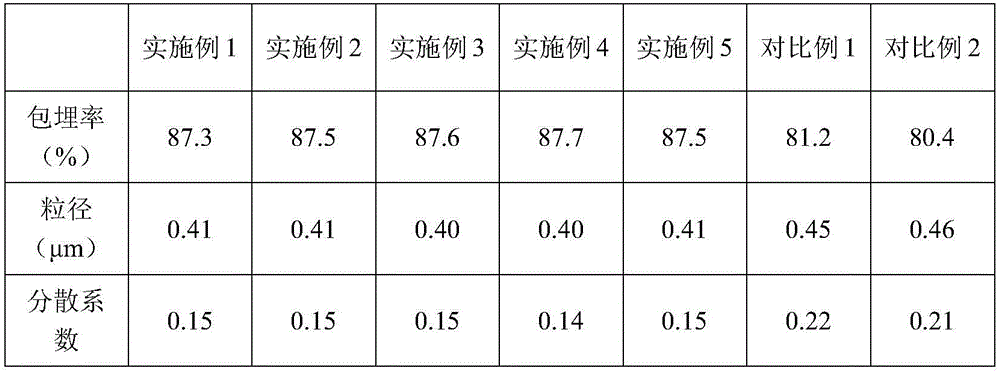

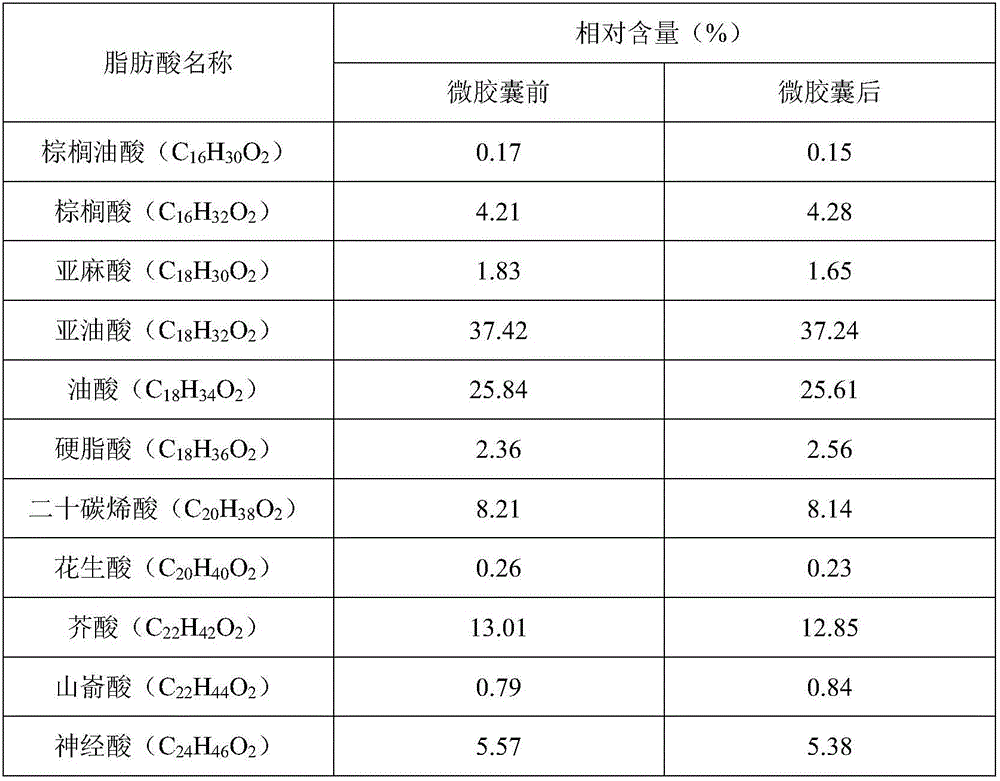

Acer truncatum oil microcapsule and preparation method thereof

InactiveCN106262927AFunction increaseHigh embedding rateSugar food ingredientsFood shapingMonoglyceridePhosphate

The invention discloses an acer truncatum oil microcapsule and a preparation method thereof, and belongs to the technical field of oil. The acer truncatum oil microcapsule is prepared by the following steps: (1) mixing modified starch, maltodextrin and distilled water, heating to 60-70 DEG C and stirring for 20-40 minutes; (2) mixing and stirring acer truncatum oil, vitamin E, sodium starch octenyl succinate, molecular distilled monoglyceride, soyabean lecithin and gellan gum for 20-40 minutes; (3) mixing the mixed solution at room temperature and stirring the mixed solution for 2-5 minutes; (4) adding the mixed solution into a homogenizer for homogenizing; (5) adding d-sodium erythorbate, tert-butylhydroquinone, hydroxy propyl distarch phosphate and glucose, and continuing to homogenize for 2-5 minutes; and (6) adding the solution into a spray dryer for spray drying to obtain the acer truncatum oil microcapsule. The acer truncatum oil microcapsule is high in embedding rate, high in stability, rich in unsaturated fatty acid and slight in change of composition of fatty acid before and after microencapsulation, and can effectively retain the intrinsic good functions and properties of the acer truncatum oil.

Owner:SHAANXI UNIV OF SCI & TECH

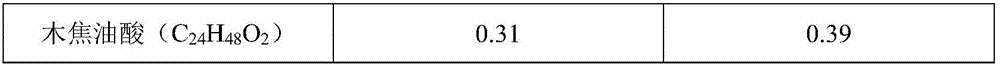

High oil-resistant sealing element rubber material and its preparation method

The invention discloses a high oil-resistant sealing element rubber material, which is mixed by A and B rubber compounds in equal proportion. The two rubber compounds have the following material components by weight: A rubber compound: 85-95 of nitrile-butadiene rubber, 0.3-0.5 of sulphur, 4-6 of zinc oxide, 3-4 of eleaostearic acid, 1-2 of an anti-oxidant 2, 5-ditert-butylhydroquinone-DTBHQ, 1-2 of an antiager RD, 1-2 of an antiager 4010NA, 3-4 of paraffin, 22-25 of fast extruded carbon black N660, 62-65 of high abrasion carbon black, 18-22 of dioctyl-phthalate, 25-35 of calcium carbonate, 3-4 of an accelerator DM, 1-2 of an accelerator TMTD, 1-2 of an accelerator TETD; B rubber compound: 82-87 of monohomopolymerized epichlorohydrin rubber, 12-18 of copolymerized epichlorohydrin rubber, 1-2 of zinc stearate, 1-3 of an antiager RD, 0.4-0.6 of Gum easy T-78, 1-2 of rhein wax, 45-55 of fast extruded carbon black, 10-14 of diatomite, 5-8 of dioctyl-phthalate, 4-6 of lead tetraoxide, 0.4-0.6 of sulphur, and 1-2 of an accelerator Na-22. The rubber material can be used to produce oil-resistant sealing elements (oil cylinder sealing gaskets) with the advantages of oil resistance, thermoresistance, air impermeability, flame retardation and tear resistance and low cost.

Owner:芜湖禾田汽车工业有限公司

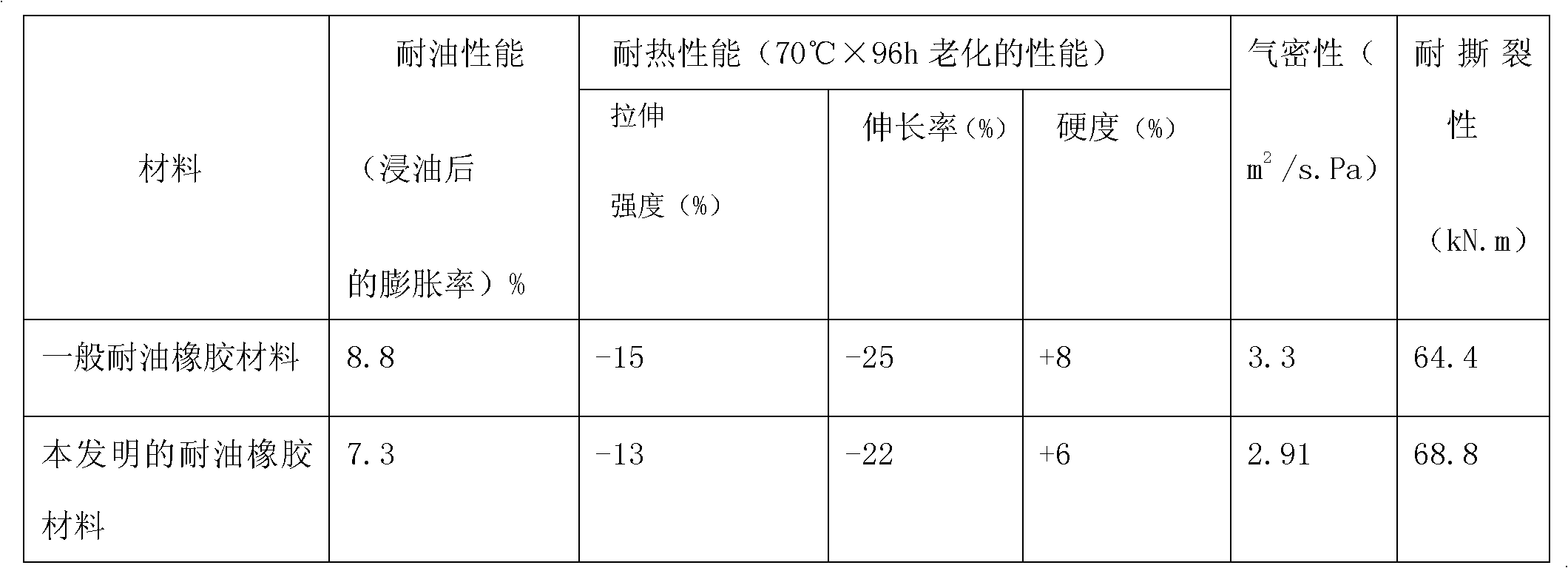

Efficient bacterium-restraining composite essential oil and preparation method thereof

PendingCN108651710AImprove antibacterial propertiesImprove antioxidant capacityAccessory food factorsPerilla oilEugenol

The invention discloses efficient bacterium-restraining composite essential oil and a preparation method thereof. The efficient bacterium-restraining composite essential oil comprises the following components of carvacrol, thymol, cinnamic aldehyde, eugenol, anise oil, purple perilla oil, caprylic-capric acid blend, lactic acid, tertiary butylhydroquinone, a Neotame solution, white carbon black and palm oil. The efficient bacterium-restraining composite essential oil disclosed by the invention has favorable bacterium resisting capacity, and bacterium-restraining tests confirm that under the compounding of various raw materials, the efficient bacterium-restraining composite essential oil has better bacterium restraining effects. Through reasonable compounding and improvement of a preparation technology, and the caprylic-capric acid blend and the lactic acid are added to be used as a synergist and a chelating agent, so that the bacterium resisting capacity of the composite essential oilis substantially improved, the efficient bacterium-restraining composite essential oil has better oxidation resisting property, and the growth properties of animals are effectively improved. The efficient bacterium-restraining composite essential oil is simple in processing technology, low in cost and green and safe, and the efficient bacterium-restraining composite essential oil as a replacementof a feed antibiotic can be well popularized and applied.

Owner:济南牧德生物科技有限公司

Sheet-shaped ghee and making method thereof

The invention relates to the field of cream processing, and especially relates to sheet-shaped ghee and a making method thereof. The sheet-shaped ghee comprises the following components by weight percentage: 52-67% of refined plant oil, 15-30% of edible butter, 1% of salt, 0.5% of fatty acid monoglyceride or fatty acid diglyceride, 0.5% of polyglycerin ricinoleate, 0.3% of edible perfume, 0.1% of potassium sorbate, 0.018% of tertbutyl hydroquinone, 0.003% of beta-carotene, and 15.579% of water. The sheet-shaped ghee can be made through steps of emulsification, sterilization, fast cooling, and kneading and package, and the problems of poor brittleness, over-soft or over-hard mouthfeel after moulding, rough mouthfeel, difficult satisfaction for consumer requirement of the traditional sheet-shaped ghee can be solved, The sheet-shaped ghee made by the method has the advantages of light color, rich milk flavor, nature, rich taste, and excellent local flavor.

Owner:漯河创联油脂有限公司

Soldering flux for improving film-forming property

InactiveCN103801860AImprove performanceHalogen freeWelding/cutting media/materialsSoldering mediaTriclosanGlutaric acid

The invention discloses soldering flux for improving the film-forming property. The soldering flux is prepared from 10-20 parts of activating agent, 2-6 parts of surface active agent, 0.3-0.8 part of cosolvent, 0.2-2 parts of film-forming agent, 0.04-0.09 part of corrosion inhibitor, 1-4 parts of antioxidant and the balance of deionized water, wherein the film-forming agent is prepared from at least one of PEG-1000, PEG-2000, PEG-4000 and PEG-6000, the surface active agent is prepared from at least one of FMEE and lutensol to (3,5,7,9) compounds, BTA and BIA are mixed to form the corrosion inhibitor, the antioxidant is prepared from at least one of tertiary butylhydroquinone, triclosan, tetrachloroisophthalonitrile and allicin, and the activating agent is prepared from at least two of glutaric acid, DL-malic acid, methylsuccinic acid and itaconic acid. With the method, the soldering flux for improving the film-forming property has the advantages of being free of halogen, low in residue, free of washing, environmentally friendly and the like.

Owner:SUZHOU LOTTE CHEM TECH

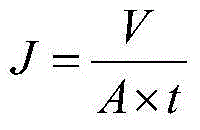

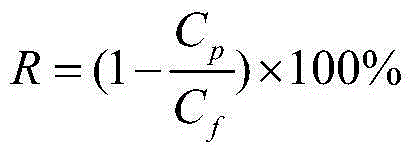

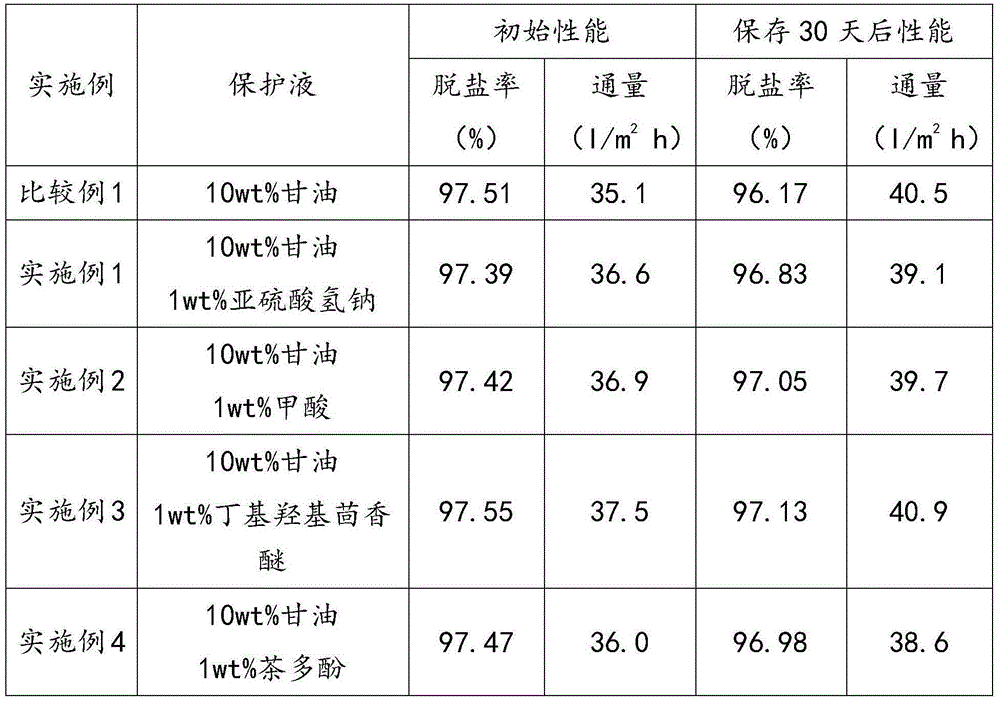

Preparation method for dried reverse osmosis composite membrane

ActiveCN105148742ASolve the problem of separation performance degradationReverse osmosisReverse osmosisPotassium

The invention relates to a preparation method for a dried reverse osmosis composite membrane. The preparation method comprises the following steps: soaking a conventional reverse osmosis composite membrane in a protector-containing aqueous solution, wherein the soaking temperature is 10-50 DEG C and the soaking time is 1-10 minutes; and then carrying out thermal treatment for 8-12 minutes in an oven at 80-100 DEG C, wherein the protector is one or a mixture of more of sodium hydrogen sulfite, potassium hydrogen sulfite, ammonium hydrogen sulfite, formic acid, oxalic acid, citric acid, dipotassium glycyrrhizate, butylated hydroxyanisole, butylated hydroxytoluene, propylgallate, tert-butylhydroquinone, tea polyphenol, 3,4,5,7-tetrahydroxy flavone and a glycyrrhisoflavone solution. The preparation method provided by the invention not only can be used for realizing dry state storage of the reverse osmosis composite membrane, but also can effectively solve the problem that the dried reverse osmosis composite membrane is attenuated in performance in a long-term storage process.

Owner:HANGZHOU FANGRAN MEMBRANE TECH

Heavy metal sewage treatment method

InactiveCN106007118ASimple processImprove removal efficiencyWater/sewage treatment by irradiationSpecific water treatment objectivesIon exchangeEtidronic acid

The invention discloses a method for treating heavy metal sewage, which is extracted by polymerizing ferrosilicon sulfate, polyacrylamide, aluminum tripolyphosphate, petroleum ether, octadecyl dimethyl, manganese sulfate, hydroxyethylidene diphosphonic acid and brown algae Compound sewage treatment agent formulated with alum, tertiary butyl hydroquinone, pyrrolidone, thiabendazole, and ethyl naphthol reacts with sewage by stirring, after ultrasonic treatment, the ion exchange column is eluted through the column, and the flocculant is stirred, flocculated and precipitated , the flocculation supernatant is passed through a column adsorption resin, filtered through a membrane filter, and sterilized to obtain discharge standard treated water. The method has high removal efficiency for heavy metals in sewage, simple and easy process, strong operability, no pollution to the environment, can meet the requirements of the industry, and has good application prospects.

Owner:陈昌

Special antistatic heat-conducting binding material for LED (light-emitting diode) lamps and preparation method thereof

InactiveCN106047284AHigh thermal conductivityHigh surface resistanceNon-macromolecular adhesive additivesWax adhesivesEpoxyAcrylic resin

The invention discloses a special antistatic heat-conducting binding material for LED (light-emitting diode) lamps and a preparation method thereof. The special antistatic heat-conducting binding material for LED (light-emitting diode) lamps comprises the following main raw materials in parts by weight: 5-15 parts of phenol formaldehyde epoxy vinyl ester resin, 5-15 parts of polyethylene terephthalate, 5-15 parts of rosin resin, 5-15 parts of acrylic resin, 5-15 parts of antistatic heat-conducting aid, 5-10 parts of nano silicon dioxide powder, 1-3 parts of silane coupling agent, 1-3 parts of tert-butylhydroquinone and 1-3 parts of hindered amine light stabilizer. The antistatic heat-conducting aid comprises the following main raw materials in parts by weight: 25-30 parts of calcium carbonate powder, 10-20 parts of liquid paraffin, 10-20 parts of sulfite and 5-10 parts of magnesium hydroxide. The special antistatic heat-conducting binding material for LED lamps has the advantages of excellent comprehensive properties, favorable processability, high heat conductivity, high antistatic capacity, low cost and the like.

Owner:刘雷

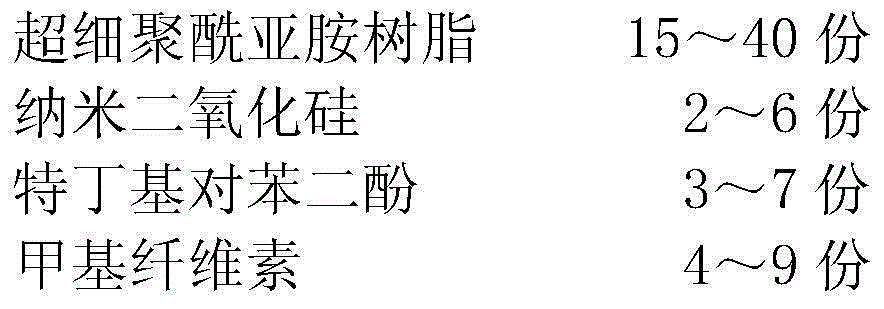

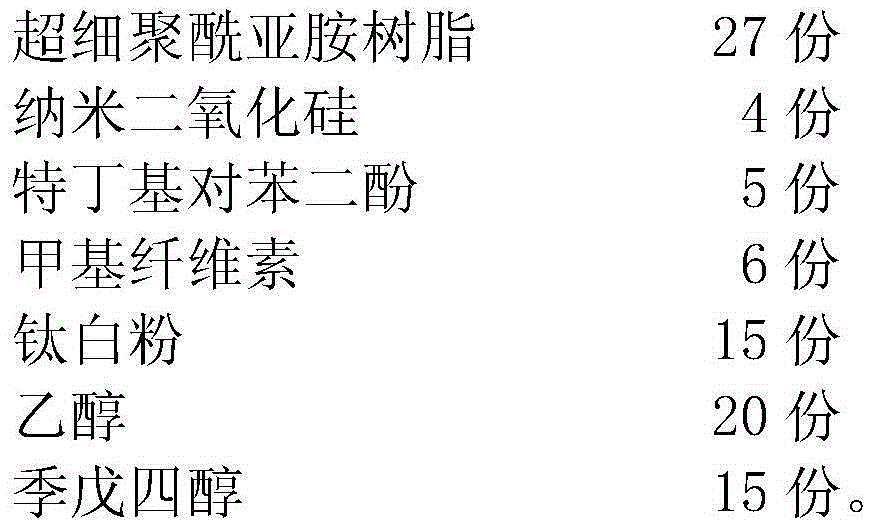

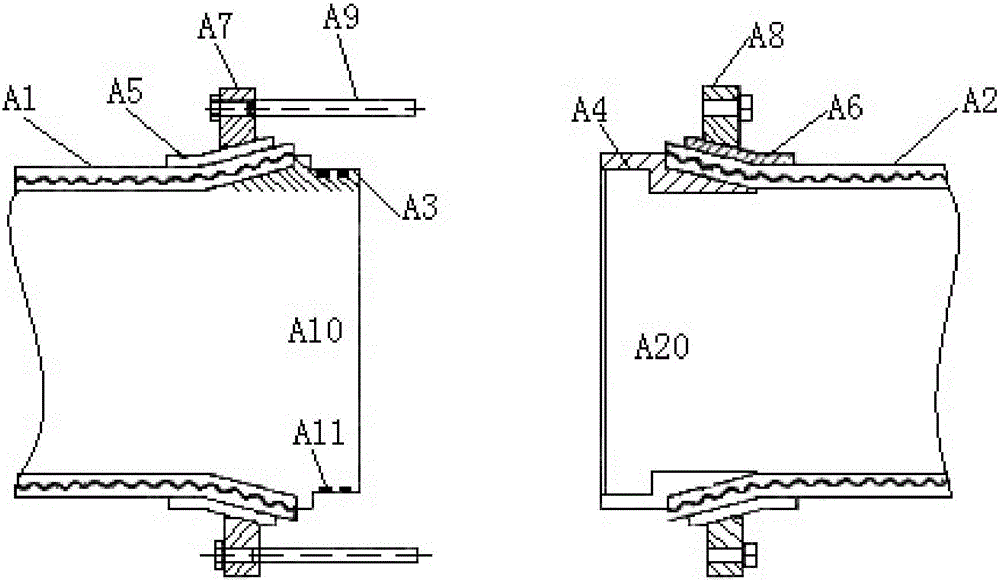

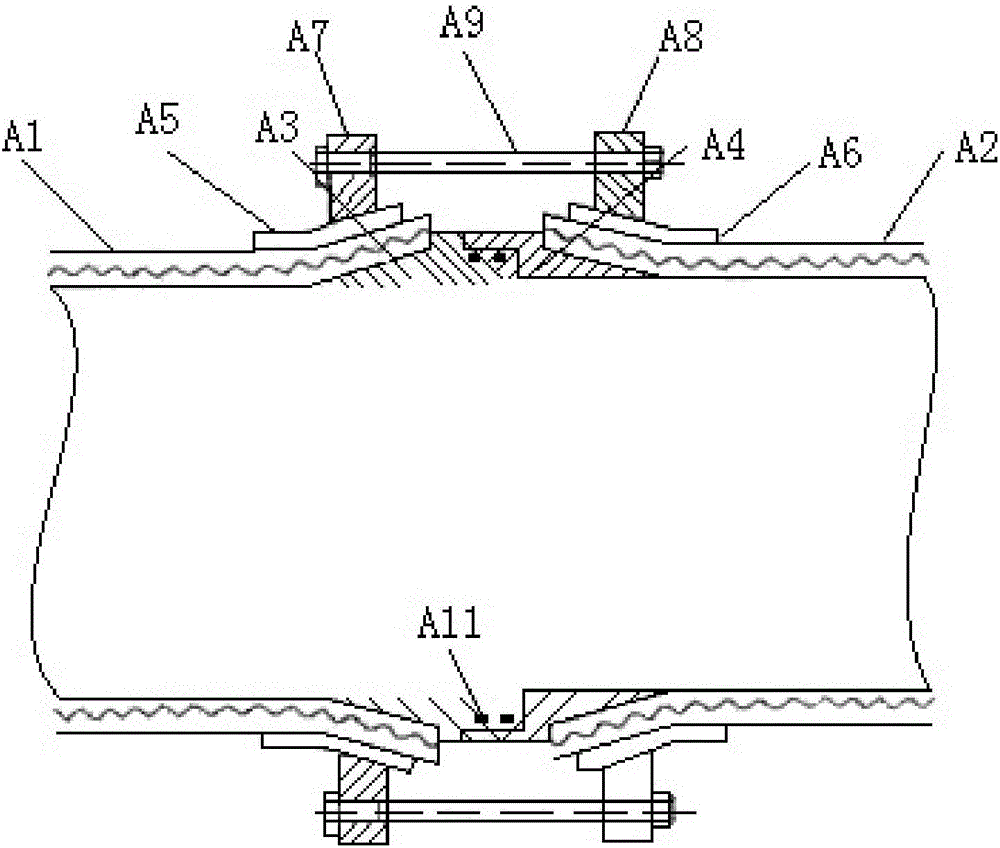

High-adhesive force printing ink

The invention relates to the technical field of printing ink and in particular relates to high-adhesive force printing ink. The high-adhesive force printing ink is prepared from the following raw materials in parts by weight: 15-40 parts of a superfine polyimide resin, 2-6 parts of nano silicon dioxide, 3-7 parts of tert-butylhydroquinone, 4-9 parts of methyl cellulose, 12-19 parts of titanium dioxide, 15-25 parts of ethanol and 10-20 parts of pentaerythritol. The printing ink disclosed by the invention has high adhesive force, does not contain any toxic substance, is environment-friendly to a human body and harmless to the environment, has high wear resistance and fire resistance and can emit ultraviolet rays so as to prevent fading.

Owner:韦棋

Egg yolk lecithin soft capsule and its production process

InactiveCN1475216AOvercome water absorptionOvercoming the disadvantages of oxidationOrganic active ingredientsDigestive systemYolkCold chain

A yolk lecithin capsule is prepared from yolk lecithin 100 (wt. portions), vegetative oil 100-150, VE3, and tert-butylhydroquinone 0.03 as antioxidizing agent. Its advantages are no need of cold-chain transportation, and high content of phosphatidylcholine and linolenic acid.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Electrostatic spraying anti-rust oil

InactiveCN103980997AImprove rust resistanceGood removal effectLubricant compositionSucrosePhenyl Ethers

The invention discloses electrostatic spraying anti-rust oil. The electrostatic spraying anti-rust oil comprises, by weight, 71-80 parts of 150SN base oil, 6-8 parts of barium dinonylnaphthalenesulfonate, 2-4 parts of polyglycerol fatty acid ester, 0.7-1 part of potassium fluotitanate, 2-3 parts of sucrose fatty acid ester, 0.6-1 part of polyoxyethylene nonyl phenyl ether, 1-2 part of tert-butylhydroquinone, 1-2 parts of turpentine, 0.7-1 part of dodecyldimethylamine oxide, 0.1-0.2 parts of sodium peroxide and 10-16 parts of a film-forming assistant. The electrostatic spraying anti-rust oil has excellent rust resistance and oil film removal effects on a cold-rolled steel plate and a galvanized steel plate, has good damp-heat resistance and overlapping resistance, and has good object stampability and electrophoresis painting technology compatibility satisfying car and household electrical appliance manufacturing industry requirements.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Technology for preparing tert-butylhydroquinone (TBHQ) quality goods

InactiveCN103864580AIncrease profitCause bodily harmOrganic chemistryOrganic compound preparationPhosphoric acidHydroquinone Compound

The invention discloses a technology for preparing tert-butylhydroquinone (TBHQ) quality goods. The technology comprises the following steps: 1) pouring 2-4 parts by weight of phosphoric acids and 0.1-0.4 part by weight of water into a mixing cylinder, and then adding 5-7 parts by weight of hydroquinone to the mixing cylinder to agitate; 2) putting a mixed solution into a reaction kettle to heat to 55-65 DEG C after agitating, and then feeding 7-9 parts by weight of tertiary butanol to the reaction kettle; 3) heating to 75-85 DEG C, and then preserving heat for 2-3 hours to react; 4) centrifugally separating, washing and dewatering a reaction product to obtain a TBHQ crude product; 5) heating 1-3 parts by weight of acids and 93-96 parts by weight of water after mixing, adding 4.5-6.5 parts by weight of TBHQ crude product when heating to 82-88 DEG C, heating while agitating, and heating to 92-95 DEG C; and 6) carrying out the first centrifugal separation on the solution obtained in the step 5), separating out DTBHQ (ditert-butylhydroquinone) which is not dissolved into water in TBHQ, and then cooling the solution, carrying out the second centrifugal separation when cooling to below 45 DEG C, washing, dewatering and baking the obtained TBHQ crystal, so as to obtain the TBHQ quality goods.

Owner:GUANGZHOU TAIBANG FOOD TECH

Preparation process of tert-butylhydroquinone

ActiveCN105294403AReduce usageLow DTBHQ contentOrganic chemistryOrganic compound preparationWarm waterEthylic acid

The invention relates to the technical field of antioxidant preparation methods, and particularly relates to a preparation process of tert-butylhydroquinone (TBHQ). The preparation process comprises the following steps of (1) simultaneously adding excessive dilute sulphuric acid, equimolar hydroquinone and tertiary butyl acetate to a reaction still, wherein the weight ratio of the dilute sulphuric acid to the tertiary butyl acetate is 1:(3 to 6); (2) stirring and heating to 85 to 95 DEG C, and reacting for 1 to 8 hours; (3) stopping stirring, cooling to 65 to 75 DEG C, and then performing centrifugal filtration, wherein filtrate of sulphuric acid is recycled, and obtained filter residues are washed with 1 to 3 times warm water, so as to obtain a crude product of the TBHQ. Compared with the prior art, the preparation process has the advantages that the hydroquinone and the tertiary butyl acetate are used as raw materials, and the dilute sulphuric acid is used as a catalyst and a reaction solvent, so as to promote a reaction; tertiary butyl is supplied by the tertiary butyl acetate, so that side reactions are reduced; the crude product contains 70% to 75% of TBHQ, the content of DTBHQ (Di-Tert-Butylhydroquinone) as a by-product is low, the yield can reach 65 to 70% after purification, the yield is greatly increased, and great economic benefits are obtained.

Owner:东莞市感恩食品科技有限公司

Acid-soluble pressure-bearing plugging agent for drilling fluid and preparation method

The invention relates to an acid-soluble pressure-bearing plugging agent for drilling fluid and a preparation method. The acid-soluble pressure-bearing plugging agent contains a friction material, a bridging material, a filler material, iron tailing sand, volcanic ash powder, woody activated carbon powder, nano calcium-zinc phosphate, paraffin, polyalcohol fatty acid ester, titanium white, red clay, alginic acid, dimethyl diallyl ammonium chloride, polyvinyl acetate, glyceryl monostearate, a glued stone cementing material, copper oxide, Dibenzyl disulfide, alpha-n-octyl-cyanoacrylate, sodium caseinate, steel slag, white carbon black, dolomite powder, manganese dioxide, diatomite, dibutyl phthalate, polyvinyl alcohol, tert-butylhydroquinone, phthalic anhydride and H2O. According to the acid-soluble pressure-bearing plugging agent for the drilling fluid and the preparation method, by using the preparation method, the defects in the prior art that on-site operating methods are tedious, operating requirements are strict, plugging performance is often poor due to invasion of surrounding solid-state particulate matters, a plugging framework is damaged, and a motor shaft or rotating shaft is subjected to expanding and contracting under the action of stress of the shaft during rotating due to infirm connection are avoided.

Owner:河南省遨太化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com